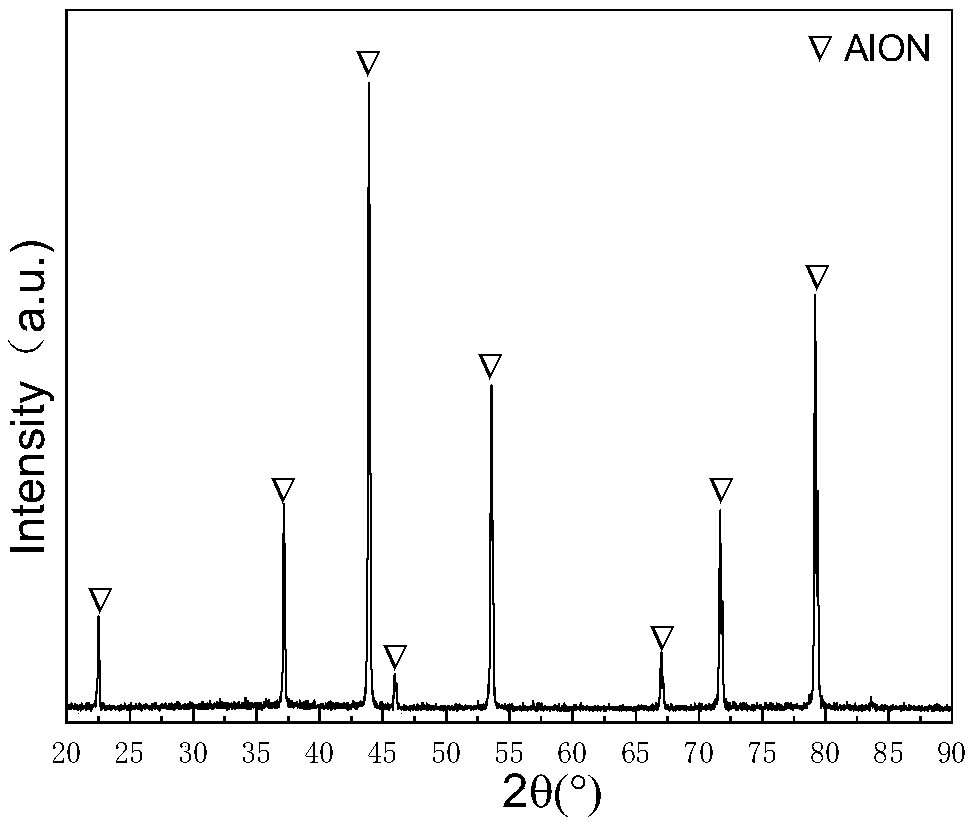

Fractionation method for AlON transparent ceramic powder

A technology of transparent ceramics and powders, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of high sintering temperature of AlON transparent ceramics, large powder particle size, difficulty in obtaining powders, etc., and achieve easy separation , stable performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing AlON transparent ceramic powder suspension and differential centrifugal separation of particles of different sizes, said method comprising the following process steps:

[0037] Weigh 10g of ball-milled AlON transparent ceramic powder and 0.5g of polyvinylpyrrolidone (PVP), pour them into a container together with 200g of absolute ethanol (analytical grade), and place them in an ultrasonic cleaner for 5min (ultrasonic frequency: 40kHz) ) to obtain an anhydrous ethanol suspension of AlON powder, ~4g.

[0038] Take ~80ml of AlON powder suspension in absolute ethanol and place it in a centrifuge tube, and centrifuge at 1000rpm for 1min to complete the first centrifugation of AlON transparent ceramic powder. Pour out the upper liquid, and the obtained precipitate is the first centrifuged particles of AlON powder after ball milling.

[0039] Pour 40ml of absolute ethanol into the separated AlON powder, ultrasonically clean for 5min, soak for 10min, the...

Embodiment 2

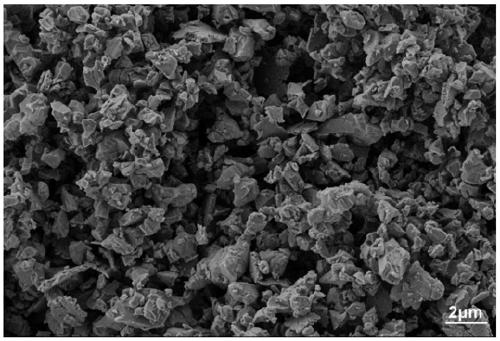

[0041] Put the upper layer liquid after centrifugation in Example 1 into a centrifuge tube, centrifuge at a speed of 2000rpm for 3 minutes for the second centrifugation, remove the centrifuged upper layer liquid, and the precipitate in the centrifuge tube is the AlON powder obtained from the second separation body. Using the alcohol washing method shown in Example 1 to add absolute ethanol, ultrasonication, and centrifugation again, the alcohol washing of the AlON powder is completed. The difference from the alcohol washing in Example 1 is that according to the amount of sediment, each alcohol washing uses no The amount of water ethanol is 20ml, and the rotating speed is 4000rpm. The SEM image of the AlON powder obtained after the second centrifugation is shown in the appendix Figure 4 , the particle size of AlON powder obtained after this separation is mainly 1.0-2.0 μm.

Embodiment 3

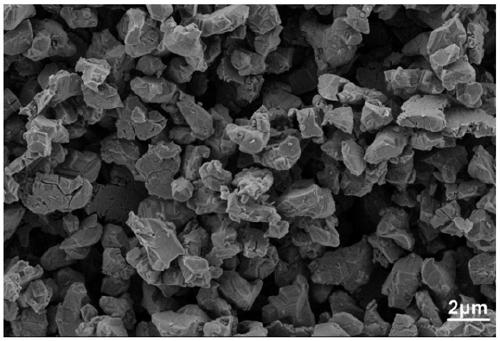

[0043] The difference between embodiment 3 and embodiment 2 is that the object of centrifugation is the upper layer liquid of embodiment 2, the centrifugation speed is 3000rpm, and the centrifugation time is 7min, and when the centrifuged sediment is washed with alcohol, the anhydrous The amount of ethanol is 15ml, and the rotation speed is 5000rpm. The SEM image of the AlON powder obtained after the third centrifugation is shown in the appendix Figure 5 , the particle size of AlON powder obtained after this separation is mainly 0.6-1.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com