Microemulsified fuel oil and preparation thereof

A technology of micro-emulsion and fuel oil, which is applied in the direction of water treatment and refining, etc. It can solve the problems of short shelf life, poor stability, and poor reversibility of emulsified oil, and achieve the effects of reduced exhaust emissions, good lubricating performance, and clear appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of complex fatty acid amide emulsifier:

[0030] Treatment method of waste oil: acidify waste oil with 5%-10% hydrochloric acid for 2 times, wash with water once, separate and remove water, and dry for later use.

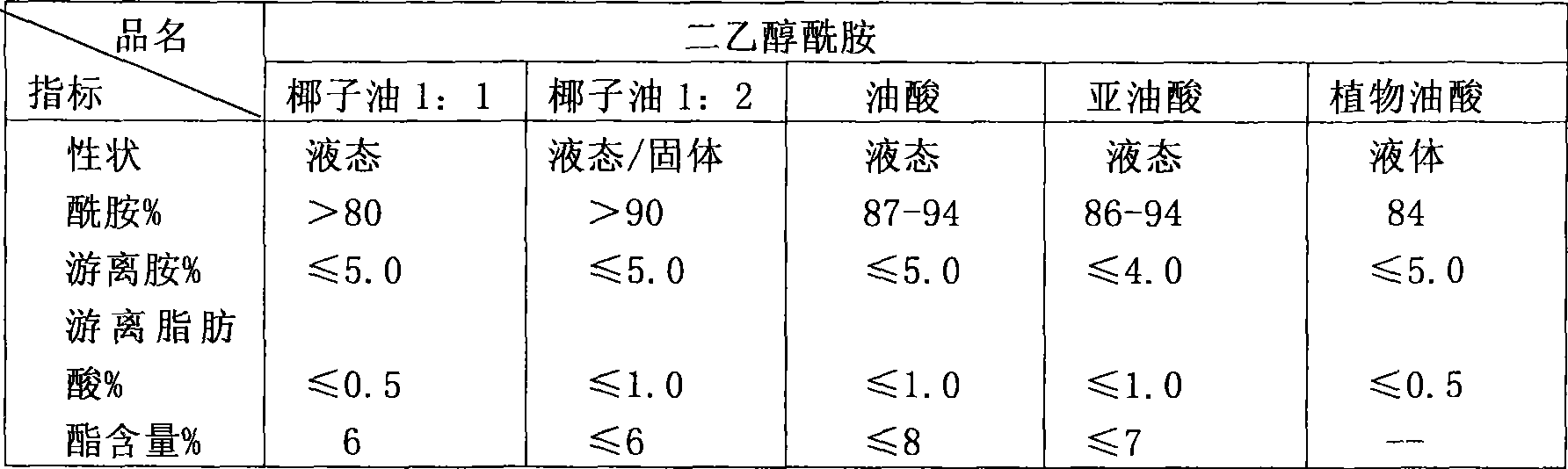

[0031]Put 1 mol of waste oil and 0.5 mol of diethanolamine into a four-neck flask equipped with a stirrer, a water separator, a reflux condenser and a thermometer, add 40 ml of 20% sodium hydroxide, and carry out the aminolysis reaction under alkaline conditions. The time is 2 hours, the reaction temperature is 100°C, and the amide ester is synthesized. In the second step, 0.4mol diethanolamine is added to carry out the aminolysis reaction. The time is 1 hour, and the reaction temperature is 100°C, so that the amine mono(bis)ester in the product is converted into an amide In the third step, add an excess of 0.2mol alkanolamine, the reaction time is 1h, and the reaction temperature is 100°C, and a three-step aminolysis reaction is carried out to co...

Embodiment 2

[0035] Preparation of Microemulsion Fuel Oil

[0036] Composition of microemulsion fuel oil:

[0037] model Complex fatty acid amide emulsifier National standard diesel water

[0038] A 12 76 12 B 10 80 10 C 8 84 8

[0039] According to the above ratio, mix national standard diesel oil, emulsifier and water, heat to 30°C, refine the material to 0.1um-2um by high-shear homogenizer or high-pressure homogeneous emulsifier, and prepare micro-emulsified vehicle fuel (its See Table 2 for quality standards).

Embodiment 3

[0041] Waste oil treatment method: acidify the oil foot with 10% hydrochloric acid once, wash it twice with water, separate and remove the water, and dry it for later use.

[0042] Put 1 mol of oil bottoms and 0.6 mol of diethanolamine into a four-necked flask equipped with a stirrer, a water separator, a reflux condenser and a thermometer, add 20 ml of 30% sodium hydroxide, and carry out the aminolysis reaction under alkaline conditions. The time is 1h, the reaction temperature is 100°C; in the second step, 0.4mol diethanolamine is added to carry out the amino decomposition reaction, the time is 1h, and the reaction temperature is 100°C, so that the amine mono(bis)ester in the product is converted into an amide; the third step Then add an excess of 20% mole of alkanolamine, the reaction time is 1 h, and the reaction temperature is 100°C. The amide mono(bis)ester in the product is converted into amide, the heating is stopped, the reaction product is cooled, and the filtered cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com