Equipment for removing lead in wastewater of lead storage battery

A lead-acid storage battery and lead removal technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of small footprint and inability to meet the standard stably, and achieve the goal of occupying an area of Small area, shortened settling time, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

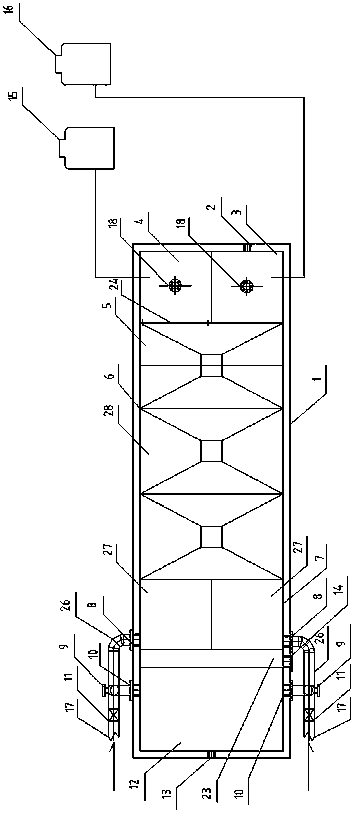

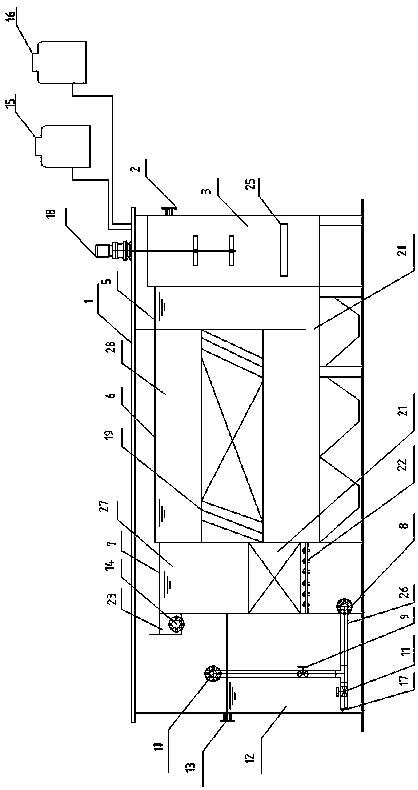

[0030] Such as figure 1 and figure 2 Shown is a lead-removing equipment 1 for lead-acid battery wastewater, comprising: a primary reaction zone 3, a secondary reaction zone 4, a sedimentation zone 6, a filter zone 7 and a water outlet zone 13, and the primary reaction zone 3 side The upper end of the wall is provided with a water inlet 2, and the primary reaction zone 3 is connected with the secondary reaction zone 4 through the primary reaction zone water outlet 25 at the lower end, and the secondary reaction zone 4 is connected with the secondary reaction zone water outlet 24 at the upper end. The settling area 6 is connected, and the settling area 6 is connected with the filter area 7, and the water is distributed by overflowing water, and the filter area 7 is connected to the two sides of the water outlet area 12 through the filter area outlet pipes 26 at the bottom of both sides. connection; wherein the primary reaction zone 3 is also connected to the dosing device 16 o...

Embodiment 2

[0032] According to embodiment 1, a kind of lead-acid storage battery wastewater high-efficiency deleading reactor processes the process and results of lead-acid storage wastewater as follows, the lead-acid battery factory production wastewater lead content is 32.6mg / L, and the waste water volume is 20m 3 / h, drainage 8h per day, the waste water is collected and processed through lead battery waste water high-efficiency deleading reactor 1, then pumped up and enters the primary reaction zone 3 through the water inlet 2, and the inflow flow rate is 10m 3 / h, while the lead-removing agent dosing device 16 connected to the primary reaction zone 3 adds the lead-removing agent, the used lead-removing agent sodium sulfide content is 25%, and the polyaluminum chloride content is 20%, and the dosage is based on sodium sulfide and The lead content (mass ratio) in the wastewater is 8:1, and the dosage of lead removal agent is 1.0L / m 3 , stirred by the stirring device 18, the waste water ...

Embodiment 3

[0034] According to embodiment 1, a kind of lead-acid battery waste water high-efficiency deleading reactor processes lead-acid battery waste water process and result as follows, a certain lead-acid battery factory produces waste water lead content 51.4mg / L, and waste water volume is 15m 3 / h, drainage 10h per day, after the waste water is collected, it will be processed through the high-efficiency deleading reactor 1 for lead-acid battery waste water, and will be lifted by the pump to enter the primary reaction zone 3 through the water inlet 2, and the inflow flow rate is 10m 3 / h, while the lead-removing agent dosing device 16 connected to the primary reaction zone 3 adds the lead-removing agent, the used lead-removing agent sodium sulfide content is 50%, and the polyaluminum chloride content is 20%, and the dosage is based on sodium sulfide and The lead content (mass ratio) in the waste water is added at 5:1, and the dosage of the lead removal agent is 0.5L / m 3 , stirred by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com