Pond engineering circulating water zero-discharge culture system

A breeding system and engineering technology, applied in the field of pond engineering circulating water zero discharge breeding system, can solve the problems of short water use time, low water treatment effect, regular water change, etc., and achieve good water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

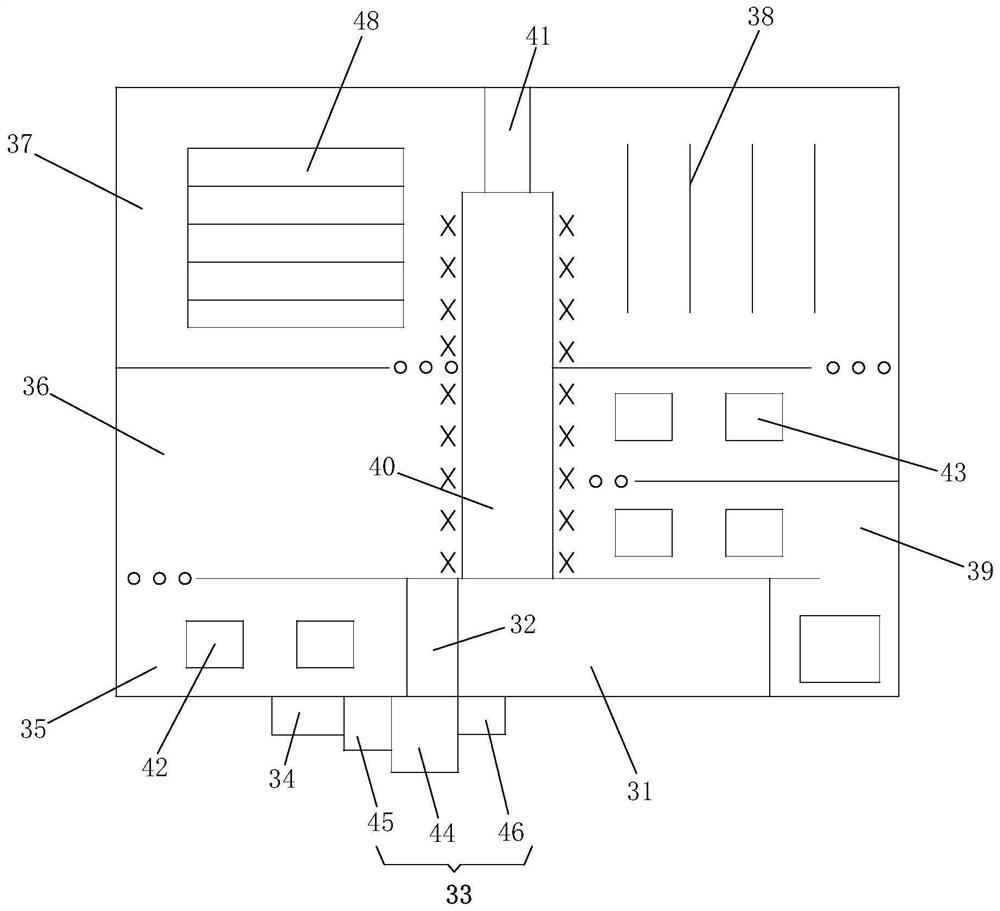

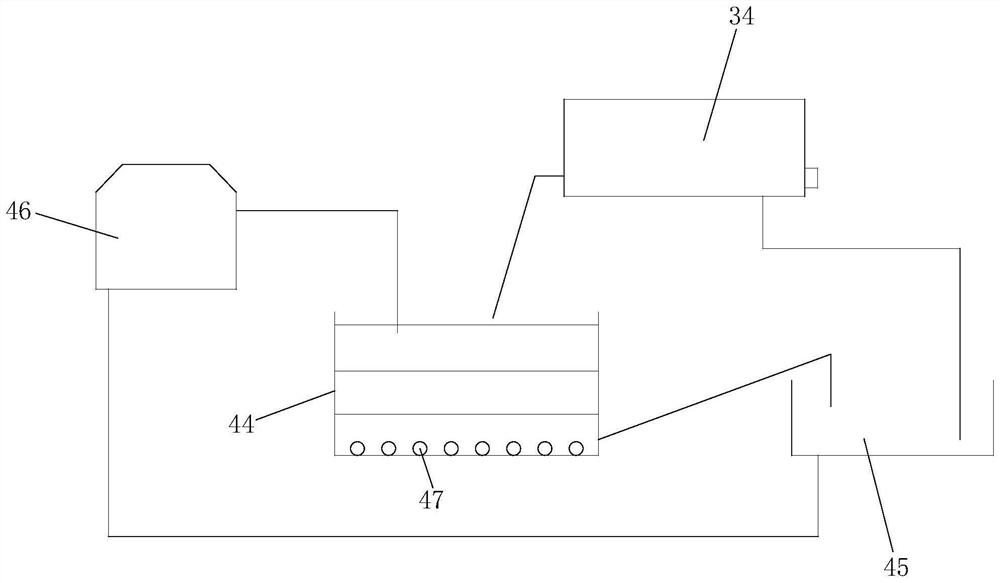

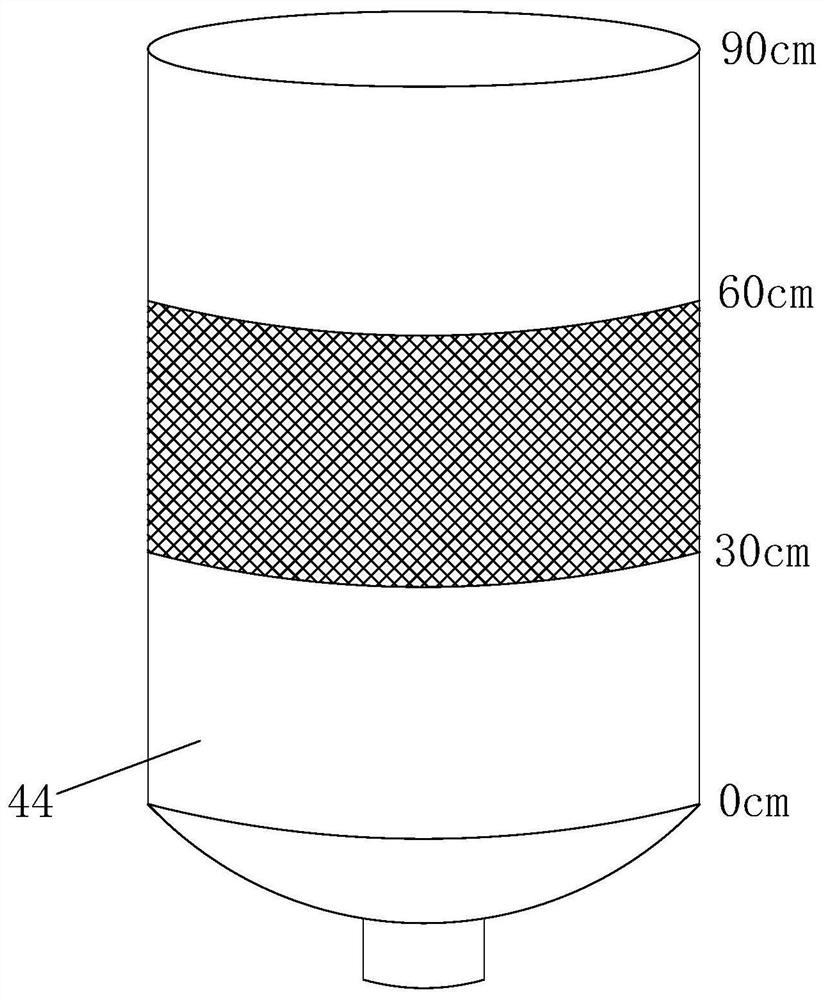

[0077] see figure 1 , figure 2 as well as image 3 , the present embodiment provides a zero-discharge pond engineering circulating water aquaculture system, the aquaculture system can form a circulatory system, the aquaculture water body can be used repeatedly, and constitutes a small ecological system. Wherein, the breeding system includes a breeding area 31, a sewage collection area 32, a waste collection area 33, a solid-liquid separation device 34, a purification area 35, a filter-feeding area 36, a precipitation area 37, a biochemical area 38, and a purification area 2 39, A central dam 40 and an over dam 41 may also be included. Among them, the breeding area 31 , the sewage collection area 32 , the purification area 1 35 , the filter-feeding area 36 , the sedimentation area 37 , the biochemical area 38 and the purification area 2 39 are set around and form a closed-loop structure.

[0078] The breeding area 31 is used for cultivating various aquatic products, such ...

Embodiment 2

