Patents

Literature

136 results about "Treatment phases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variations Within Treatment Phases. The phase model assumes that, although many patients need long-term MAT, the types and intensity of services they need vary throughout treatment and should be determined by individual circumstances.

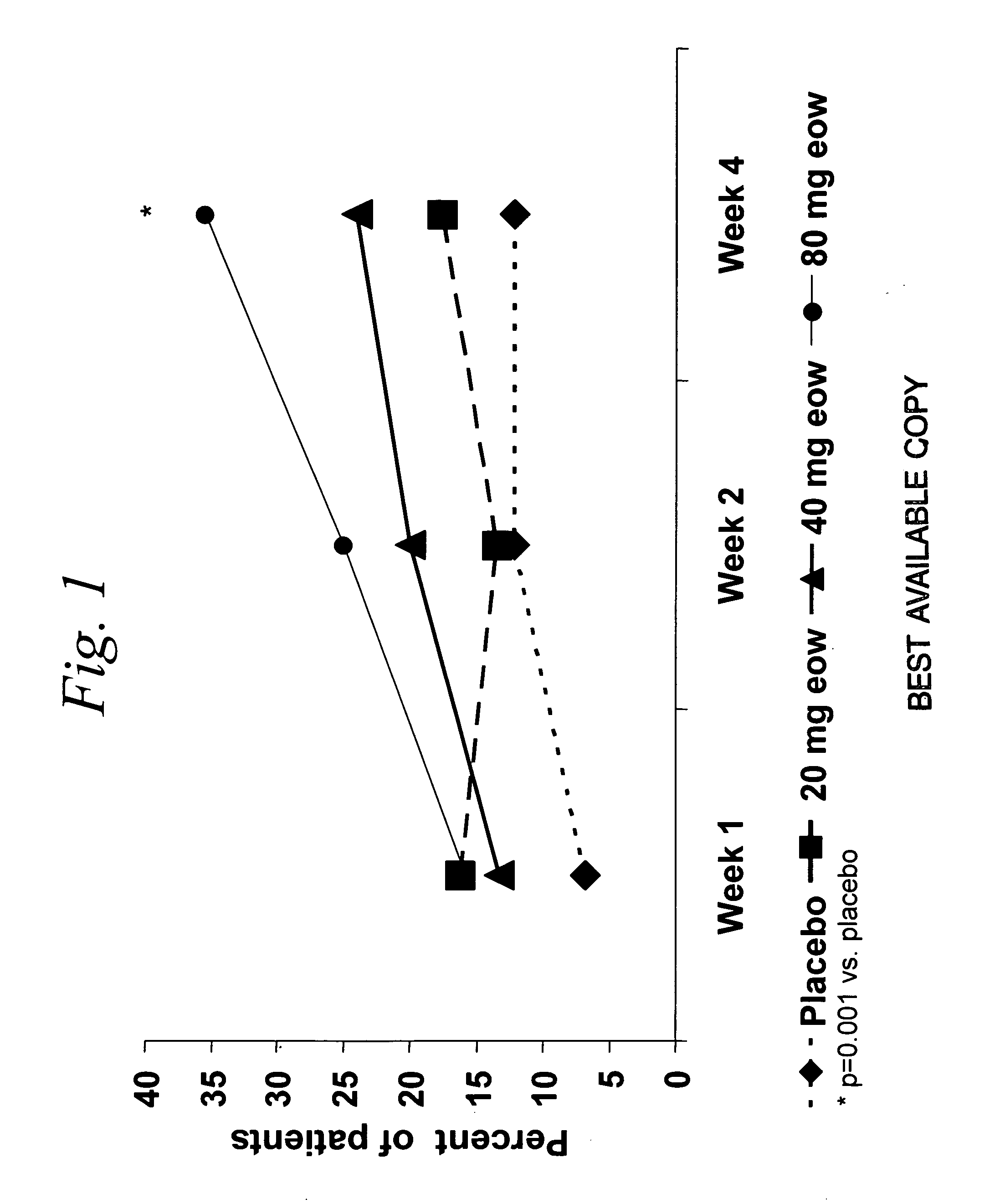

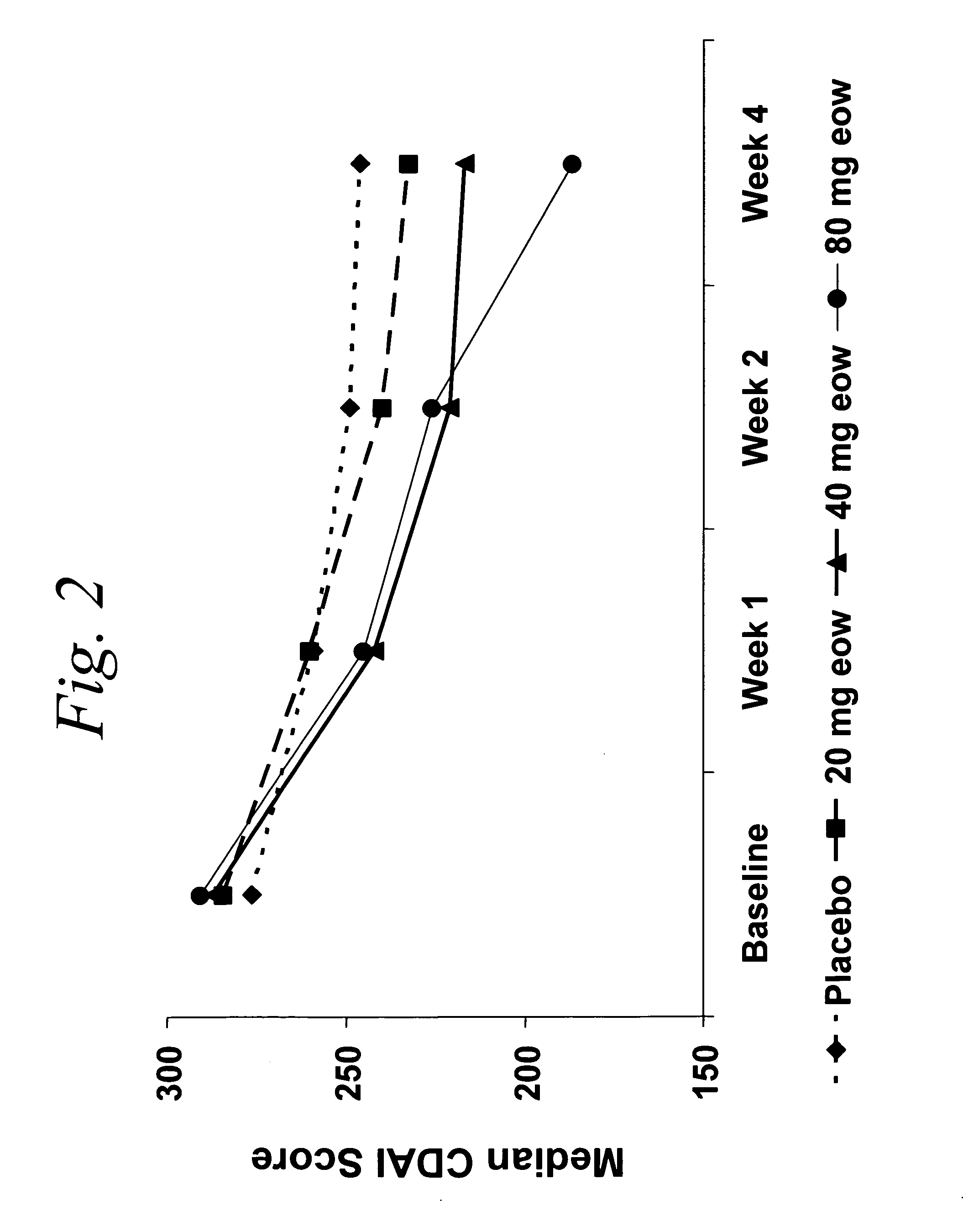

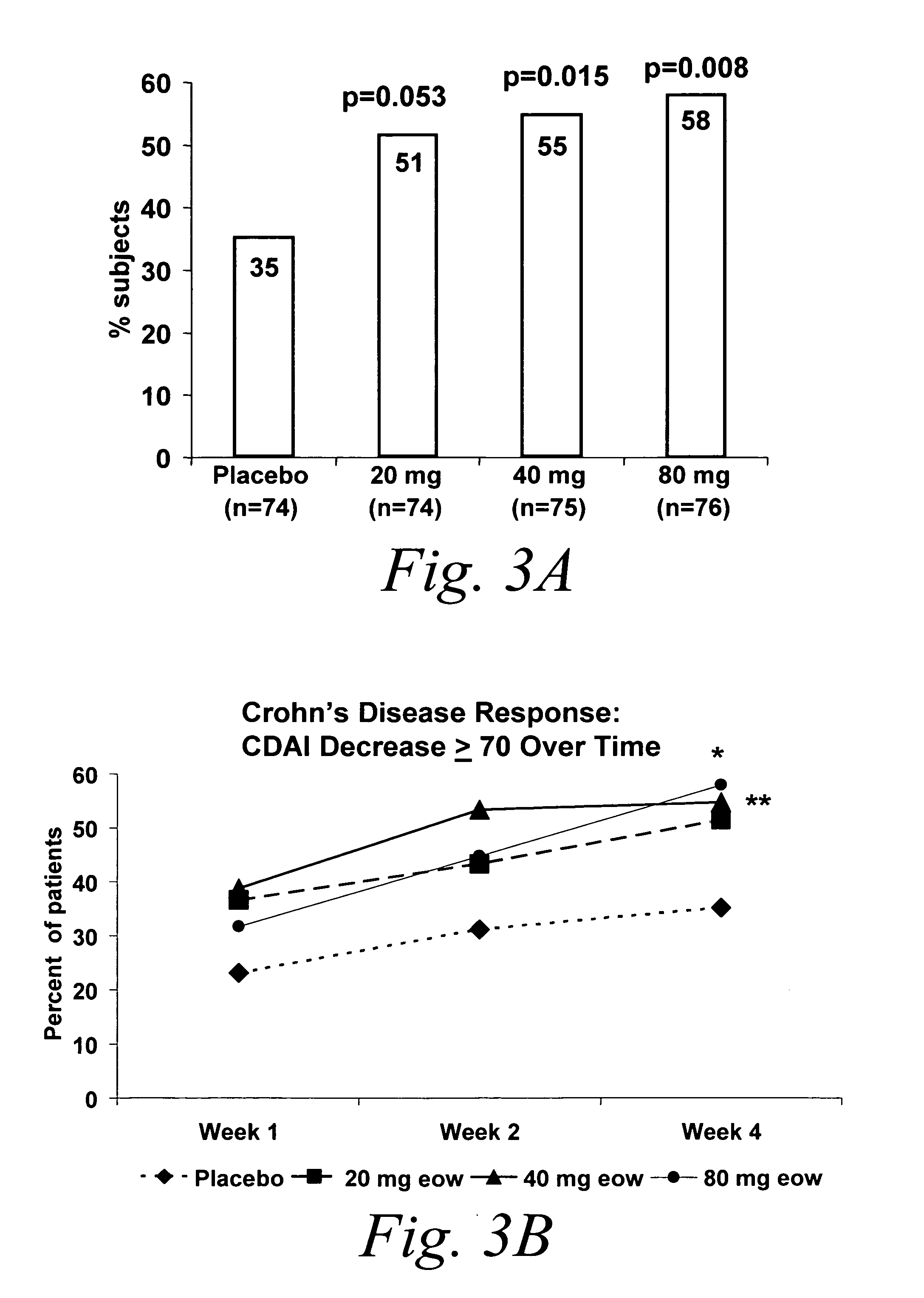

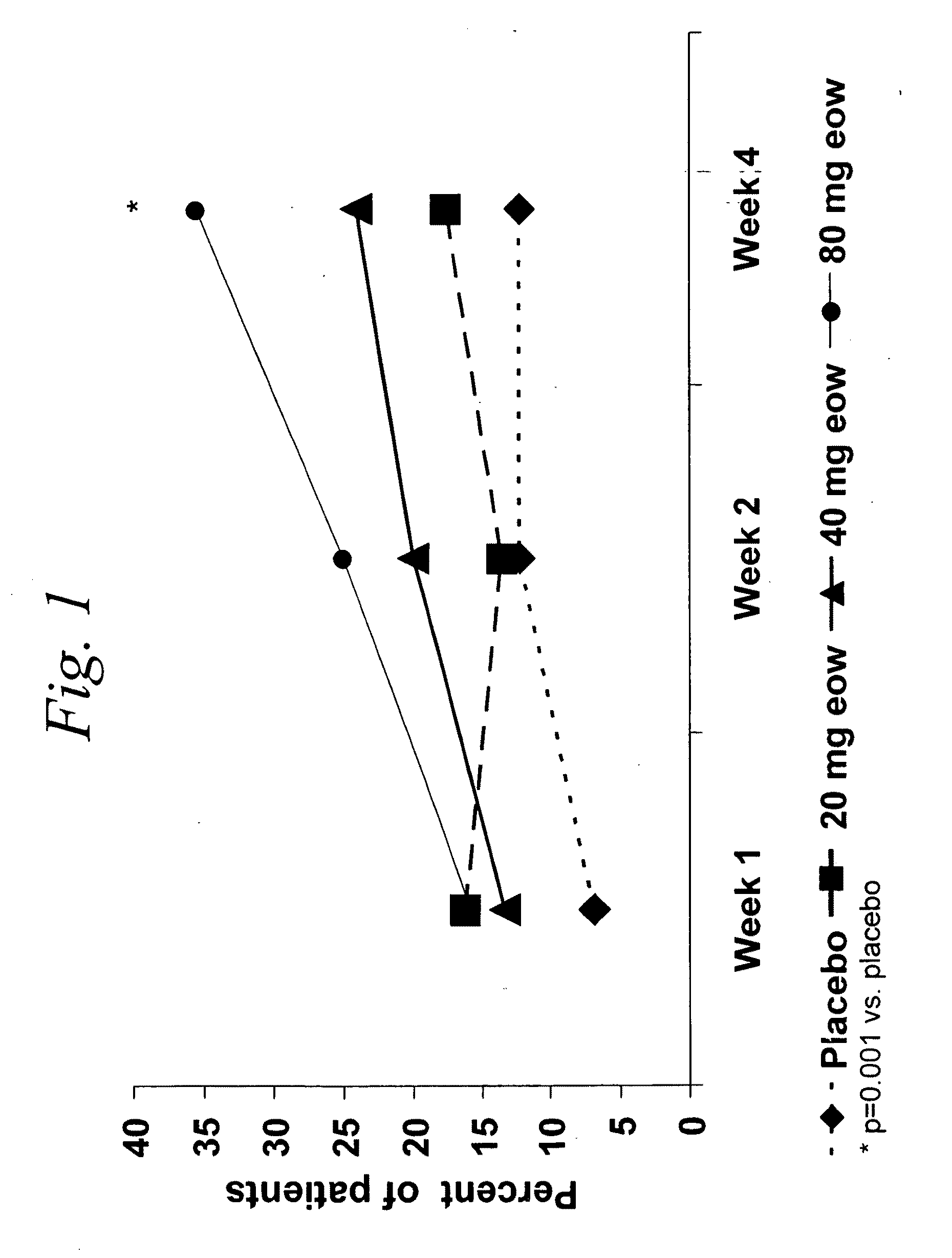

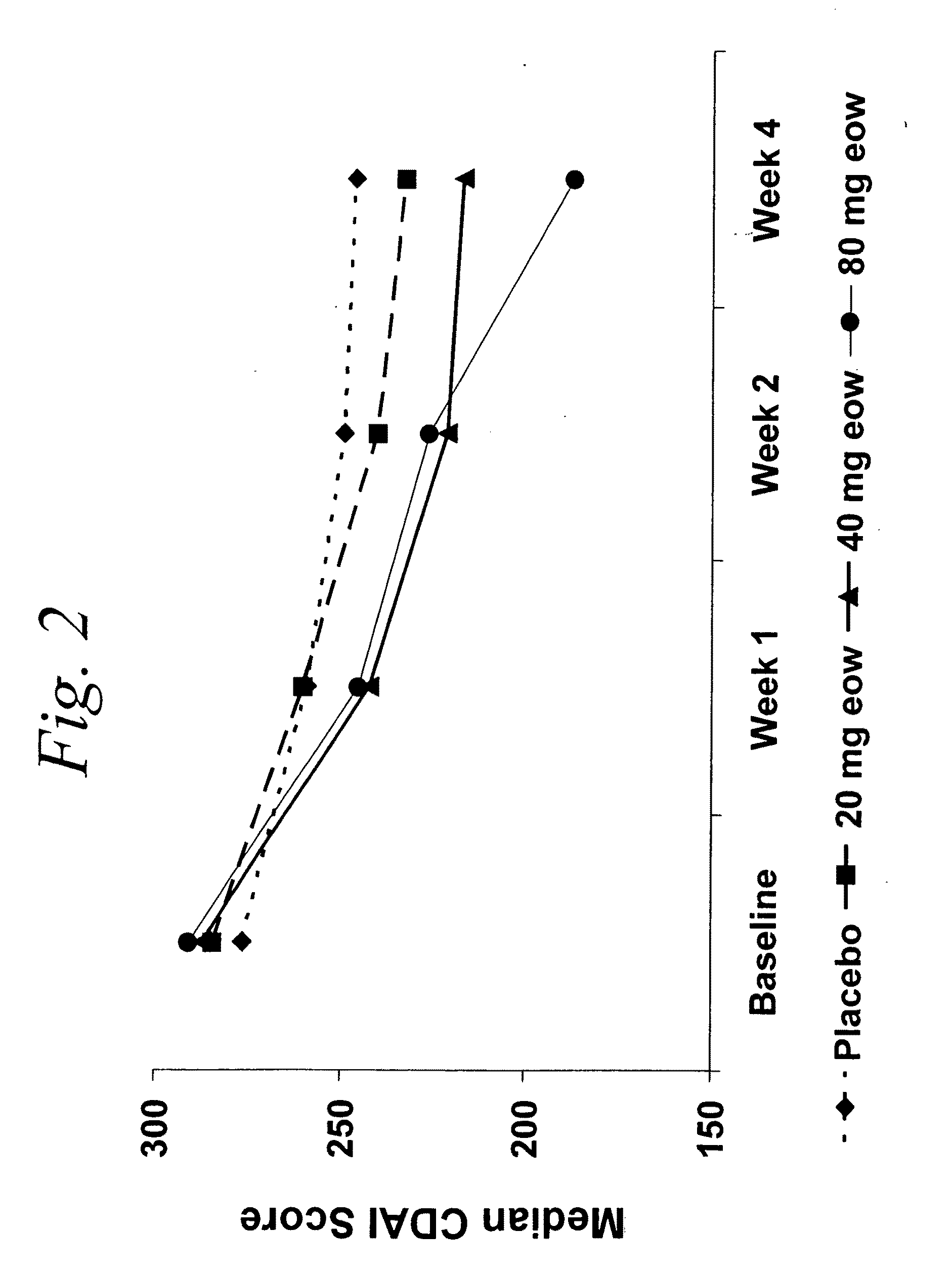

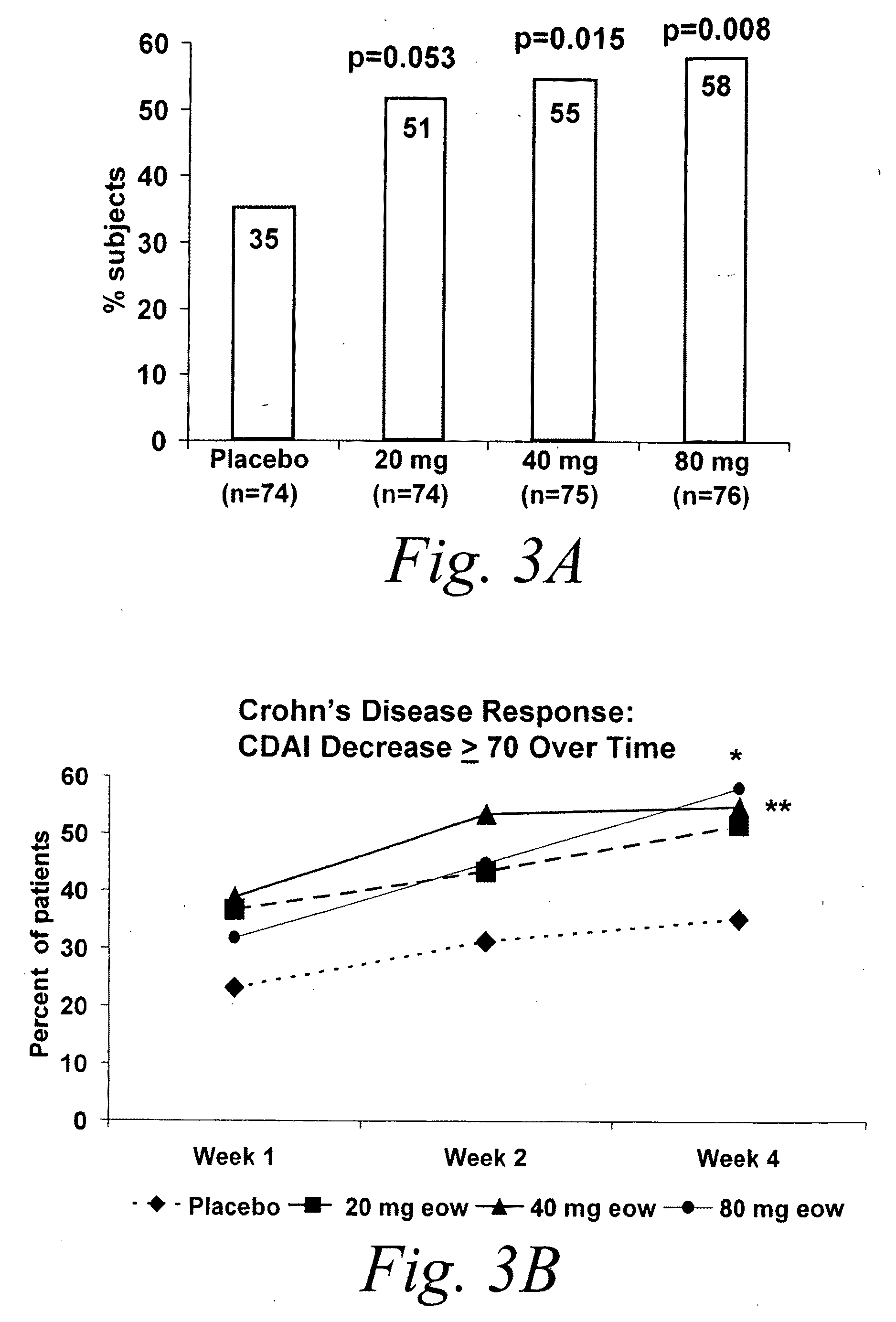

Multiple-variable dose regimen for treating TNFalpha-related disorders

ActiveUS20060009385A1Reduce decreaseIncrease the areaBiocideOrganic active ingredientsDosing regimenRegimen

Multiple-variable dose methods for treating TNFα-related disorders, including Crohn's disease and psoriasis, comprising administering TNFα inhibitors, including TNFα antibodies, are described. Multiple-variable dose methods include administration of a TNF-inhibitor in an induction or loading phase followed by administration of the agent in a maintenance or treatment phase, wherein the TNF-inhibitor is administered in a higher dosage during the induction phase.

