Intelligent roller friction testing machine of conveyor belt

A friction testing machine and conveyor belt technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve problems such as large human injury, untimely test data recording, and inability to record conveyor belt breakage, and reduce the environment. The effect of pollution index and good market application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

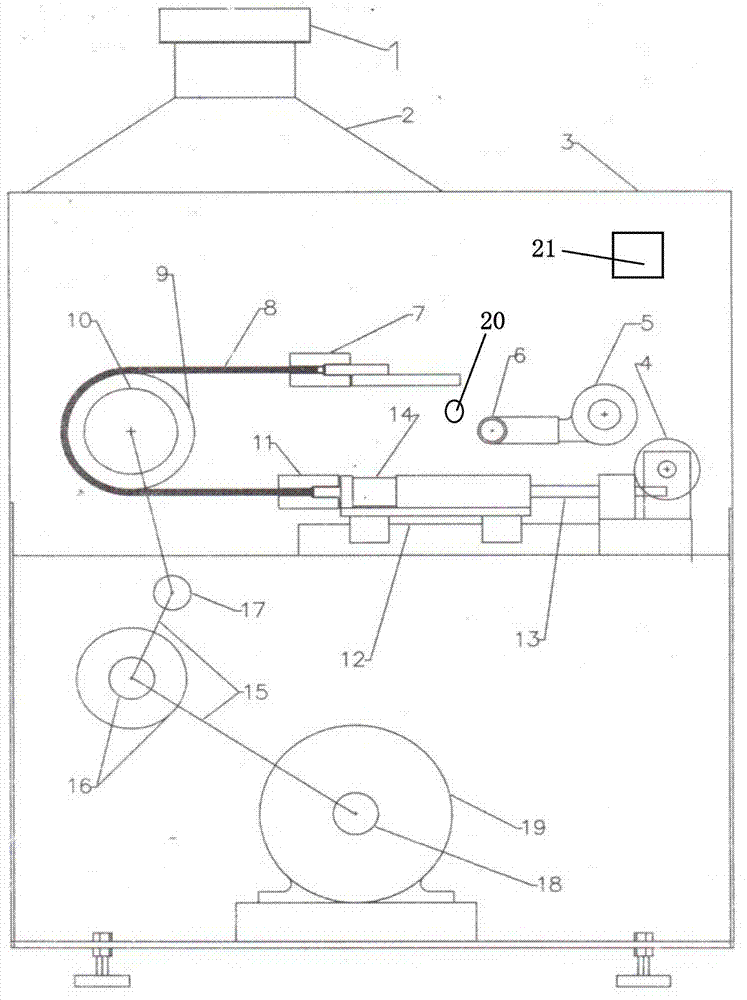

[0015] The testing machine of the present invention wraps the sample 8 of the conveyor belt to be inspected on the roller 9 of the testing device with a wrap angle of 180°, and bears the tensile force set to meet the standard. The roller 9 moves at a prescribed speed, thereby causing friction between the sample 8 to be inspected on the conveyor belt and the roller 9 . During operation, the tension sensor 14 automatically detects and compares with the set value, and the DC motor 4 adjusts the tension in real time to keep the tension constant, and increase the standard tension according to the standard.

[0016] Such as figure 1 As shown, the testing machine of the present invention includes a transmission system for driving the rotation of the drum 9 and a tension system for real-time adjustment of the tension of the sample 8 to be tested. The tension system includes a tension sensor 14 installed on the linear guide rail 12 and capable of automatically detecting tension, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com