Apparatus for producing water-in-oil emulsified fuel and supplying the same

A technology of emulsified fuel and water-in-oil, which is used in the field of devices that produce emulsified fuel and supply it to boilers, which is always supplied in a uniform state, can solve the problem of difficulty in reducing fuel oil and unsatisfactory combustion efficiency. Satisfaction, unstable oil-water injection quantity and injection ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

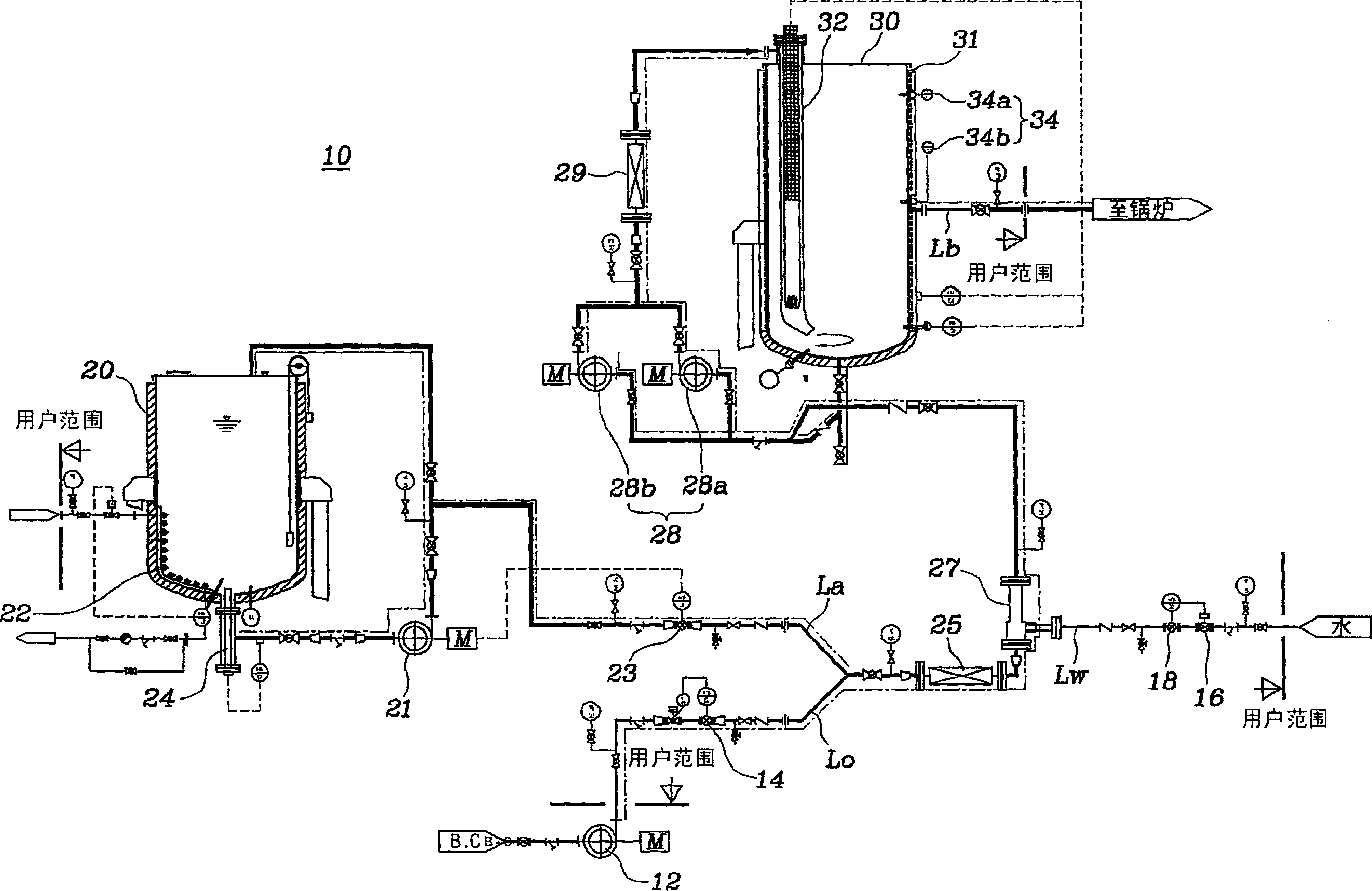

[0046] figure 1 is a structural diagram of a device for producing and supplying water-in-oil emulsion fuel according to the first embodiment of the present invention.