Owner:ABBVIE BIOTECHNOLOGY LTD

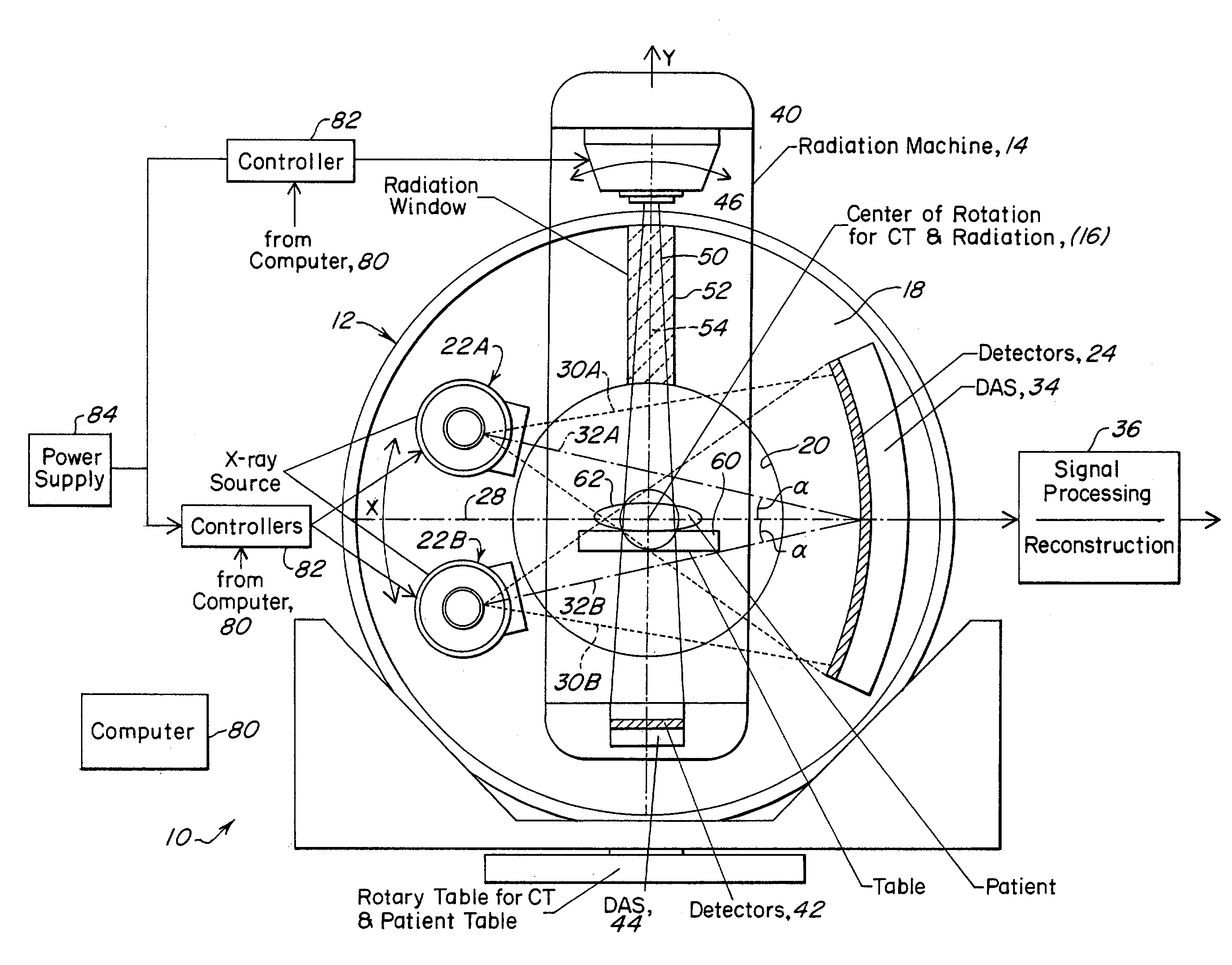

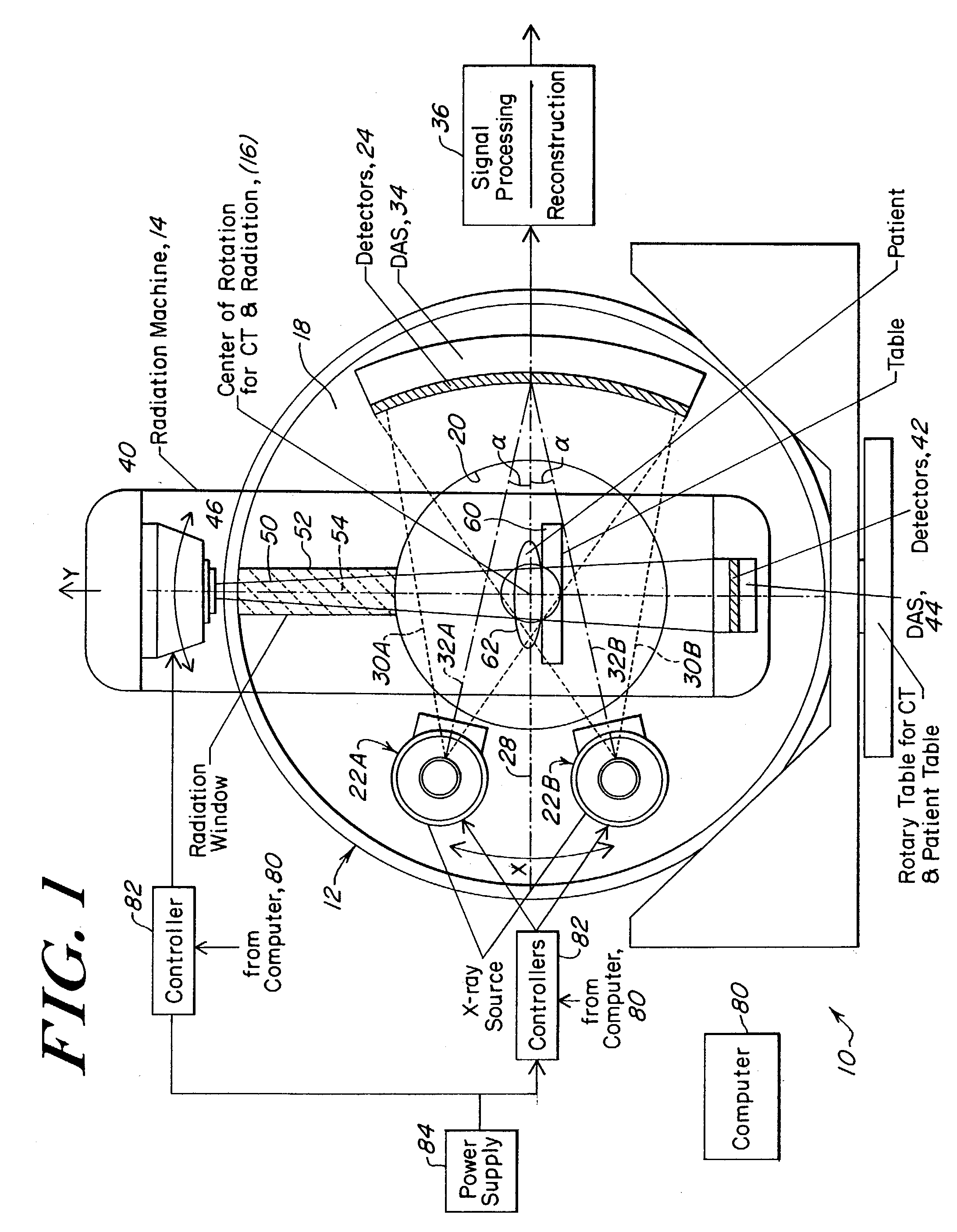

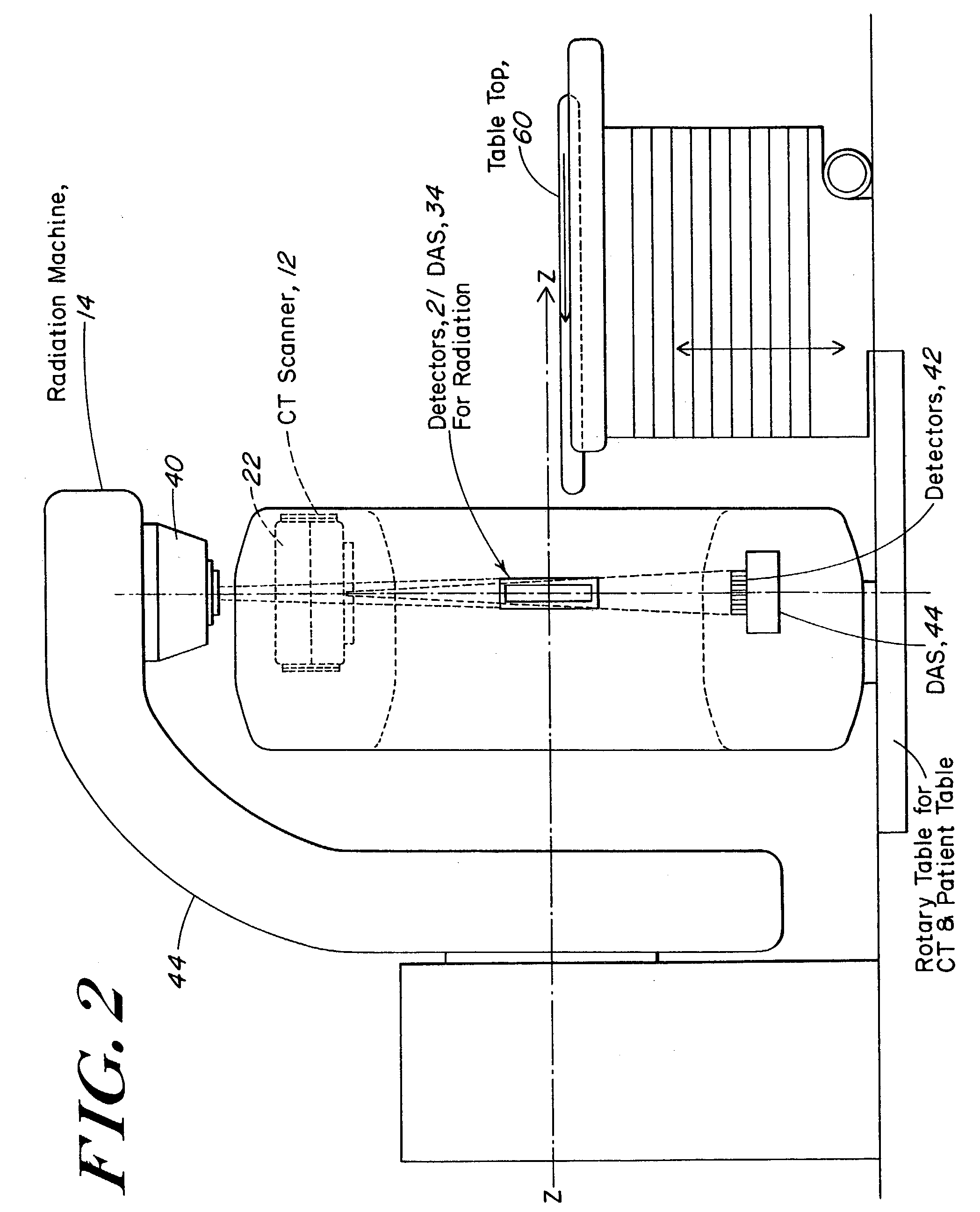

Combined radiation therapy and imaging system and method

InactiveUS20030048868A1X-ray/infra-red processesMaterial analysis using wave/particle radiationX-rayRadiation therapy

A method of and system for locating a targeted region in a patient uses a CT imaging subsystem and a radiotherapy subsystem arranged so the targeted region can be imaged with the imaging system and treated with a beam of therapeutic X-ray radiation using a radiotherapy subsystem. The beam of therapeutic X-rays is in a plane that is substantially fixed relative to, and preferably coplanar with, a slice plane of the CT imaging subsystem so that the targeted region can be imaged during a planning phase, and imaged and exposed to the therapeutic X-rays during the treatment phase without the necessity of moving the patient.

Owner:ANLOGIC CORP (US)

Multiple-variable dose regimen for treating TNFa-related disorders

InactiveUS20090304682A1Reducing remissionReducing signOrganic active ingredientsPeptide/protein ingredientsDosing regimenRegimen

Owner:ABBVIE BIOTECHNOLOGY LTD

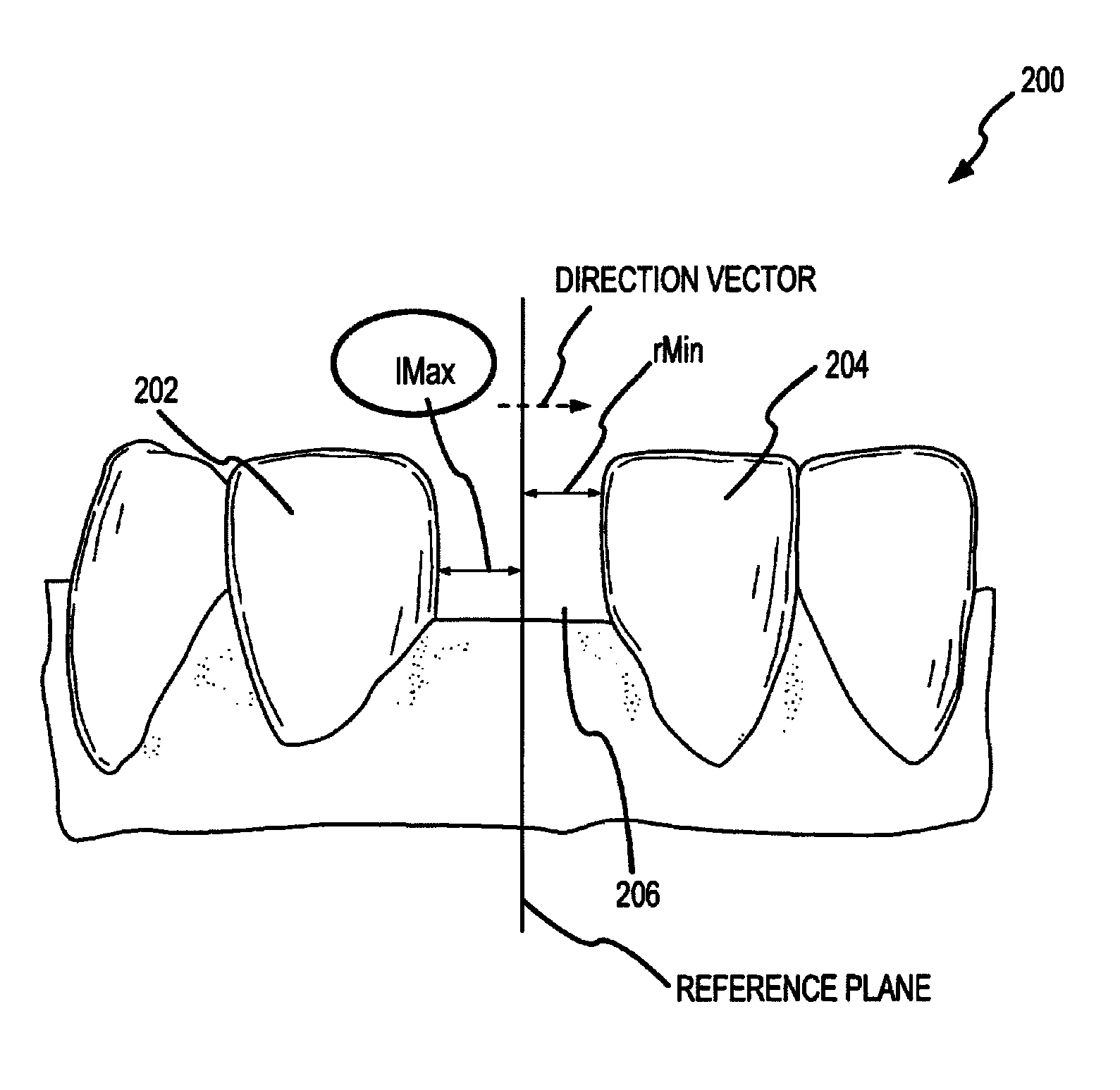

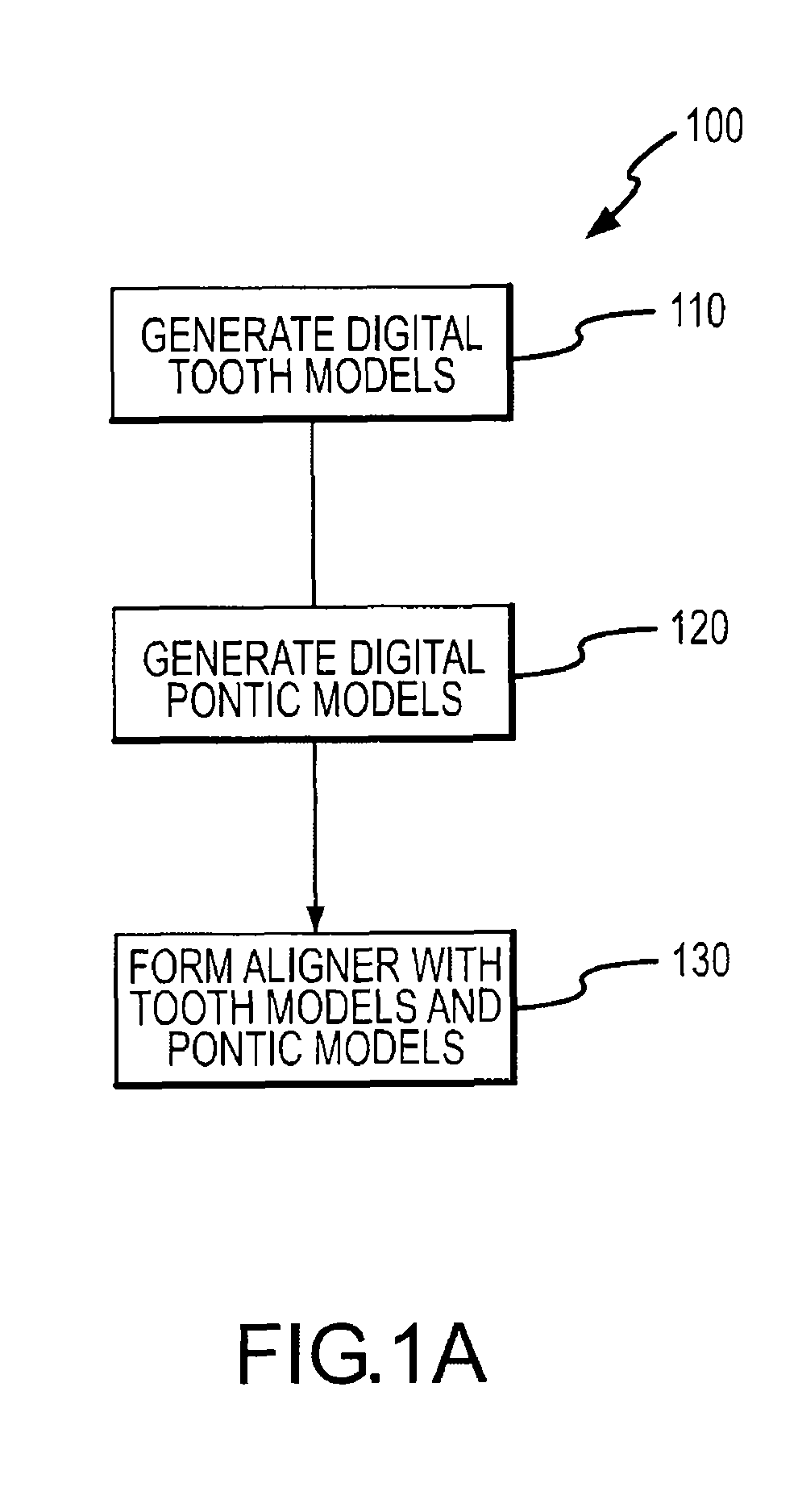

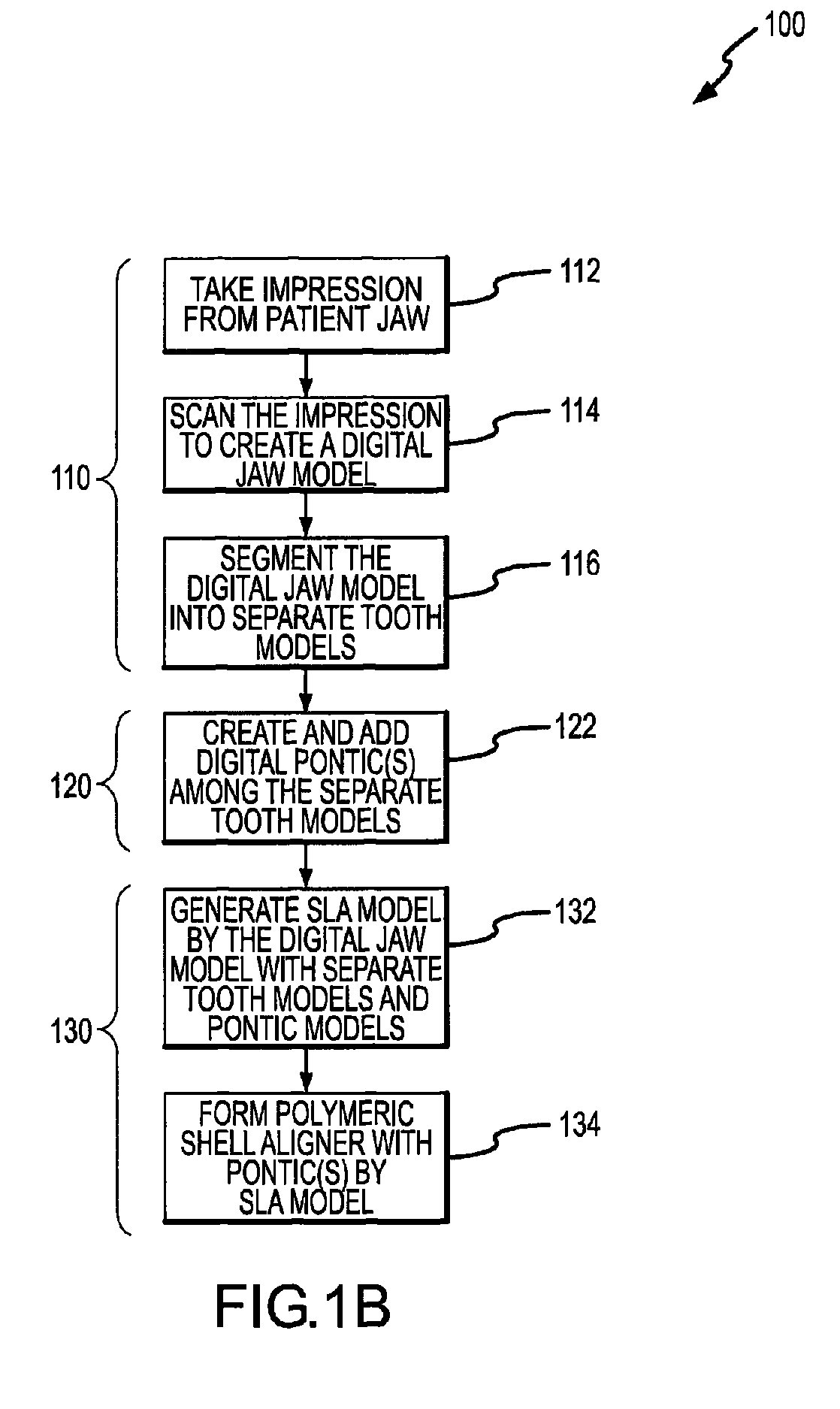

System and method for representation, modeling and application of three-dimensional digital pontics

Modeling pontics at successive treatment stages includes: (1) calculating space measurements between first and second teeth by getting first and second tooth transformations at a treatment stage i; (2) applying the first and second tooth transformations to get positions of the first and second teeth at the stage i; (3) calculating a direction vector of the space measurements at the stage i; (4) calculating a reference plane using the direction vector as a normal; (5) determining whether the space is available for a pontic by measuring the distance from the closest point on each of the first and second teeth to the reference plane; (6) generating an original pontic geometry for a first treatment stage; and (7) generating pontic geometries at each successive stage by calculating deformation parameters based on the original pontic geometry and size characteristics of the space and of the first and second teeth at each stage.

