Alternate atomizing medium for burning efficiency of emulsion fuels, heavy oils and bitumens

a technology of emulsion fuel and atomizing medium, which is applied in the direction of combustion process, lighting and heating apparatus, and fluid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

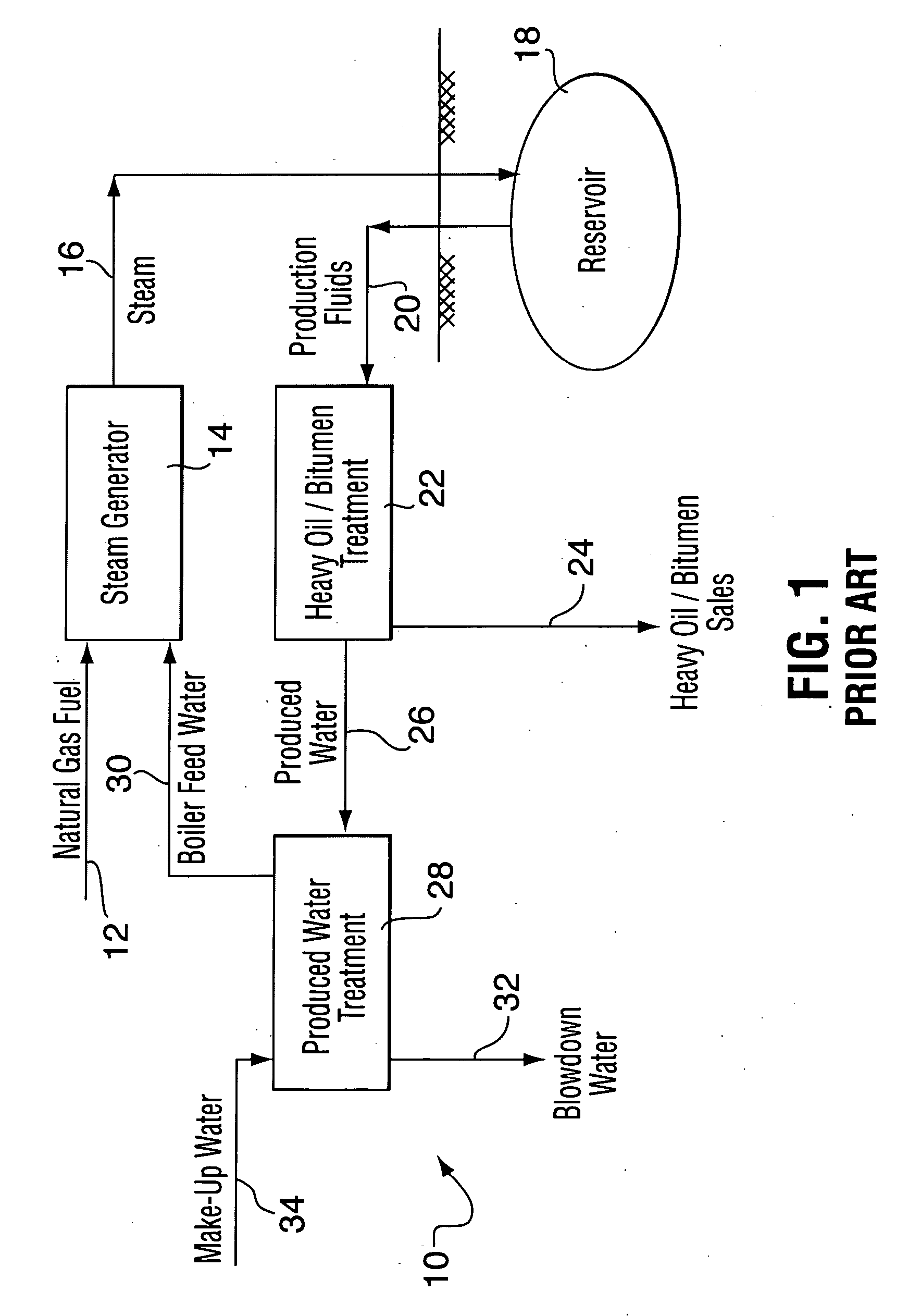

[0014]Referring now to FIG. 1, shown is a schematic representation of a conventional thermal oil operation, globally denoted by numeral 10. A source of natural gas 12 fuels the steam generator(s) 14 to generate steam 16 introduced into the hydrocarbon formation 18. Production fluids 20 (natural gas, water, viscous hydrocarbon material) are recovered and exposed to several treatment unit operations, generically referenced by numeral 22. Saleable heavy oil and bitumen is removed at 24 while produced water 26 is treated at 28 with at least a portion recycled as feed water 30 for use in generator(s) 14. Blowdown 32 is removed and make up water 34 added as required.

