Process for uniform spraying of metal framework

A metal frame, uniform technology, used in coatings, devices for coating liquids on surfaces, pretreatment surfaces, etc. The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

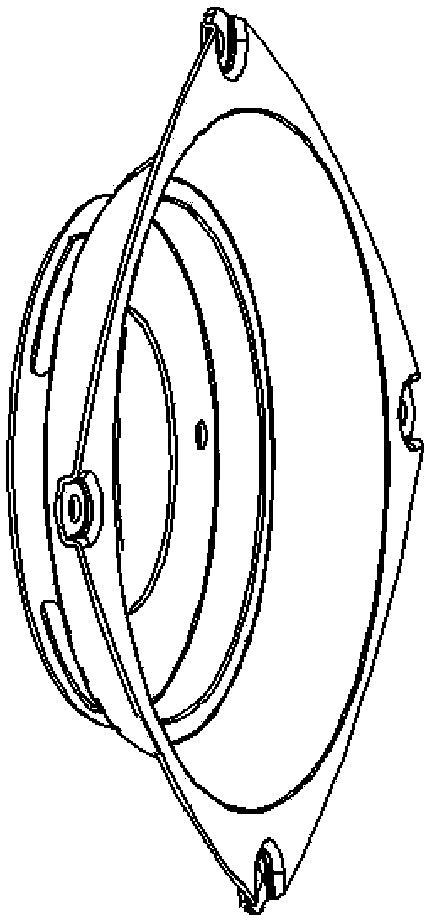

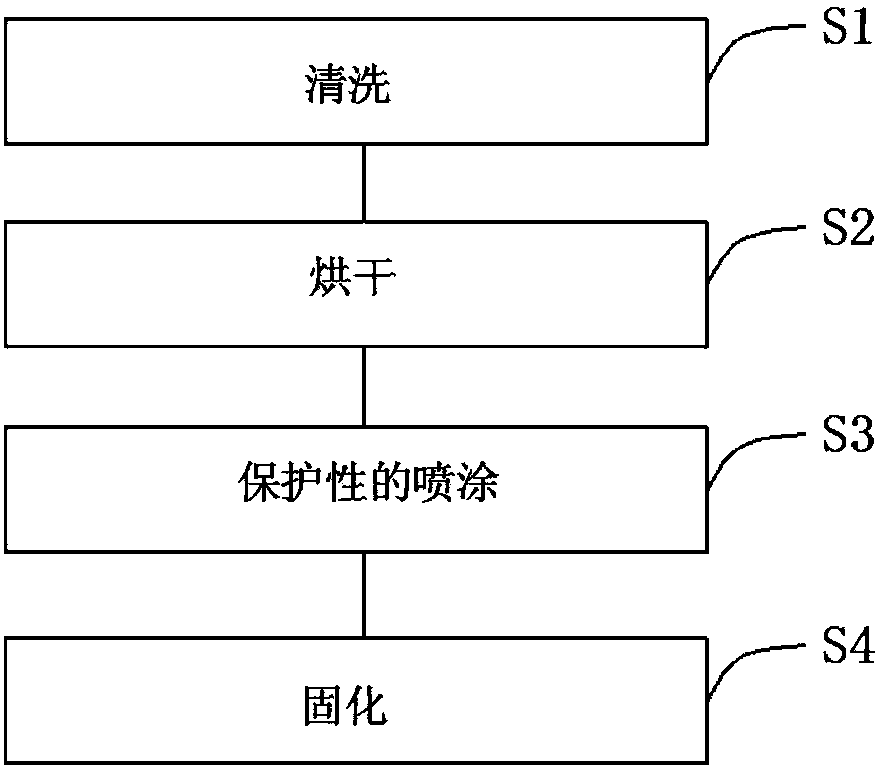

[0011] A metal frame provided by the present invention is formed by punching, and the process includes the following steps: (1) the step of cutting the material by a shearing machine, that is, cutting after positioning on the shearing machine according to the size set by the cutting production instructions; (2) ) the step of punching positioning holes on the material after cutting; (3) then, stretching; (4) after stretching, the step of punching and trimming; (5) punching the material after punching and trimming The steps of single flower and ear-ring flower; (6) flanging the material after the flower is punched; (7) the final step of spraying to form the final metal frame product.

[0012] Among the above processes, the present invention adopts a uniform spraying process different from the traditional technology.

[0013] (1) cleaning. To ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com