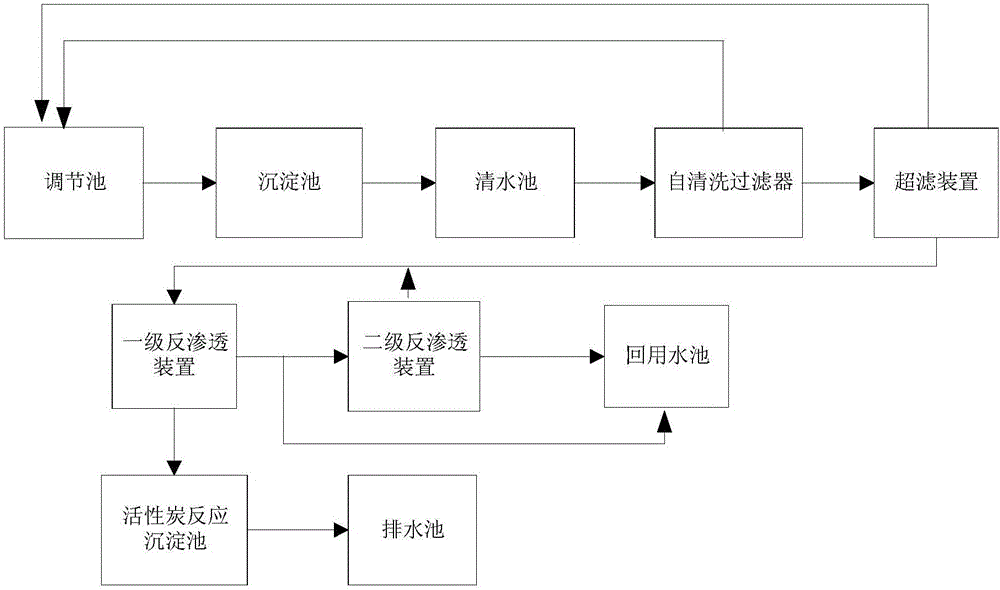

High-salt wastewater treatment reuse system and method

A high-salt wastewater recycling treatment technology, which is applied in the field of wastewater recycling systems and high-salt wastewater recycling systems, can solve the problems of low purification rate of wastewater recycling and treatment, achieve load reduction, reduce carbonate hardness, and protect normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

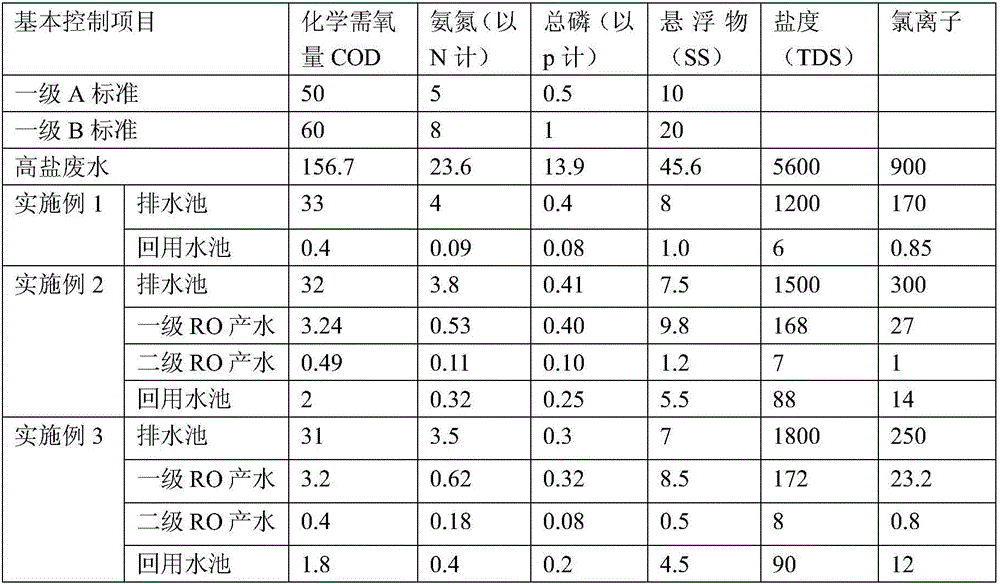

Embodiment 1

[0035] Collect 1000L of raw water into the adjustment tank, use a lift pump to place it in the sedimentation tank, add 180mg of lime, 18mg of polyaluminum chloride, and 0.8mg of polyacrylamide per liter of raw water for precipitation, and 985L of upper clear water enters the clear water tank for storage. After that, add hydrochloric acid to adjust the pH to 8, and drain the generated sludge; use the water inlet pump to lift the effluent from the clear water tank into a 150μm self-cleaning filter, and obtain 970L of produced water, and get backwashed water to enter the regulating tank for circulation;

[0036] The obtained product water enters the ultrafiltration device, and the obtained 873L ultrafiltration product water enters the ultrafiltration product water tank, and the backwash water is obtained and enters the regulating tank for circulation treatment;

[0037] The 873L water in the ultrafiltration water tank was raised by the high-pressure pump to the first-stage reverse...

Embodiment 2

[0039] Collect 1500L of raw water into the adjustment tank, use a lift pump to place it in the sedimentation tank, add 150mg of lime, 15mg of polyaluminum chloride, and 0.5mg of polyacrylamide per liter of raw water for precipitation, and 1485L of upper clear water enters the clear water tank for storage. After that, add hydrochloric acid to adjust the pH to 8.5, and drain the generated sludge; use the water inlet pump to lift the effluent from the clear water tank into a 150 μm self-cleaning filter, and obtain 1470 L of produced water, and the obtained backwash drainage enters the regulating tank for recycling treatment;

[0040] The obtained permeated water enters the ultrafiltration device, and 1337L of ultrafiltered permeated water enters the ultrafiltration permeated water tank, and the obtained backwash water enters the regulating tank for circulation treatment;

[0041] The 1337L water in the ultrafiltration water production pool was raised by a high-pressure pump to the...

Embodiment 3

[0043] Collect 800L of raw water into the adjustment tank, use a lift pump to place it in the sedimentation tank, add 200mg of lime, 20mg of polyaluminum chloride, and 1mg of polyacrylamide to each liter of raw water for precipitation, and 789L of upper clear water enters the clean water tank for storage. Add hydrochloric acid to adjust the pH to 9, and drain the generated sludge; use the water inlet pump to lift the effluent from the clear water tank into a 150μm self-cleaning filter, and obtain 785L of produced water, and the obtained backwash water enters the regulating tank for recycling;

[0044] The obtained permeated water enters the ultrafiltration device, and 722L of ultrafiltered permeated water enters the ultrafiltration permeated water tank, and the obtained backwash water enters the regulating tank for circulation treatment;

[0045] The 722L water in the ultrafiltration water production pool was raised by the high-pressure pump to the first-stage reverse osmosis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com