Self-supporting super capacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of limited loading, high preparation cost of carbon nanotubes, low utilization rate, etc., achieve high mechanical stability, and eliminate the need for electrodes. Preparation process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

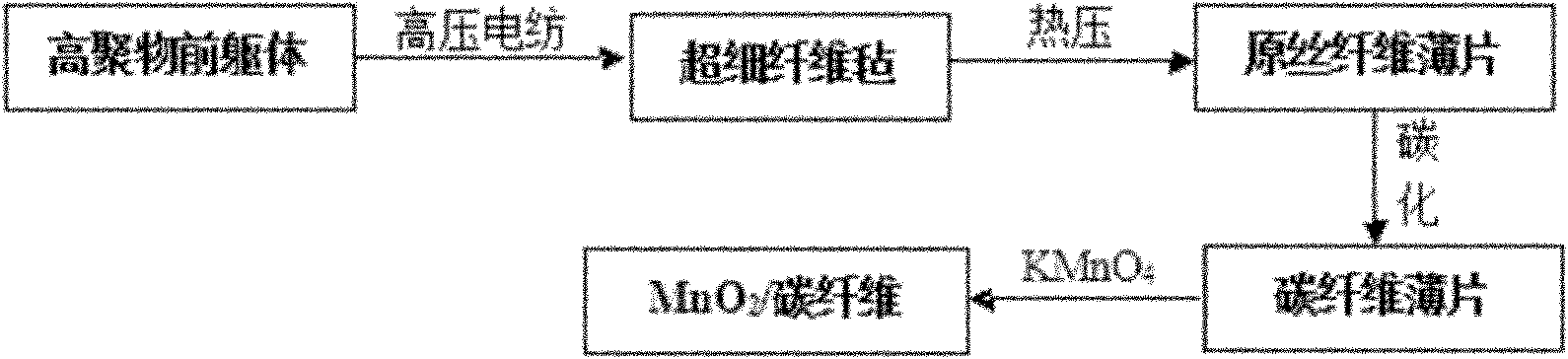

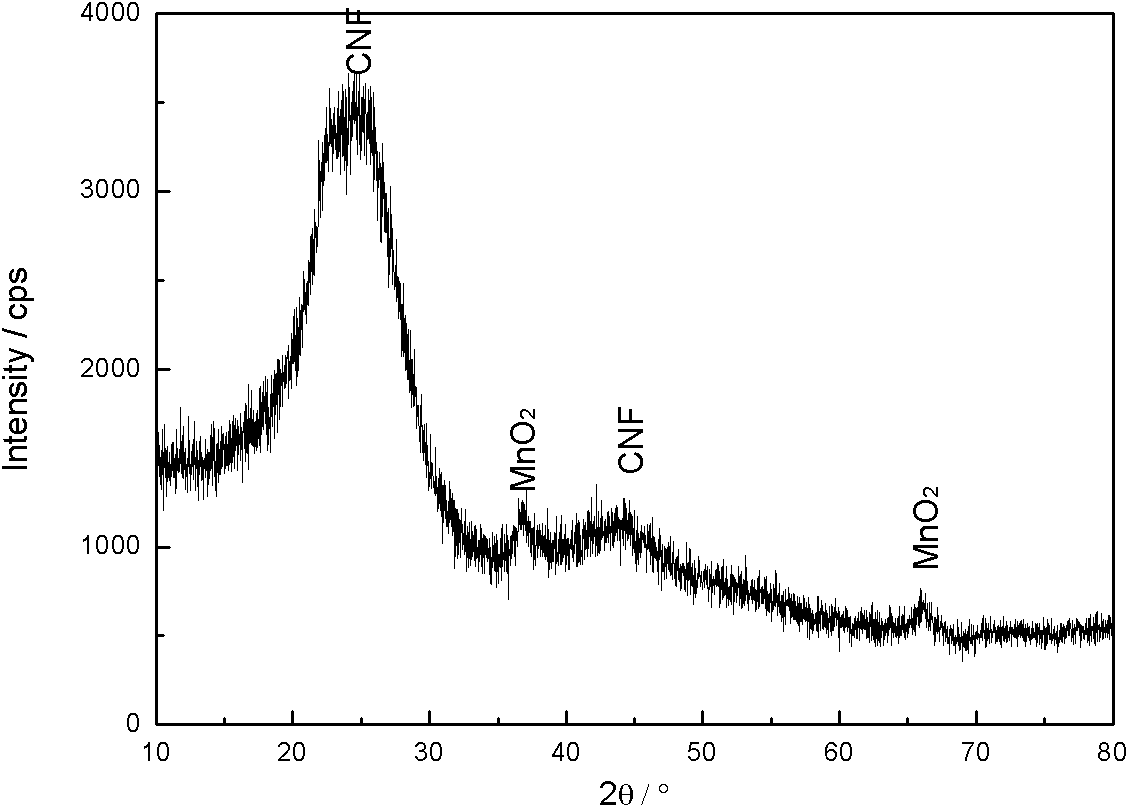

Embodiment 1

[0026] Embodiment 1: take a certain amount of polyacrylonitrile (PAN), add in dimethylformamide (DMF) solvent, be mixed with the PAN-DMF solution that mass fraction is 10wt.%, regulating voltage is 16kV, and receiving distance is 18 cm, the solution feed rate was 0.6 ml / h, and the solution was electrospun into a fiber mat. Heat the hot press to 100°C, put in the fiber mat and pressurize it to 5 MPa, then keep it warm for 5 minutes to obtain a tightly bonded fiber mat sheet. Then put the fiber felt sheet into a box-type atmosphere furnace, under the protection of nitrogen, heat it to 250°C and 1000°C at a heating rate of 5°C / min, and keep it warm for 2 hours for pre-oxidation and carbonization, respectively, to obtain carbon nanofiber sheets. Prepare a 0.1mol / L potassium permanganate solution, add concentrated sulfuric acid to adjust the solution to pH = 2, then soak the carbon nanofiber sheet prepared above in the solution for 15 minutes, take it out and wash it with deionized...

Embodiment 2

[0027] Embodiment 2: take a certain amount of polyvinyl alcohol (PVA), add deionized water, be mixed with the PVA aqueous solution that mass fraction is 15wt.