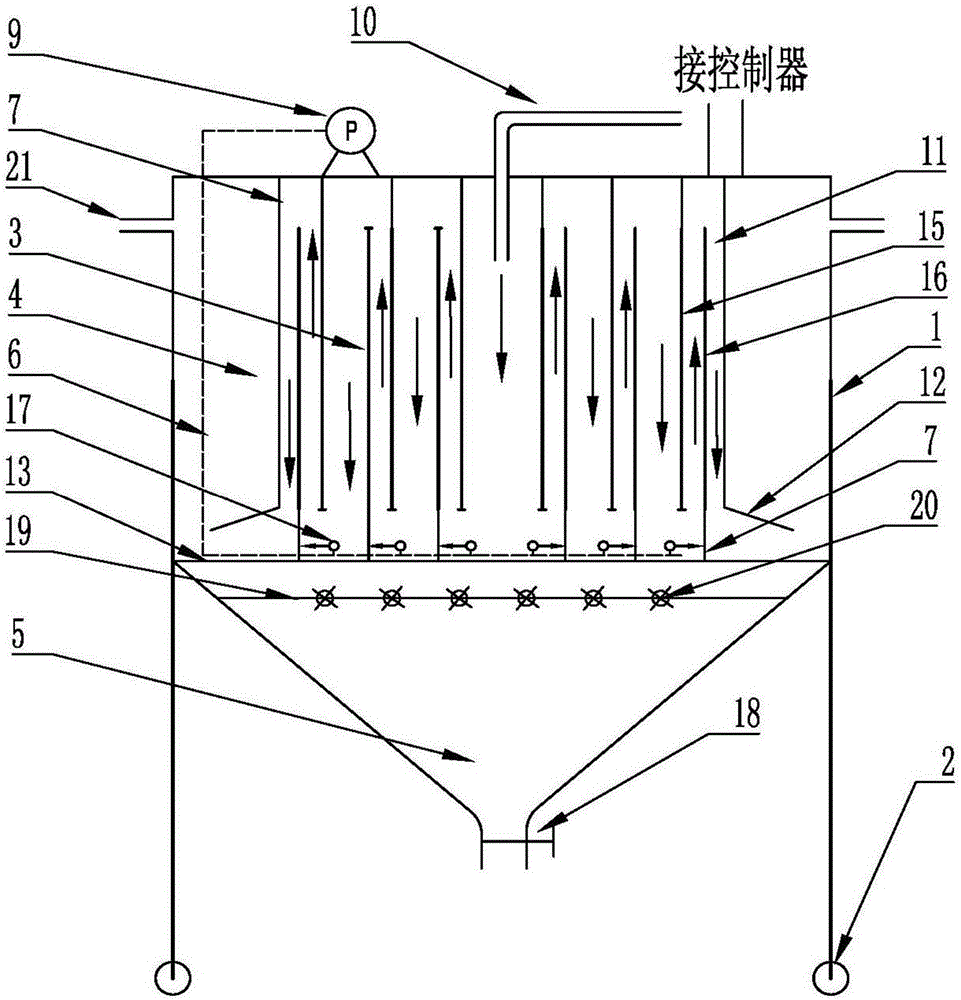

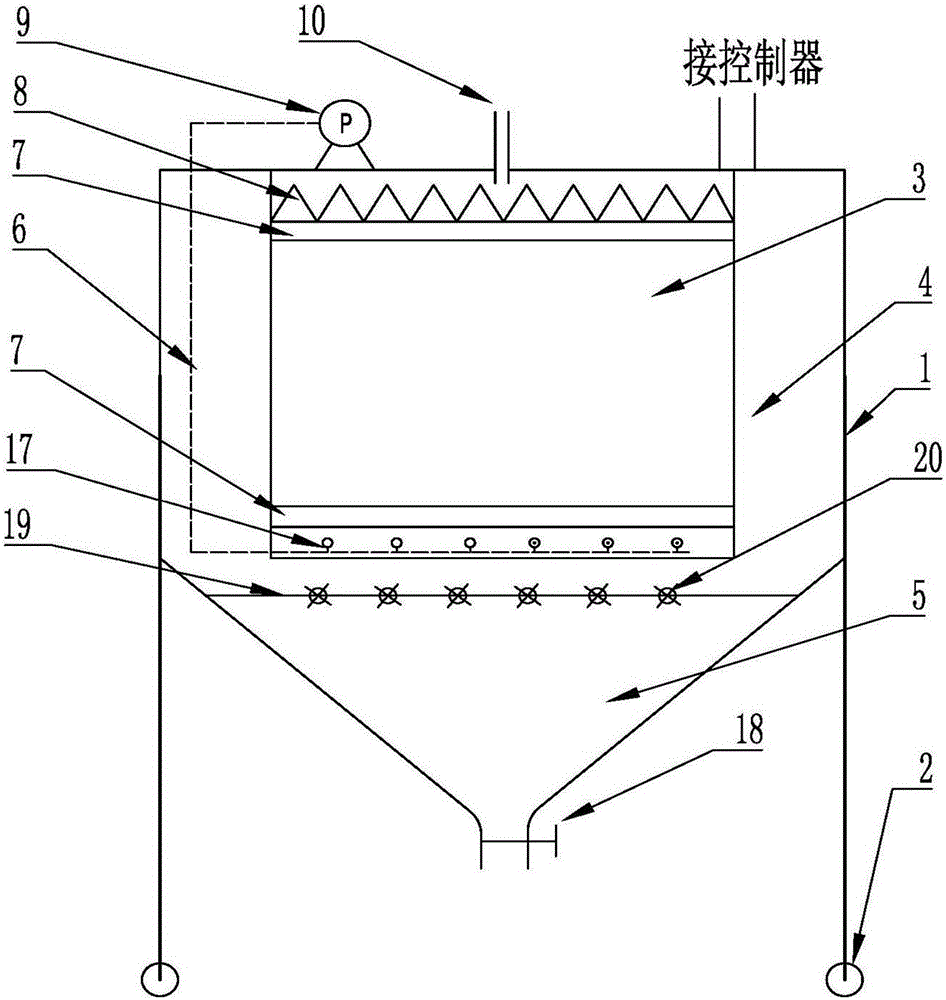

High-concentration suspended substance electric-flocculation/floc separation precipitation integrated treatment device

A treatment device and high-concentration technology, applied in water/sewage treatment, water/sludge/sewage treatment, vehicle washing facility wastewater treatment, etc. problems, to achieve the effect of improving the solid-liquid separation effect, high utilization of the device space, and ensuring the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

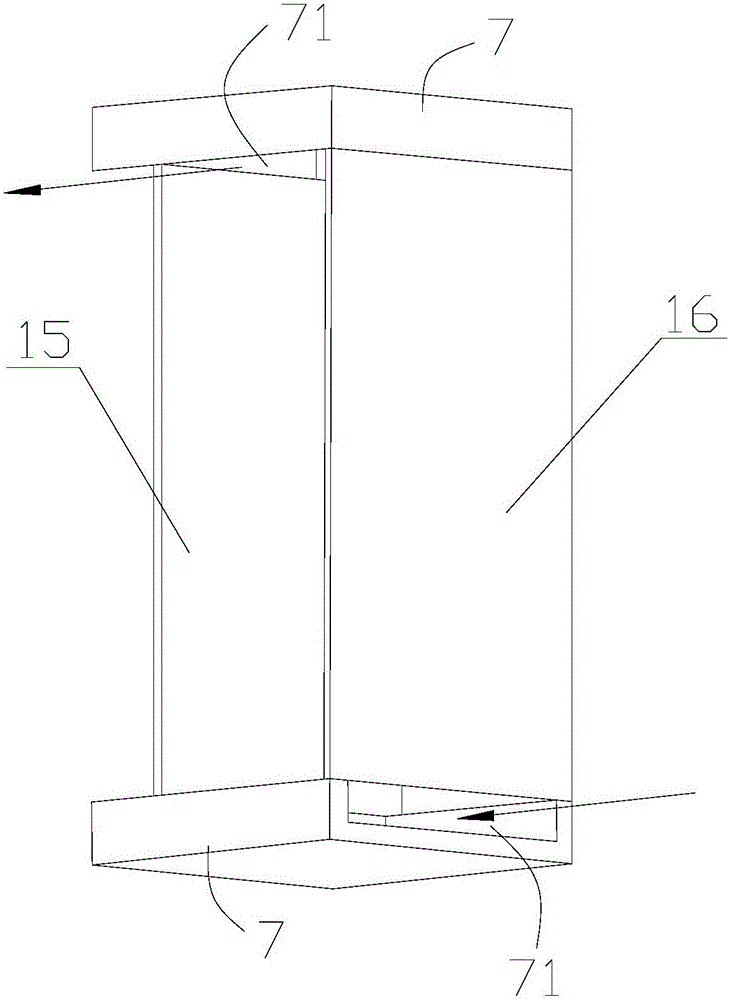

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Stone processing wastewater treatment

[0042] Collect a certain stone processing wastewater and use the prototype product of this device for continuous treatment. The concentration of influent suspended solids is 2812mg / L, and the flow rate is 1.82m 3 / h, the working current intensity is 0.06A / m 2 , the concentration of suspended solids in the effluent after treatment is reduced to 52mg / L, which is lower than the 100mg / L stipulated in the first-level discharge standard of the "Integrated Wastewater Discharge Standard" (GB8978-1996), the removal rate of suspended solids reaches 98.15%, and the energy consumption is about 0.20 yuan / ton of water. After flocculation, the particle size of high-concentration suspended solids changed significantly, specifically, the large particle components decreased, and the overall particle size became smaller. After flocculation, the median particle size decreased from 35.5 μm to 7.21 μm (Table 1).

[0043] Table 1 The ...

Embodiment 2

[0046] Example 2: Treatment of sand and gravel aggregate processing wastewater

[0047] Collect sand and gravel aggregate processing wastewater (concentration about 10,000 mg / L) from a hydropower station after primary sedimentation, and use the prototype product of this device for continuous treatment. Using the method of adding water to dilute, set the concentration range of influent suspended solids to 2500mg / L-10000mg / L, and the working current intensity is 1.82m 3 / h, the current intensity is 0.06A / m 2 , after treatment, see Table 2 for the concentration and median particle size of effluent suspended solids. It can be seen from Table 2 that the device can treat the sand and gravel aggregate processing wastewater to the first-level discharge standard of the "Integrated Wastewater Discharge Standard" (GB8978-1996). Under this working current intensity, the cost of electrolysis energy consumption does not exceed 0.30 yuan / ton.

[0048] Table 2 Electrocoagulation treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com