[0096] see Figure 4-7 , this embodiment provides a pond engineered circulating water zero-discharge aquaculture system, which adds an automatic sewage suction device on the basis of embodiment 1. The sewage suction device is used for suctioning sewage in the sewage collecting area 32 in the pond engineering circulating aquaculture system. The sewage suction device can suck out the solid phase particles in the sewage collection area 32, and transport the sewage containing the solid phase particles to the waste collection area 33 of the cultivation system. In this embodiment, the sewage suction device includes a grille 21, a sewage suction cover 22, a water outlet pipe 24, an ultraviolet fluorescent sensor 26, a sewage suction pipe, a sewage suction pump, a driving mechanism and a controller.

[0097] There are multiple grids 21 , and the multiple grids 21 are parallel to each other and arranged at the bottom of the sewage collection area 32 at equal intervals. The plurality ...

Embodiment 3

[0111] see Figure 8 , Figure 9 as well as Figure 10 , this embodiment provides a pond engineered circulating water zero-discharge aquaculture system, which adds a water pushing device on the basis of Embodiment 1. The water pushing device is used to provide a culture area 31 with dissolved oxygen and fluid culture water. The water pushing device can be arranged at the front end of a culture area 31 of a culture system, and deliver the circulating water produced by the culture system to the culture area 31 . Wherein, the water pushing device includes a bottom frame 1 , a side plate 2 , a water baffle 3 , a rear baffle 4 , and an air-lift water assembly, and may also include a top frame 5 .

[0112] The bottom frame 1 mainly plays the role of connection and support for the whole device. It generally adopts a rectangular frame. In this embodiment, it will make corresponding adjustments according to other components. It only needs to ensure that the bottom frame 1 can pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com