Method for recovering sulfur and making hydrogen from hydrogen sulfide

A hydrogen sulfide and sulfur technology, which is applied in the preparation/purification of sulfur, electrolysis process, electrolysis components, etc., can solve the problem of difficulty in continuous and efficient absorption of hydrogen sulfide to recover sulfur, difficulty in hydrogen sulfide absorption rate reaching 100%, and insufficient gas-liquid contact. and other problems, to achieve the effect of improving resource utilization, prolonging gas-liquid contact time, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

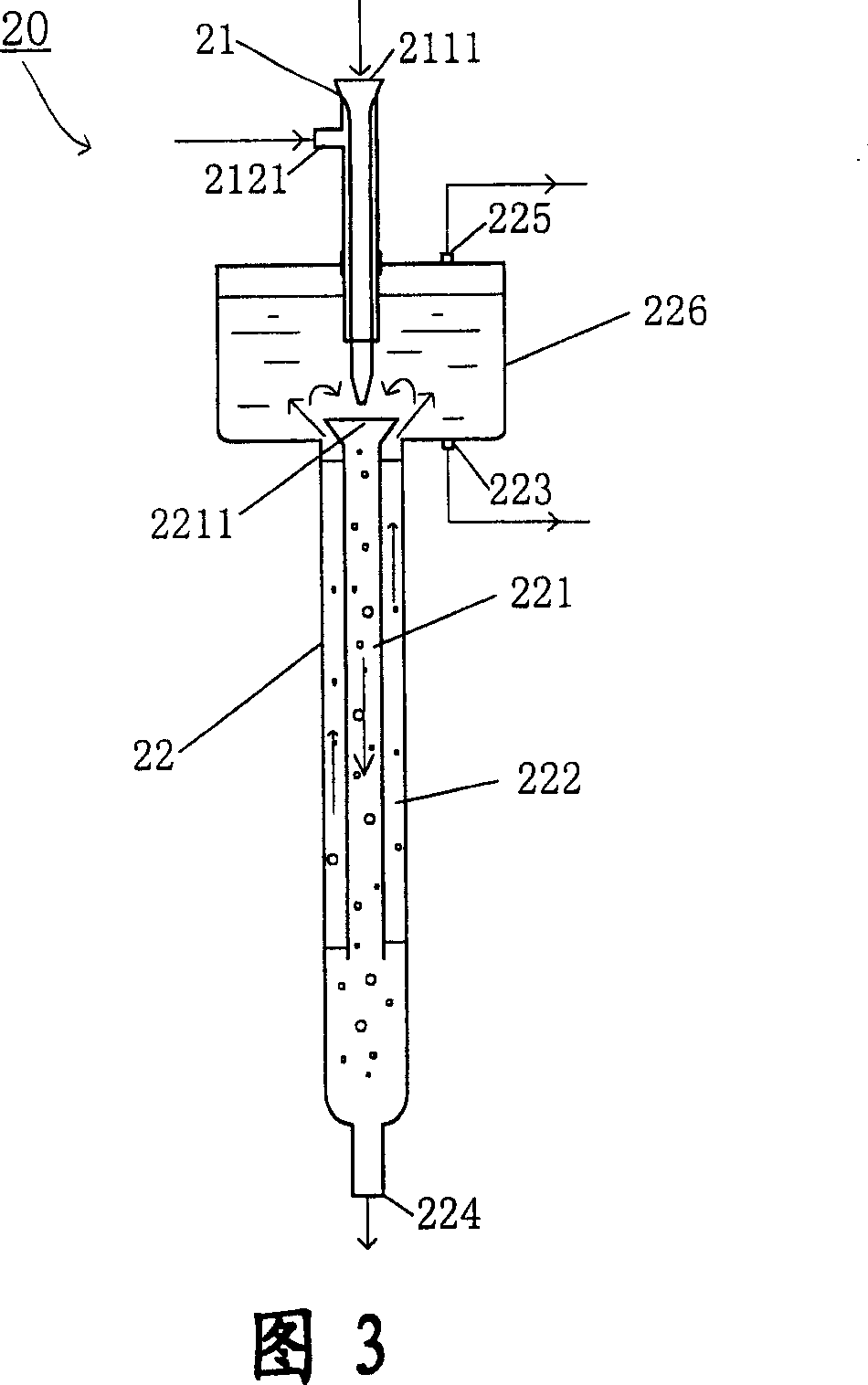

[0055] Example 1: Internal circulation jet absorber

[0056] Please refer to Fig. 3 and Fig. 4, this embodiment provides a simple and practical absorption reactor.

[0057] The absorption reactor 20 is composed of a nozzle 21 and a reaction tube 22. The nozzle 21 is composed of an inner tube 211 and a sleeve 212. The inner tube 211 is basically a hollow tube with a liquid inlet 2111 at the upper end and a tapered liquid outlet 2112 at the lower end. , the sleeve 212 is sleeved outside the inner tube 211, the upper part is closed with the outer wall of the inner tube, and the lower part is connected to the outside world. There is an annular gap 213 between the sleeve 212 and the inner tube 211, and the side wall of the sleeve 212 is suitable There is a gas inlet 2121 in communication with the annulus 213; as shown in FIG. 4 , the length of the inner tube 211 is slightly longer than that of the casing 212, and the liquid outlet 2112 at the lower end extends out of the casing 212...

