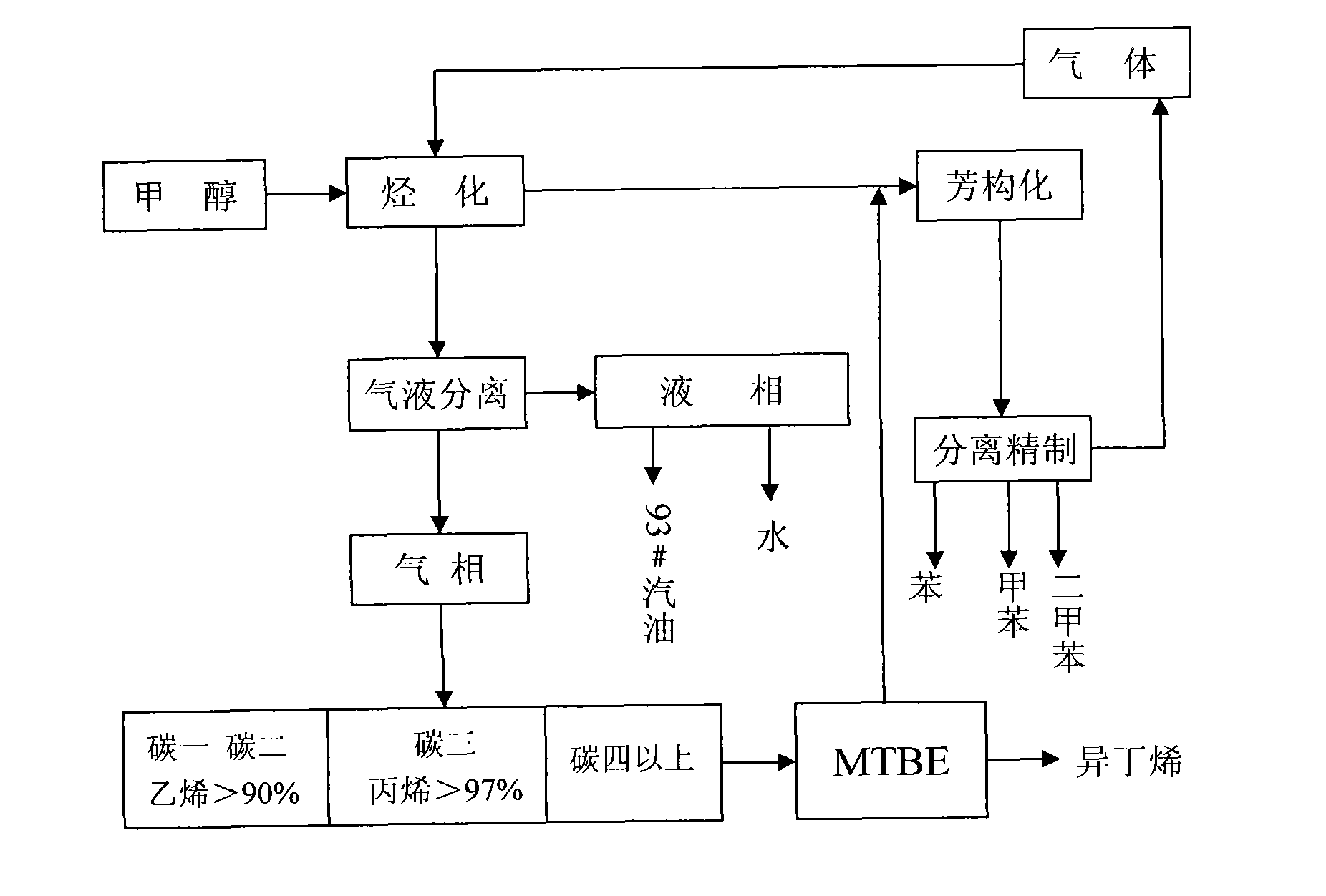

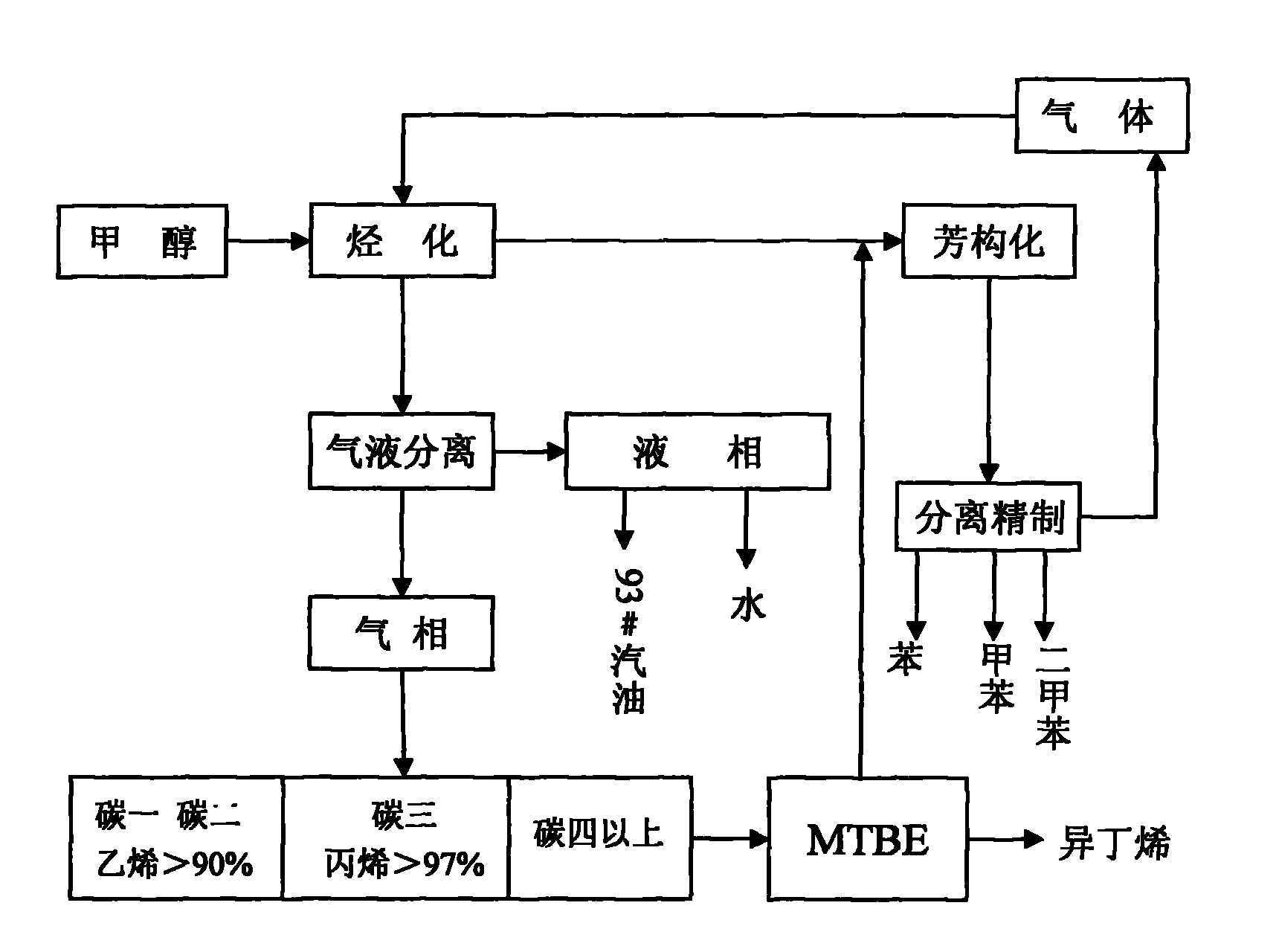

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

A technology of low-carbon olefins and methanol, which is applied in the field of olefins and aromatics to produce alkanes, can solve the problems of slow development of oil substitution strategy and huge investment, and achieve the effect of not harsh construction conditions, low investment, and low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

