Semiconductor silicon crystal bar slicing processing equipment and silicon powder recovery method thereof

A technology for processing equipment and silicon crystal rods, which is applied to the semiconductor silicon crystal rod slicing processing equipment and the field of silicon powder recycling, can solve the problems of falling and adhesion of the surface quality of silicon wafers, shorten the time, ensure the water permeability, improve the The effect of the ability to keep working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

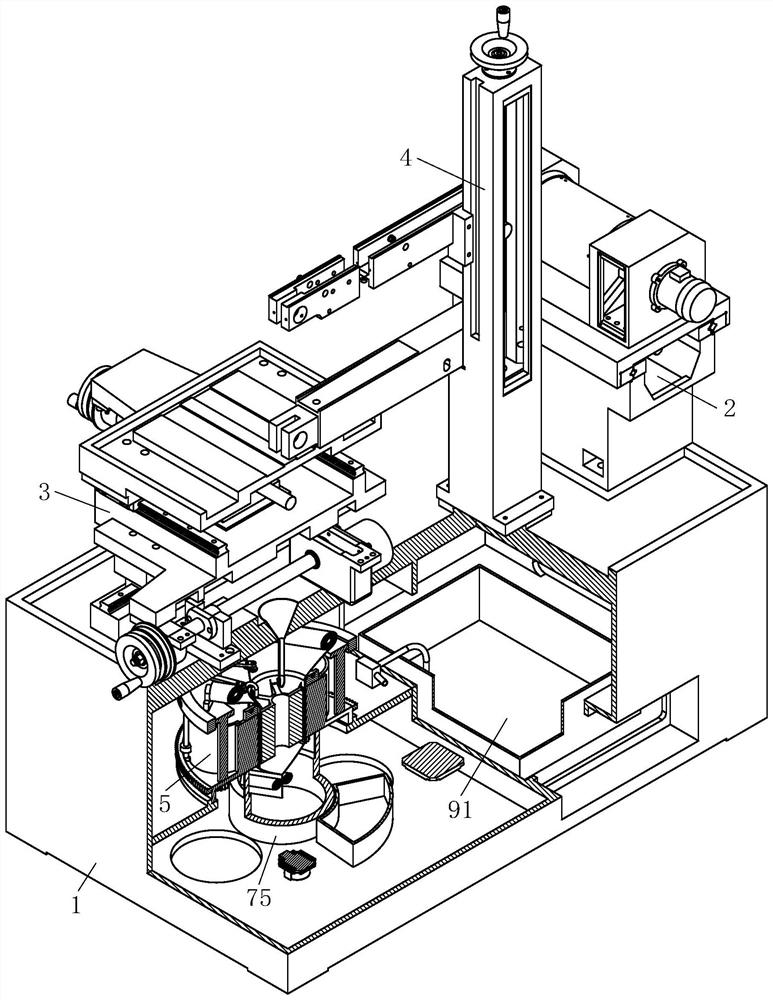

[0046] like Figure 1 to Figure 10 As shown, a semiconductor silicon ingot slicing processing equipment includes a bed 1, a wire conveying mechanism 2, a worktable 3, a wire rack 4 and a cooling liquid circulation component 5; Wire transport mechanism 2 and wire rack 4; the wire rack 4 is located between the workbench 3 and the wire transport mechanism 2; the workbench 3, the wire transport mechanism 2 and the wire rack 4 are all fixed connected to the bed body 1; the cooling liquid circulation component 5 is arranged inside the bed body 1;

