Polymetallic ore beneficiation wastewater recycling method

A technology for polymetallic ore and beneficiation wastewater, which is used in flocculation/sedimentation water/sewage treatment and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for recycling polymetallic ore dressing wastewater, wherein: comprising two steps of physical treatment and biological treatment, the specific method is as follows:

[0024] (1) Physical treatment process of polymetallic mineral processing wastewater:

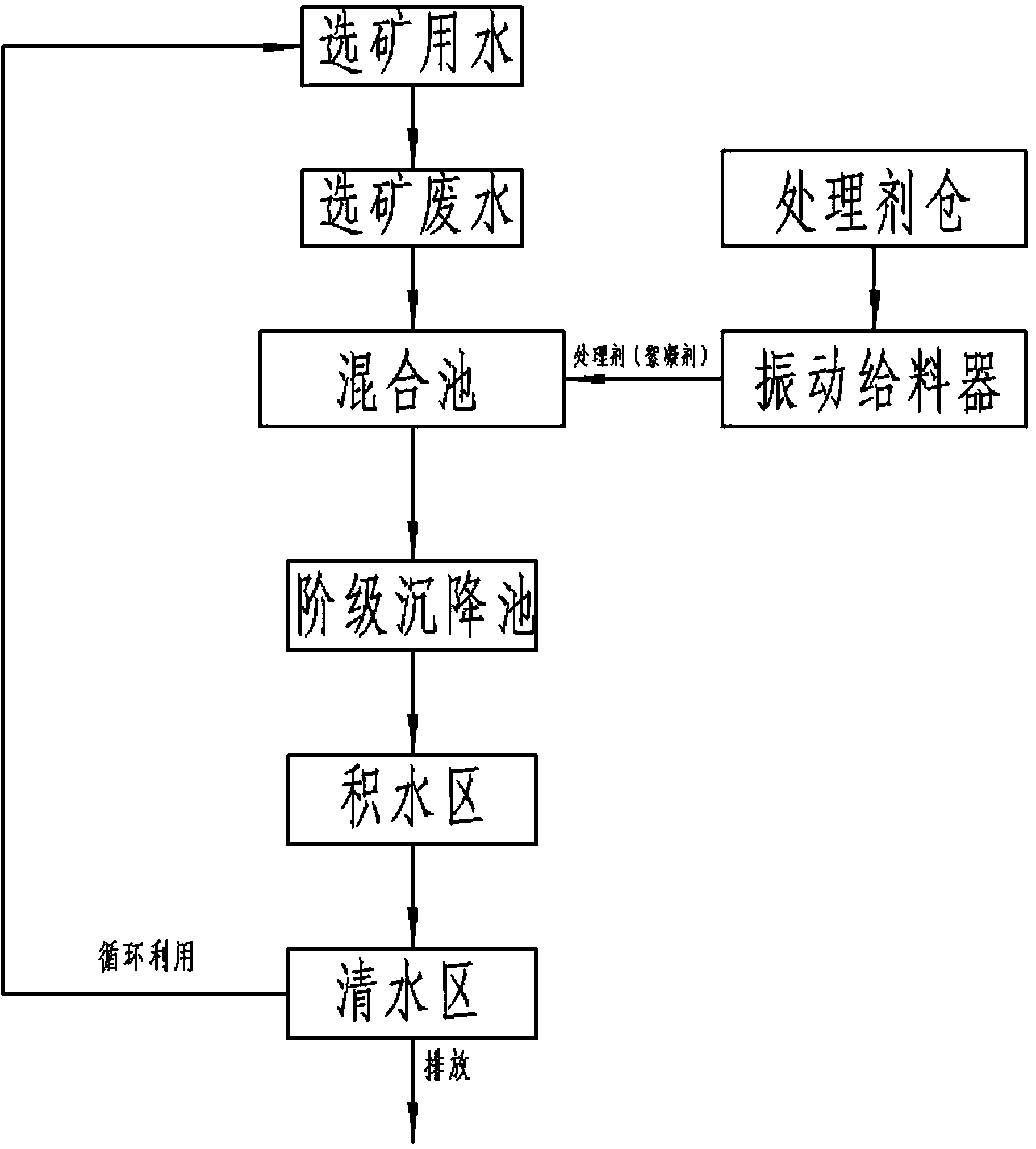

[0025] The polymetallic ore beneficiation wastewater produced by the polymetallic ore dressing plant is input into the mixing tank through the pump, the treatment agent is added into the treatment agent bin, and respectively input into the vibrating feeder through the pipeline, and the vibrating feeder is used The treatment agent is quantitatively added to the mixing tank, and under the condition of sufficient stirring, the treatment agent is mixed with the polymetallic ore beneficiation wastewater to generate flocculation water, and the flocculation water is input into the settlement tank through the waste water output pump, and the flocculation water is discharged in the settlement tank The flocs settle natura...

Embodiment 2

[0034] A method for recycling polymetallic ore dressing wastewater, wherein: comprising two steps of physical treatment and biological treatment, the specific method is as follows:

[0035] (1) Physical treatment process of polymetallic mineral processing wastewater:

[0036] The polymetallic ore beneficiation waste water produced by the polymetallic ore dressing plant is input into the mixing tank through the pump, the treatment agent is added into the treatment agent bin, and respectively input into the vibrating feeder through the pipeline, and the vibrating feeder is used The treatment agent is quantitatively added to the mixing tank, and under the condition of sufficient stirring, the treatment agent is mixed with the polymetallic mineral processing wastewater to generate flocculation water, which is input into the settlement tank through the waste water output pump, and the flocculation water is discharged in the settlement tank The flocs settle naturally, and the clarif...

Embodiment 3

[0046] A method for recycling polymetallic ore dressing wastewater, wherein: comprising two steps of physical treatment and biological treatment, the specific method is as follows:

[0047] (1) Physical treatment process of polymetallic mineral processing wastewater:

[0048] The polymetallic ore beneficiation waste water produced by the polymetallic ore dressing plant is input into the mixing tank through the pump, the treatment agent is added into the treatment agent bin, and respectively input into the vibrating feeder through the pipeline, and the vibrating feeder is used The treatment agent is quantitatively added to the mixing tank, and under the condition of sufficient stirring, the treatment agent is mixed with the polymetallic mineral processing wastewater to generate flocculation water, which is input into the settlement tank through the waste water output pump, and the flocculation water is discharged in the settlement tank The flocs settle naturally, and the clarif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com