Owner:ALIGN TECH

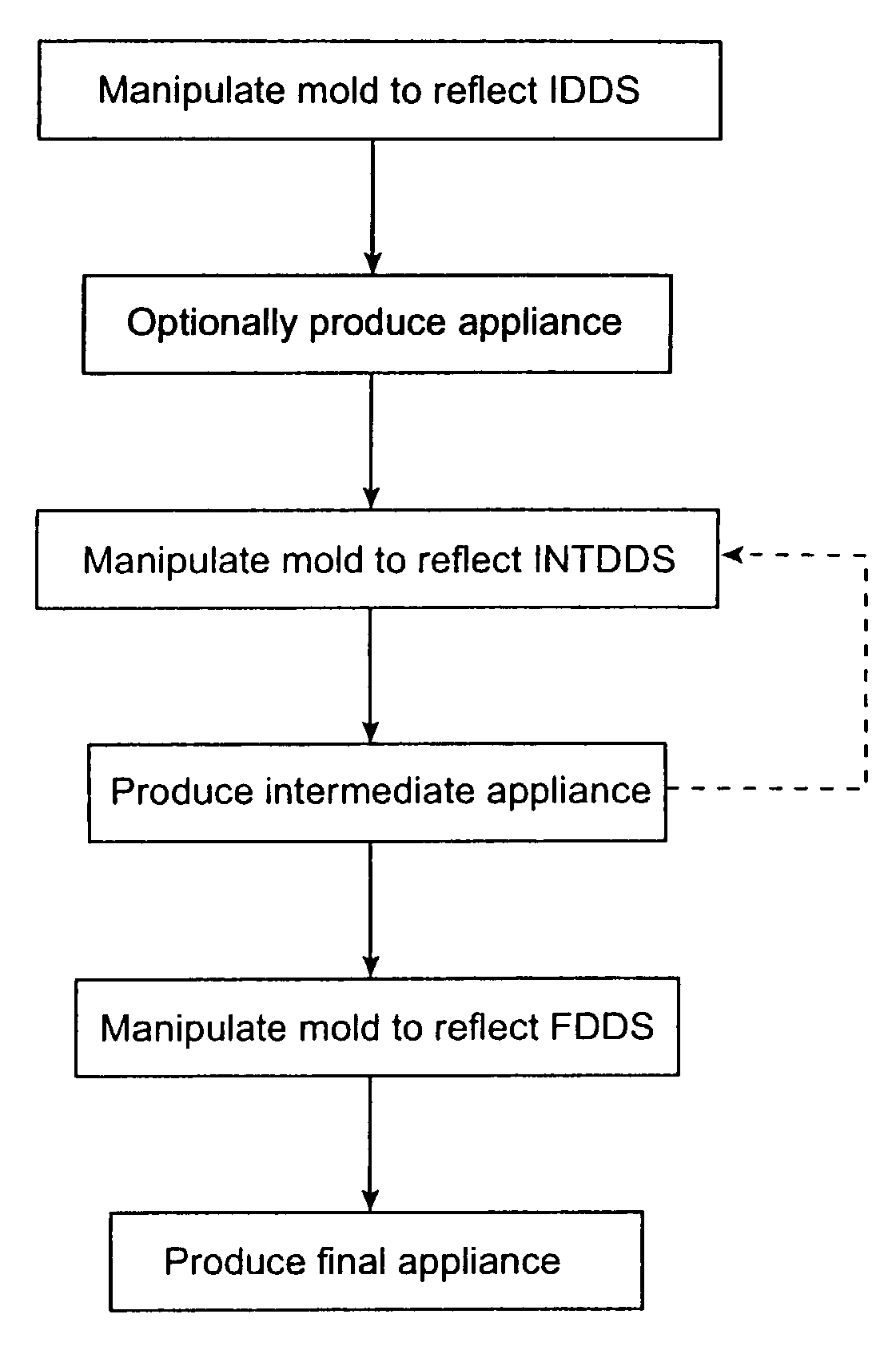

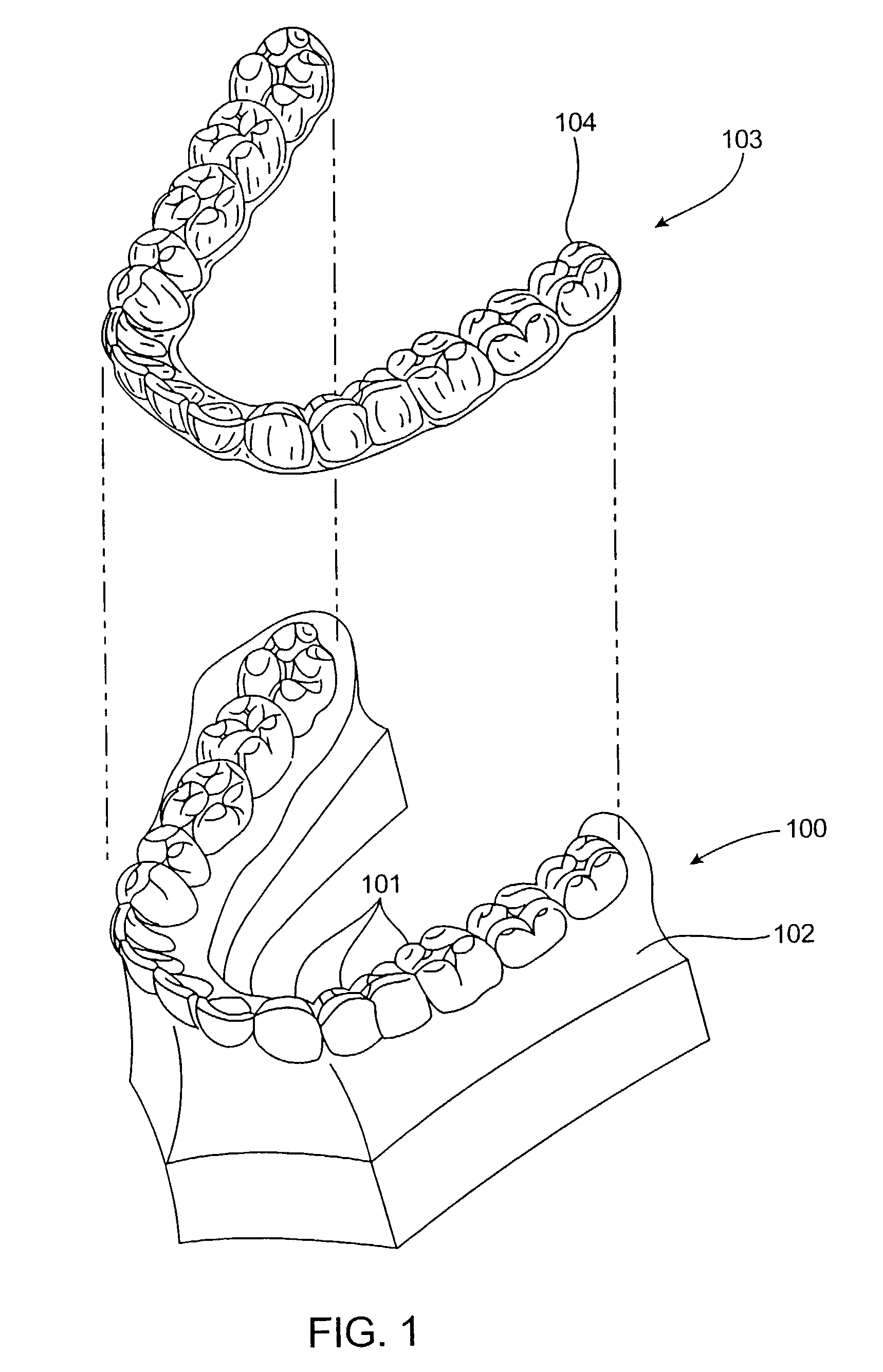

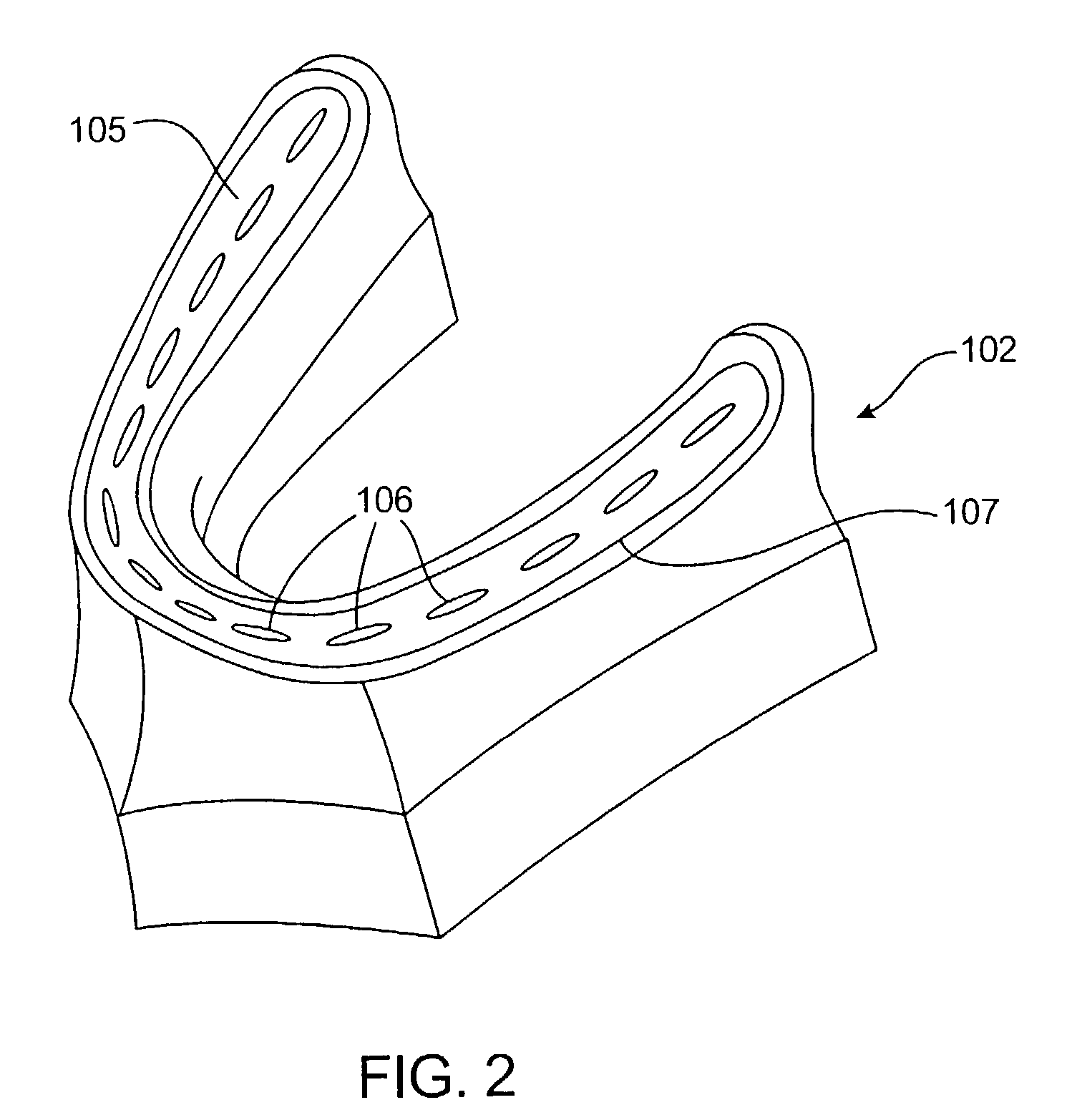

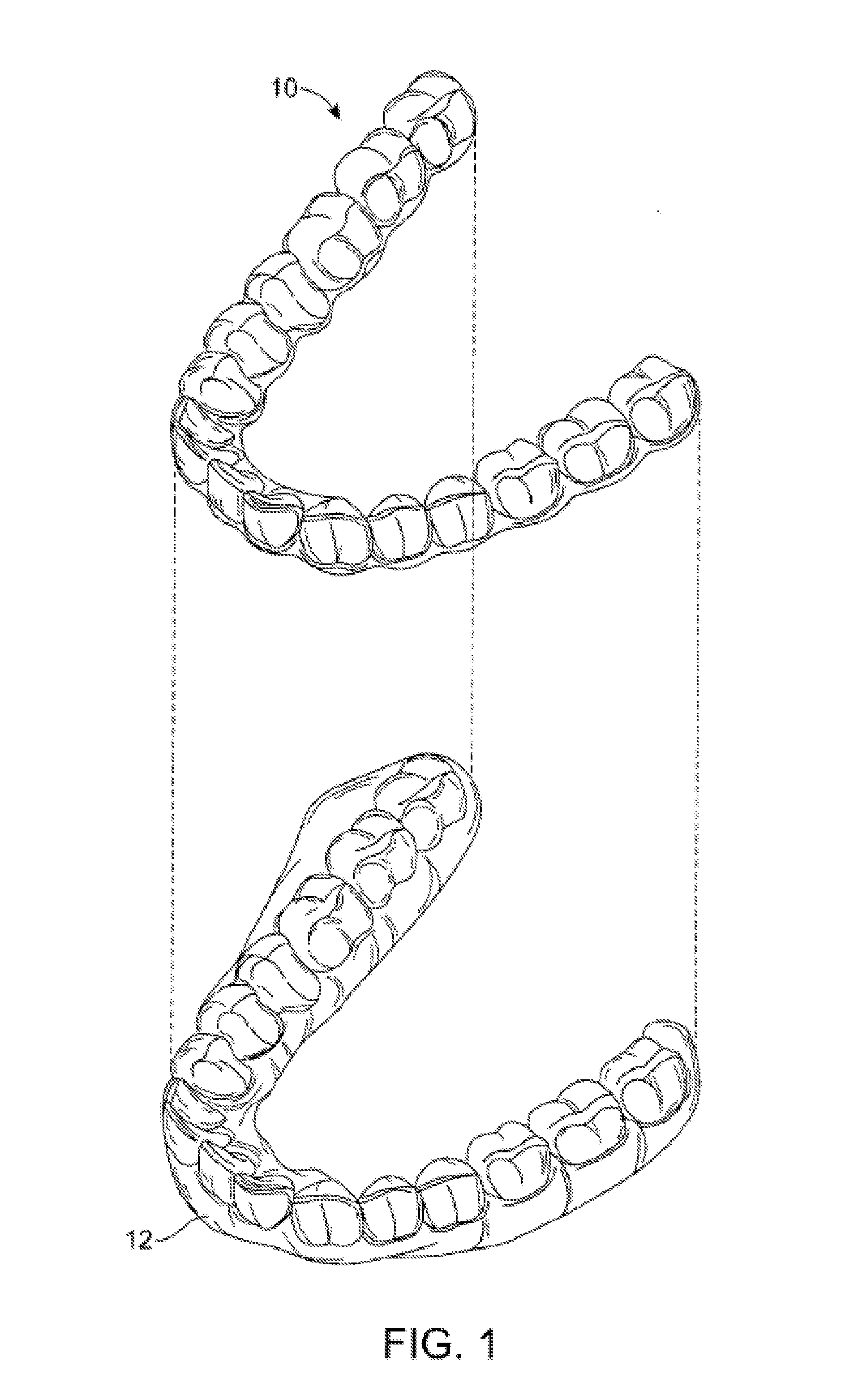

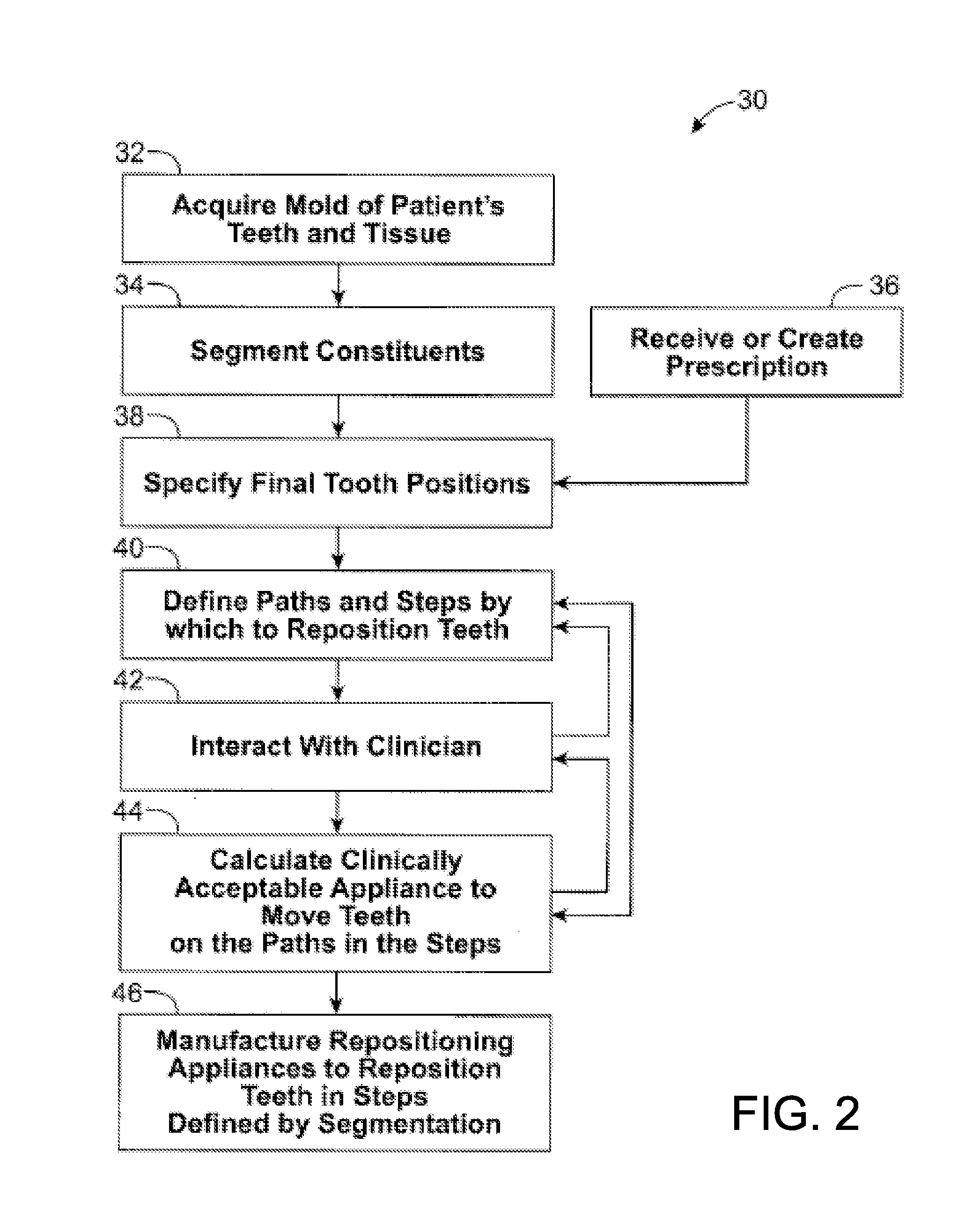

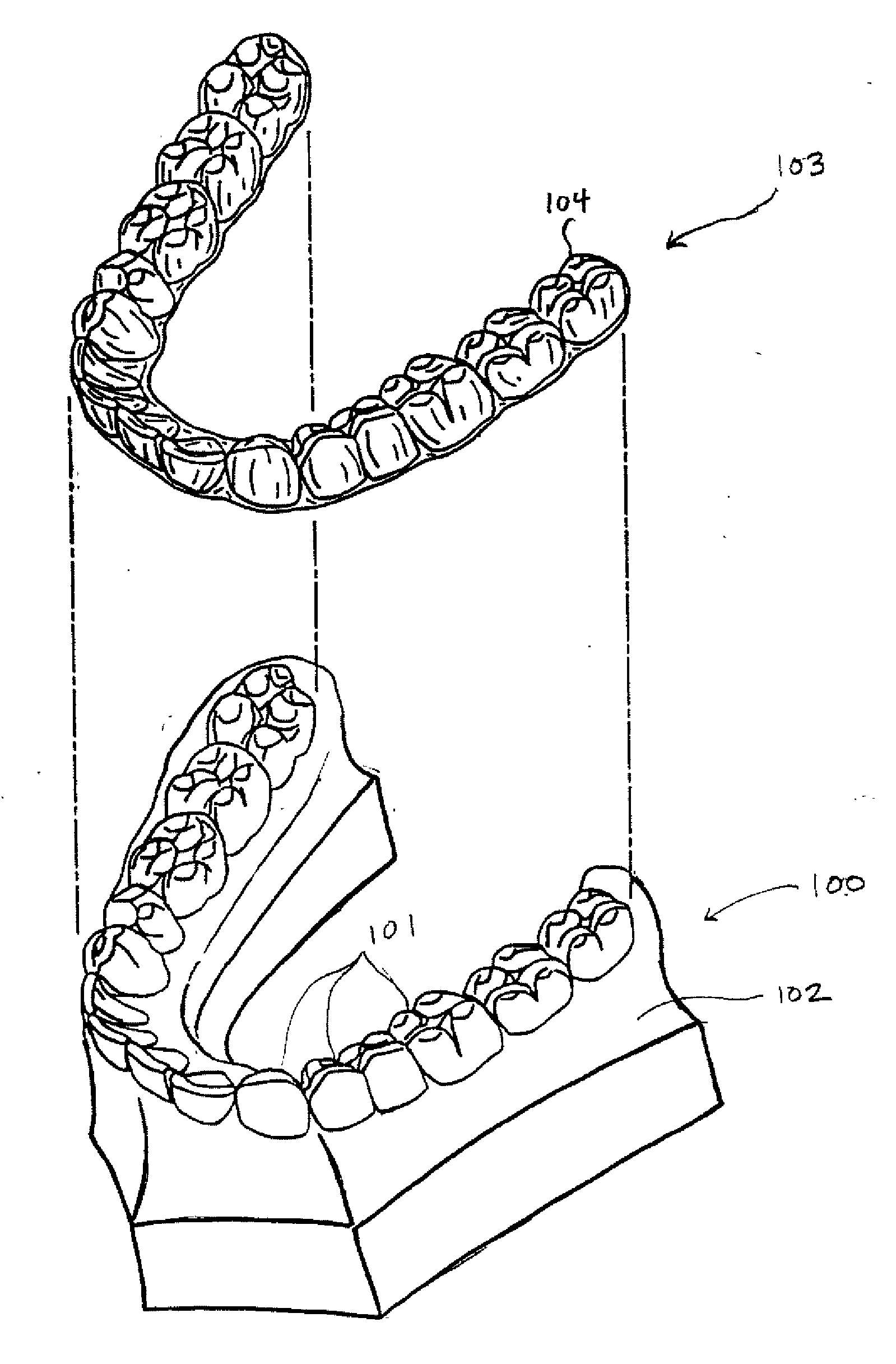

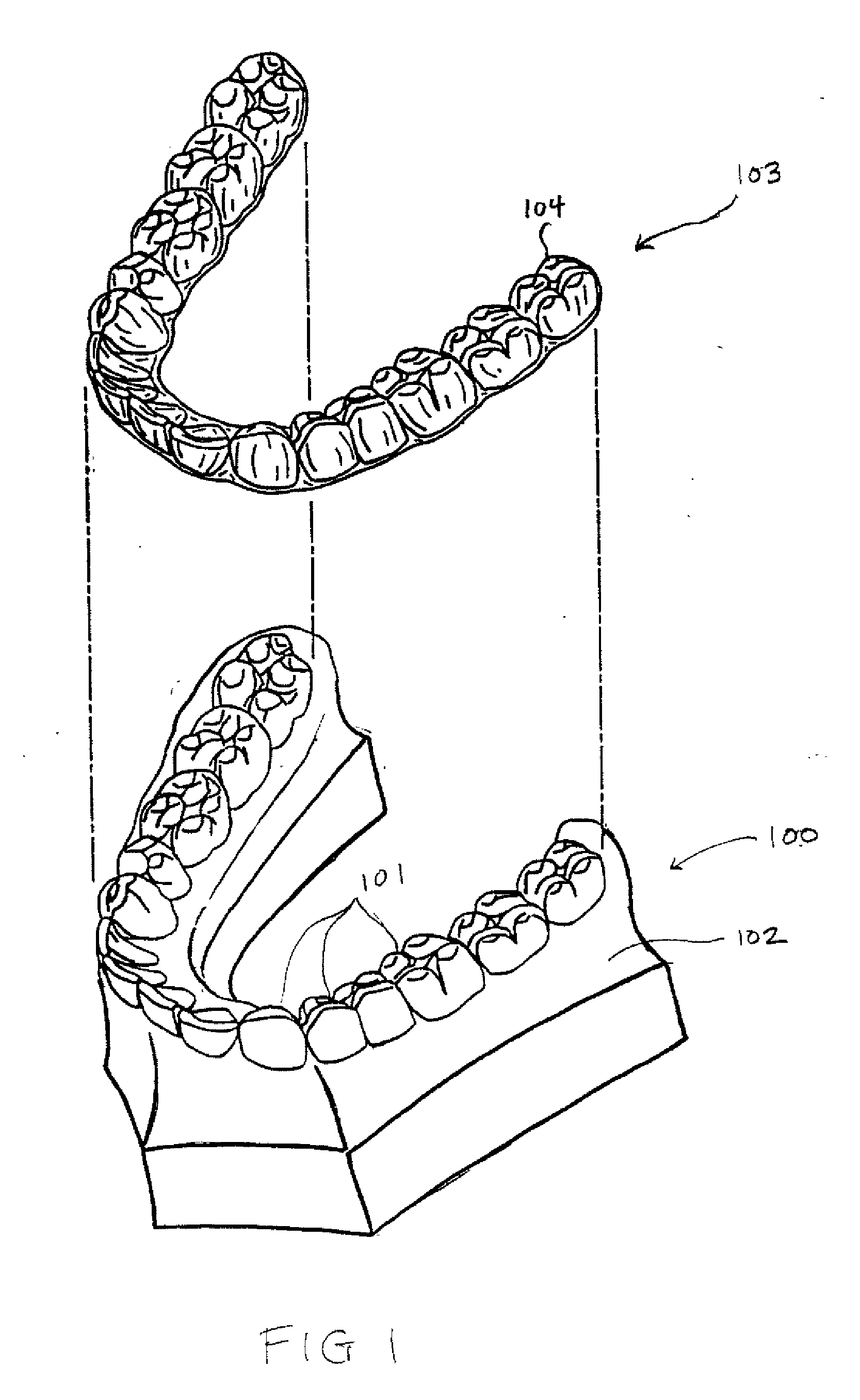

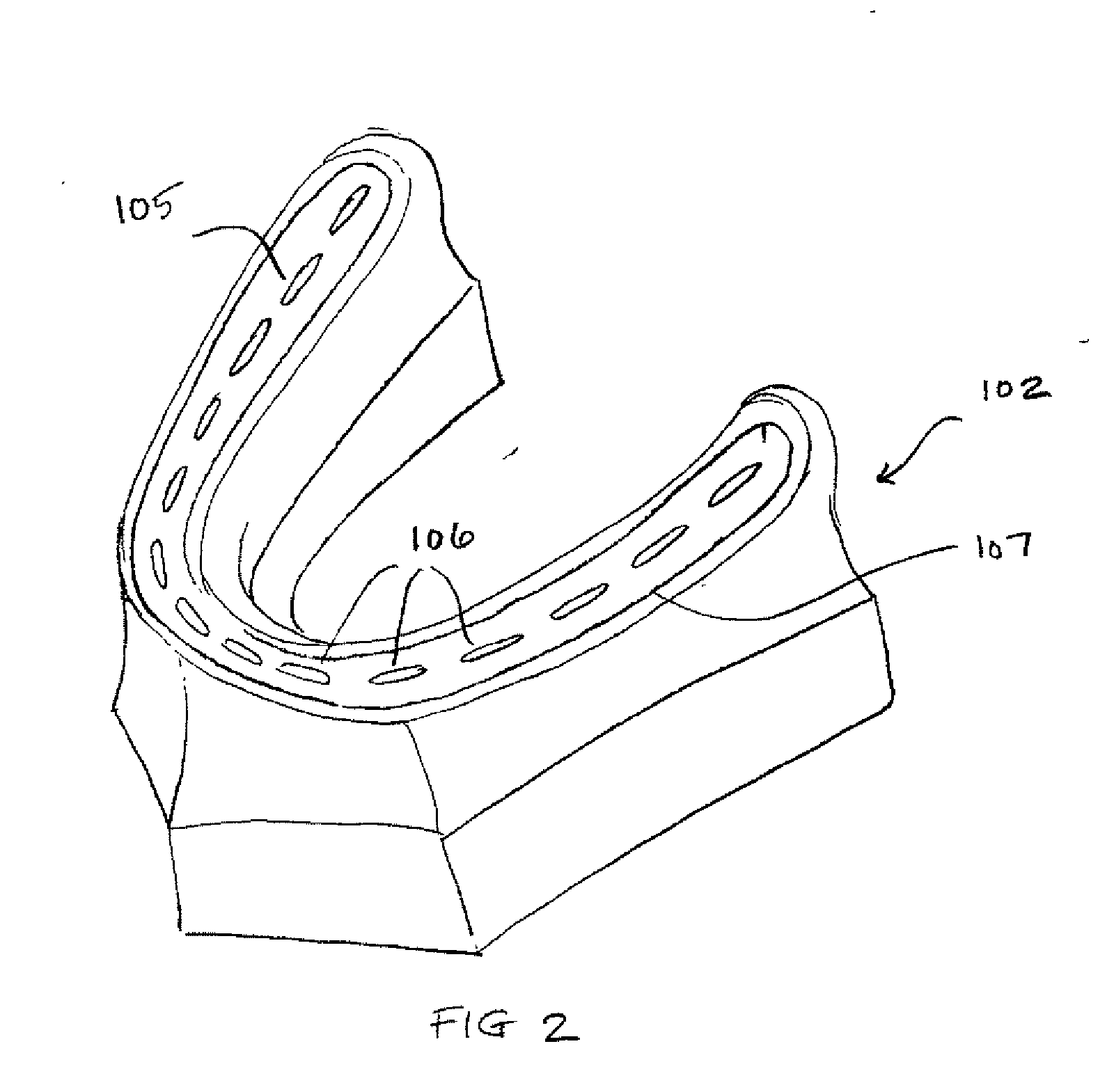

Methods for correcting tooth movements midcourse in treatment

Appliances are made using a dental mold representing a patient's dental configuration. In particular, thermoformable plastic positioning appliances which fit over the patient's teeth may be formed over a three-dimensional mold of the patient's dentition. An apparatus and methods which employ a manipulable or reconfigurable mold to model patient dentition and gingiva at each stage of treatment. The apparatus and methods are particularly useful for performing midcourse corrections during orthodontic procedures using a plurality of such appliances in sequence.

Owner:ALIGN TECH

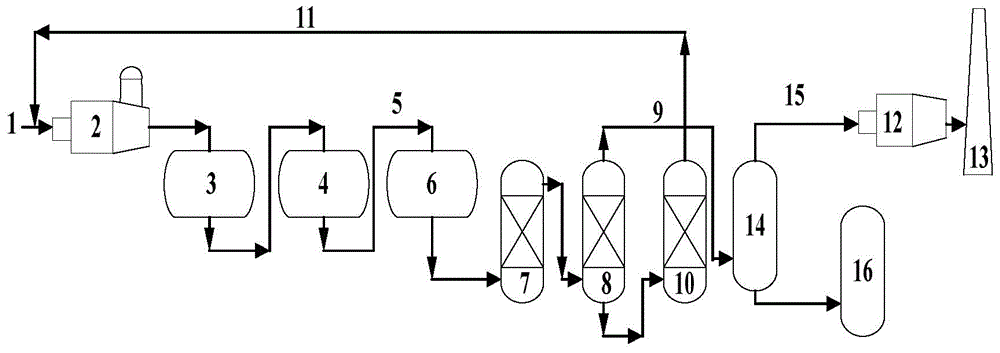

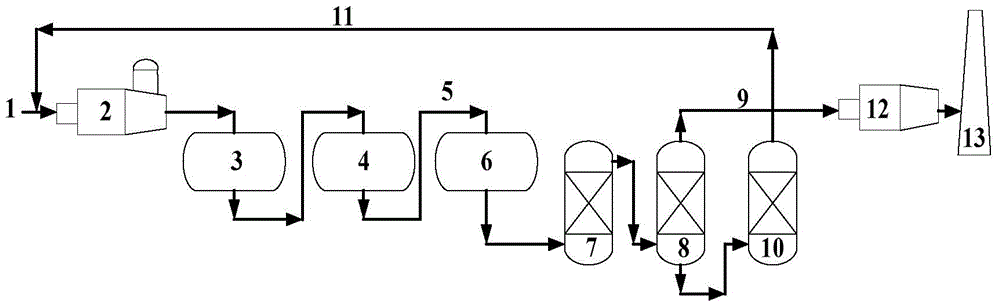

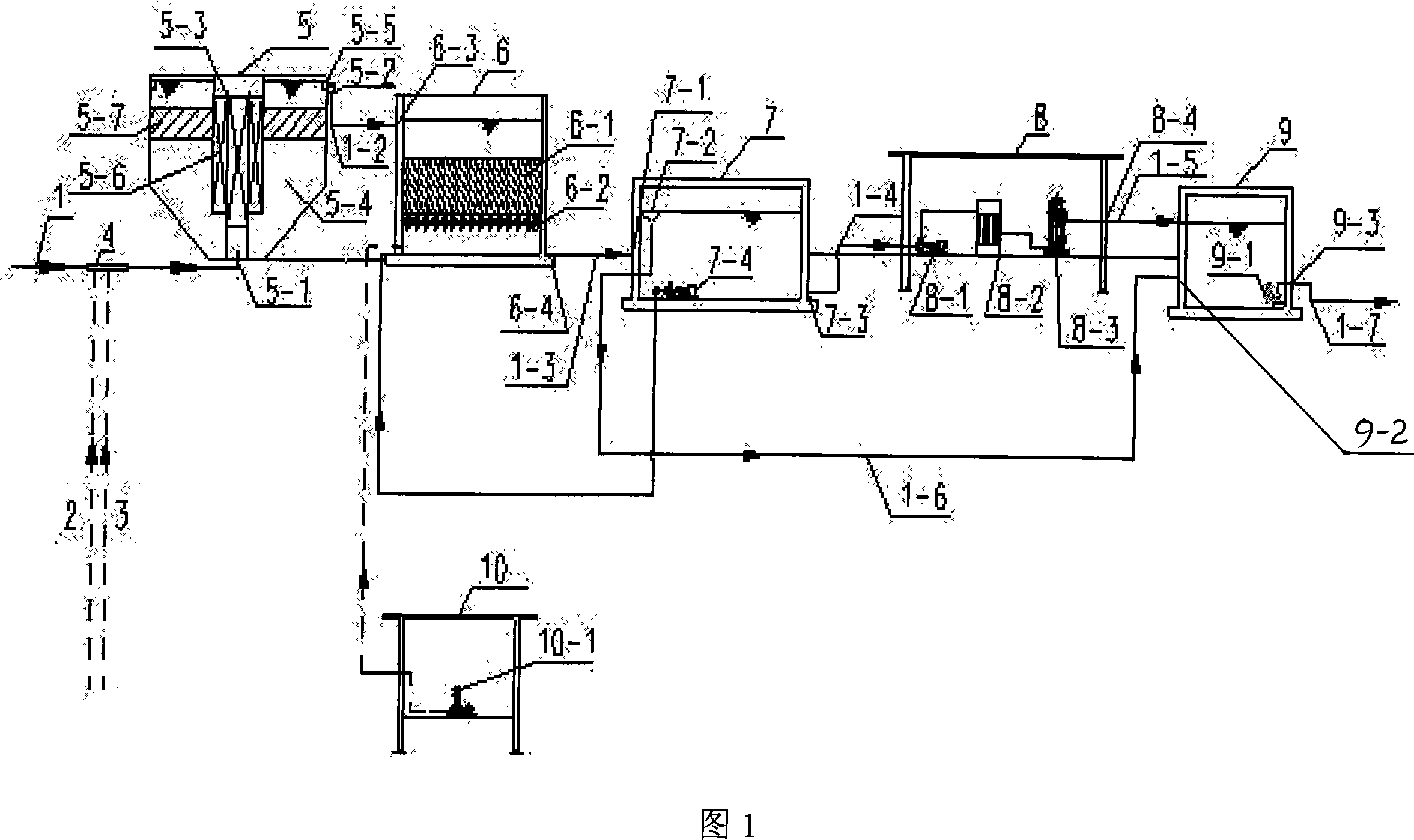

Purified gas treatment process of sulfur recovery device

InactiveCN104555939AReduce contentDispersed particle separationSulfur preparation/purificationHydrogenation reactionSulfur

The invention relates to a purified gas treatment process of a sulfur recovery device. The purified gas treatment process comprises a thermal reaction phase, a catalytic reaction phase and a tail gas purifying treatment phase, wherein in the tail gas purifying treatment phase, the Claus tail gas generated in the catalytic reaction phase is sequentially subjected to a hydrogenation reaction, cooling in a rapid quenching tower and amine liquid absorption, then the purified tail gas is fed to alkali liquor to be subjected to H2S removal treatment, and the tail gas removed from H2S is combusted and then discharged; the amine liquid amine-rich liquid absorbing H2S is fed to a regeneration tower to be regenerated, the regenerated acid gas is mixed with the acid gas, and then returned to the thermal reaction phase to further recover elemental sulfur; the exhausted lye removed from H2S is subjected to caustic dross biological treatment or acidic water stripping treatment. With adoption of the purified gas treatment process disclosed by the invention, H2S in the purified gas can be removed to 5 mg / m<3> below, the SO2 content in the smoke is obviously reduced within the reduction range of 100-1000 mg / m<3>; the exhausted lye treatment method is further provided, and the exhausted lye is subjected to the caustic dross biological treatment or the acidic water stripping treatment, so that pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

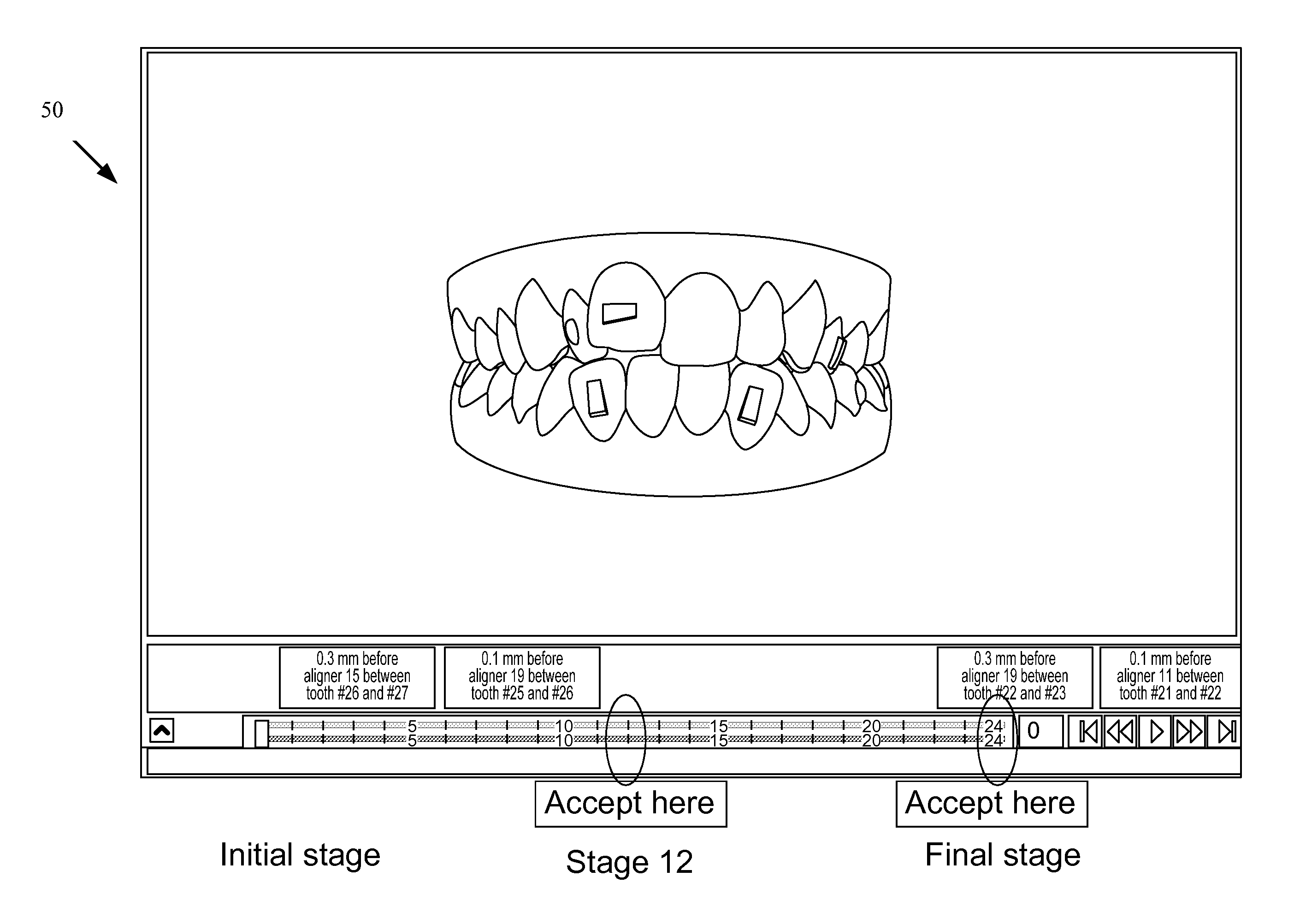

Comparative orthodontic treatment planning tool

A comparative orthodontic treatment planning tool that can provide multiple treatment plan options based on a single initial tooth data set. A user can use the treatment planning tool to select a treatment plan based on factors, including cost, treatment duration, treatment complexity, and material or feature selection. Tooth arrangements at different treatment stages can be compared. In some cases, a tooth arrangement at one treatment stage can be superimposed over a tooth arrangement at a different treatment stage or over a tooth arrangement from a different treatment plan.

