Preparation method and application of load type nano-gold catalyst

A catalyst and nano-gold technology, which is applied in the field of preparation of supported nano-gold catalysts, can solve the problem of no aluminosilicate nano-gold catalyst, etc., and achieve the effects of small catalyst dosage, high loading efficiency and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of supported nanometer gold catalyst comprises the steps:

[0017] 1) Add 2.0 g of halloysite nanotube carrier, 2.05 to 6.15 mL of chloroauric acid solution with a concentration of 10 g / L, and 40 to 120 mL of deionized water into a 250 mL three-necked flask;

[0018] 2) Place the flask in an oil bath at 60°C, adjust the pH of the solution to 8-12 with 4.0M ammonia water, then stir and reflux at 95-105°C for 1 hour, filter, rinse with 10-20mL of 4.0M ammonia water for 5 minutes, and rinse for 15-105°C Wash with 20 mL of hot water twice, dry at 100°C for 1 to 2 hours, and finally calcine in air at 300°C for 3 to 4 hours to obtain a supported nano-gold catalyst.

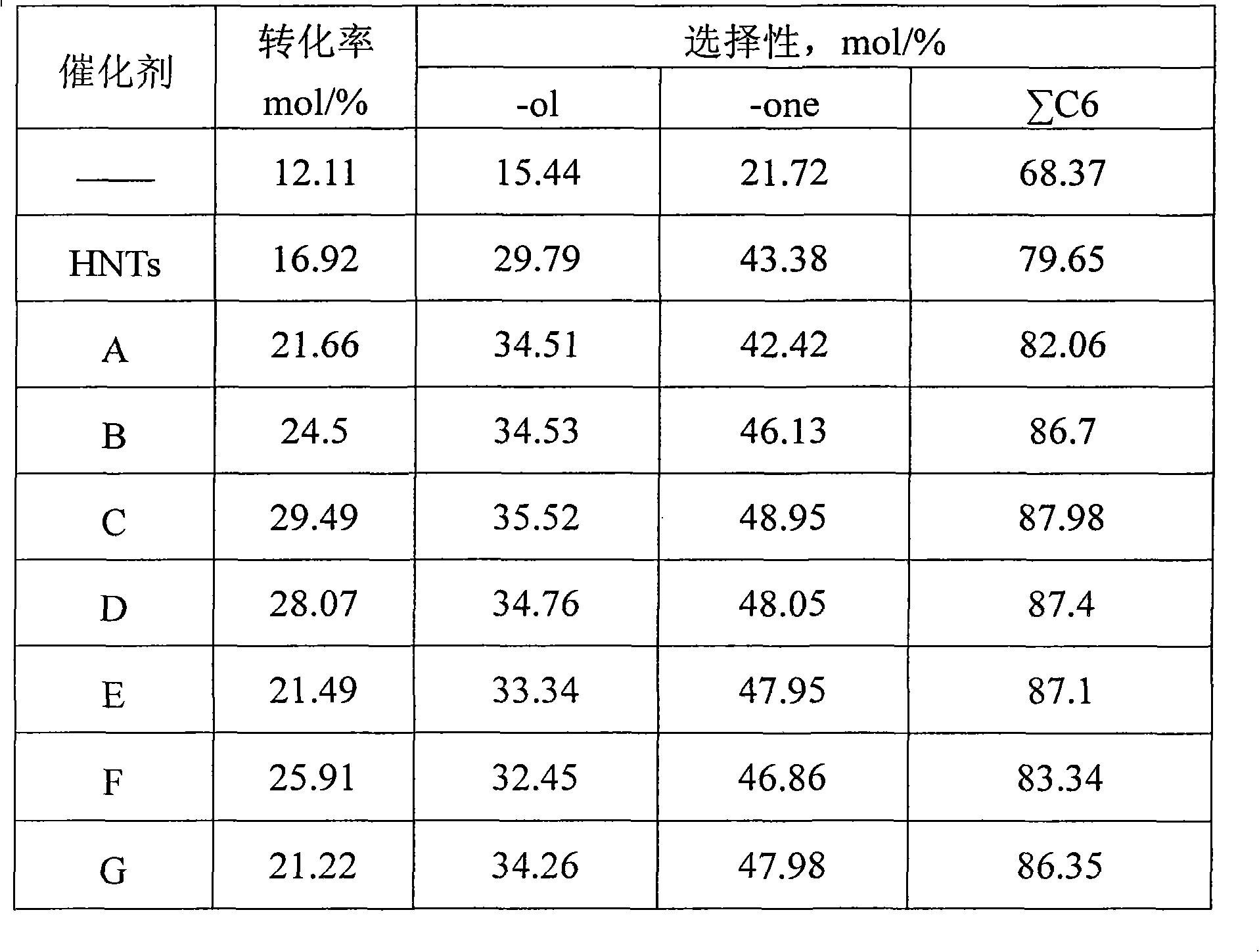

[0019] Supported nano-gold catalyst for selective oxidation of cyclohexene to cyclohexenol and cyclohexenone.

Embodiment 1

[0021] Preparation of Catalyst A. Add 2.0 g of halloysite nanotube carrier, 4.10 mL of chloroauric acid solution with a concentration of 10 g / L, and 80 mL of deionized water into a 250 mL three-neck flask. The flask was placed in an oil bath at 60°C, the pH of the solution was adjusted to 8 with 4.0M ammonia water, and then stirred and refluxed at 100°C for 1 h. Finished, filtered, rinsed with 15mL of 4.0M ammonia water for 5min, pumped twice with 20mL of hot water, dried at 100°C for 1h, and finally calcined in air at 300°C for 3h to obtain catalyst A.

Embodiment 2

[0023] Preparation of Catalyst B. Add 2.0 g of halloysite nanotube carrier, 4.10 mL of chloroauric acid solution with a concentration of 10 g / L, and 80 mL of deionized water into a 250 mL three-neck flask. The flask was placed in an oil bath at 60°C, the pH of the solution was adjusted to 9 with 4.0M ammonia water, and then stirred and refluxed at 100°C for 1 h. Finished, filtered, rinsed with 15mL of 4.0M ammonia water for 5min, pumped twice with 20mL of hot water, dried at 100°C for 2h, and finally calcined in air at 300°C for 3h to obtain catalyst B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com