Heavy soundproof material, producing method thereof and baffles using the same

A sound insulation board and sound insulation material technology, which is applied in the field of sound barriers such as sound insulation boards and composite heavy sound insulation materials, can solve the problems of uneconomical, unsatisfactory sound insulation effect, and high cost of sound insulation materials to protect the ecological environment , Significant environmental and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

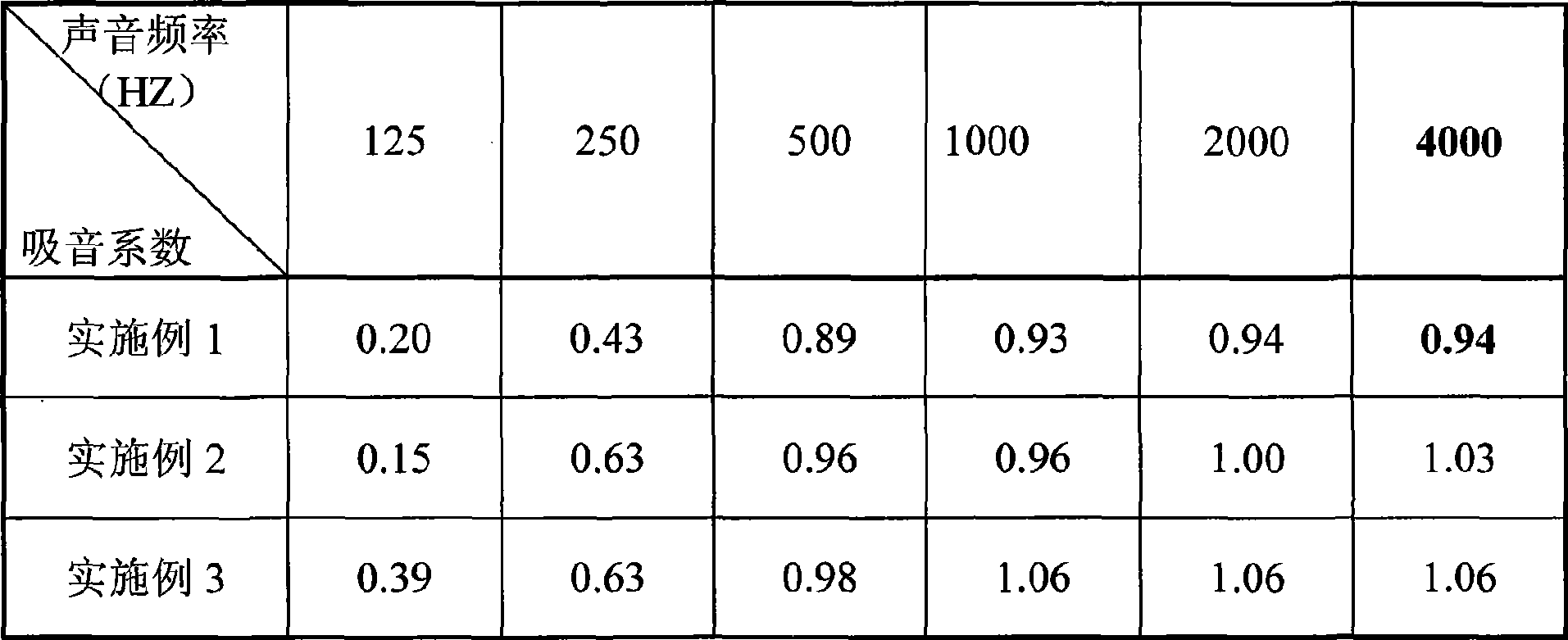

Embodiment 1

[0040] Example 1 Component formulation of lead-zinc tailings heavy sound insulation material

[0041] Lead-zinc tailings coarse grain 3-5mm (particle size) 25wt.%

[0042] Lead-zinc tailings medium particle 2mm (particle size) 30wt.%

[0043] Lead-zinc tailings fine particles 1mm (particle size) 30wt.%

[0044] Hard asphalt 6wt.%

[0045] Soft asphalt 9wt.%

[0046] The loss factor (%) of the final product of this formulation is 25-40%.

Embodiment 2

[0047] Example 2 Component formulation of lead-zinc tailings heavy sound insulation material

[0048] Lead-zinc tailings coarse grain 4-6mm (particle size) 15wt.%

[0049] Lead-zinc tailings medium particle 2-4mm (particle size) 35wt.%

[0050] Lead-zinc tailings fine particles 1mm (particle size) 30wt.%

[0051] Hard asphalt 8wt.%

[0052] Soft asphalt 12wt.%

[0053] The loss factor (%) of the final product of this formulation is 20-45%.

Embodiment 3

[0054] Example 3 Component formulation of lead-zinc tailings heavy sound insulation material

[0055] Lead-zinc tailings coarse grain 4-6mm (particle size) 30wt.%

[0056] Lead-zinc tailings medium particle 2mm (particle size) 25wt.%

[0057] Lead-zinc tailings fine particles 1mm (particle size) 25wt.%

[0058] Hard asphalt 10wt.%

[0059] Soft asphalt 10wt.%

[0060] The loss factor (%) of the final product of this formulation is 25-50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average sound insulation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com