Method for wet-process vanadium extraction by using vanadium- and titanium-containing converter slag

A technology for converter slag and vanadium-titanium slag, which is applied in the field of vanadium-containing titanium converter slag treatment, can solve the problems of strong corrosion, high equipment material requirements, unfavorable continuous production, etc., and achieve low equipment requirements, environmental friendliness, and realization The effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

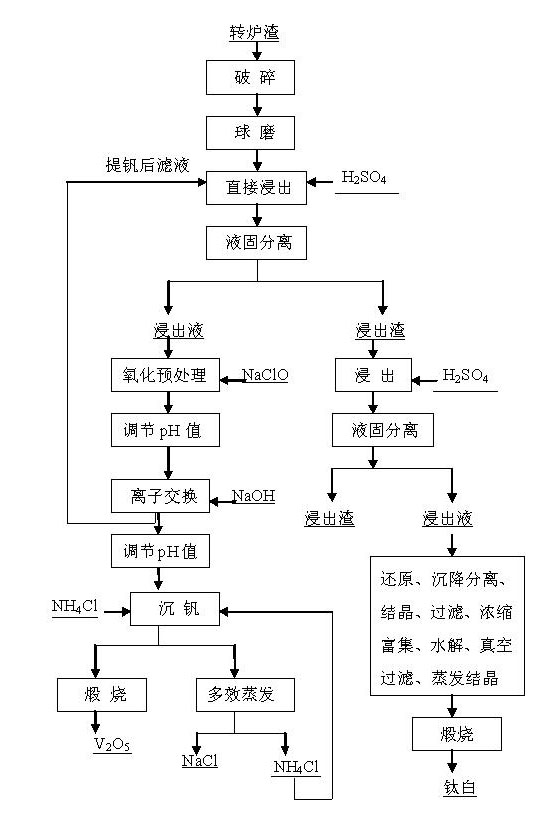

[0040] The process steps of the wet vanadium extraction method using vanadium-containing titanium converter slag (the main component is 1# in Table 2) are as follows:

[0041] (1) Direct acid leaching

[0042] The vanadium-titanium slag is crushed and ball-milled to 150 μm, and then directly leached with 20% sulfuric acid in an autoclave without adding an oxidant, so that vanadium enters the leaching solution in the form of vanadyl sulfate, and titanium is enriched in the leaching slag. The leaching process conditions are: the volume of sulfuric acid: the mass of vanadium-titanium slag, the ratio of sulfuric acid to vanadium-titanium slag is 20:1, the leaching temperature is 120°C, the leaching time is 150min, and the stirring speed is 500rpm. Liquid-solid separation is carried out after leaching to obtain vanadyl sulfate-containing leaching solution and titanium-enriched leaching residue.

[0043] (2) Purification and separation of vanadium-containing leachate

[0044] Add ...

Embodiment 2

[0054] The process steps of the wet vanadium extraction method using vanadium-containing titanium converter slag (the main component is 1# in Table 2) are as follows:

[0055] (1) Direct acid leaching

[0056] The vanadium-titanium slag is crushed and ball-milled to 250 μm, and then directly leached with sulfuric acid with a mass concentration of 30% in the autoclave without adding an oxidant, so that vanadium enters the leaching solution in the form of vanadyl sulfate, and titanium is enriched in the leaching residue. The leaching process conditions are: according to the volume of sulfuric acid: the mass of vanadium-titanium slag, the ratio of sulfuric acid to vanadium-titanium slag is 2:1, the leaching temperature is 200°C, the leaching time is 30min, and the stirring speed is 1000rpm. Liquid-solid separation is carried out after leaching to obtain vanadyl sulfate-containing leaching solution and titanium-enriched leaching residue.

[0057] (2) Purification and separation o...

Embodiment 3

[0067] The process steps of the wet vanadium extraction method using vanadium-containing titanium converter slag (the main component is 2# in Table 2) are as follows:

[0068] (1) Direct acid leaching

[0069] The vanadium-titanium slag is crushed and ball-milled to 38 μm, and then directly leached with sulfuric acid with a mass concentration of 5% in the autoclave without adding an oxidant, so that vanadium enters the leaching solution in the form of vanadyl sulfate, and titanium is enriched in the leaching residue. The leaching process conditions are: sulfuric acid volume: mass of vanadium-titanium slag, the ratio of sulfuric acid to vanadium-titanium slag is 40:1, the leaching temperature is 50°C, the leaching time is 300min, and the stirring speed is 50rpm. Liquid-solid separation is carried out after leaching to obtain vanadyl sulfate-containing leaching solution and titanium-enriched leaching residue.

[0070] (2) Purification and separation of vanadium-containing leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com