Recycle and reuse method of by-product from production of silicon carbide

A technology of silicon carbide and by-products, which is applied in the field of recycling of by-products in silicon carbide production, can solve problems such as environmental pollution and waste of resources, achieve environmental benefits, realize reuse, and improve utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

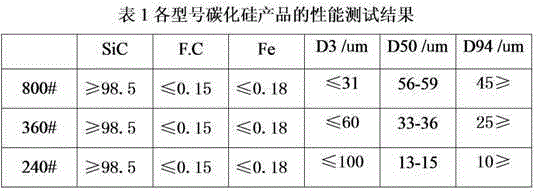

Image

Examples

Embodiment 1

[0018] Embodiment 1: a method for recycling by-products in silicon carbide production, comprising the following steps:

[0019] (1) Slurry making: Put silicon carbide products with a particle size greater than 1000# in the slurry making tank, add water and stir evenly to obtain a slurry with a mass percentage of silicon carbide micropowder of 30%;

[0020] (2) Impurity removal: the uniformly mixed slurry is firstly deironed by a magnetic separator, and then carbon is removed to remove iron impurities and carbon impurities in the slurry; then the pH value of the slurry is adjusted to 7-8;

[0021] (3) Primary classification: Put the slurry obtained in step (2) into the classification tank, add polyethyleneimine accounting for 0.5‰ of the slurry mass, settle naturally for 30 minutes, and classify to obtain 800# silicon carbide products;

[0022] (4) Secondary classification: add polyethyleneimine accounting for 0.9‰ of its mass to the slurry obtained in step (3), settle naturall...

Embodiment 2

[0025] Embodiment 2: a method for recycling by-products in silicon carbide production, the difference from embodiment 1 is that

[0026] Step (3), add polyethyleneimine and marine polysaccharide mixture accounting for 0.6‰ of slurry mass, settle naturally for 25 minutes, and grade to obtain 800# silicon carbide products;

[0027] Step (4), add a mixture of polyethyleneimine and marine polysaccharides accounting for 0.8‰ of the slurry mass, settle naturally for 25 minutes, and grade to obtain 360# silicon carbide products;

[0028] Step (5), add polyethyleneimine and marine polysaccharide mixture accounting for 1.0‰ of the slurry mass, settle naturally for 25 minutes, and classify to obtain 240# silicon carbide products.

Embodiment 3

[0029] Example 3: A method for recycling by-products in silicon carbide production, the difference from Example 1 is that in step (1), the mass percentage of silicon carbide micropowder in the slurry is 20%;

[0030] Step (3), add polyethylene glycol accounting for 0.7‰ of the mass of the slurry, settle naturally for 30 minutes, and grade to obtain 800# silicon carbide products;

[0031] Step (4), add polyethylene glycol accounting for 0.8‰ of the slurry mass, settle naturally for 25 minutes, and obtain 360# silicon carbide products by classification;

[0032] Step (5), add polyethylene glycol accounting for 1.1‰ of the mass of the slurry, settle naturally for 20 minutes, and grade to obtain 240# silicon carbide products;

[0033] The molecular weight of polyethylene glycol used is 600~1000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com