%, regulating voltage is 18kV, and receiving distance is 18cm, and solution feed rate is 0.8ml / h, the solution was electrospun into a fiber mat. Then put the fiber mat sheet into a box-type atmosphere furnace, and under the protection of nitrogen, heat it to 1200°C at a heating rate of 5°C / min, keep it warm for 1.5h for carbonization, and obtain a carbon nanofiber sheet. Prepare a 0.25mol / L potassium permanganate solution, add concentrated nitric acid to adjust the solution to pH = 1, then soak the carbon nanofiber sheet prepared above in the solution for 20 minutes, take it out and wash it with deionized water and absolute ethanol several times to pH = 7, and then dried in a vacuum oven at 100°C for 8 hours to obtain MnO 2 and carbon nanofiber composite electrode materials. Calculation of MnO by weighing 2 The loadin...

Embodiment 3

[0028] Embodiment 3: Take by weighing a certain amount of polyvinylidene fluoride (PVDF) powder, add in the dimethylformamide (DMF) solvent, be mixed with the PVDF-DMF solution that mass fraction is 10wt.%, regulating voltage is 20kV, receives The solution was electrospun into a fiber mat at a distance of 15 cm and a solution feed rate of 0.5 ml / h. Then put the fiber felt sheet into a box-type atmosphere furnace, under the protection of nitrogen, heat it to 1100°C at a heating rate of 5°C / min, keep it warm for 2.5h for carbonization, and obtain carbon nanofiber sheet. Prepare a 0.05mol / L potassium permanganate solution, add concentrated sulfuric acid to adjust the solution to pH = 1, then soak the carbon nanofiber sheet prepared above in the solution for 10 minutes, take it out and wash it with deionized water and absolute ethanol several times to pH = 7, and then dried in a vacuum oven at 100°C for 8 hours to obtain MnO 2 and carbon nanofiber composite electrode materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com