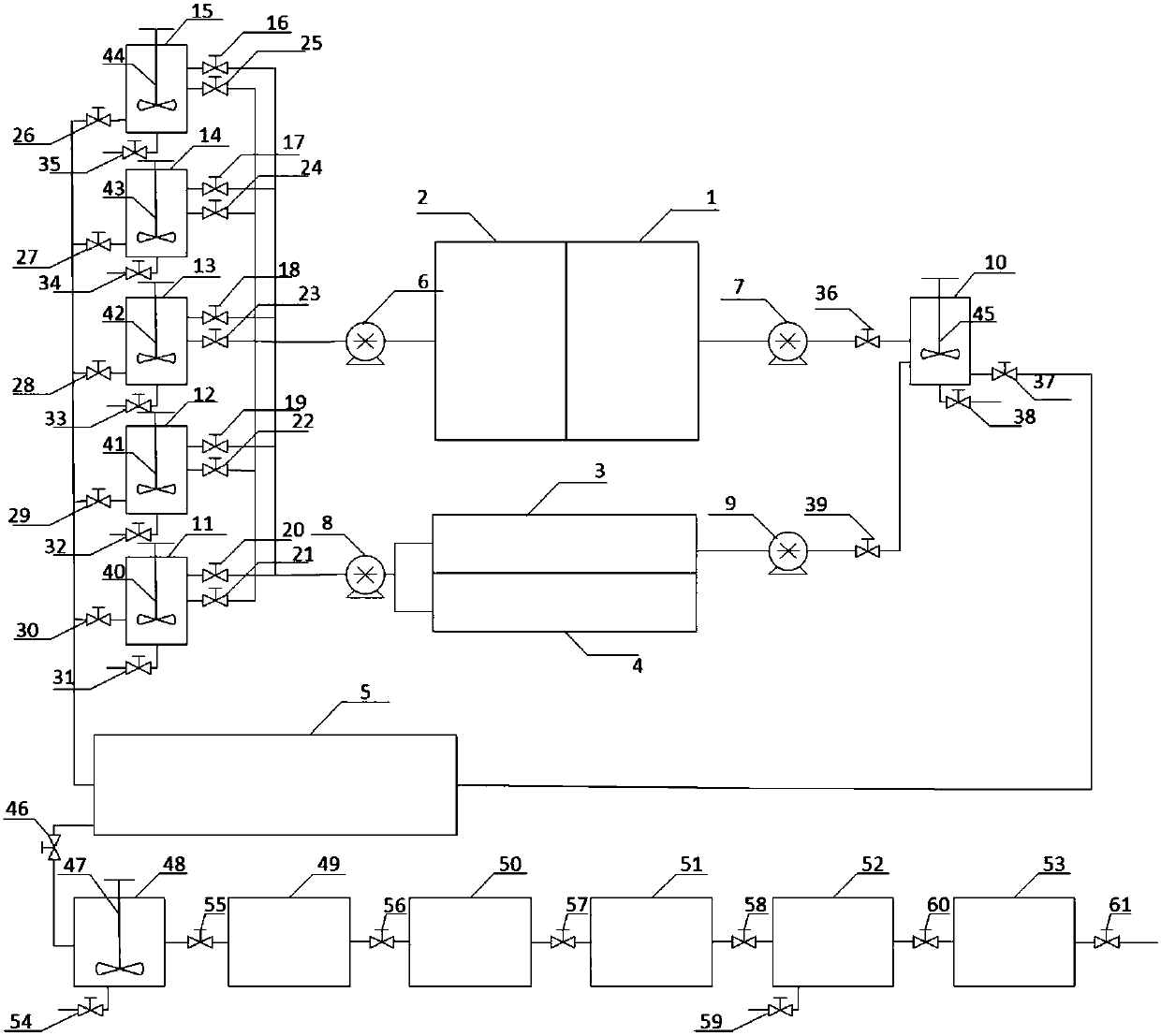

Nickel-containing industrial wastewater treatment device and process

A technology for industrial wastewater and treatment devices, which is applied in the fields of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of no classification of nickel-containing wastewater, low nickel removal efficiency, and low phosphorus COD removal rate. , to achieve good recovery value, solve the problem of chemical waste, and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Actual nickel-containing industrial waste water is processed by the above-mentioned pretreatment device according to the above-mentioned operating method. Ni in electroless nickel plating wastewater influent 2+ is 6120mg / L, COD is 32800mg / L, TP is 215mg / L, TN is 1580mg / L; 2+ It is 8120mg / L.

[0043] After stable operation, the results are as follows: Ni in water 2+ 0.05mg / L, effluent COD is 38mg / L, TP is 0.2mg / L, ammonia nitrogen is 5.9mg / L; 2+ , COD, ammonia nitrogen, and phosphorus removal have good results, and the system can always run stably.

Embodiment 2

[0045] Actual nickel-containing industrial waste water is processed by the above-mentioned pretreatment device according to the above-mentioned operating method. Ni in electroless nickel plating wastewater influent 2+ is 72500mg / L, COD is 37600mg / L, TP is 254mg / L, TN is 1850mg / L; 2+ It is 9540mg / L.

[0046] After stable operation, the results are as follows: Ni in water 2+ is 0.02mg / L, effluent COD is 45mg / L, TP is 0.31mg / L, and ammonia nitrogen is 4.5mg / L; 2+ , COD, ammonia nitrogen, and phosphorus removal have good results, and the system can always run stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com