Method for reducing rag layer volume in stationary froth treatment

a technology of stationary froth treatment and rag layer volume, which is applied in the petroleum industry, liquid hydrocarbon mixture production, etc., can solve the problems of undesirable solids and water content of bitumen, and achieve the effects of reducing the amount of water in the rag layer volume, and improving the quality of the splitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

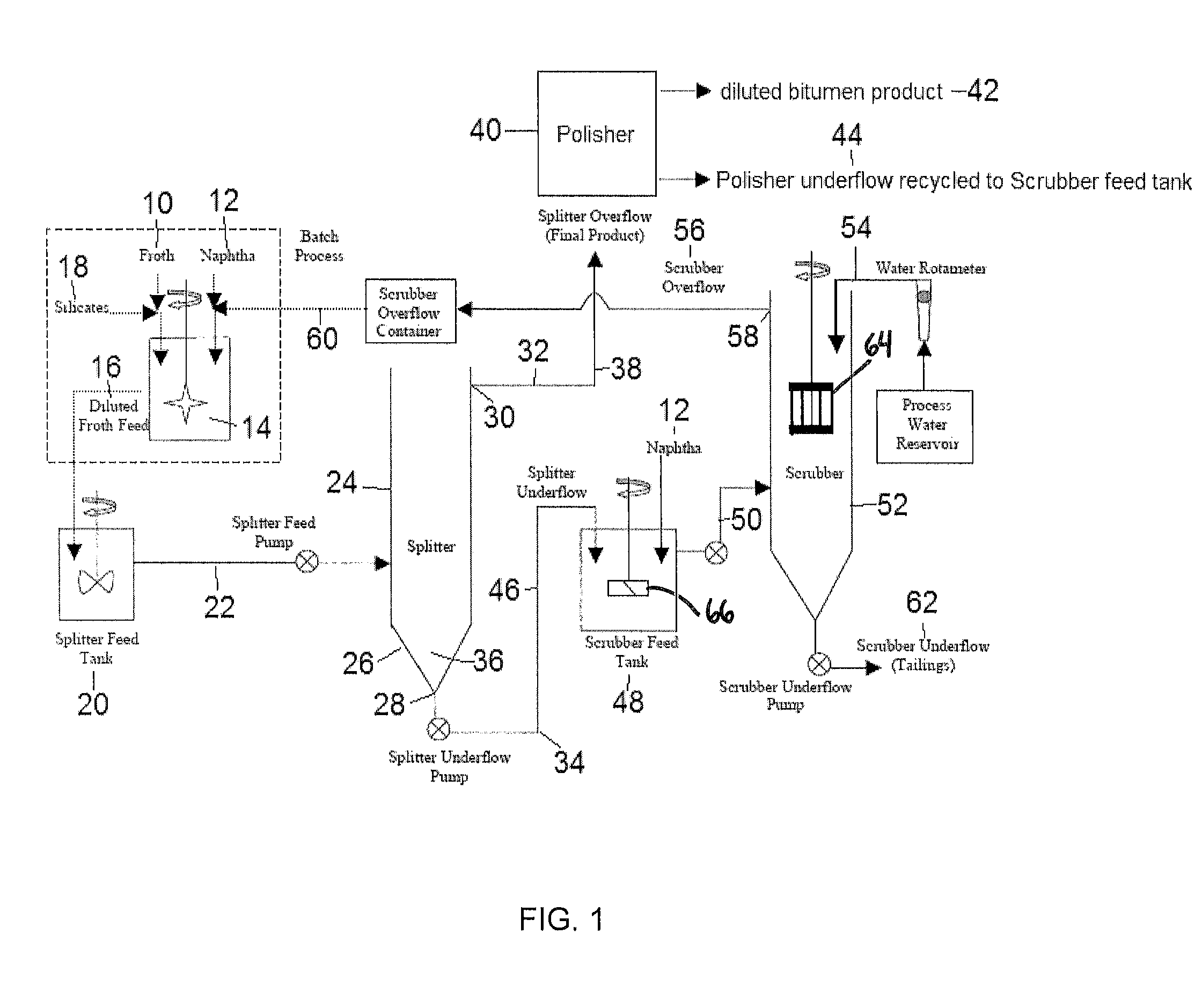

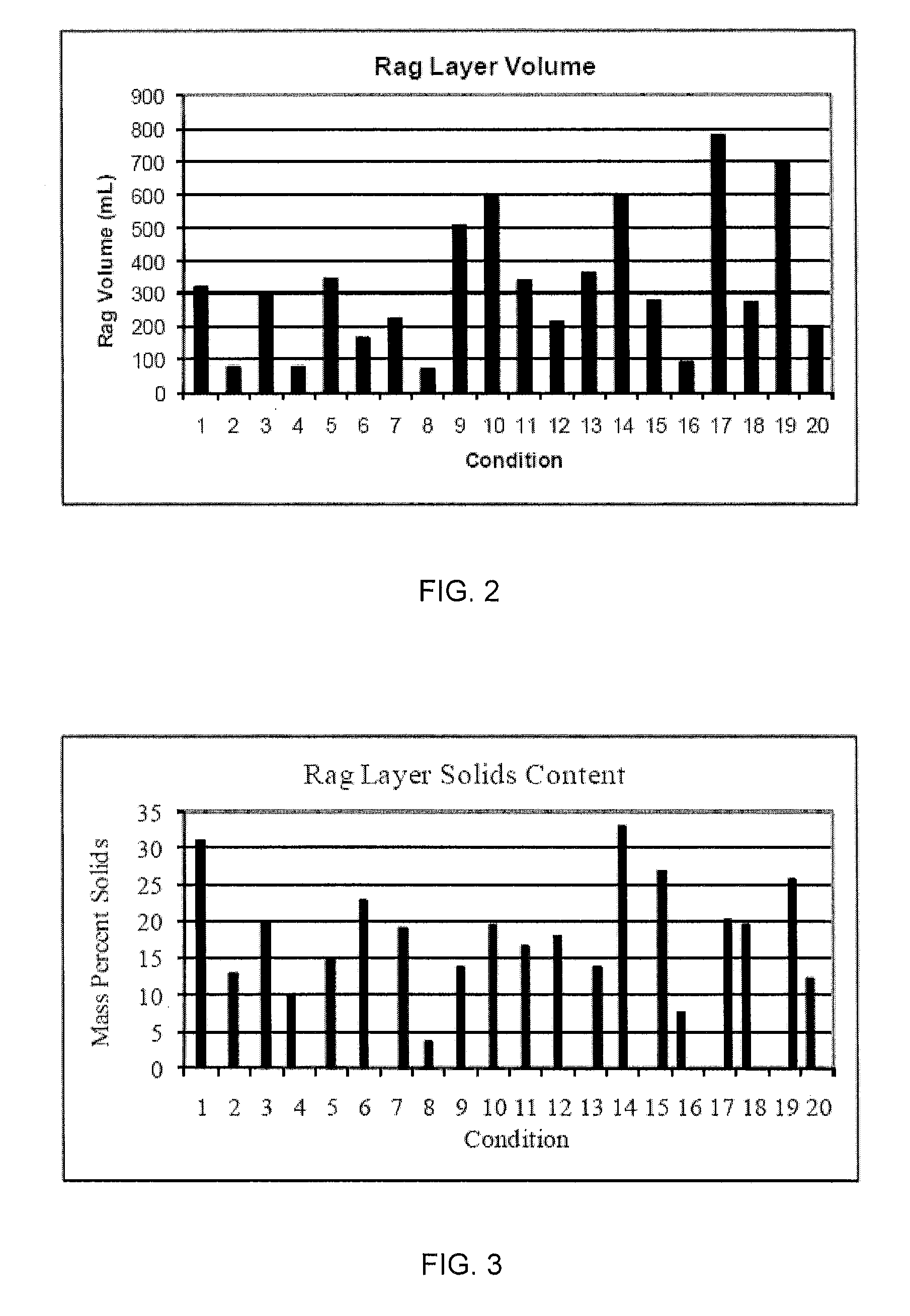

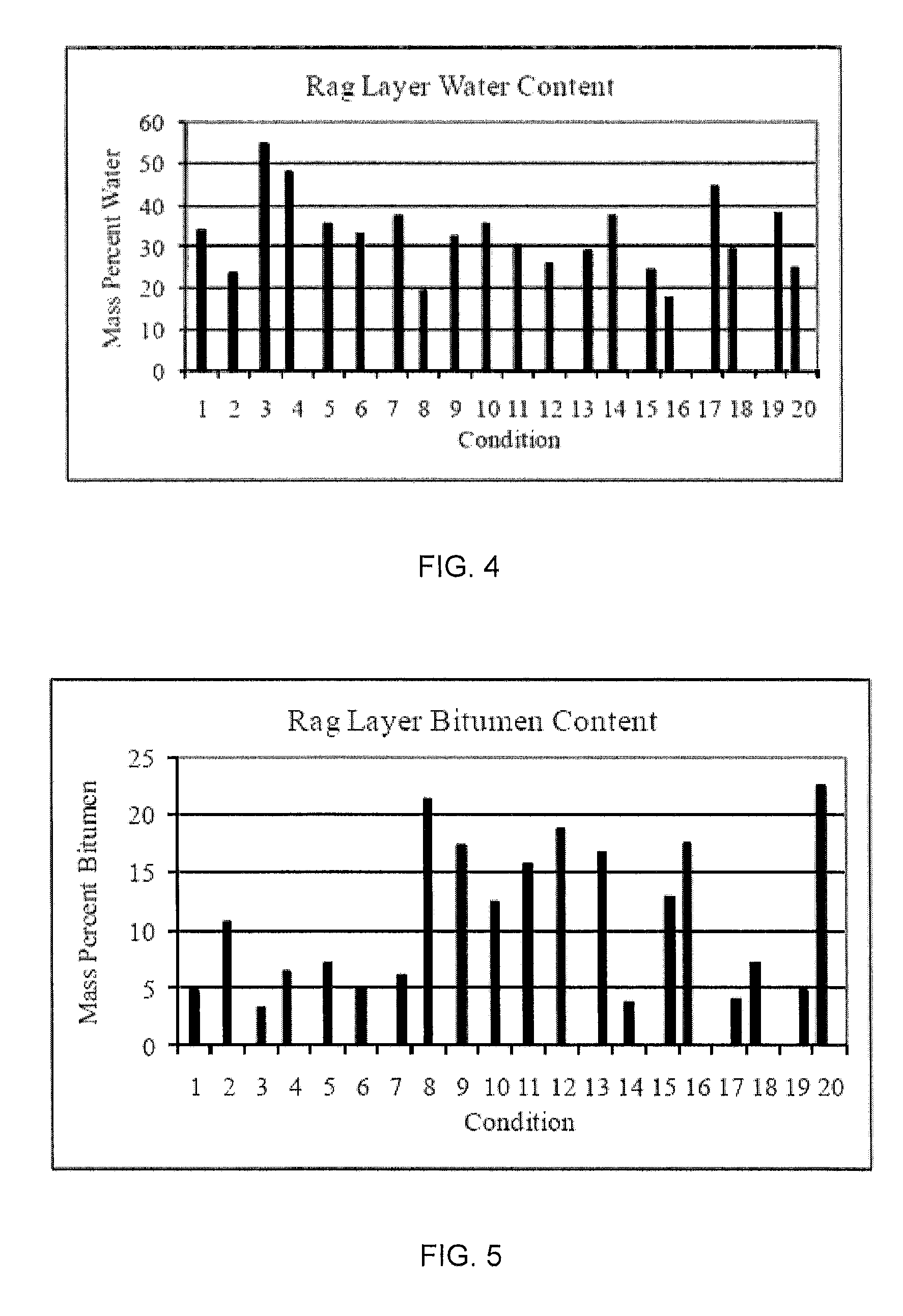

[0044]The flow sheet used for the evaluation of the rag volume reduction is essentially the same as that shown in FIG. 1 except that the polisher vessel was omitted to enable timely experimentation. Five variables including silicates concentration, water addition to rag layer, rag layer