Owner:ALIGN TECH

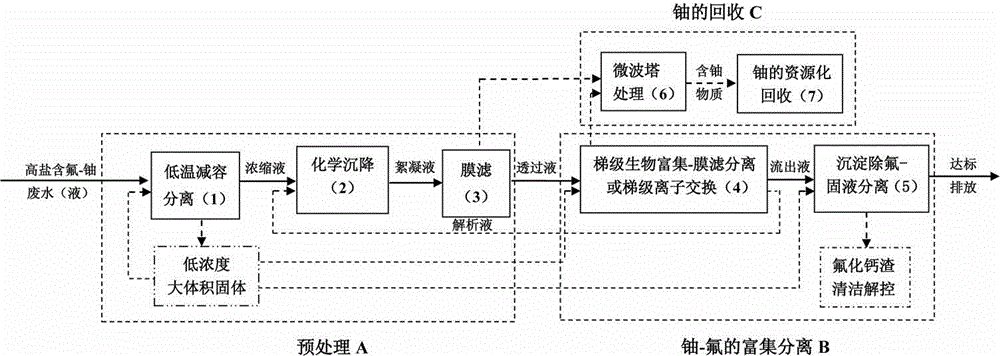

Method for deeply purifying and recovering hyperhaline fluoric-u radioactive waste solution

ActiveCN104835545AReduce lossesImprove efficiencyWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisLiquid wasteRecovery method

The invention discloses a method for deeply purifying and recovering hyperhaline fluoric-U radioactive waste solution. The method comprises three sequent treatment phases including pretreatment, enrichment and separation of U-F and recovery of U, and can be further finely divided into 7 treatment units, including lower temperature reduction separation, chemical sedimentation, film filtering, step-grade organism enrichment-film filtering separation or step ion exchange, deposit fluorine removal solid-liquid separation, microwave tower treatment and resource recovery of U; under the condition that the salinity of waste solution to be treated is 0.1-10%, the initial U concentration is 0.1-1000mg / L, and the fluorine concentration is 0.01-15g / L, after treatment, the concentration of U is not larger than 0.05mg / L, the concentration of the fluorine is not higher than 10mg / L, and the recovery rate of U is larger than 90%. The method for deeply purifying and recovering hyperhaline fluoric-U radioactive waste solution is suitable for treating hyperhaline fluoric-U radioactive waste solution and the resource recovery of radioactive U.

Owner:SOUTHWEAT UNIV OF SCI & TECH

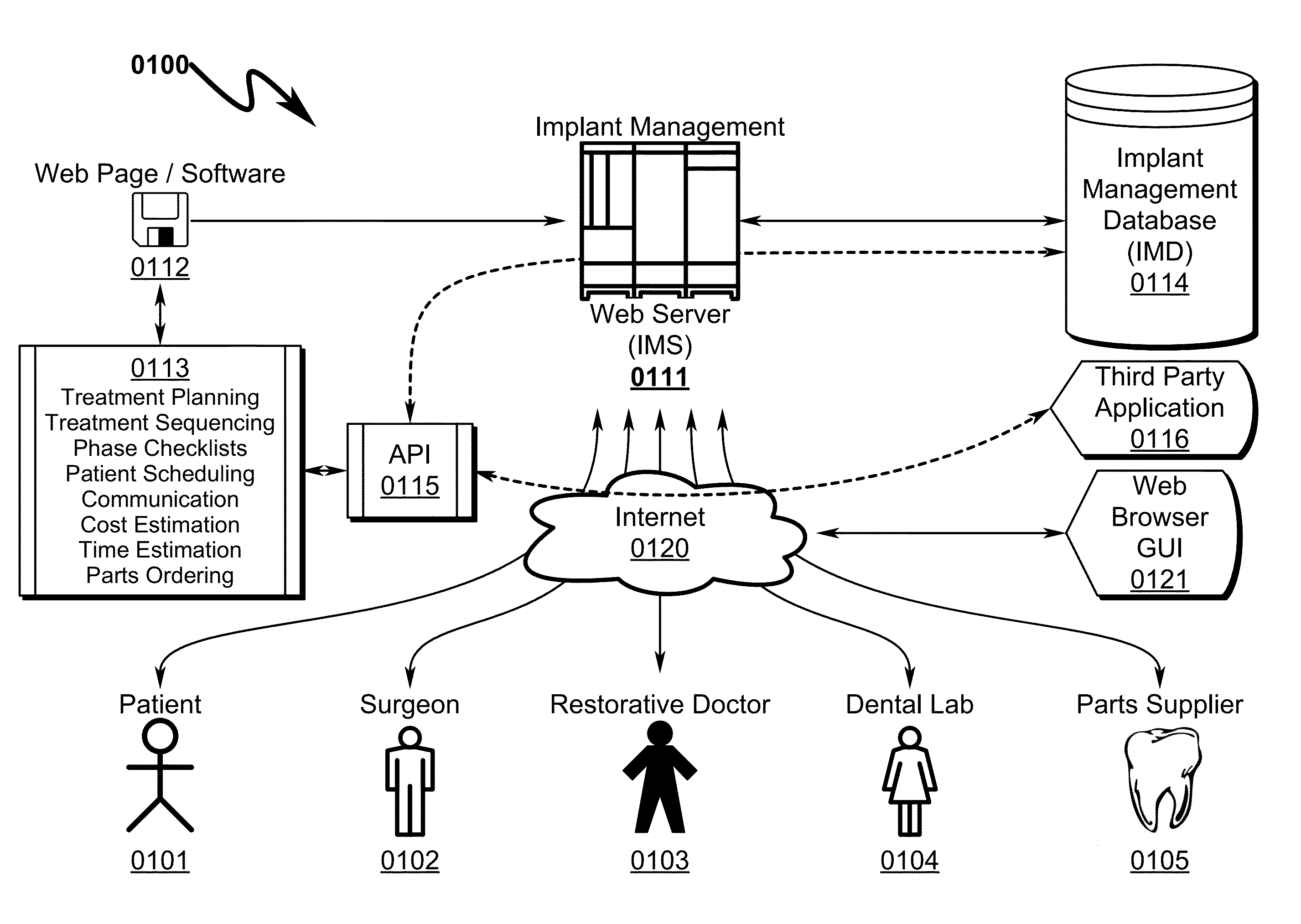

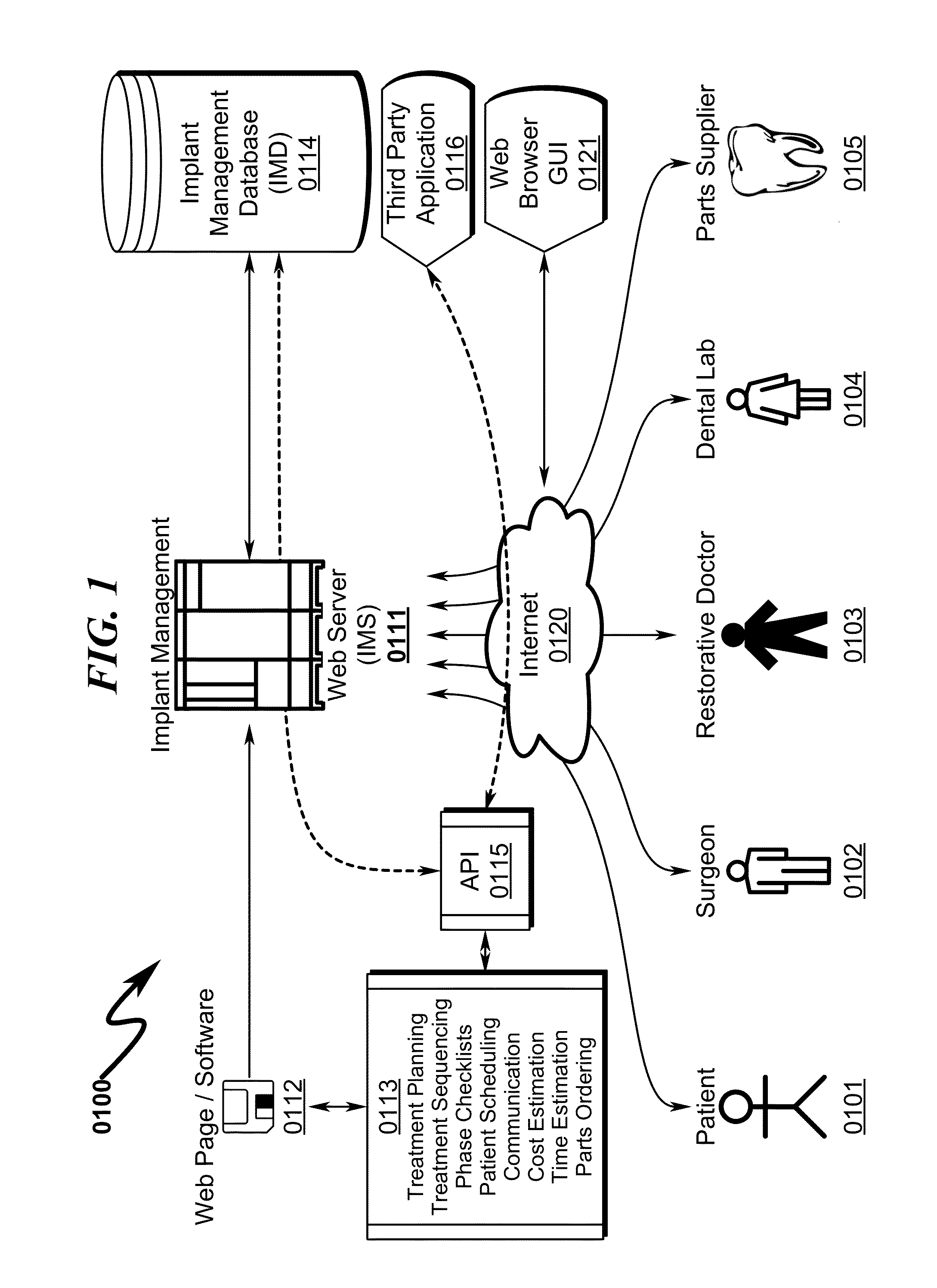

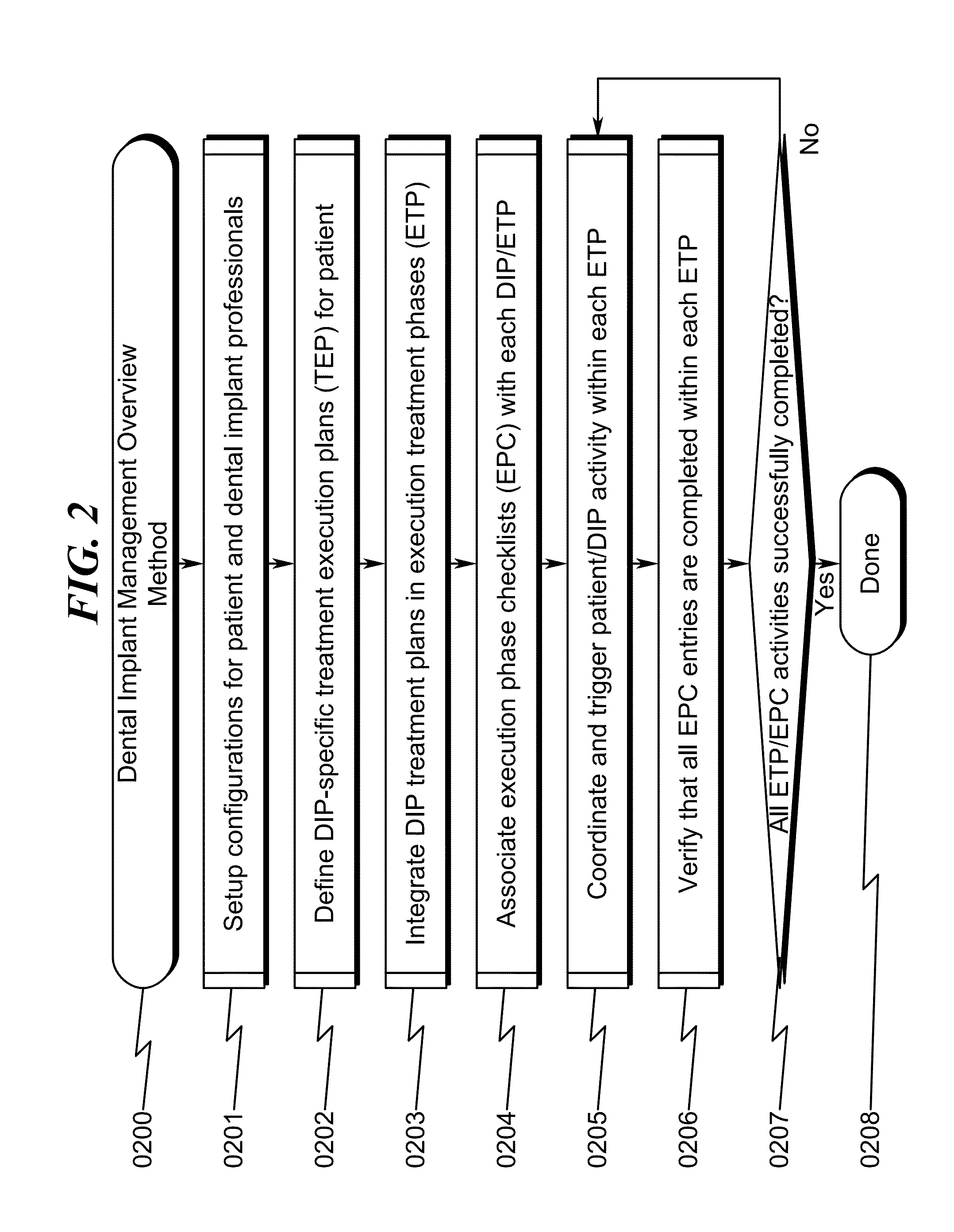

Dental implant management system and method

InactiveUS20150019252A1Good for dental healthFacilitate communicationDental implantsMechanical/radiation/invasive therapiesExecution planDental laboratory

A dental implant management system / method that improves communication and coordination between parties associated with dental implant procedures is disclosed. The system / method operates to permit each dental implant professional (DIP) (typically a surgeon, restorative doctor, and dental laboratory) to iteratively generate a patient treatment execution plan (TEP) for the dental implant procedure that is generally structured within execution treatment phases (ETP) and automatically coordinated among each DIP. The ETP typically defines FOUNDATION, IMPLANT PLACEMENT, RESTORATIVE, and MAINTENANCE phases that may each incorporate custom execution phase checklists (EPC) that permit each DIP to ensure that critical elements of their TEP are properly executed. Coordination of the various DIP-generated TEPs is integrated with treatment planning / sequencing, patient scheduling, DIP fee estimation, and dental parts procurement to ensure maximum revenue to each DIP while simultaneously improving the probability of a successful dental implant procedure for the patient.

Owner:CENTGISTIX

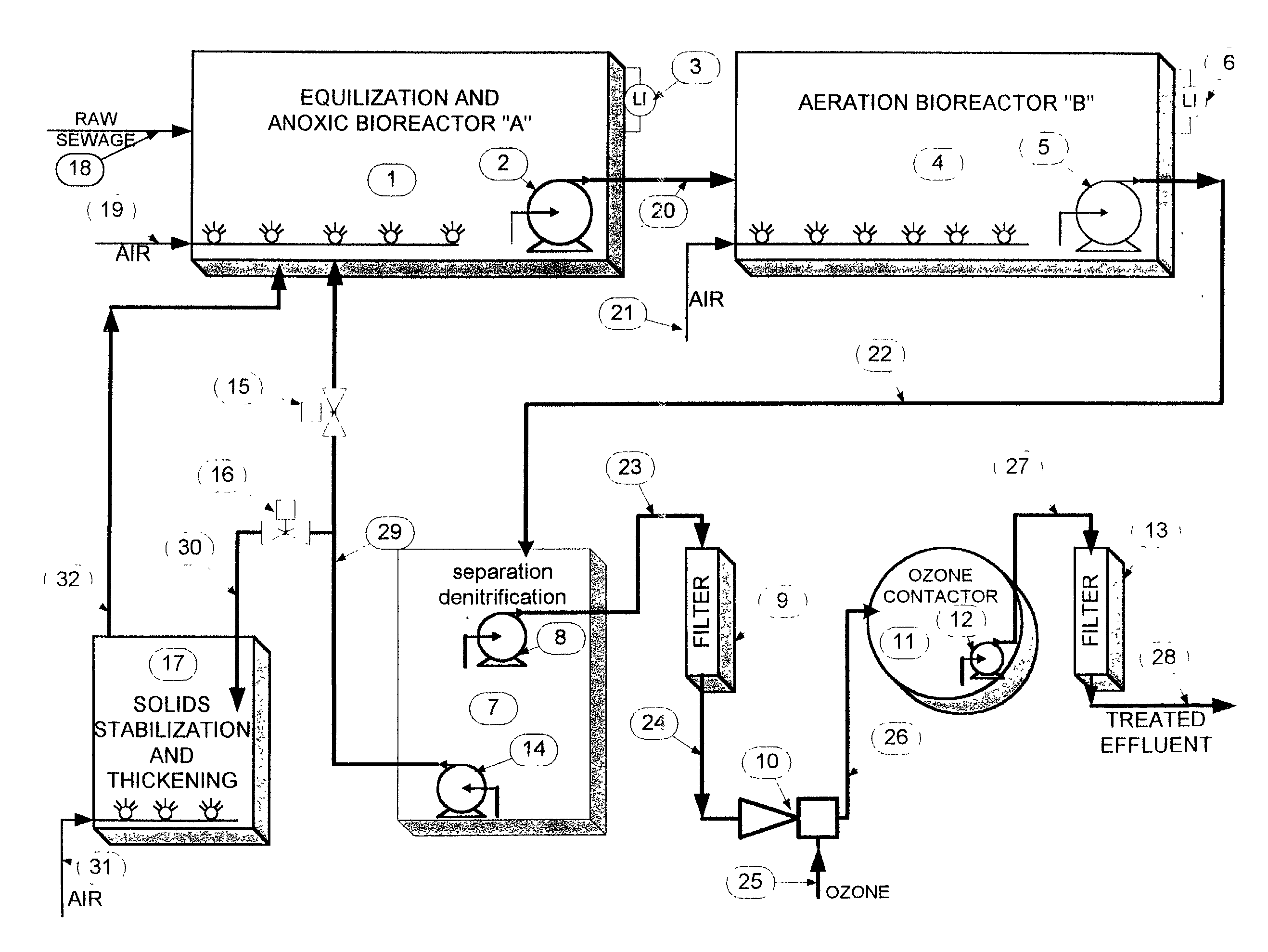

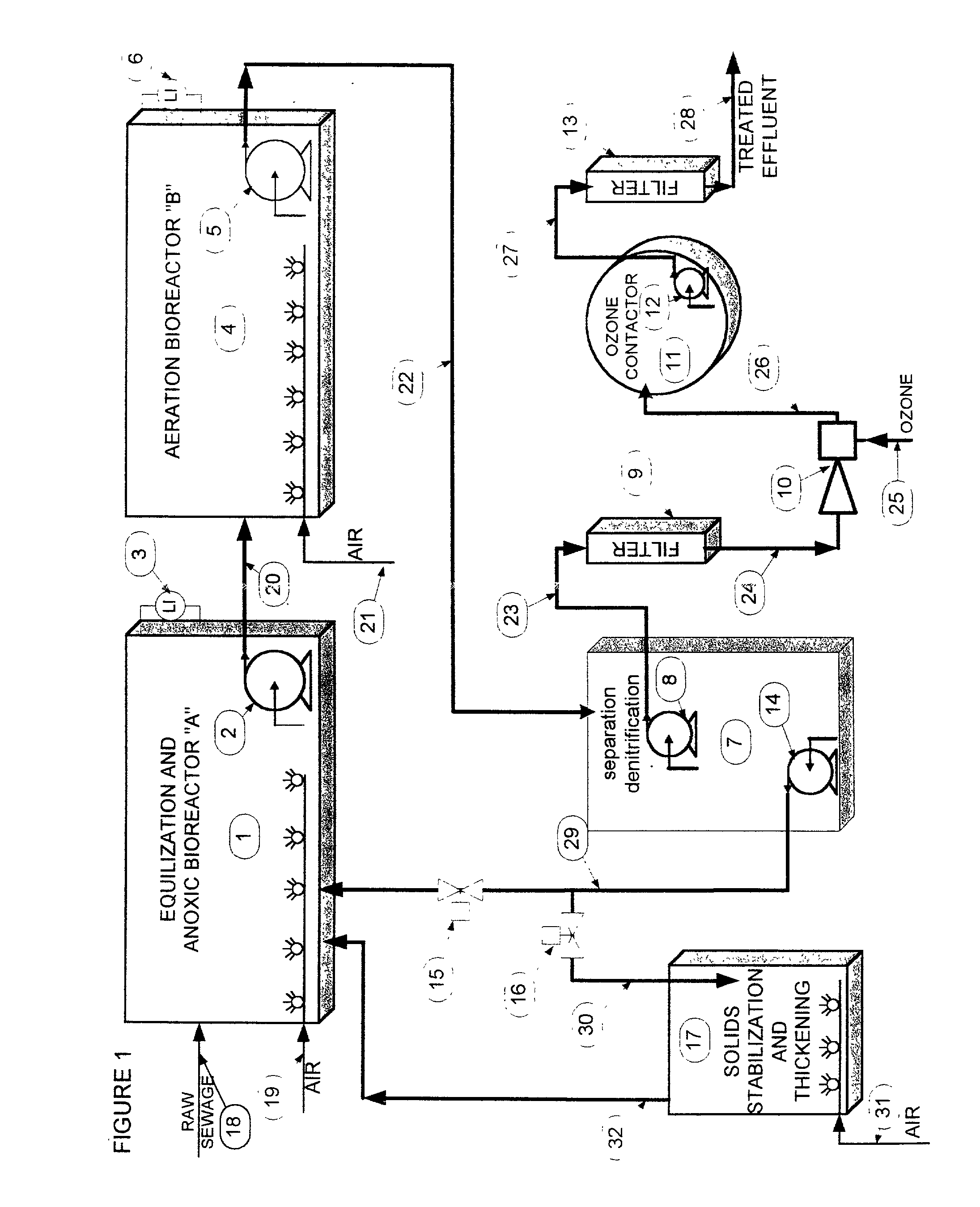

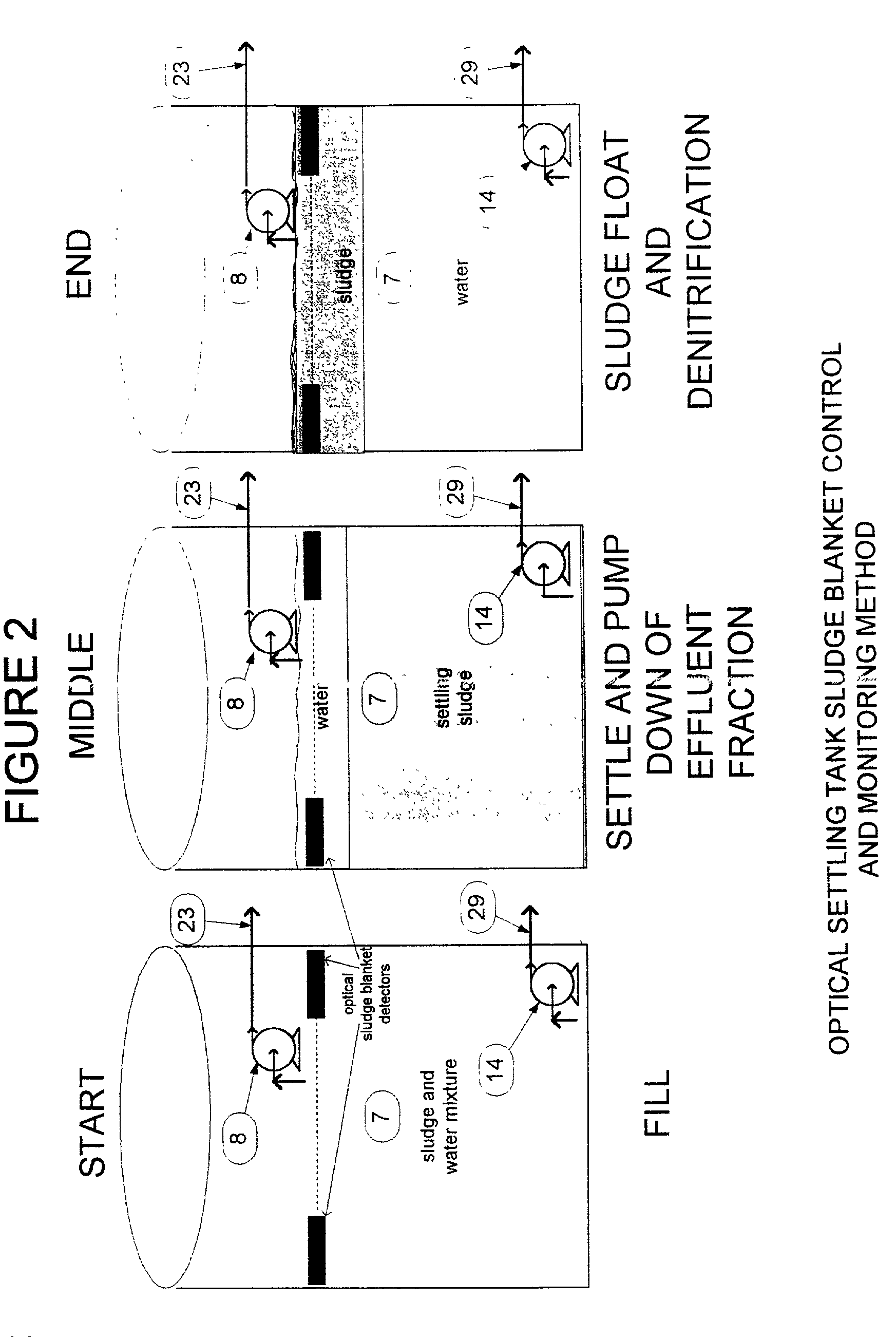

Modified intermittent cycle, extended aeration system (miceas)

InactiveUS20030015469A1Water treatment parameter controlTreatment using aerobic processesFiltrationSludge

A semi batch biological waste treatment process used to treat municipal and industrial wastes containing BOD, nitrogen and phosphorous. The process uses two biological reactors in series, with each maintaining a mixed liquor inventory. Inputs and outputs from the reactor series are performed through the addition and removal of small batches. The reactors can be configured in multiple ways for different waste conditions. The preferred embodiment is an integrated batch process that includes an anoxic equalization vessel, an aerobic biological reactor, a clarification step with denitrification, a tertiary effluent treatment phase with ozone injection and filtration and an automatic sludge wasting method with thickening and stabilization. The process has two denitrification phases and has very high nitrogen removal rates.

