A system and method for treatment of oil sand tailings or oil sand ore pulp

A technology of treatment system and treatment method, applied in the field of treatment system of oil sand tailings or oil sand slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

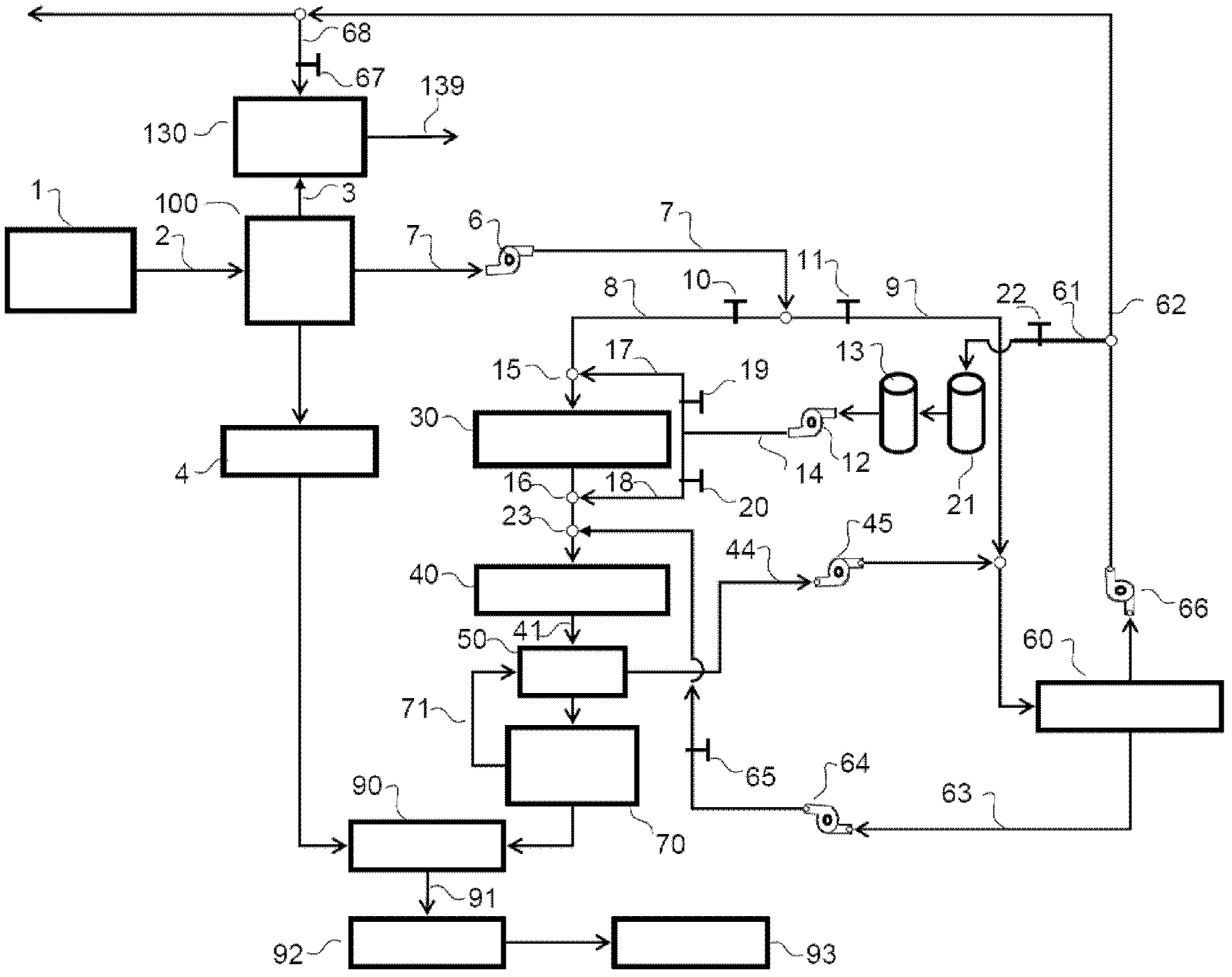

[0049] As an embodiment, the oil sand tailings solidification device includes an agglomerate mixer 90, the inlet of the agglomerate mixer 90 is connected to the coarse sand outlet of the bitumen recovery device and the oil sand tailings thickening device The fine soil mud outlet is connected. The outlet of the agglomerate mixer 90 may communicate with the inlet of the belt conveyor 92 so as to transport the agglomerate mixture of coarse sand and fine earth mud discharged from the outlet of the agglomerate mixer 90 to a designated location. Of course, other conveying devices such as a belt conveyor 92 can also be arranged between the coarse sand outlet of the asphalt recovery device, the fine soil mud outlet of the oil sand tailings thickening device and the inlet of the agglomerate mixer 90 During the period, the agglomerate mixer 90 is set at a designated position, so that the coarse sand and fine soil mud are first transported to the designated position and then solidified. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com