Dyeing wastewater treating agent and preparing method thereof

A printing and dyeing sewage and treatment agent technology, applied in the direction of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, etc., can solve the problems of easy scaling and poor decolorization effect in the treatment process, and achieve cost reduction Low, accelerated settling time, strong adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

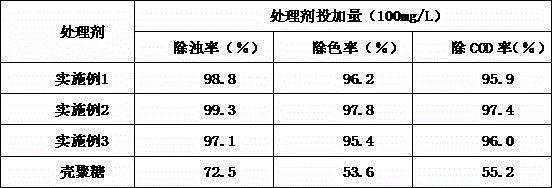

Examples

Embodiment 1

[0013] A printing and dyeing sewage treatment agent, prepared from the following raw materials in parts by weight: 16 parts of aluminum hydroxide gel, 15 parts of sodium metaaluminate, 10 parts of lime, 3 parts of corn starch, 8 parts of sodium silicate, lignin sulfonate 2 parts of sodium bicarbonate, 3 parts of activated carbon, 1.2 parts of powder additives, 2 parts of urea, 40 parts of water.

Embodiment 2

[0015] A printing and dyeing sewage treatment agent, prepared from the following raw materials in parts by weight: 17 parts of aluminum hydroxide gel, 18 parts of sodium metaaluminate, 11 parts of lime, 4 parts of corn starch, 9 parts of sodium silicate, lignin sulfonate 3 parts of sodium bicarbonate, 4 parts of activated carbon, 1.3 parts of powder additives, 4 parts of urea, and 50 parts of water.

[0016] Example 1

[0017] A printing and dyeing sewage treatment agent, prepared from the following raw materials in parts by weight: 18 parts of aluminum hydroxide gel, 20 parts of sodium metaaluminate, 12 parts of lime, 5 parts of corn starch, 10 parts of sodium silicate, lignin sulfonate 4 parts of sodium bicarbonate, 5 parts of activated carbon, 1.5 parts of powder additives, 6 parts of urea, and 60 parts of water.

[0018] The powder additive is a mixture of fly ash, zeolite and diatomaceous earth in a weight ratio of 1:2:5.

[0019] The preparation method of the printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com