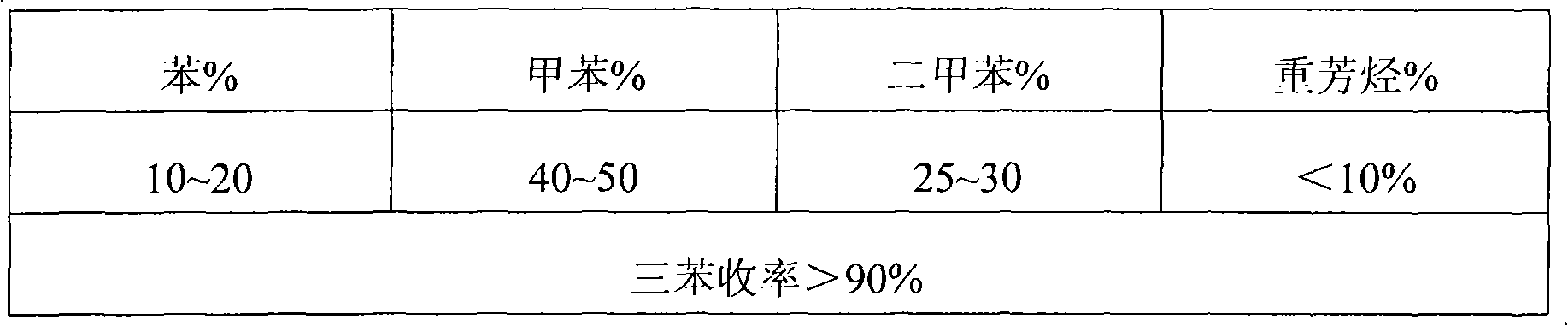

[0015] Example 1: Put 15g of molecular sieve catalyst for methanol alkylation into a methanol alkylation reactor, control the pressure at 0.1-0.5MPa, and the temperature at 180-600°C, make the molar ratio of methanol and water into 2:1, and mix 50- Put 20g of molecular sieve catalyst (preferably 40-30g) for aromatization into the aromatization reactor, and feed 30-40ml of reactants per hour. After the reaction, the single-pass liquid yield in the liquid is greater than 50%, and the total liquid yield is greater than 70%. The content of each component in the liquid is shown in Table 1 below, and the main components in the gas are hydrogen, methane and ethane.

[0016] Table 1

[0017]

Embodiment 2

[0018] Example 2: Put 30g of molecular sieve catalyst for methanol alkylation into methanol alkylation reactor, control temperature 400-500°C, pressure 0-0.5MPa, alcohol-water molar ratio 1:1, liquid space velocity 1-2, react The post gas composition is shown in Table 2 below:

[0019] Table 2

[0020]

[0021] After the above-mentioned gas is separated, the C4 gas enters the reaction bed equipped with MTBE catalyst, the molar ratio of methanol and isobutene is 2:1, and the C4 composition is as follows in Table 3:

[0022] table 3

4.5~5.5%

50~53%

39~42

[0024] The reaction temperature is 70-200°C, the pressure is 0.15-1.0MPa, and the gas composition after the reaction is shown in Table 4 below:

[0025] Table 4

[0026] Methanol

C4 component

24.1%

75.8%

>0.1%

[0027] Carry out the aromatization reaction of the gas a...

Embodiment 3

[0030] Embodiment 3: regenerate after 500 hours with the molecular sieve catalyst operation of example 1 methanol alkylation, react by example 1, single-pass liquid yield 60.5%, liquid composition (100 hour average data) sees the following table 6:

[0031] Table 6

[0032] benzene

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com