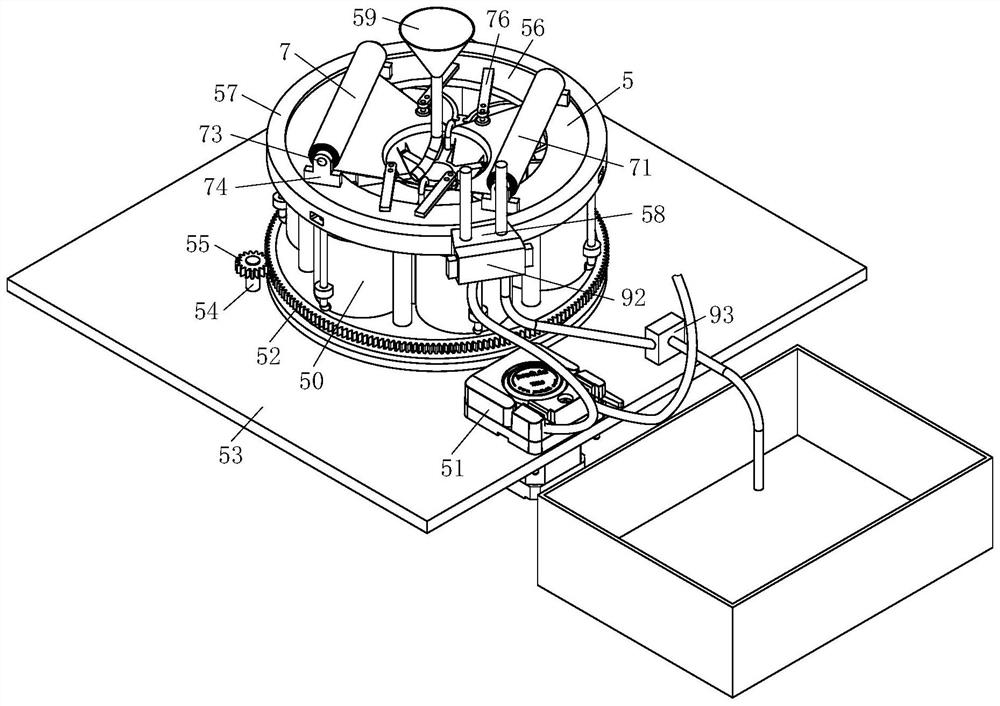

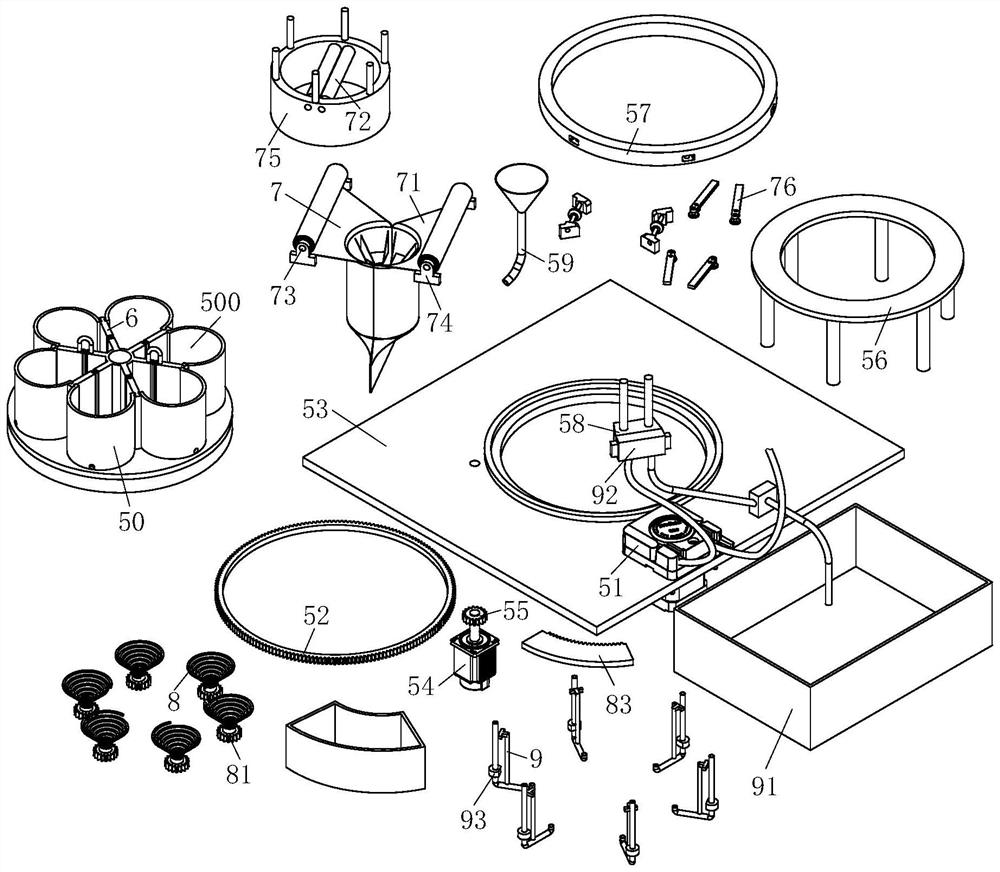

[0047] The cooling liquid circulation component 5 includes a cooling liquid tank 50, a pump 51, a ring gear 52, a chassis 53, a motor 54, a No. 1 gear 55, a support frame 56, a liquid suction ring 57 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com