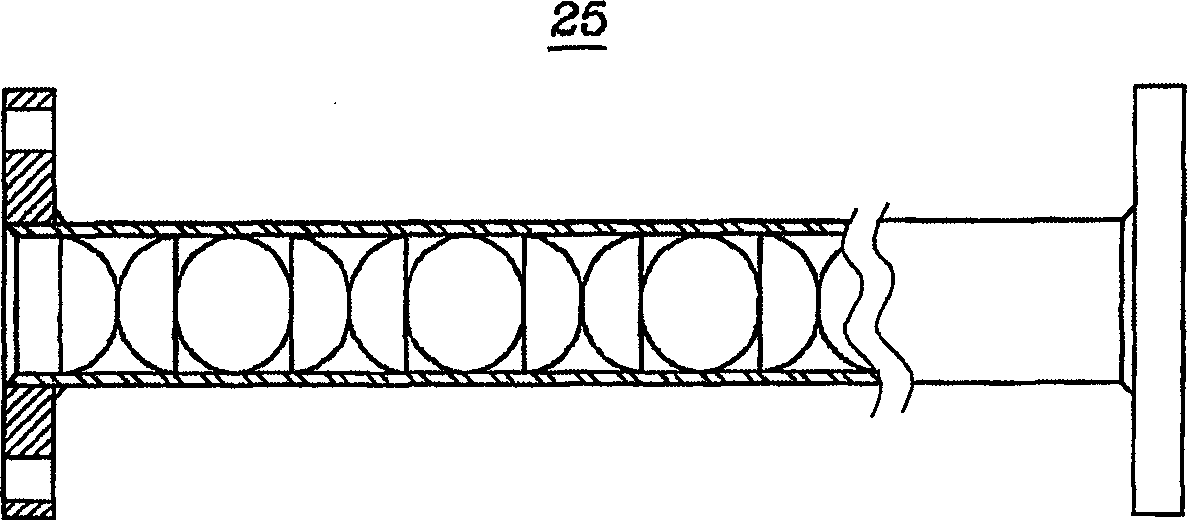

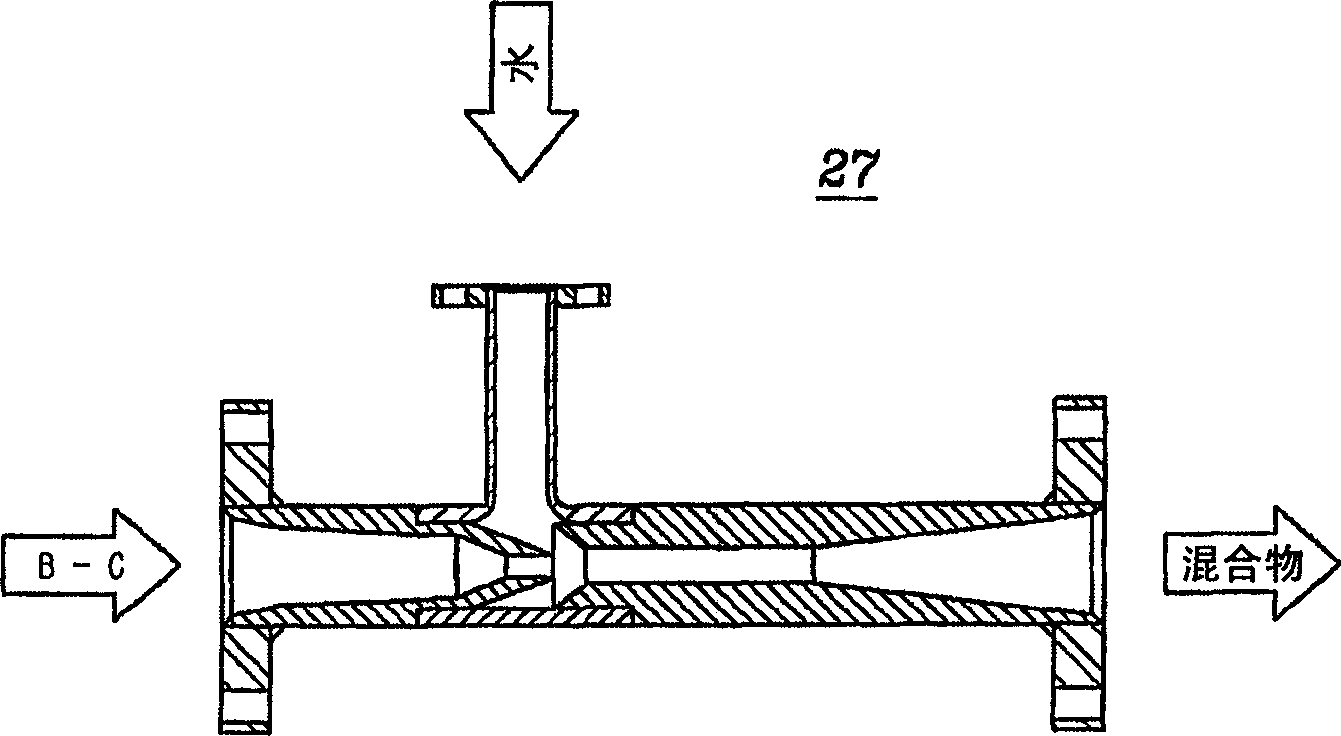

[0047] refer to figure 1 , the device 10 for producing and supplying water-in-oil emulsified fuel includes an additive storage tank 20 for storing an emulsifier; an emulsion tank 30 for storing a water-in-oil emulsified fuel; Predetermined value provides B-C oil, emulsifier, water to become water-in-oil emulsified fuel raw material; first mixing section for continuously and uniformly mixing supplied raw material; and for mixing raw material oil and pre-emulsified fuel initially mixed to carry out emulsification the second mixing section.

[0048] The emulsifier stored in the additive storage tank 20 is an additive for preventing oil-water separation when the water-in-oil emulsion fuel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com