Owner:HEDENLAND MICHAEL DAVID +2

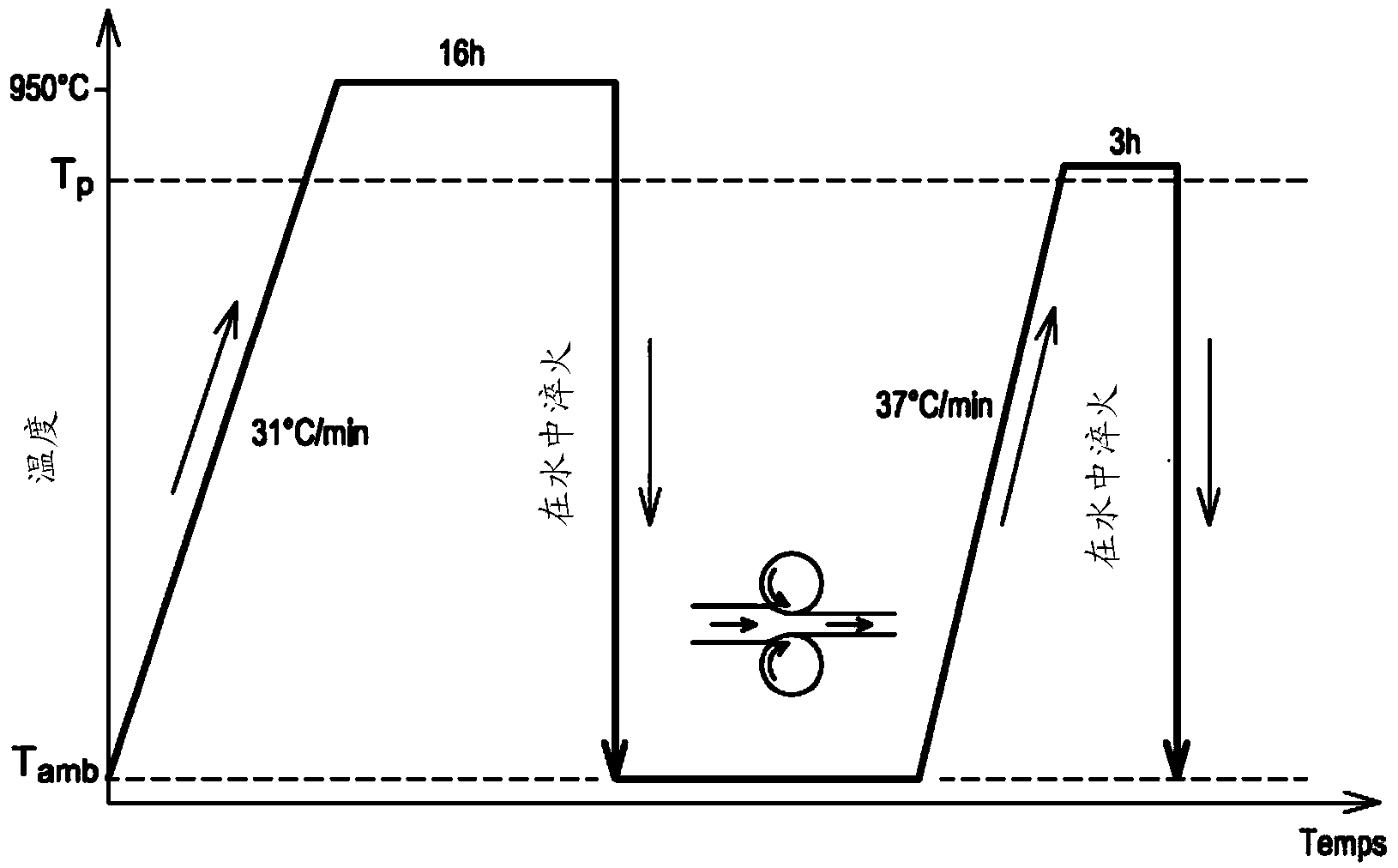

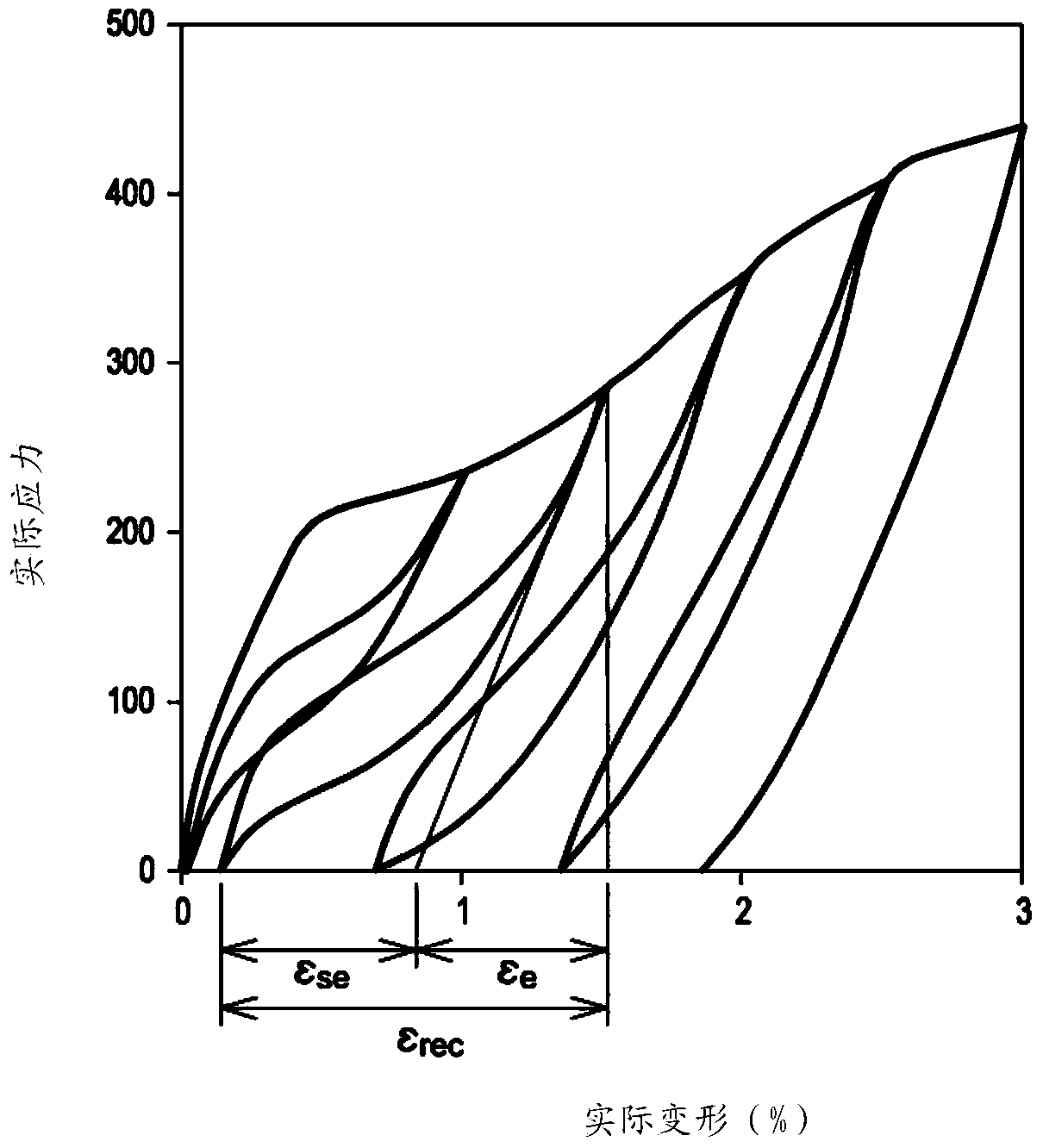

Method for manufacturing a titanium alloy for biomedical devices

InactiveCN104245975APreservation of β metastable microstructureGet super elasticSurgeryVacuum evaporation coatingBeta phaseTitanium alloy

The invention relates to a method for manufacturing a titanium alloy having superelastic properties and / or shape memory for biomedical use, which comprises the steps of: preparing an ingot by melting the various metals that form the desired alloy in a vacuum; optionally homogenising the ingot in a vacuum by high-temperature annealing (higher than 900 DEG C); first quenching; mechanical shaping (rolling, drawing, machining or the like); heat treatment for redissolution in beta phase beyond the beta transus temperature (until a second temperature and then maintaining same for a certain time); and second quenching; characterised in that said heat treatment phase is carried out in a gaseous atmosphere and also constitutes a surface treatment suitable for forming on the surface a layer of nitride, carbonitride, oxide, oxynitride or the like.

Owner:法国雷恩国立应用科学学院 +1

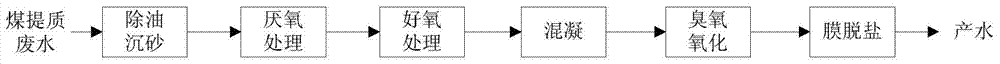

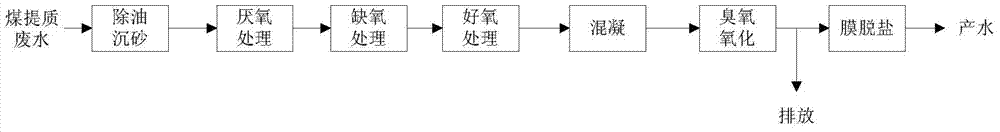

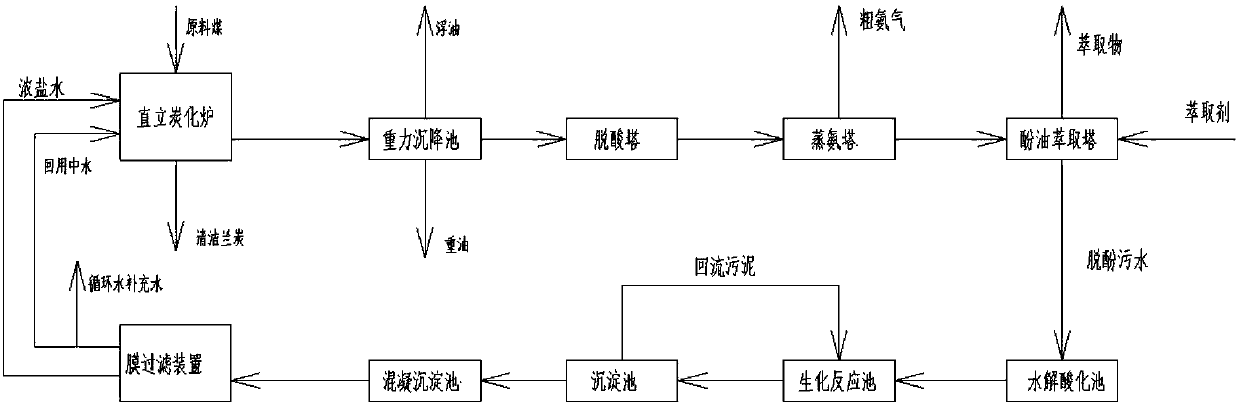

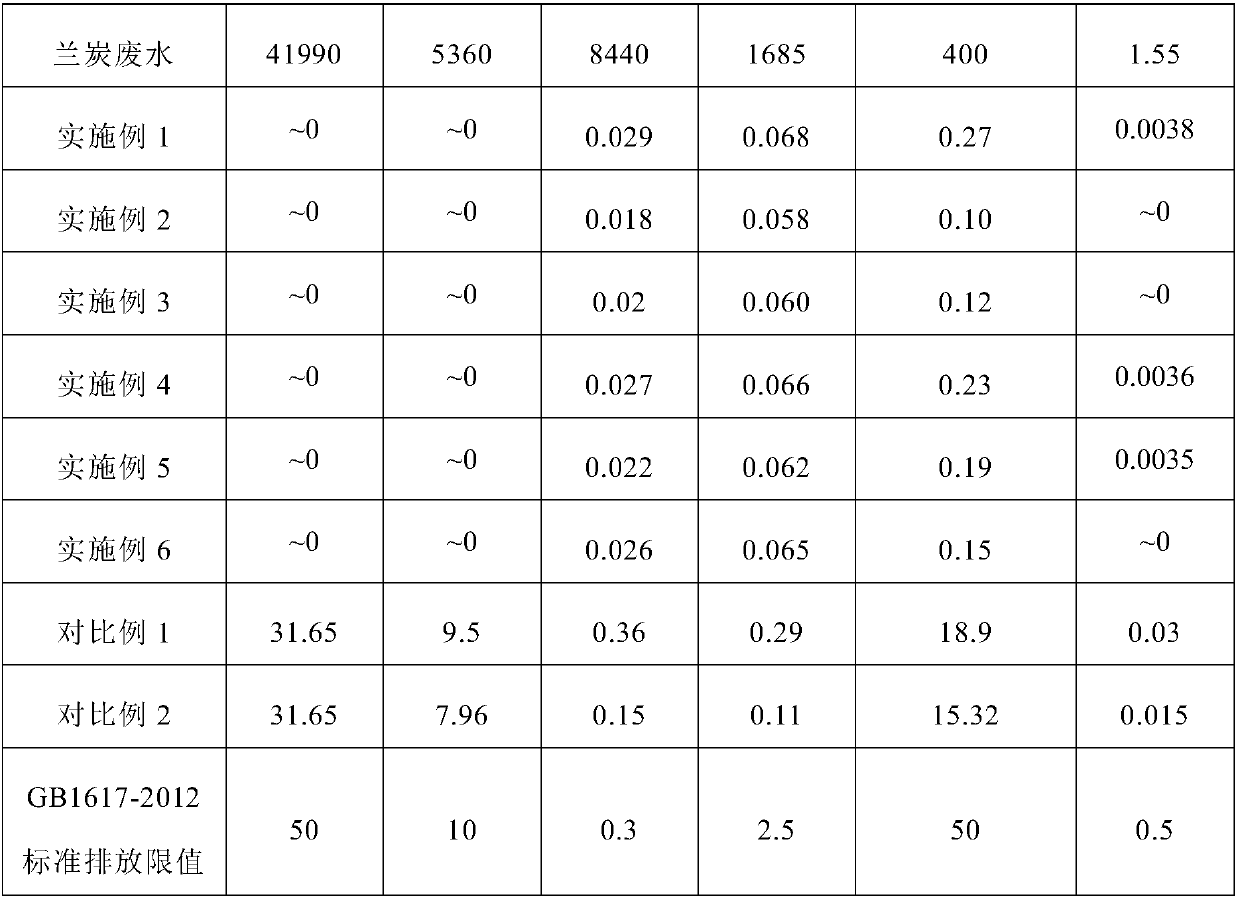

Coal upgrading wastewater treatment process

ActiveCN103613253AStrong process applicabilityStrong impact resistanceMultistage water/sewage treatmentHazardous substanceEmission standard

The invention relates to a coal upgrading wastewater treatment process and belongs to the technical field of wastewater treatment. Aiming at the characteristics that the coal upgrading wastewater is high in content of suspended solids, difficult in settling, rich in degradation-resistant organic matters even toxic and harmful materials, high in chromaticity, and the like, the wastewater is firstly subjected to oil-removing and sand-conditioning treatment to remove most of suspended solids and oil in the wastewater, so that the impact to a subsequent biochemical system is reduced; the biochemical system comprises an anaerobic tank and an aerobiotic tank, and can further comprises an oxygen-deficient tank, wherein most of pollutants are removed in a biochemical treatment phase, and then the wastewater is disinfected through ozone oxidation, decolored, and subjected to removal of the degradation-resistant pollutants so as to reach the emission standard, and can also be recycled through a film desalting system. The coal upgrading wastewater treatment process provided by the invention has the characteristics of high process applicability, good removing effect special for pollutants, easiness for operation and great impaction resistance capacity.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

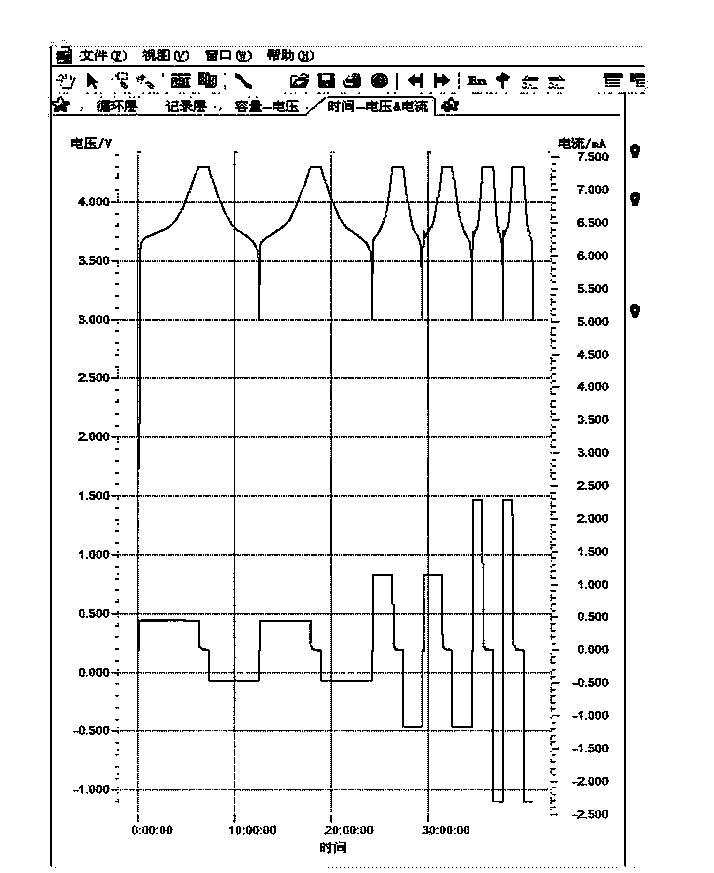

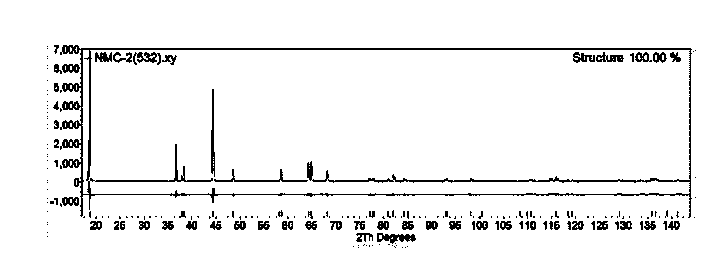

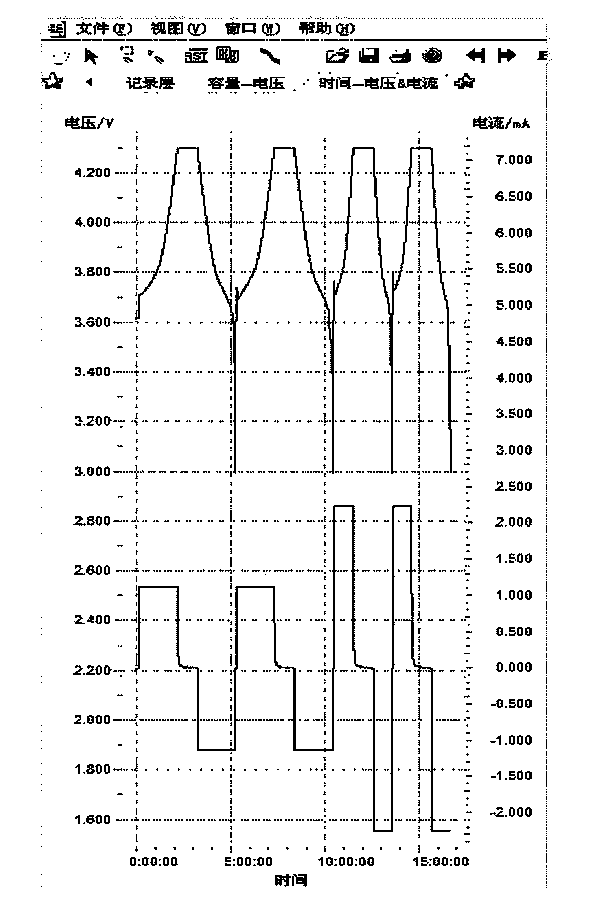

Method for producing high-capacity 523-type ternary positive material

ActiveCN103794773AFlat surfaceImprove electrochemical performanceCell electrodesTunnel kilnManganese

The invention discloses a method for producing a high-capacity 523-type ternary positive material. The method comprises process steps of mixing raw materials, sintering for three times and treating after sintering. Based on the performance characteristics of a ternary material, a three-time sintering and synthesizing process comprising primary low-temperature sintering of a tunnel kiln and secondary sintering of a roller kiln in sufficient reaction phases, and a high-temperature keeping treatment phase of the roller kiln is adopted so that a crystal structure of the product is complete and stable; the crystal structure has smooth transition and whole result standardization of nickel, cobalt and manganese is realized; the overall performance is improved. According to the method, the synthesizing process is simple and the process is easy to control; the energy consumption is low, the efficiency is high and the cost is low; the method is suitable for industrialized production; the product is high in technical performances and high in quality; the implementation effect is obvious and the application is wide so that the method has very good popularization and application values.

Owner:HENAN FUSEN NEW ENERGY TECH

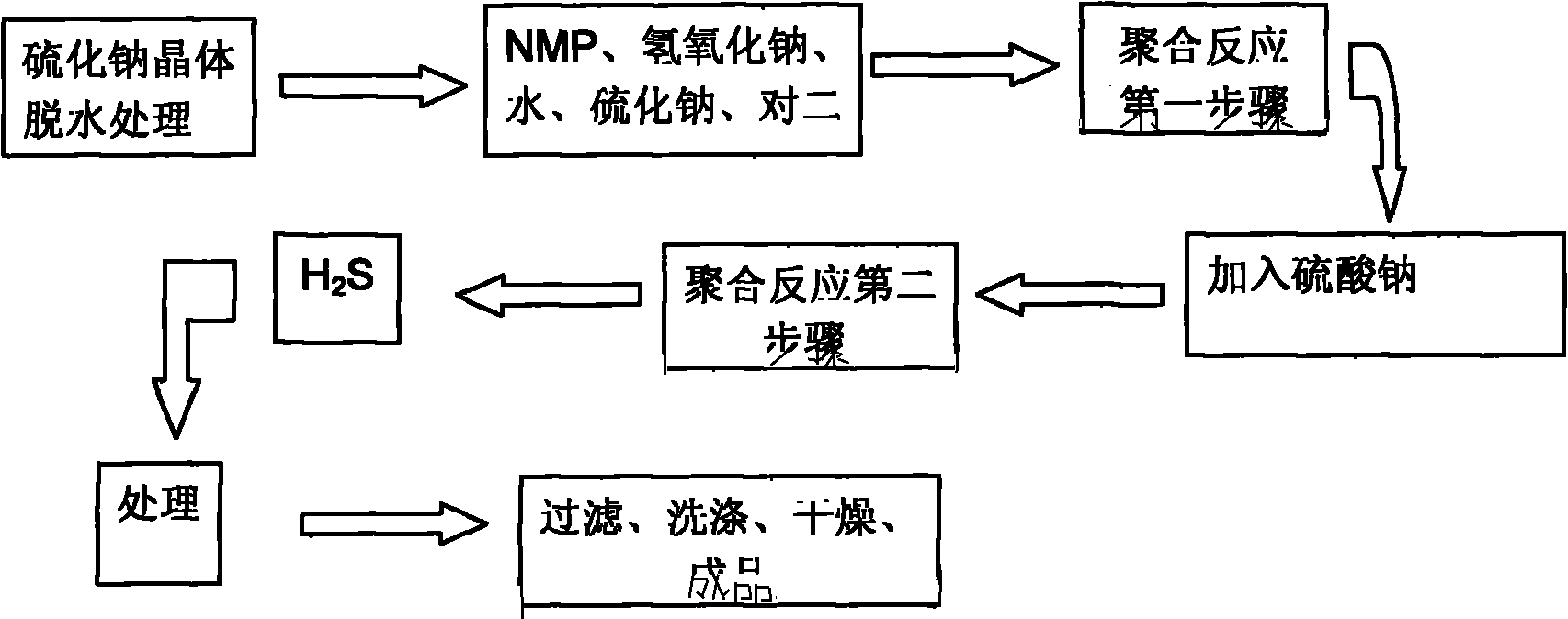

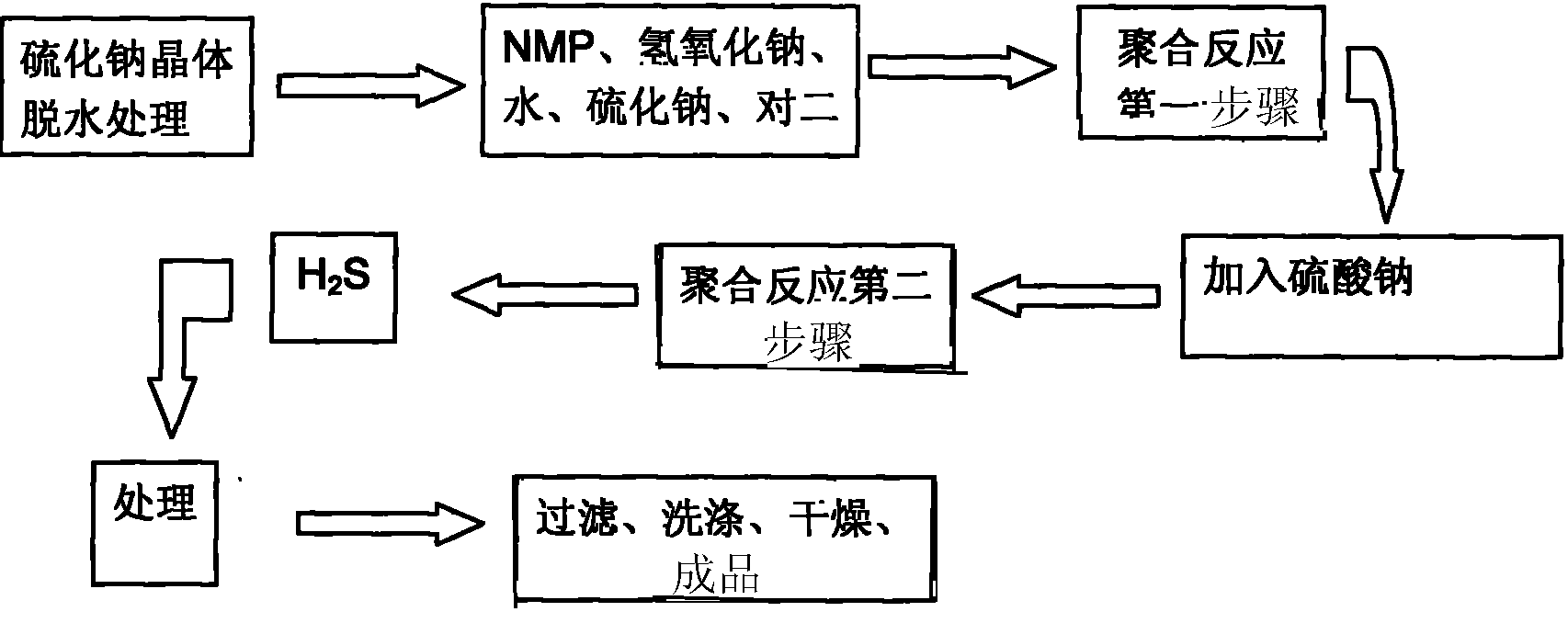

Process for synthesizing low-chlorine polyphenylene sulfide resin

The invention discloses a process for synthesizing low-chlorine polyphenylene sulfide resin. Sodium sulfide and paradichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, and the molar ratio of the sodium sulfide to the paradichlorobenzene is 1:1. The synthesis process mainly comprises the following steps of: in a sodium sulfide dehydration treatment phase, carrying out sodium sulfide solution insulating and water sucking treatment by adopting three layers of 18cm water sucking column containing a 5 angstrom molecular sieve in each layer to form a sodium sulfide solution with the water content of 1.2-1.5mol / molNa2S and adding NaOH with the molar mass of 0.1-0.3mol / molNa2S; and in the polycondensation phase, adding Na2SO4 of 0.1-0.05mol / molNa2S and H2S gas of 0.01mol / molNa2S. The invention has lower halogen total content and polydispersion coefficient in the obtained product, narrow molecular weight distribution, high oxygen index and excellent electrical insulating property and can be used as a packaging material of an electronic device.