Embodiment 2

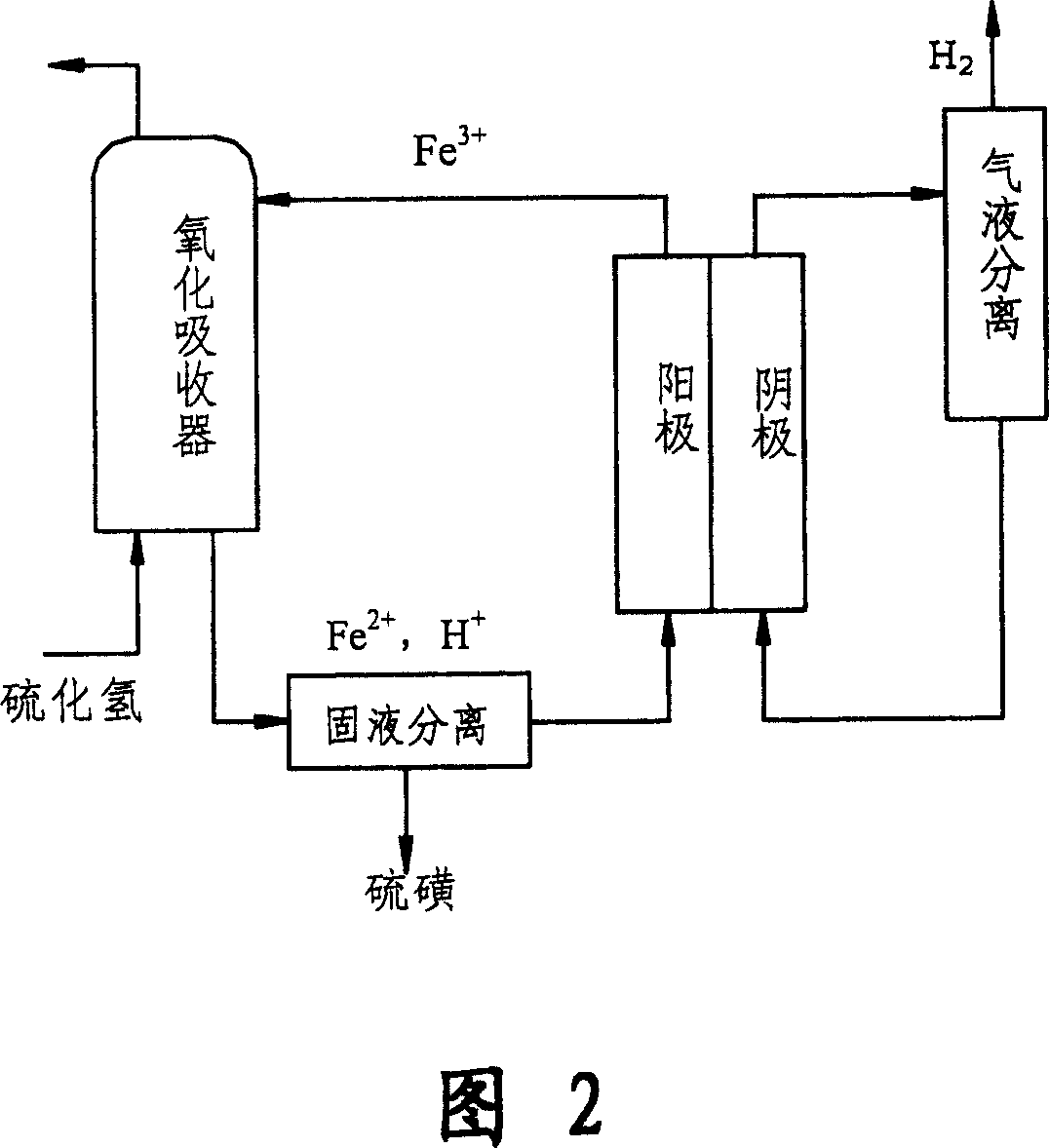

[0062] Embodiment 2: The process of simultaneously recovering sulfur and hydrogen from acid gas containing hydrogen sulfide using double reactors

[0063] Please refer to Figure 5 for the specific process, which mainly consists of three parts: absorption, separation and electrolytic regeneration. The specific description is as follows:

[0064] The acid gas containing hydrogen sulfide is metered and passed into the absorption reactor 20, and the absorption liquid (containing Fe 3+ The solution) is also sent to the absorption reactor 20 after being metered. By controlling the appropriate liquid / gas volume ratio, the absorption liquid carries the gas into the absorption reactor 20 in a jetting manner, and the oxidation reaction of the two in the reactor causes the hydrogen sulfide is absorbed to generate sulfur, and the Fe in the absorption liquid 3+ is reduced to Fe 2+ (At least partially reduced), the absorption liquid becomes the liquid to be regenerated at this time, and ...

Embodiment 3

[0070] The operation process is as described in Example 2, and the hydrogen sulfide gas velocity and absorption liquid (FeCl 3 ) flow rate to measure the hydrogen sulfide absorption rate under different absorption conditions.

[0071] 1. The gas velocity of acid gas (including hydrogen sulfide) is 40-100L / h, the liquid phase flow rate is 300-500L / h, the liquid / gas volume ratio is controlled within the range of 3-10, and the Fe in the absorption liquid is 3+ The concentration is about 0.6M, Fe in the absorption solution 2+ The concentration is about 0.6M, the hydrogen ion concentration is about 8M (HCl system), the absorption reaction is normal pressure, and the temperature is 40°C.

[0072] Record respectively the hydrogen sulfide content in the acid gas entering the absorption reactor and the tail gas discharged from the reactor (fixed liquid phase flow rate, changing the gas velocity of the acid gas), calculate the absorption rate (%) of hydrogen sulfide, and obtain the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com