agitation, scrubber feed agitation and scrubber N / B ratio were evaluated using a 25-1 fractional factorial design resulting in 16 different experimental run conditions. Table 1 summarizes the range of the independent variables and the test matrix. In addition, Table 1 includes repeat conditions and an additional run using higher rag layer agitation (Condition No. 18), resulting in a total of 20 runs completed.

TABLE 1Test MatrixWaterRag LayerSilicatesAdditionAgitationScrubber FeedScrubberConditionwt. %(g / min)RPMRPMN / B1000700>6201652700>630.1052700>640.1160700>650.116521300>6600521300>6701601300>6800527009016070010000130011016521300120.10521300130.11601300140.1001300>6150.100700160.1165270017000700>618...

example 2

[0055]An experimental condition was conducted to determine the impact of higher rag layer mixing on rag layer volume reduction. The only variable that changed was to increase the rag layer mixer speed to 188 rpm. All other rag layer mitigation variables were set at base case flow sheet conditions, i.e., no silicate or rag water addition, low scrubber feed mixer speed and high scrubber N / B ratio of greater than or equal to 6.

[0056]The rag volume comparison for the three rag mixer speeds is shown in Table 3. The rag layer volume at rag mixer speed of 52 rpm is not significantly different from the rag layer volume at rag layer mixer speed of 188 rpm. However, the rag layer volume at base case condition is significantly different from the rag layer volume at rag mixer speeds of both 52 rpm and 188 rpm.

TABLE 3RagVariableVolume, mlBase case740Base + rag layer mixing at 52 rpm249Base + high rag layer mixing at 188 rpm273

The results in Table 3 show that rag mixing (52 to 188 rpm) did signif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com