Owner:四川得阳特种新材料有限公司

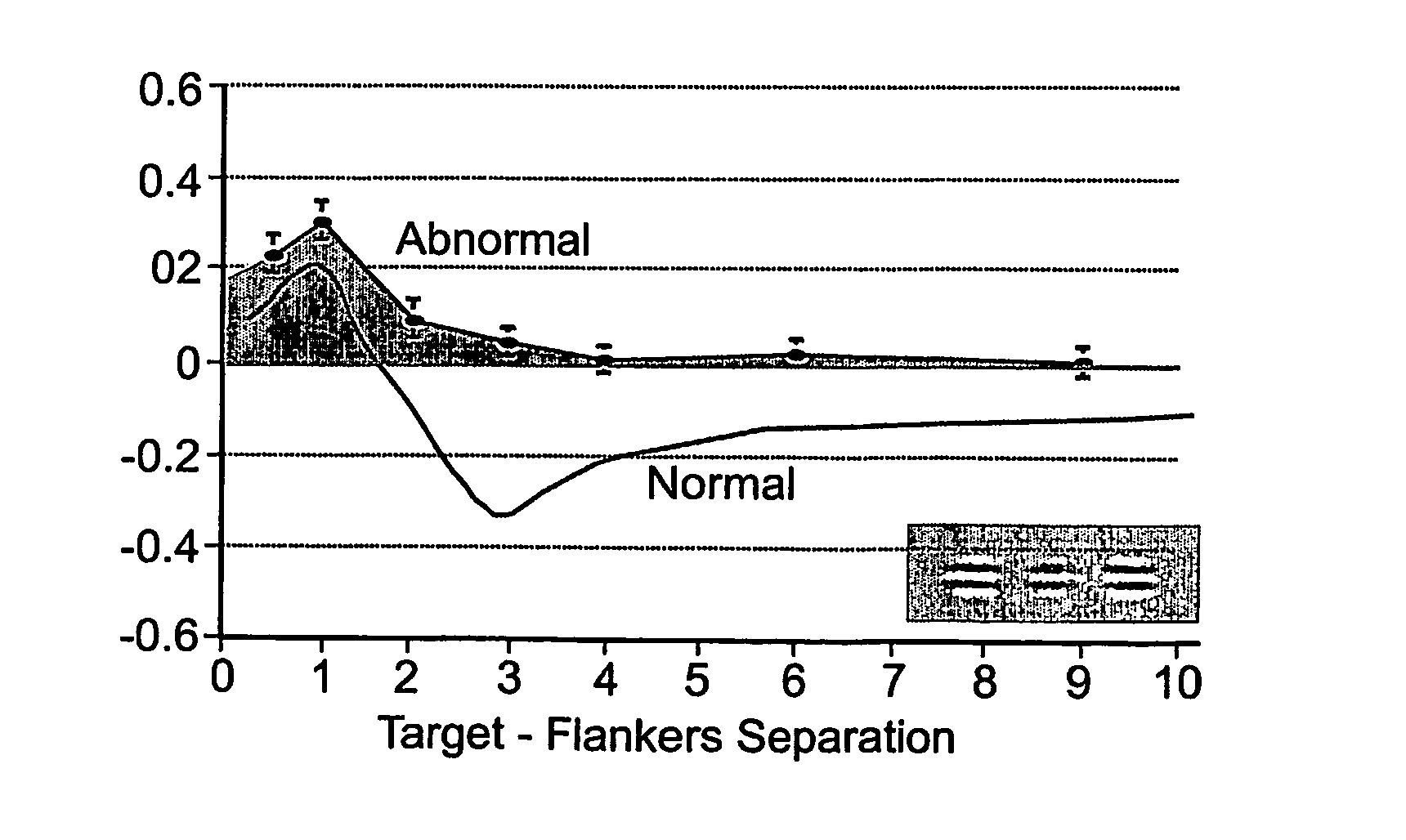

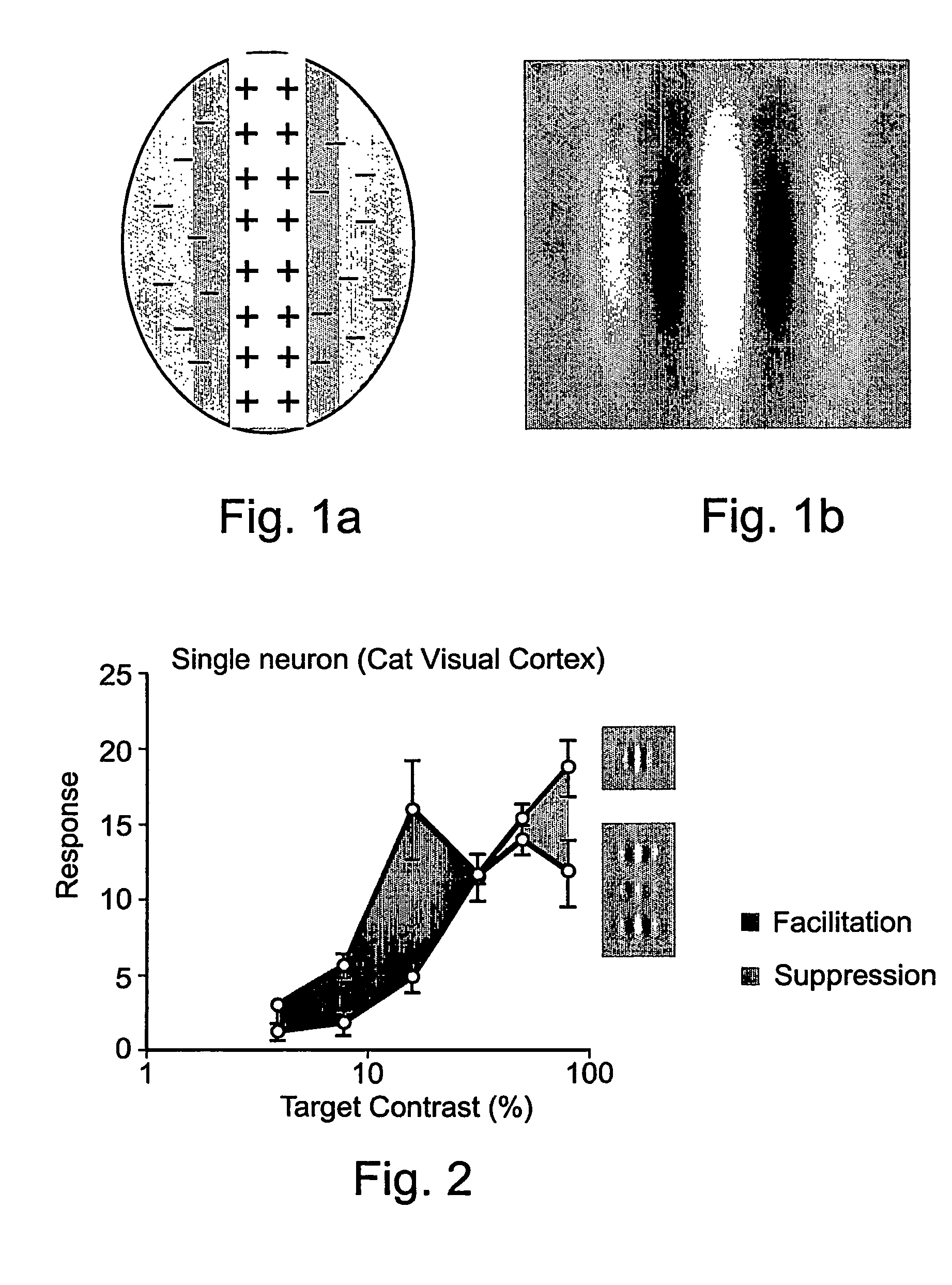

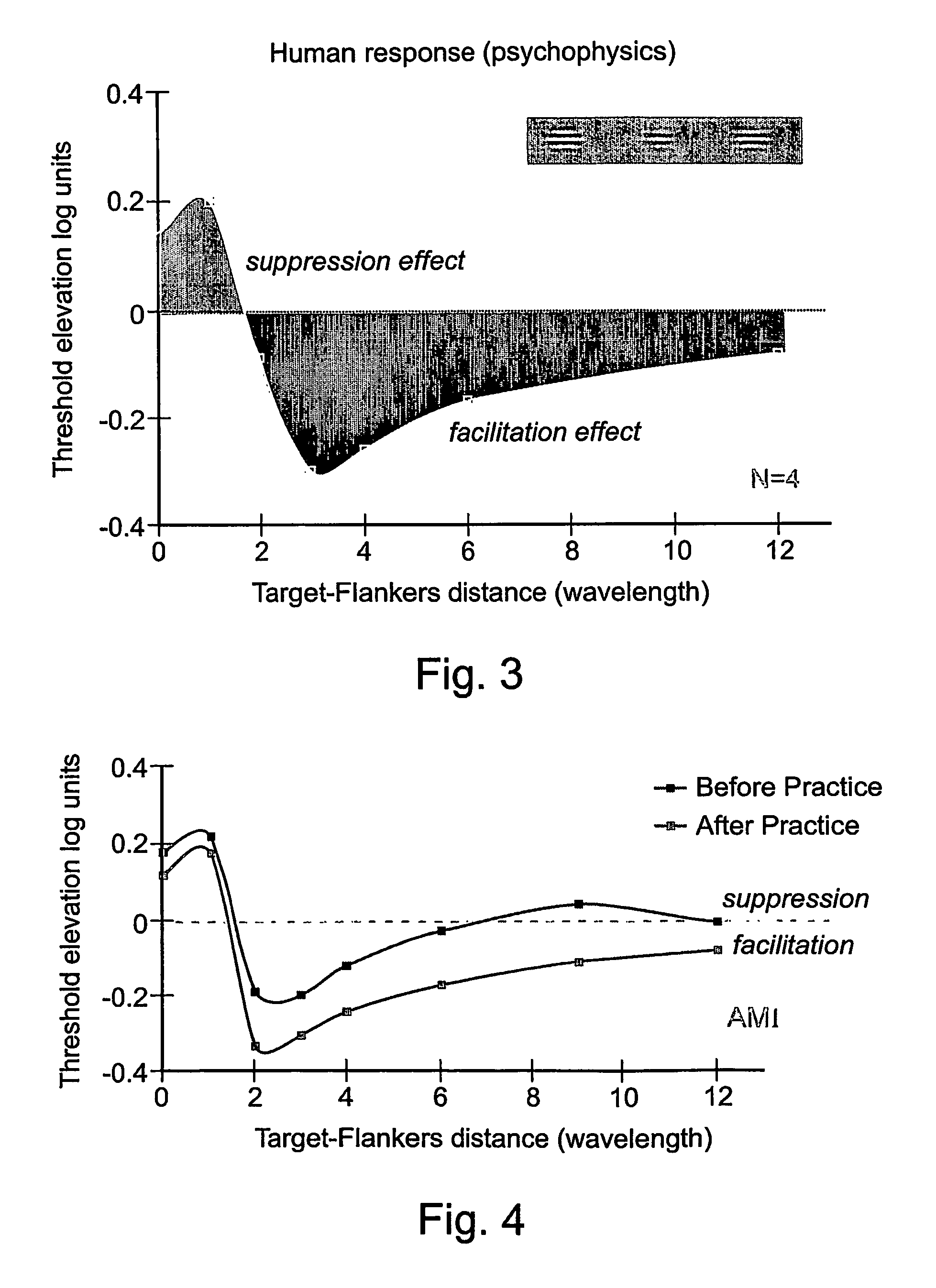

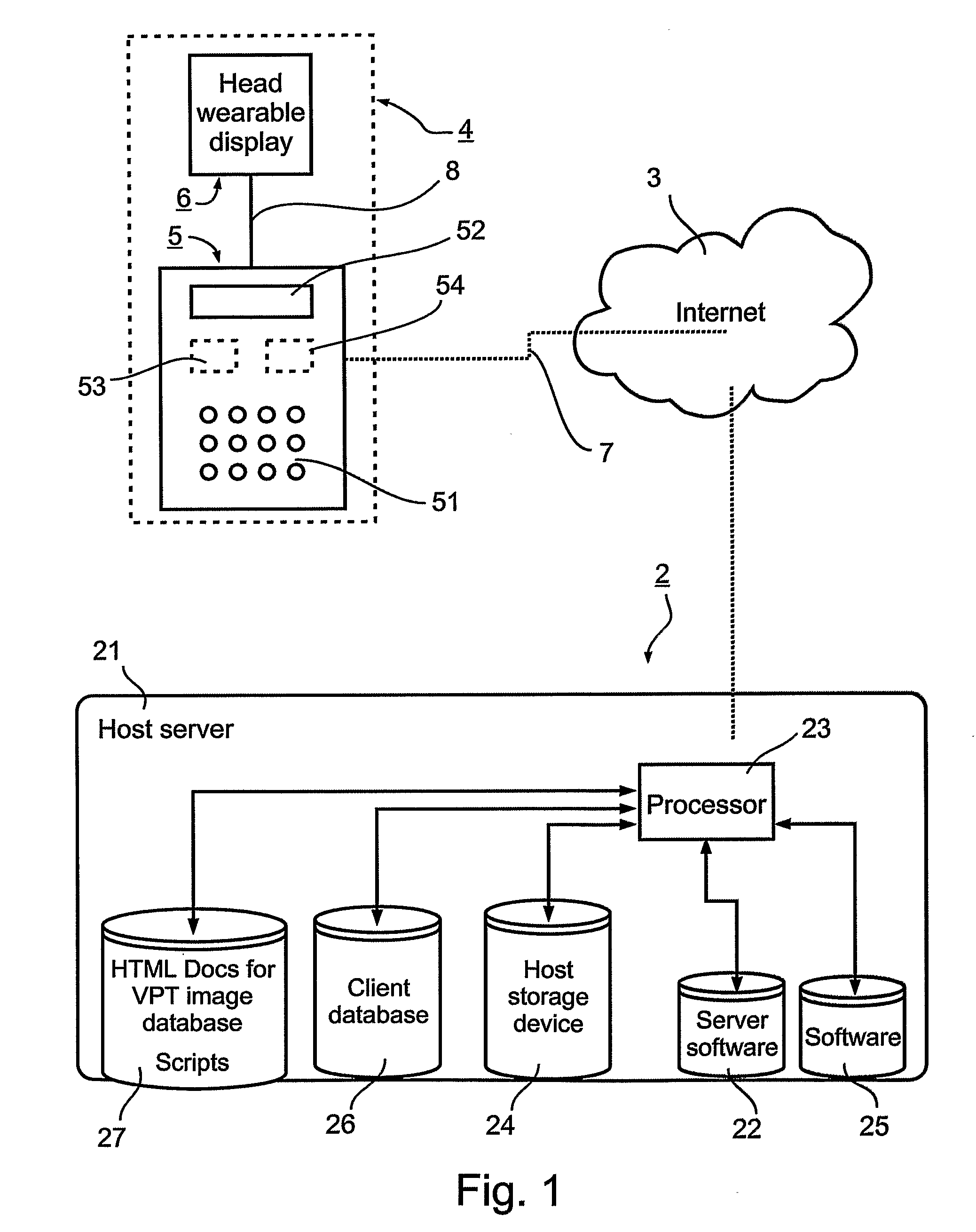

Method for improving visual perception

ActiveUS20070076168A1Improve visual effectsFacilitate cognitionEye exercisersPhoroptersContrast levelEyewear

A method of improving the visual perception ability of a person with respect to a particular eye condition of one or both eyes, by displaying to the person, in at least one evaluation session of an evaluation phase, a plurality of images selected to test the visual perception ability of the person with respect to at least one visual defect, and to elicit responses from the person indicative of the level of the person's visual perception ability with respect to the at least one visual defect; and by utilizing the responses to select another plurality of images designed to treat the person with respect to a detected visual defect and thereby to improve the visual perception ability of the person with respect to the detected visual defect; and, in a treatment phase, applying training glasses with reduced refraction for the respective eye, and displaying to the person the another plurality of images in at least one treatment session until the visual perception ability of the person has been improved with respect to the detected visual defect. The foregoing operations are performed until the desired “contrast funnel” is achieved, i.e., the desired range of contrast levels expected to be achieved in order to gain optimal visual improvement.

Owner:TALSHIR GUY MEDICAL TECH LTD

Oral appliance

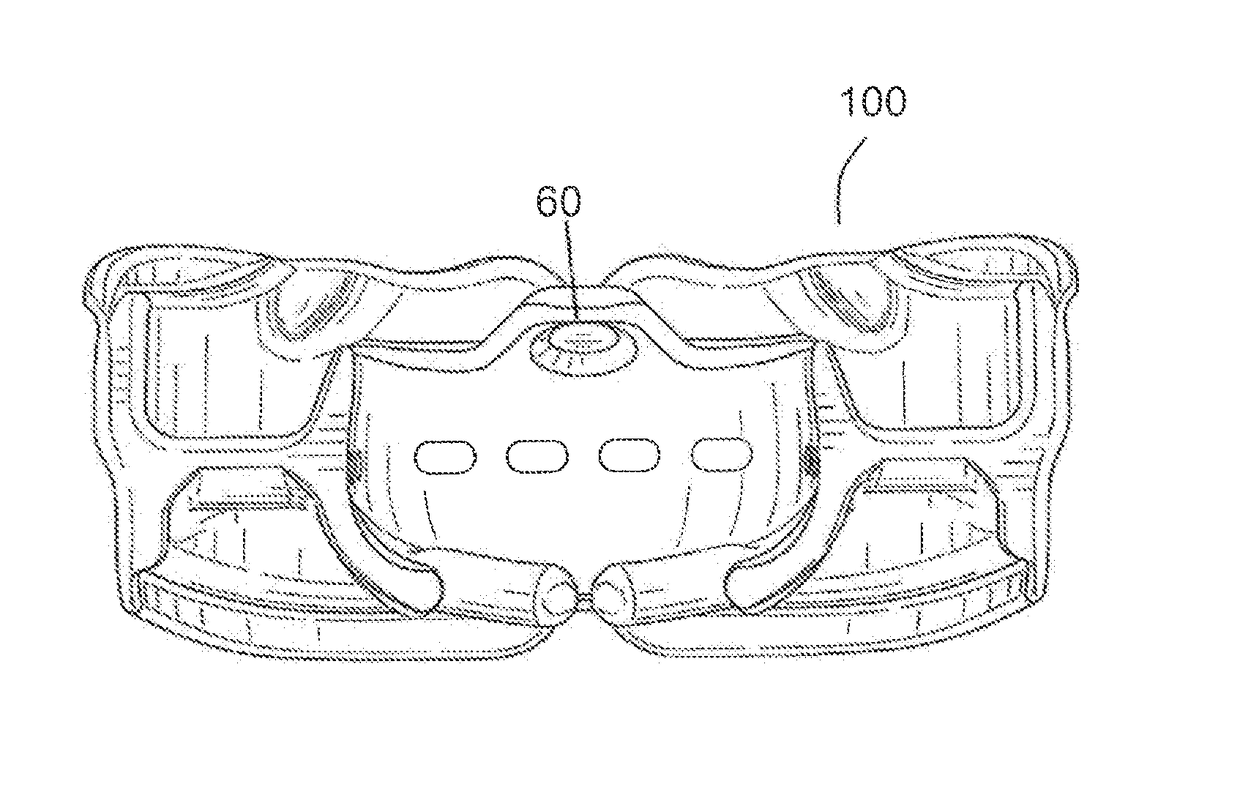

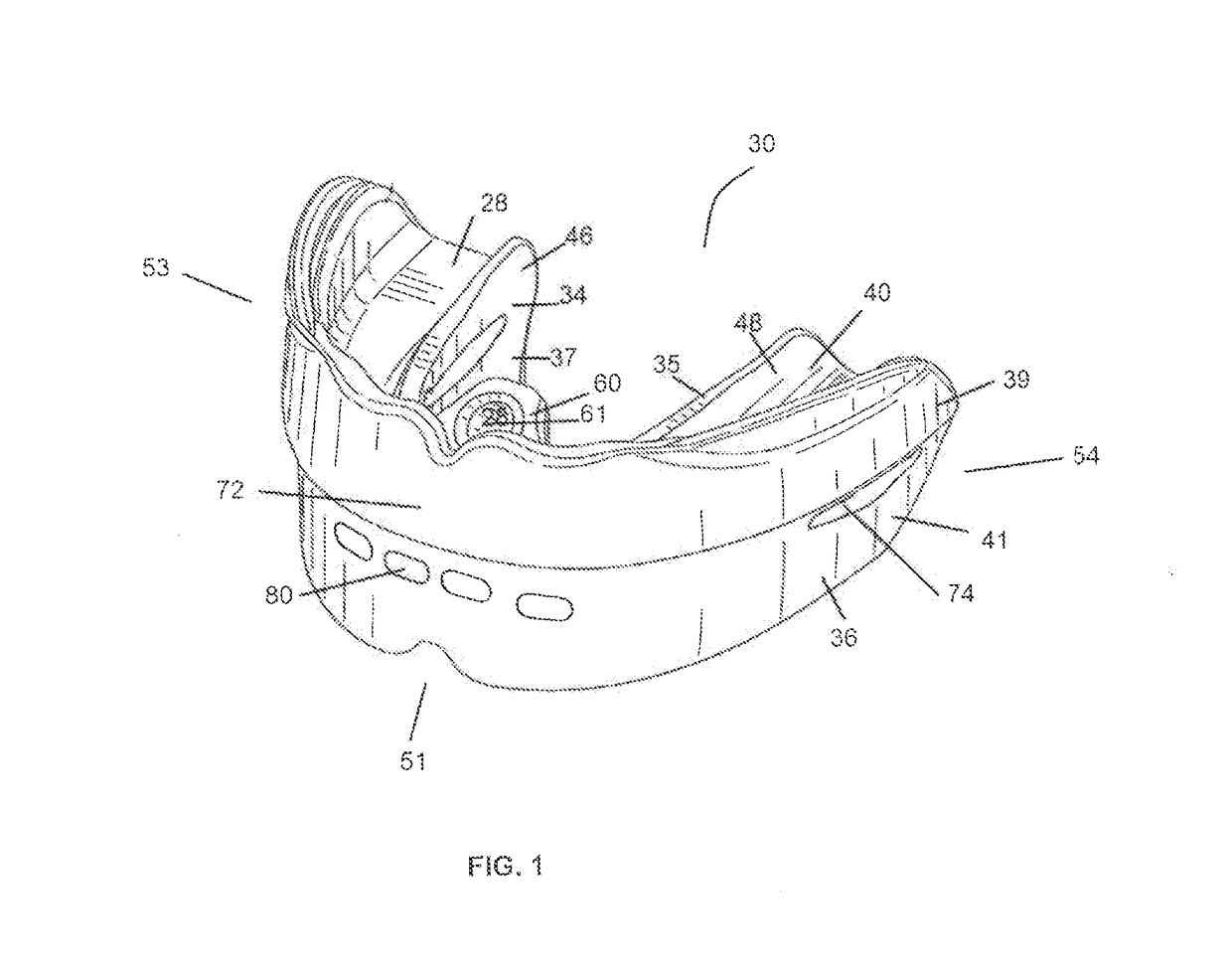

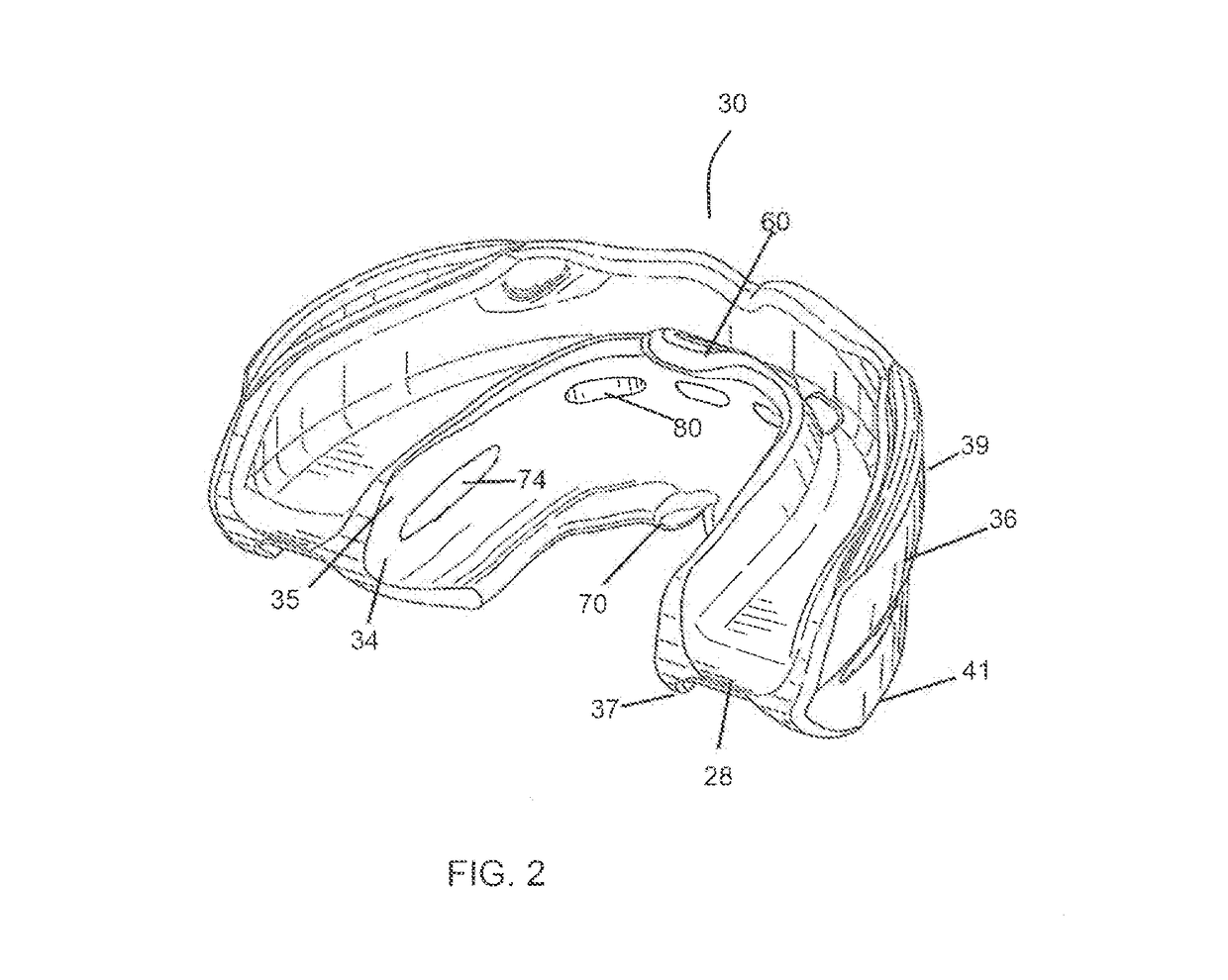

ActiveUS20180078405A1Great suctionEfficient mouth sealSnoring preventionOral applianceSleep disordered breathing

A method of treating sleep disorder breathing in a patient, the method comprising in a first step providing a set of oral appliances comprising a first and at least a second oral appliance (30). Each of the first and at least second oral appliances comprises a generally U shaped appliance body including an inner wall (34), an outer wall (36), and a web (38) interconnecting the inner wall and the outer wall. The web has a front section and two arms with trailing ends. The web comprises at least one breathing hole (80) so as to define a total cross sectional area for breathing and the total cross sectional area for breathing of the first oral appliance is larger than the total cross sectional area for breathing of the second oral appliance. In a second step, a patient wears the first oral appliance in a first treatment stage whilst sleeping for a first period of time and in a third step the patient wears the second oral appliance in a second treatment stage whilst sleeping for a second period of time.