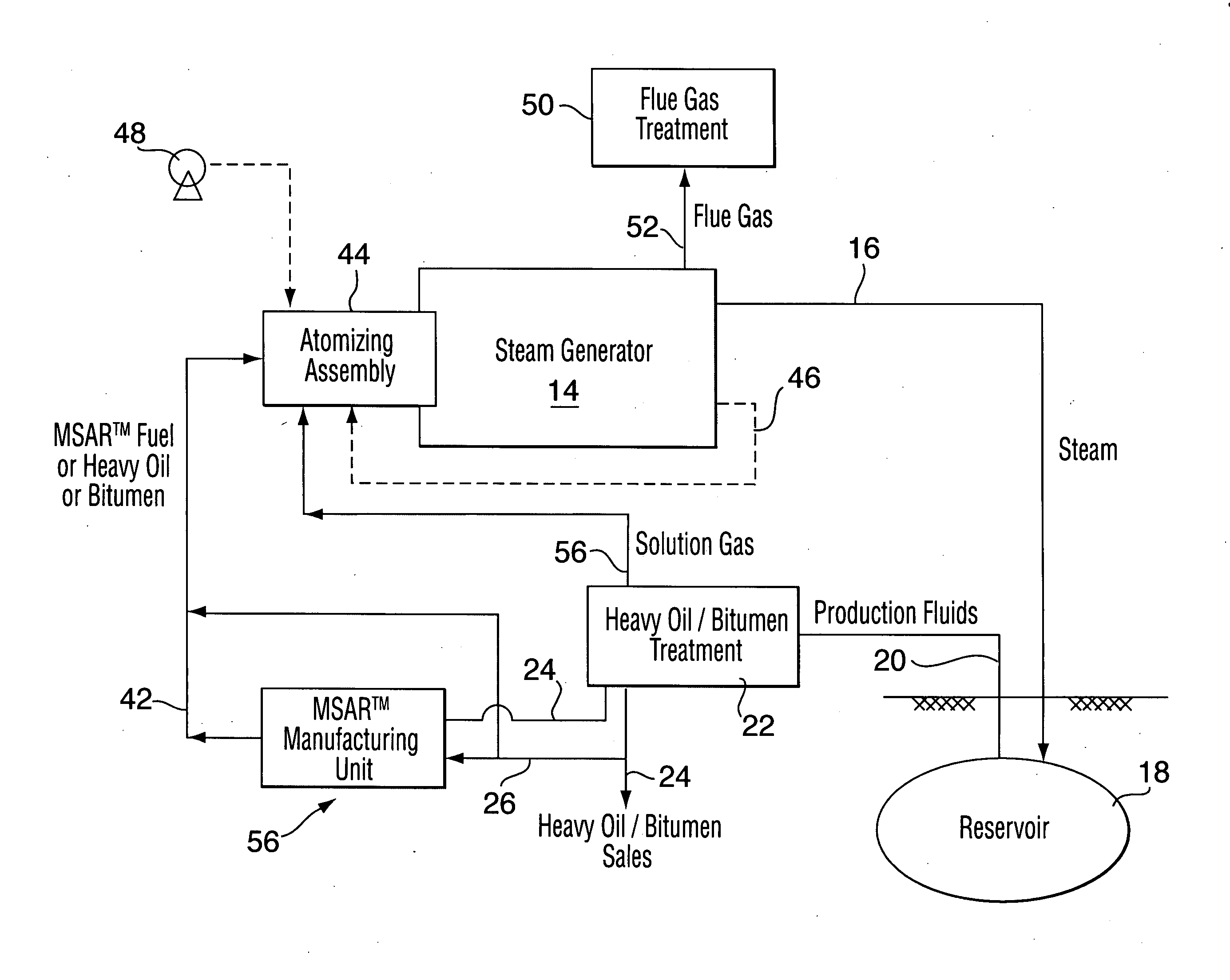

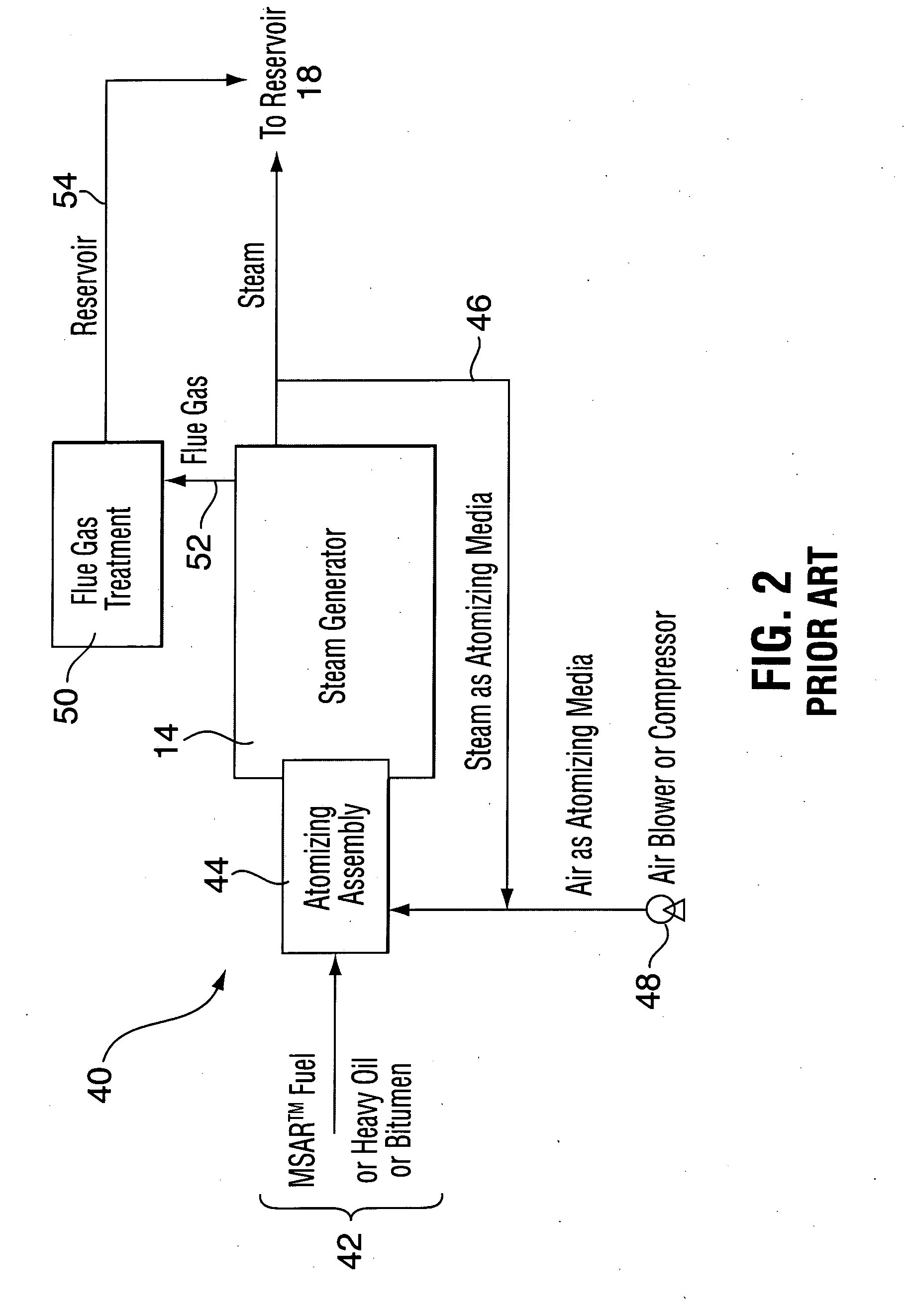

[0015]It is now trite that the cost of using natural gas to generate steam for hydrocarbon value recovery is unattractive from an economic point of view and inherently wasteful in view of the burgeoning activity and developments in alternate fuel synthesis. To this end, FIG. 2 is illustrative of a more pragmatic solution to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com