Owner:MYOSA PTY LTD

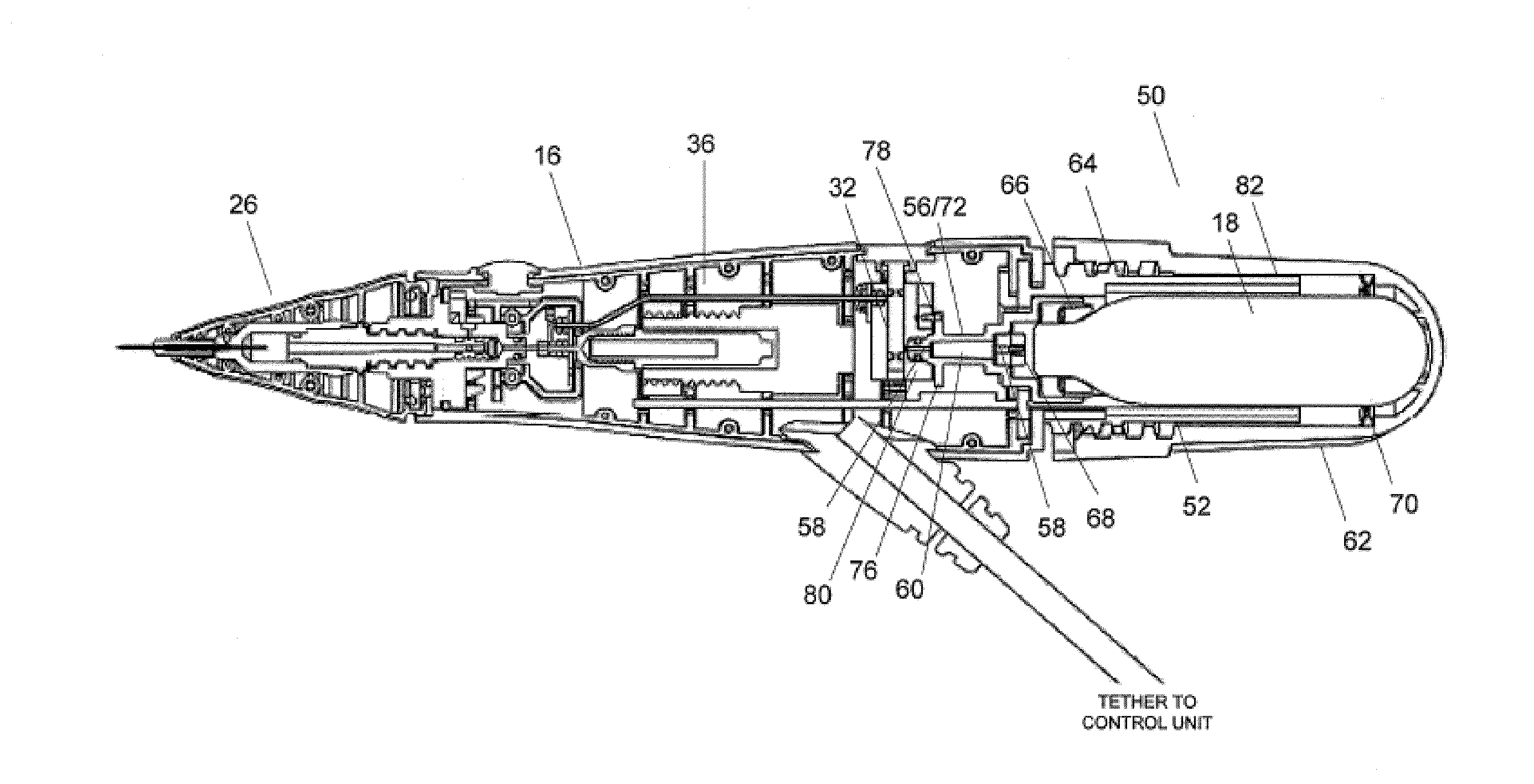

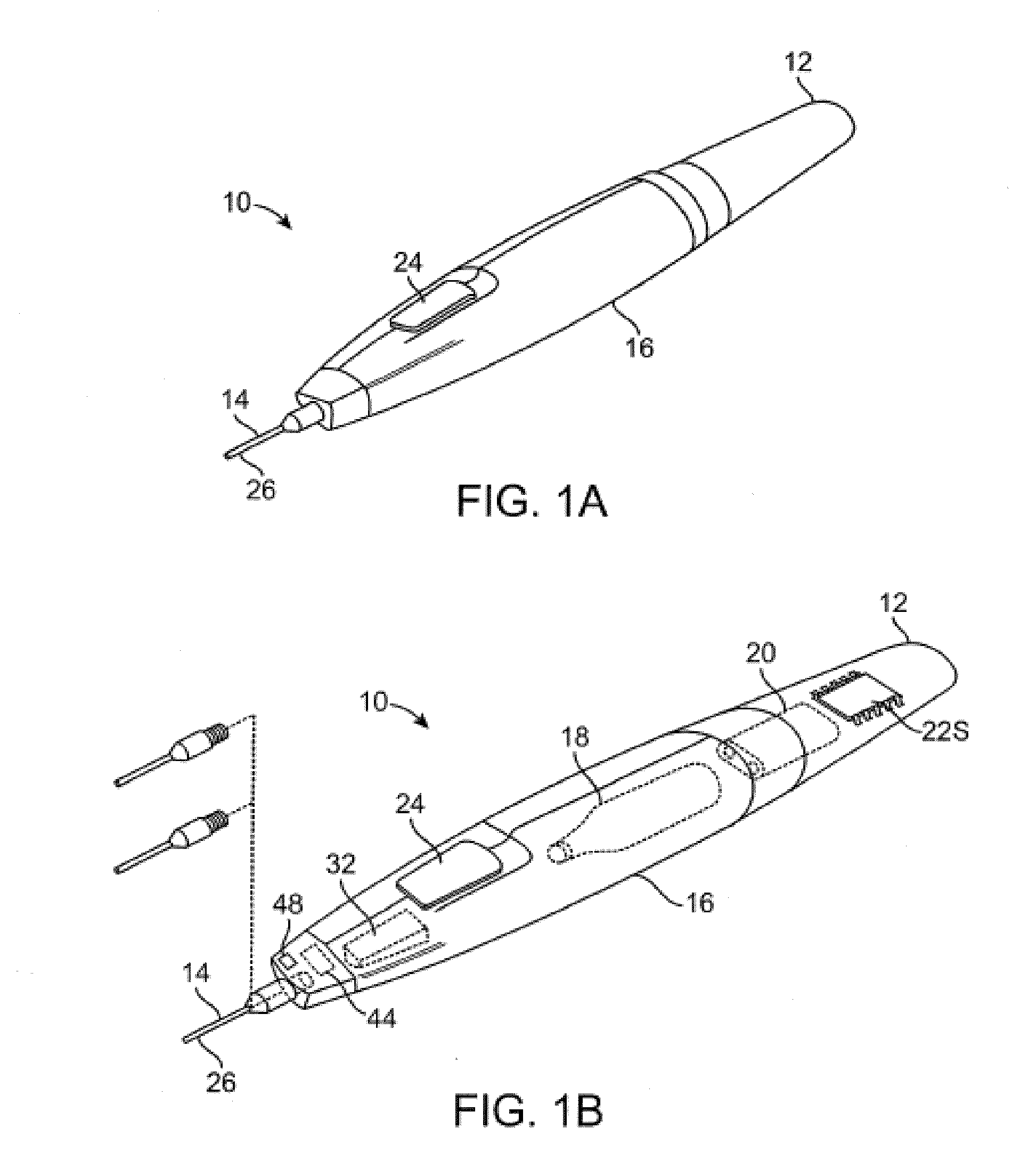

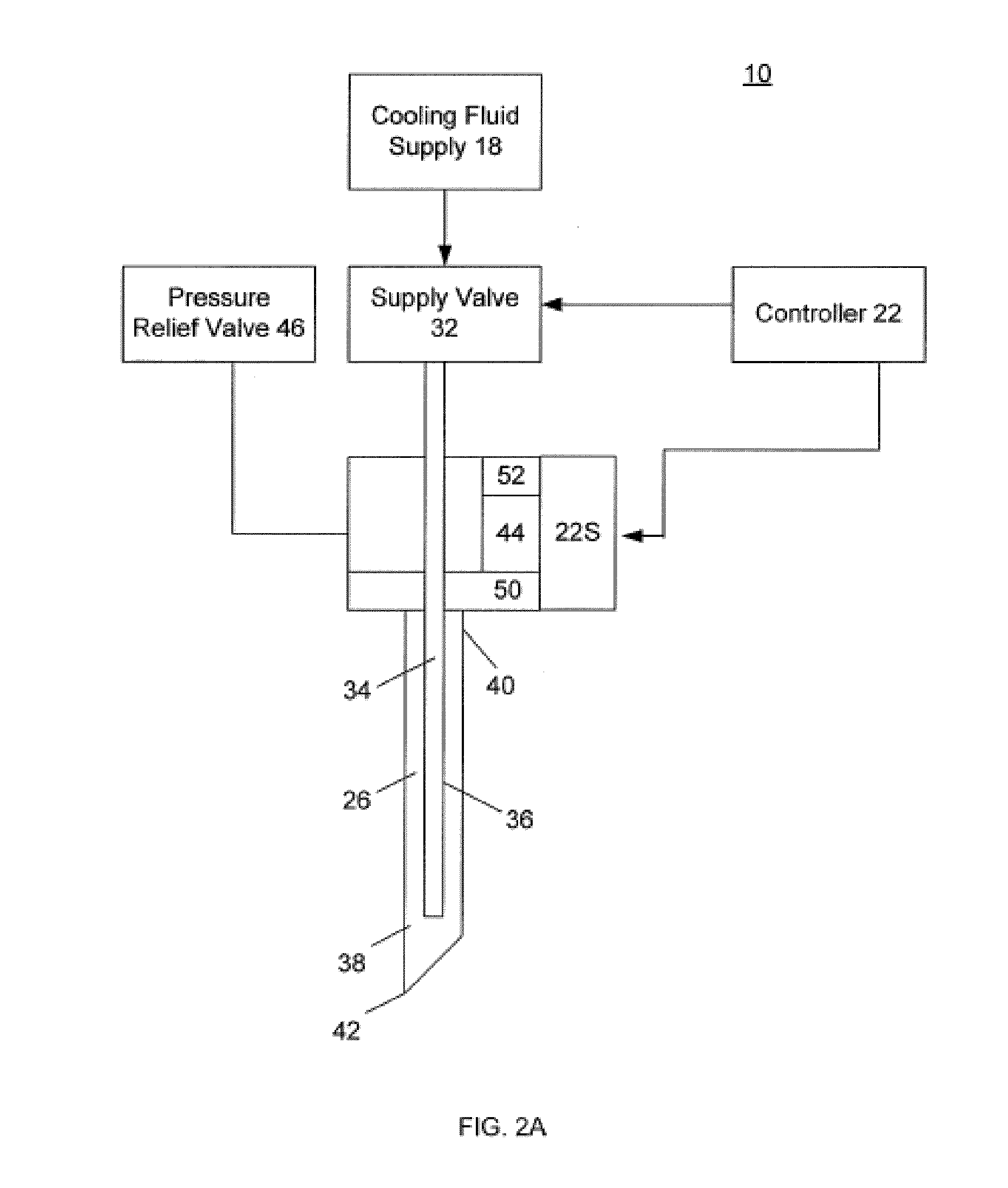

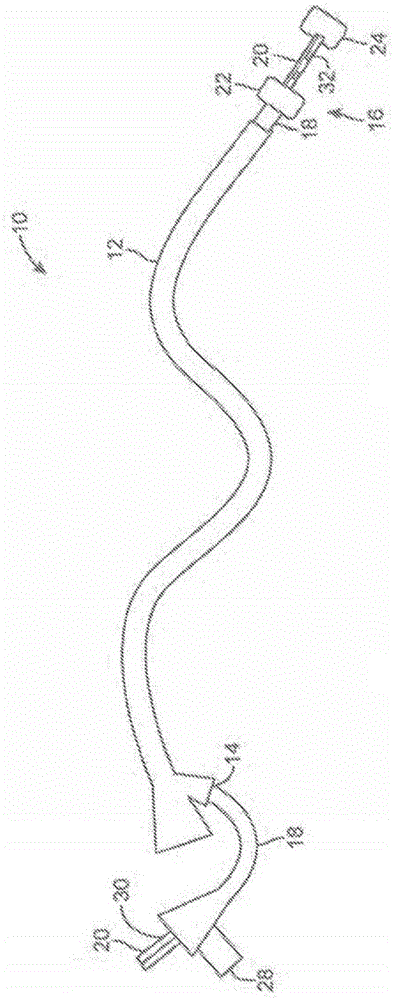

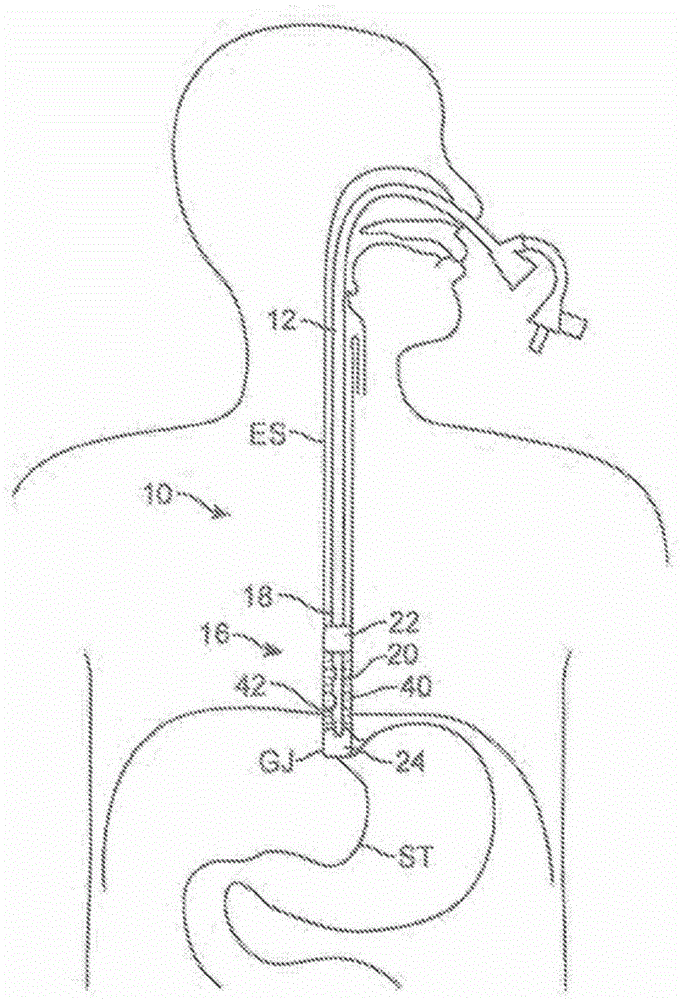

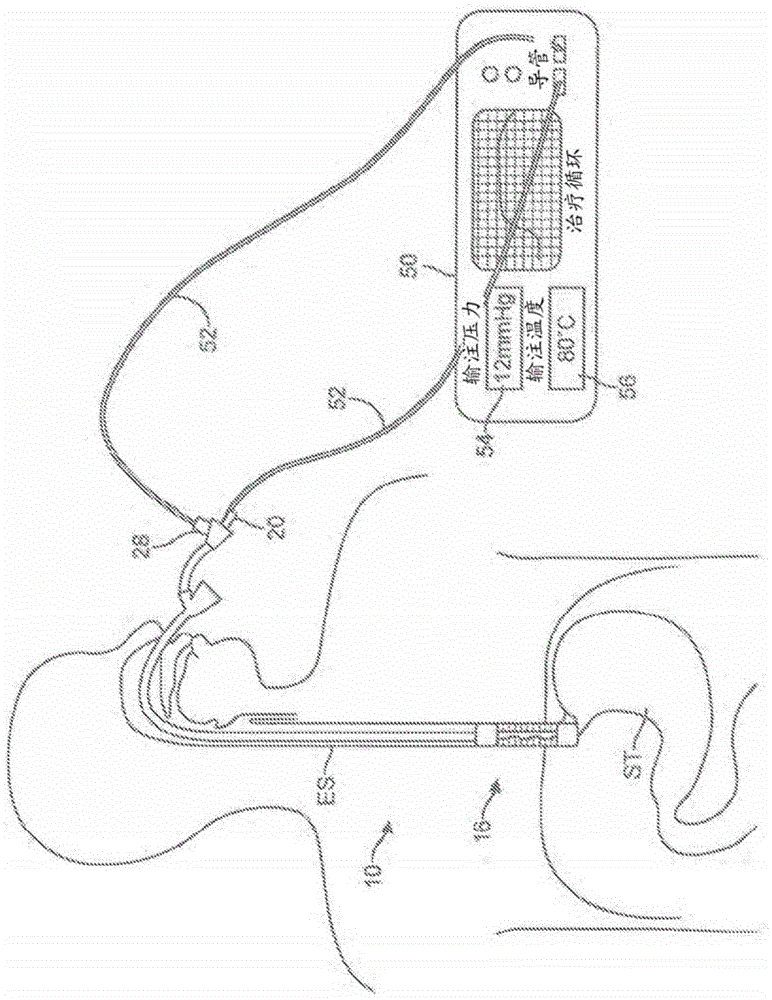

Methods and Systems for Treatment of Occipital Neuralgia

ActiveUS20140343544A1Alleviating occipital neuralgiaSurgical instruments for coolingProximateDistal portion

A system for alleviating occipital neuralgia. The system has a needle probe having at least one needle. The at least one needle has a proximal end, a distal end, and a needle lumen therebetween, the needle configured for insertion proximate to a location of the occipital nerve. A cooling fluid supply lumen extends distally within the needle lumen to a distal portion of the needle lumen. A cooling fluid source is coupled to the cooling fluid supply lumen to direct cooling fluid flow into the needle lumen. A controller that has at least one processor configured implements an occipital neuralgia treatment algorithm for controlling the cooling fluid source so that liquid from the cooling flow vaporizes within the needle lumen to provide a treatment phase to location of the occipital nerve such that the occipital neuralgia is mitigated.

Owner:PACIRA CRYOTECH INC

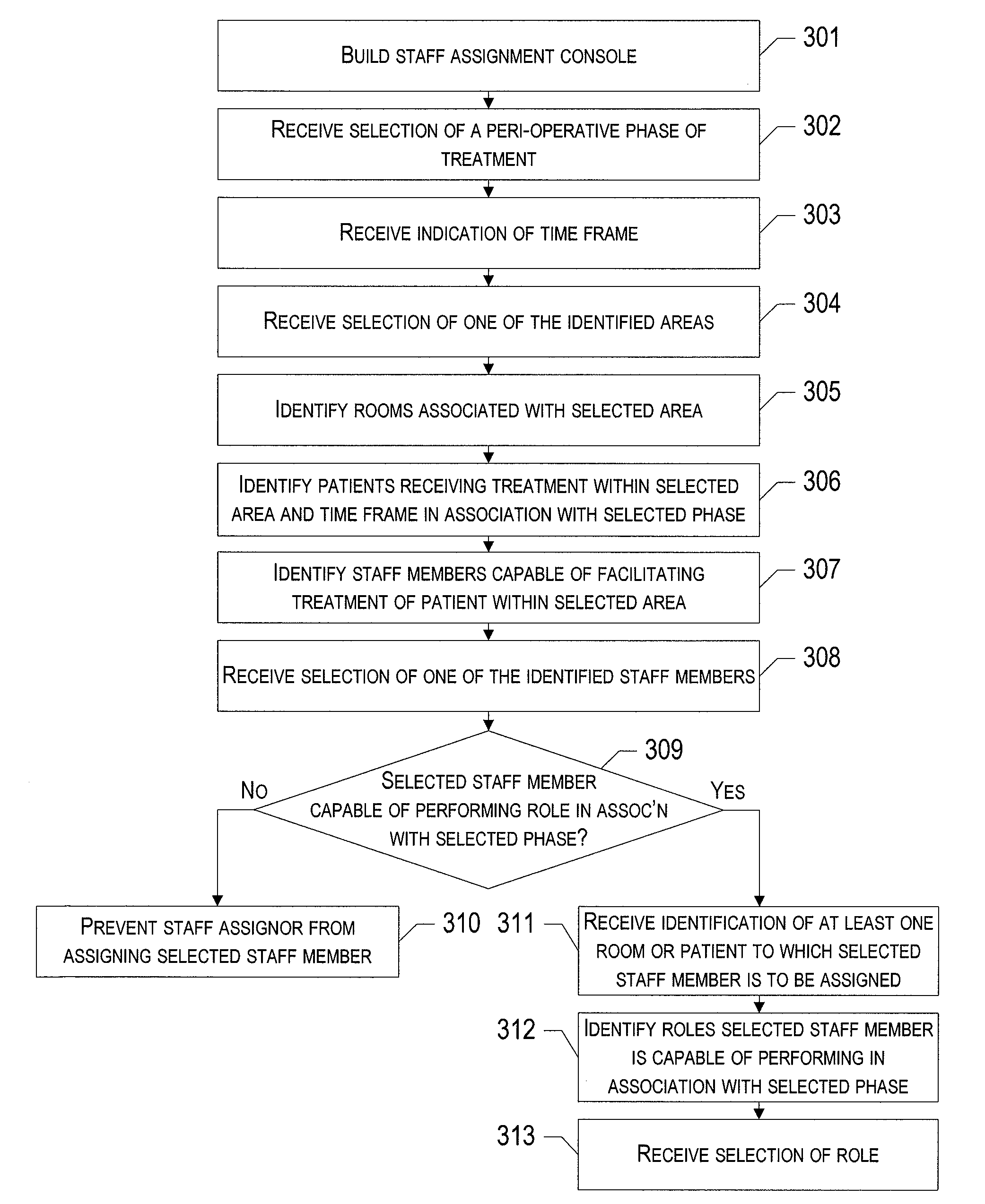

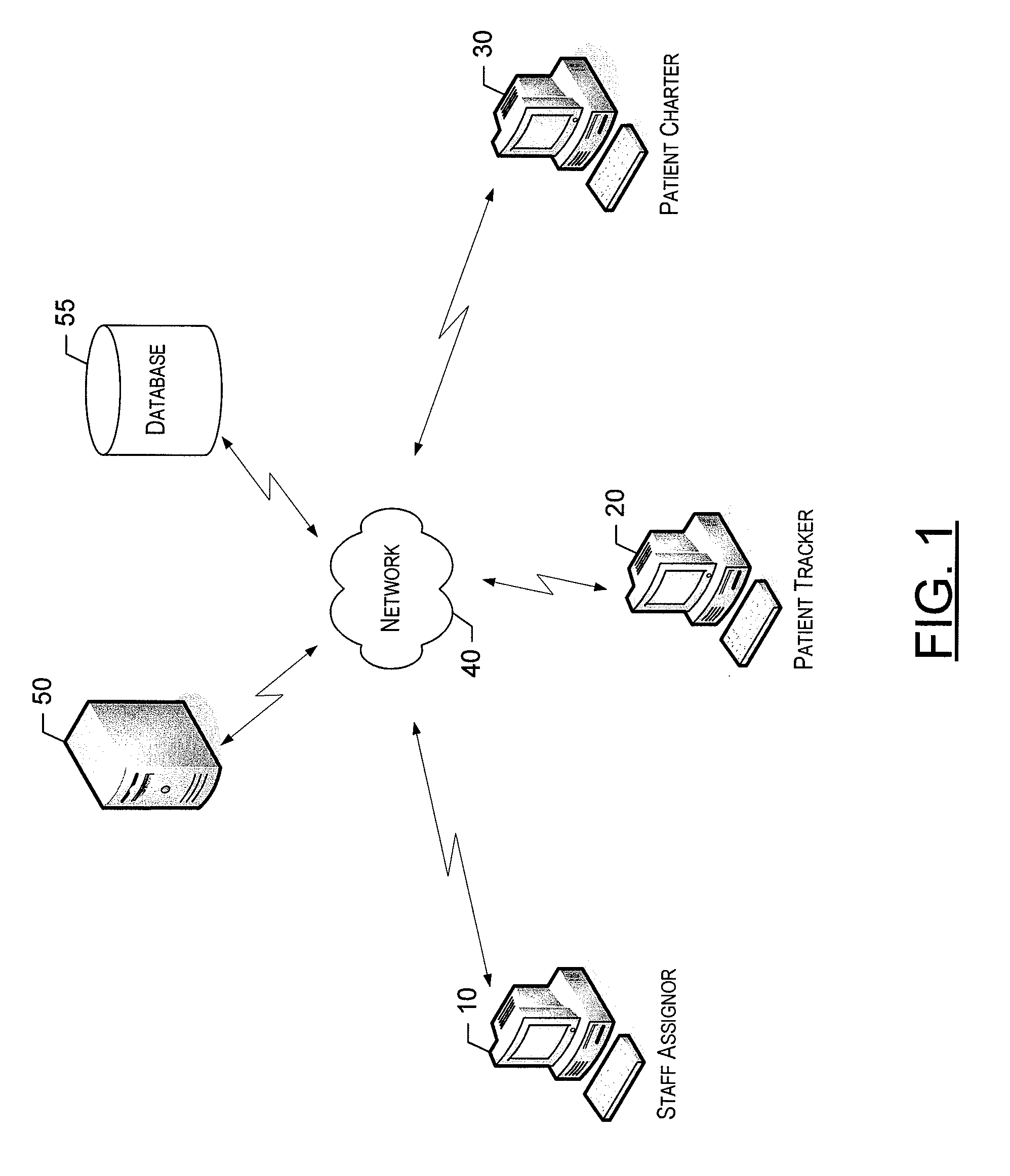

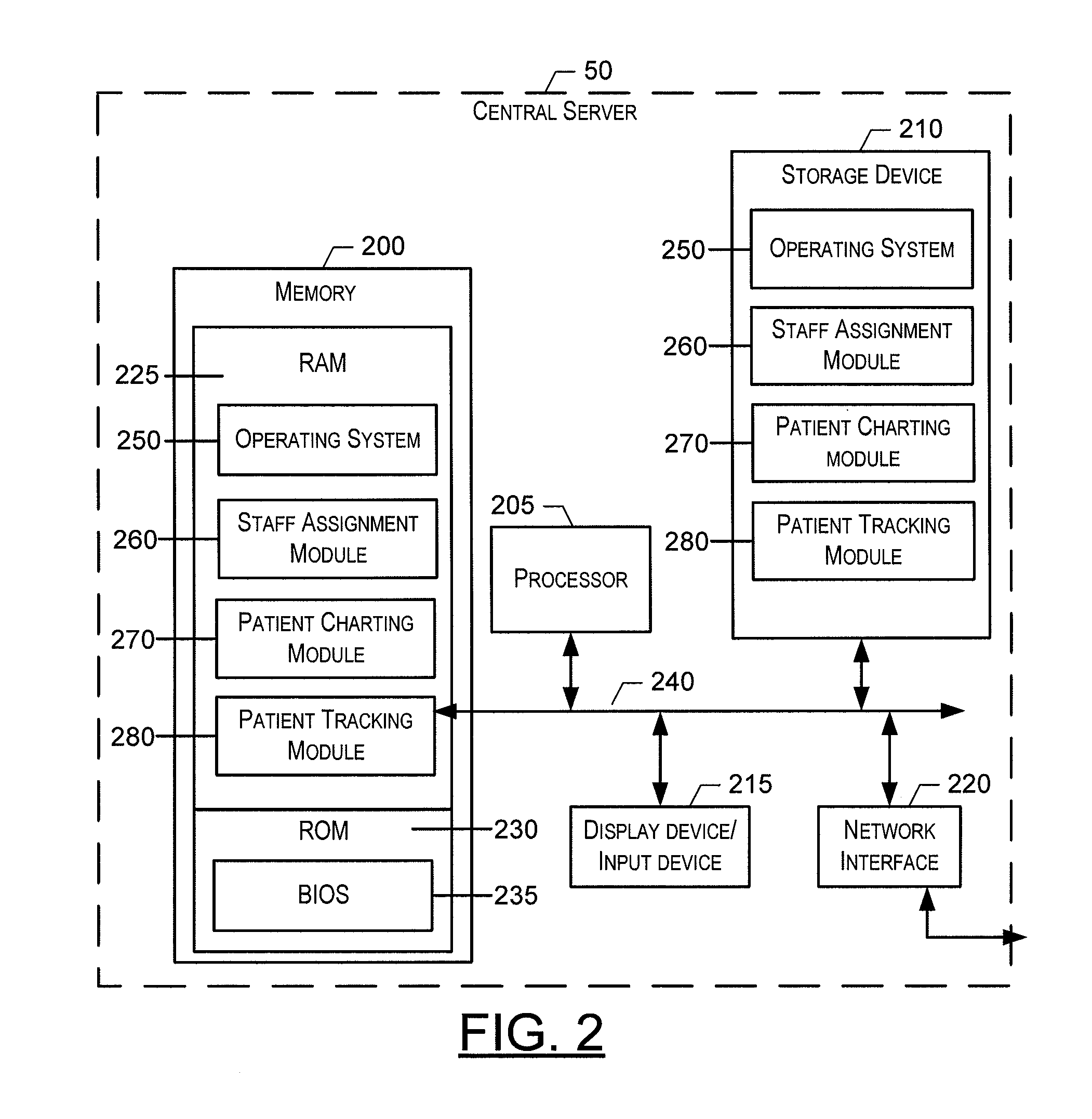

Creating and communicating staffing assignments

InactiveUS20100070294A1Reduce the burden onConvenient treatmentResourcesHealthcare resources and facilitiesPhases of clinical researchStaffing

An automated apparatus, method and system are provided for creating and communicating staffing assignments associated with a plurality of patients receiving treatment in multiple different areas within a healthcare facility and in association with multiple different phases of treatment. In particular, a centralized staff assignment application or module is provided, wherein a staff assignor may access the staff assignment application in order to identify, among other things: (1) staff members capable of facilitating treatment to patients within each area of the healthcare facility; (2) the roles each of those staff members is capable of performing; (3) the peri-operative phase associated with each phase; and (4) the patients scheduled to receive treatment in each of the areas in association with each of the phases. This information may thereafter be used to make staffing assignments, which may be communicated to individuals and applications throughout the healthcare facility.

Owner:MCKESSON FINANCIAL HLDG

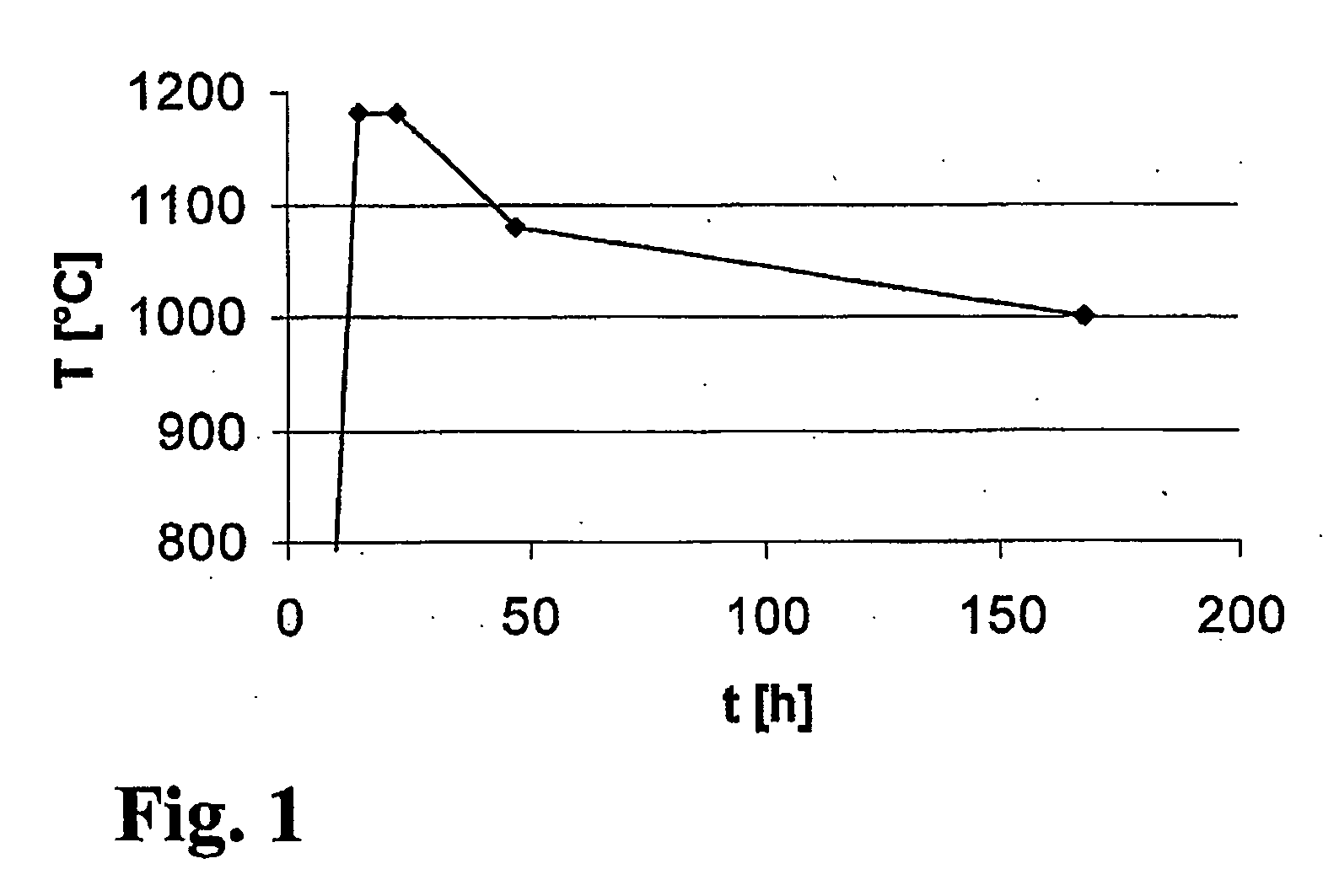

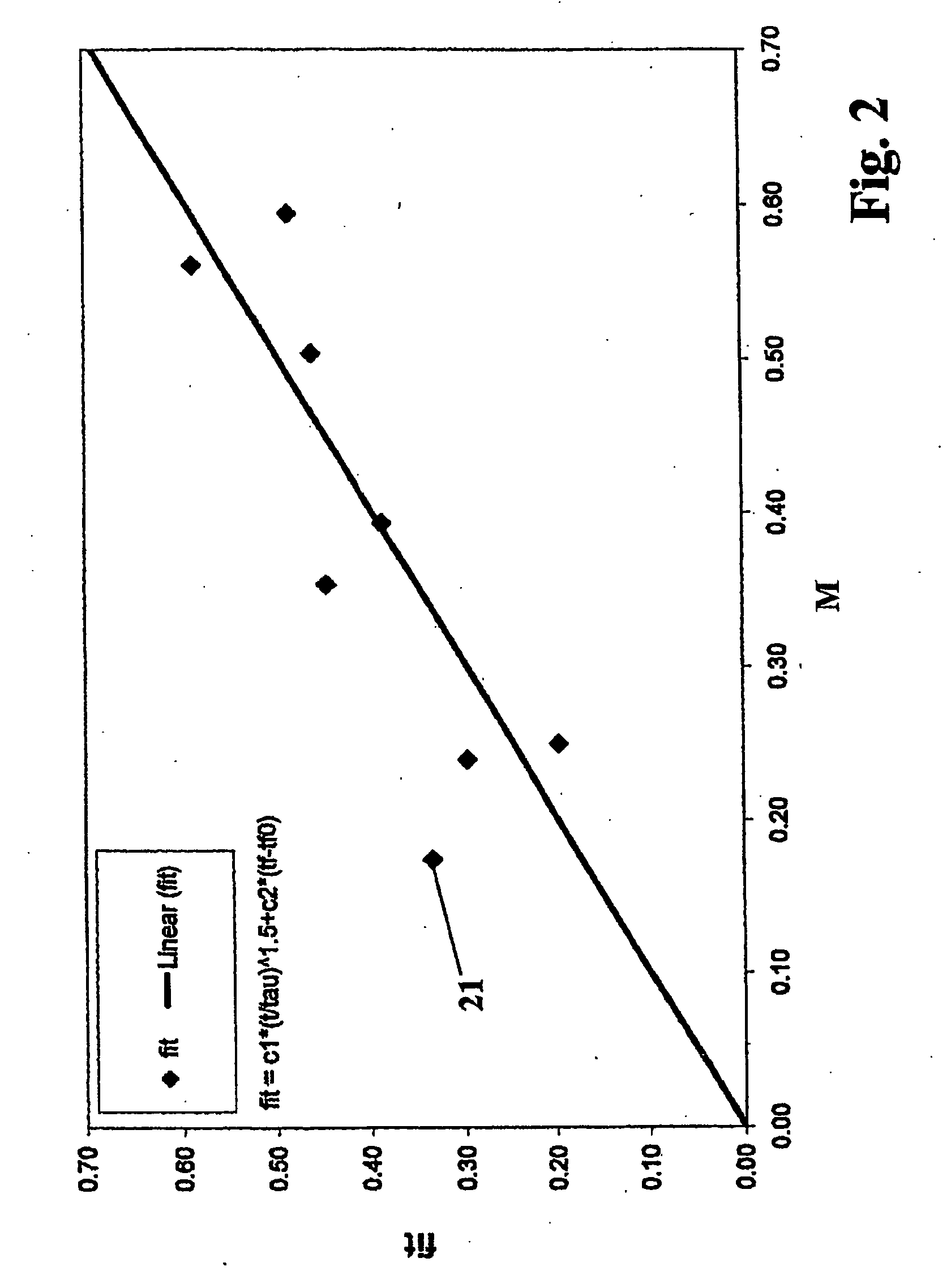

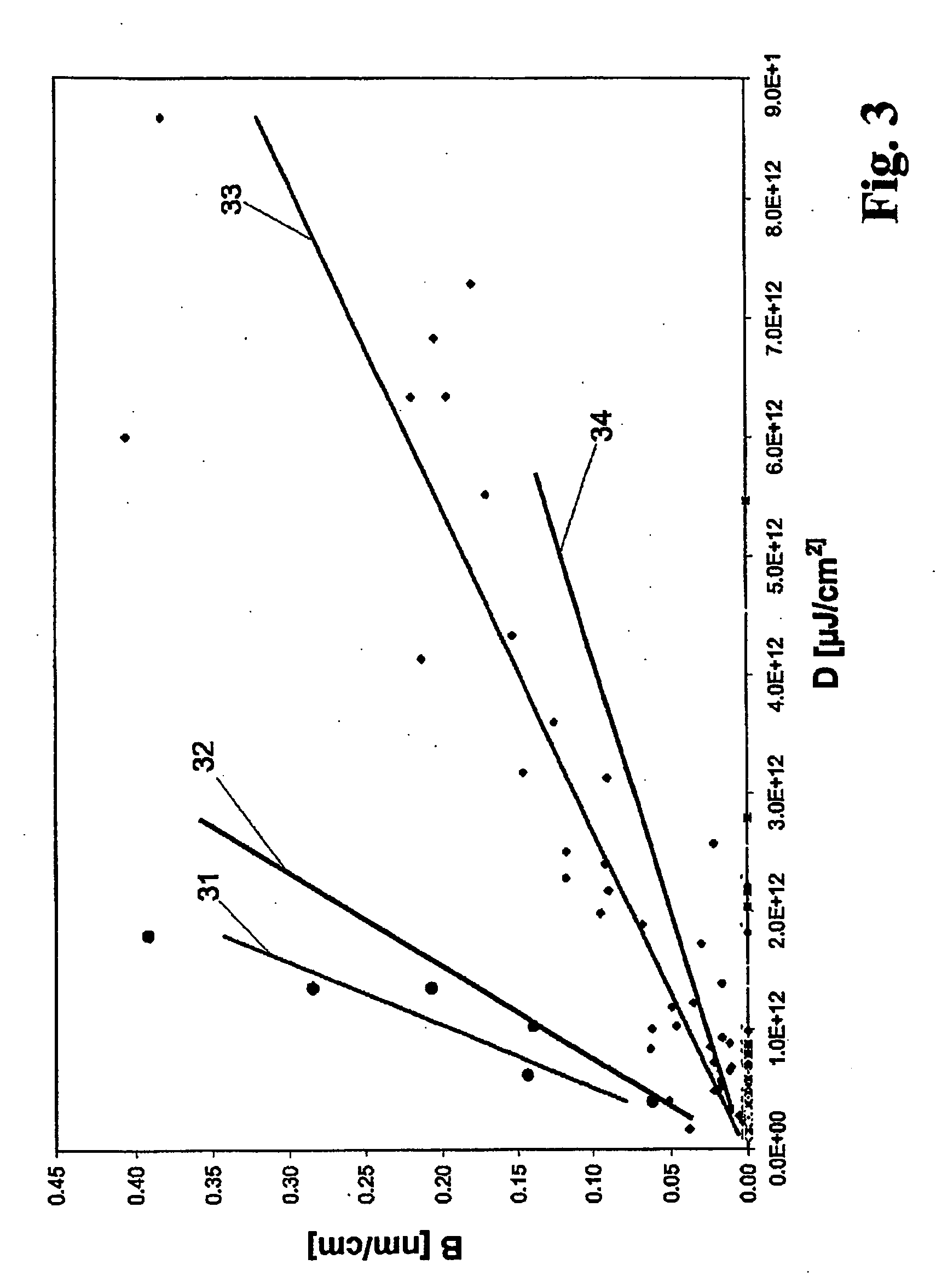

Method for producing an optical component of synthetic quartz glass with enhanced radiation resistance, and blank for producing the component

To optimize an optical component of synthetic quartz glass, in the case of which a quartz glass blank is subjected to a multistage annealing treatment, with respect to compaction and central birefringence, the present invention suggests a method comprising the following steps:(a) a first treatment phase during which the quartz glass blank is treated in an upper temperature range between 1130° C. and 1240° C.,(b) cooling the quartz glass blank at a first-higher-mean cooling rate to a quenching temperature below 1100° C., a fictive temperature with a high mean value of 1100° C. or more being reached in the quartz glass,(c) a second treatment phase which comprises cooling of the quartz glass blank at a second-lower-mean cooling rate, and in which the quartz glass blank is treated in a lower temperature range between 950° C. and 1100° C. such that a fictive temperature is reached in the quartz glass with a low mean value which is at least 50° C. lower than the high mean value of the fictive temperature according to method step (b).

Owner:HERAEUS QUARZGLAS

Technique and device for treating sewage to reclaimed water

InactiveCN101215052AGuaranteed uptimeLow costGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisFiberFlocculation

The invention discloses a technique for treating sewage water to reclaimed water and the device thereof, the technique of which includes the following phases: flocculation and dosing phase, fiber filter phase, water distribution phase, integrated module system treatment phase and wine blending phase. The device includes a pipe-line mixer with sequential connection in series, micro eddy flocculation reacting clarification tank, a high effective fabric filter tank, a middle water tank, the integrated module system and a clean water tank. The invention has the advantages that the desalinization of the reverse osmosis device is taken as center, sequentially takes micro eddy flocculation, high effective fabric filtration and ultrafiltration as pretreatment and arranges an original water adjusting tank on the end to secure the stable operation of the reverse osmosis device. Employing mixed water scheme to effectively reduce the manufacturing price and operation cost. The technique provides the technique and the device of the recycling of recirculated cooling sewage water of power plant, the outlet water is taken as the replenishing water of recirculated cooling system of the power plant. The process has the advantages of reasonable design, simple operation and stable work, all the indexes of the outlet water can satisfy the recycling need which has a guiding and referencing meaning for reclaimed water recycling system.

Owner:张大群

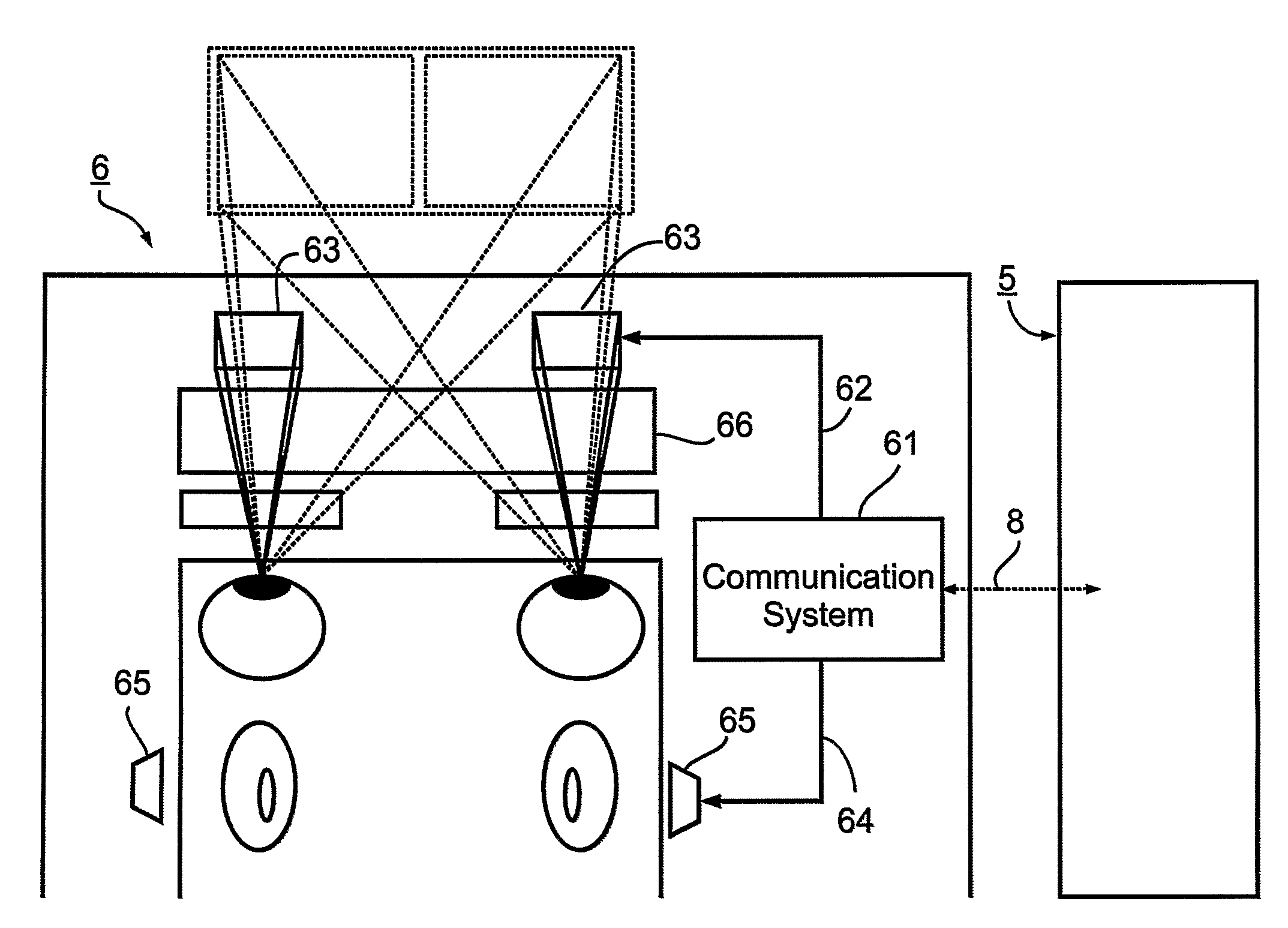

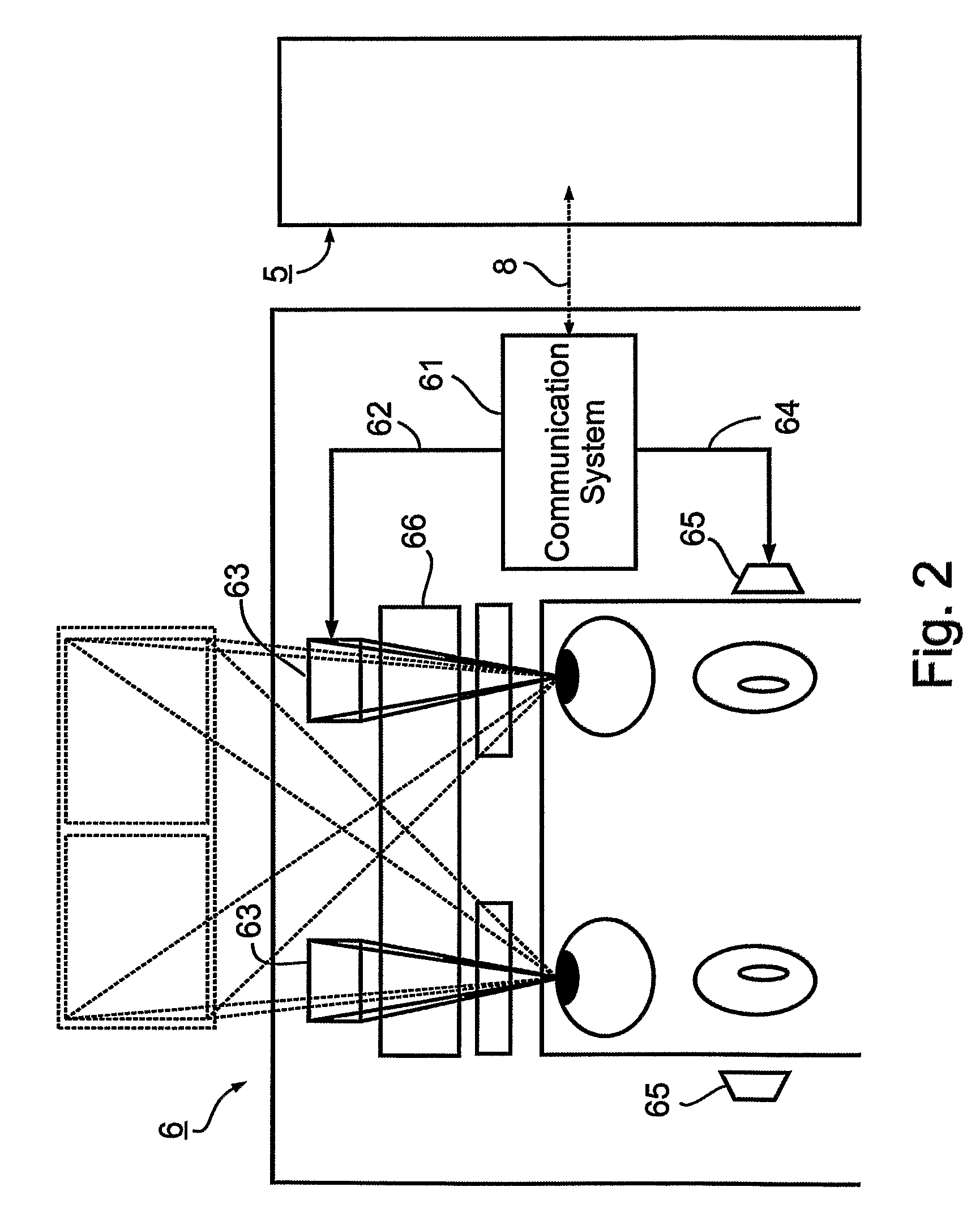

Apparatus for Improving Visual Perception

InactiveUS20090109398A1Improve visual effectsFacilitate cognitionEye exercisersPhoroptersDisplay deviceComputer science

Apparatus for improving the visual perception ability of a person with respect to a particular eye condition of at least one eye, includes a client terminal including display device for displaying images to the person, and an input device for inputting responses by the person to images displayed in said display device; and a processor system programmed such that in an evaluation phase, the processor controls said display device to display to the person a plurality of images selected to test the visual perception ability of the person with respect to at least one visual defect, and utilizes responses inputted by the person via said input device to select another plurality of images designed to improve the visual perception ability of the person with respect to a detected visual defect; and in a treatment phase, the processor controls said display device to display to the person said another plurality of images to thereby improve the visual perception ability of the person with respect to said detected visual defect. The display device is a head-wearable display wearable over the eyes of said person and controlled by said processor system to display said plurality of images during both said evaluation phase and said treatment phase.

Owner:TALSHIR GUY MEDICAL TECH LTD

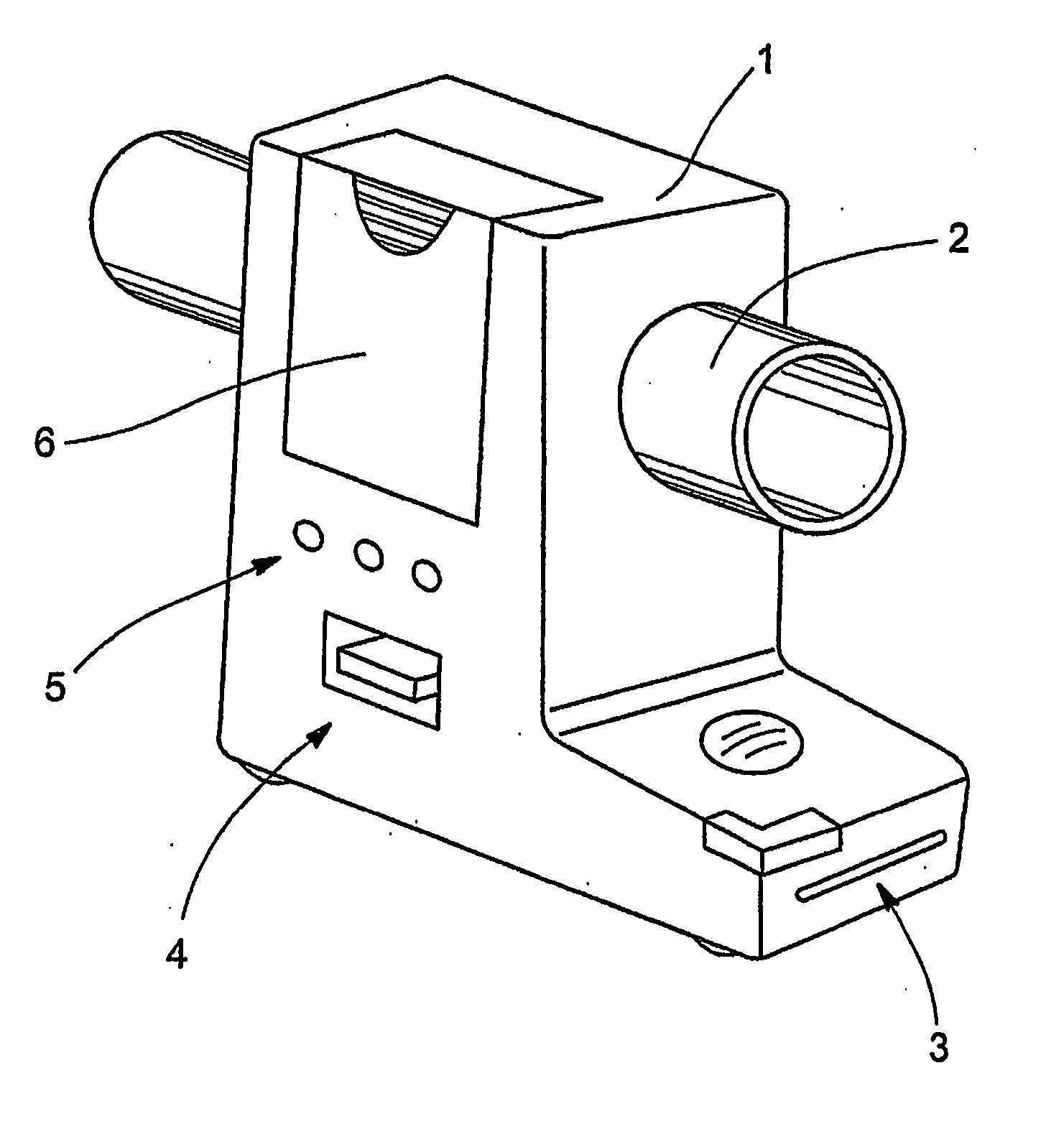

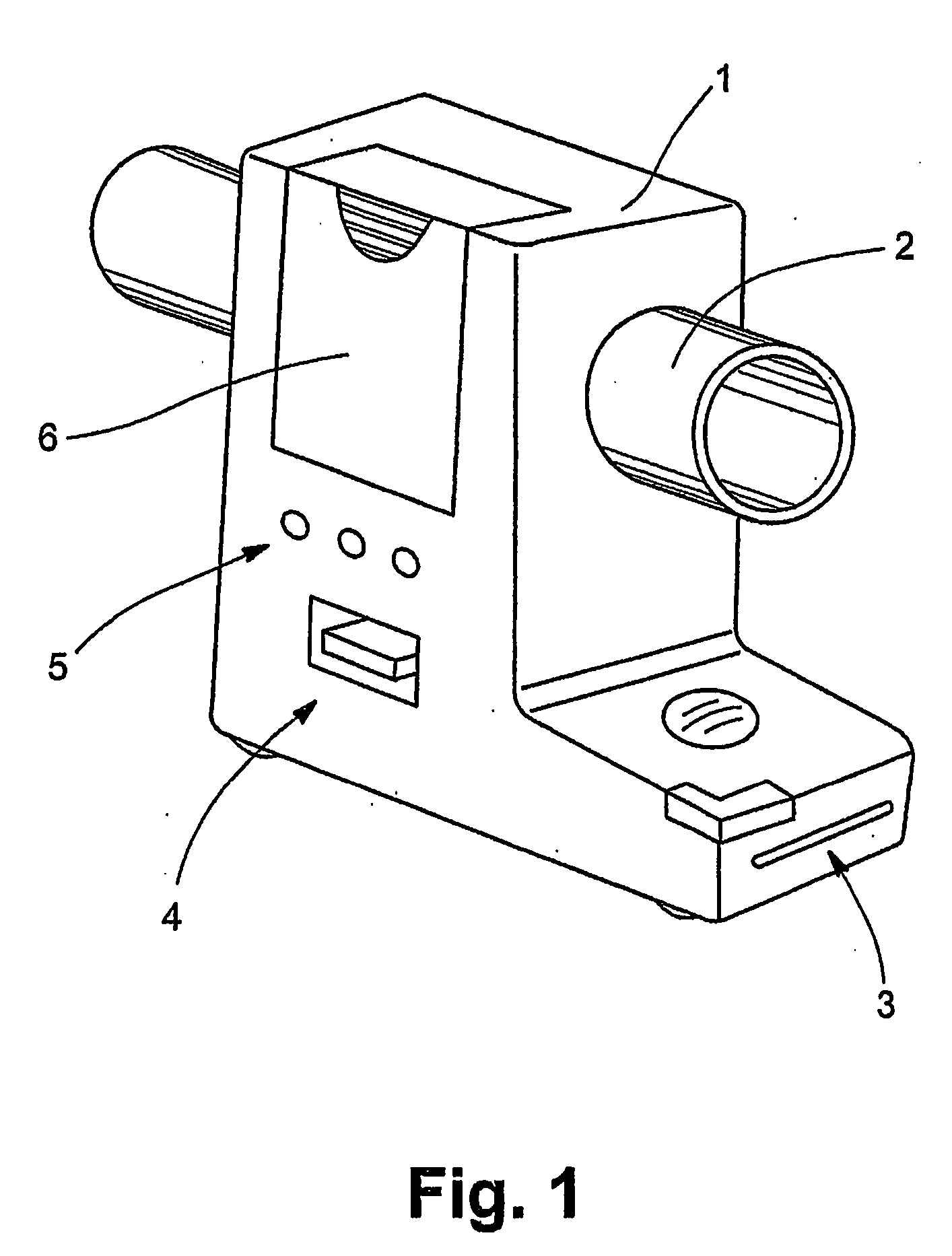

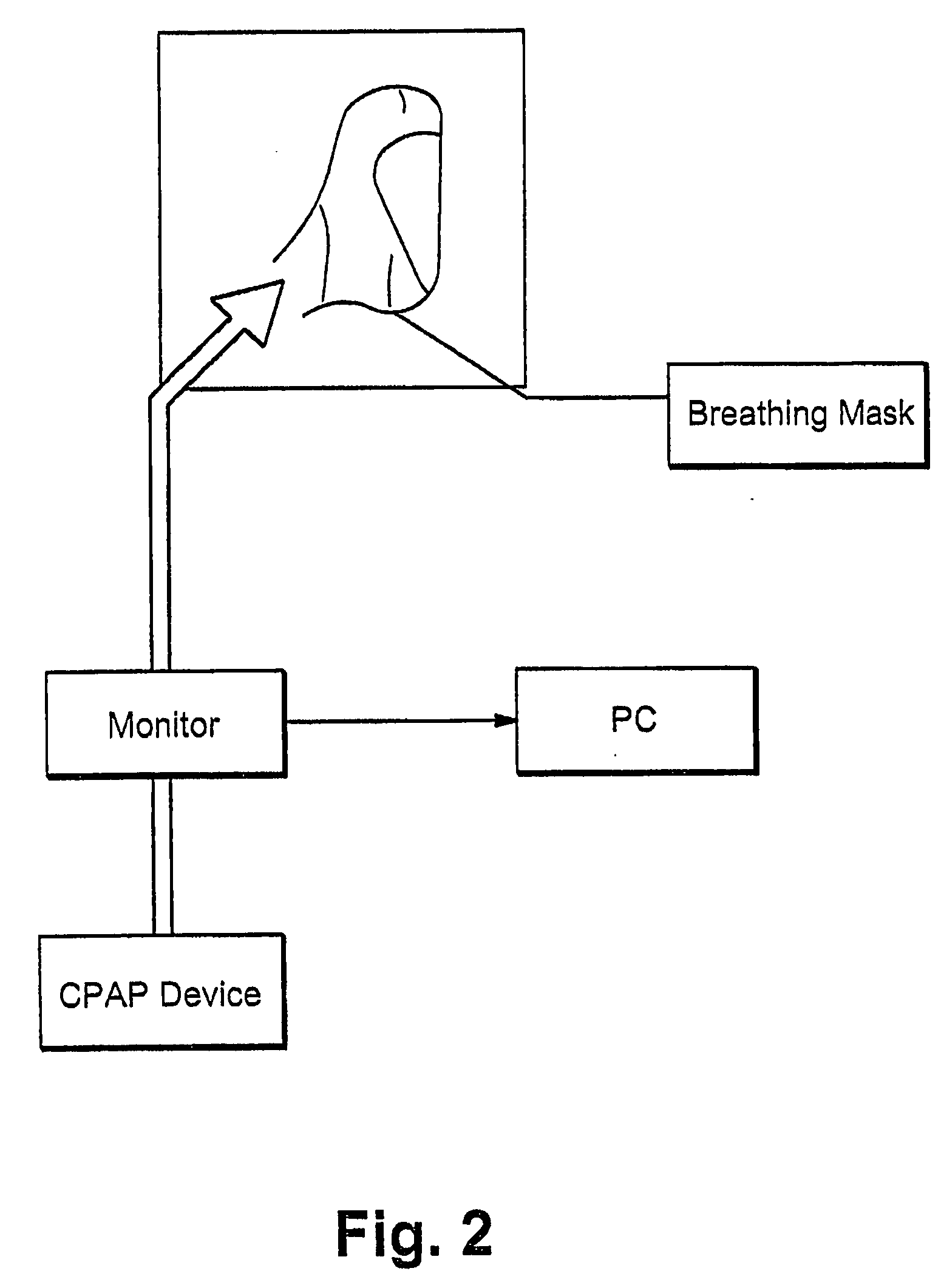

Monitor For Cpap/Ventilator Apparatus

A monitor for surveying measurement values indicative of a person's breathing, to enable an improved assessment, in terms of conclusiveness and reliability, in the course of a treatment phase or a diagnosis. The monitor has a housing structure defining a gas flow path, a measurement line segment provided in the housing structure and structured to communicate with a breathing gas line segment, a sensor in communication with the gas flow path and structured to generate a signal indicative of the breathing gas flow flowing along the gas flow path, and an electronic recording device to record one or more signals indicative of the breathing gas flow, and / or information derived from them. It thus becomes advantageously possible, in treating a patient by using a CPAP device, for instance, to determine the quality of treatment in an objective and standardized way.

Owner:MAP MEDIZIN-TECHNOLOGIES GMBH

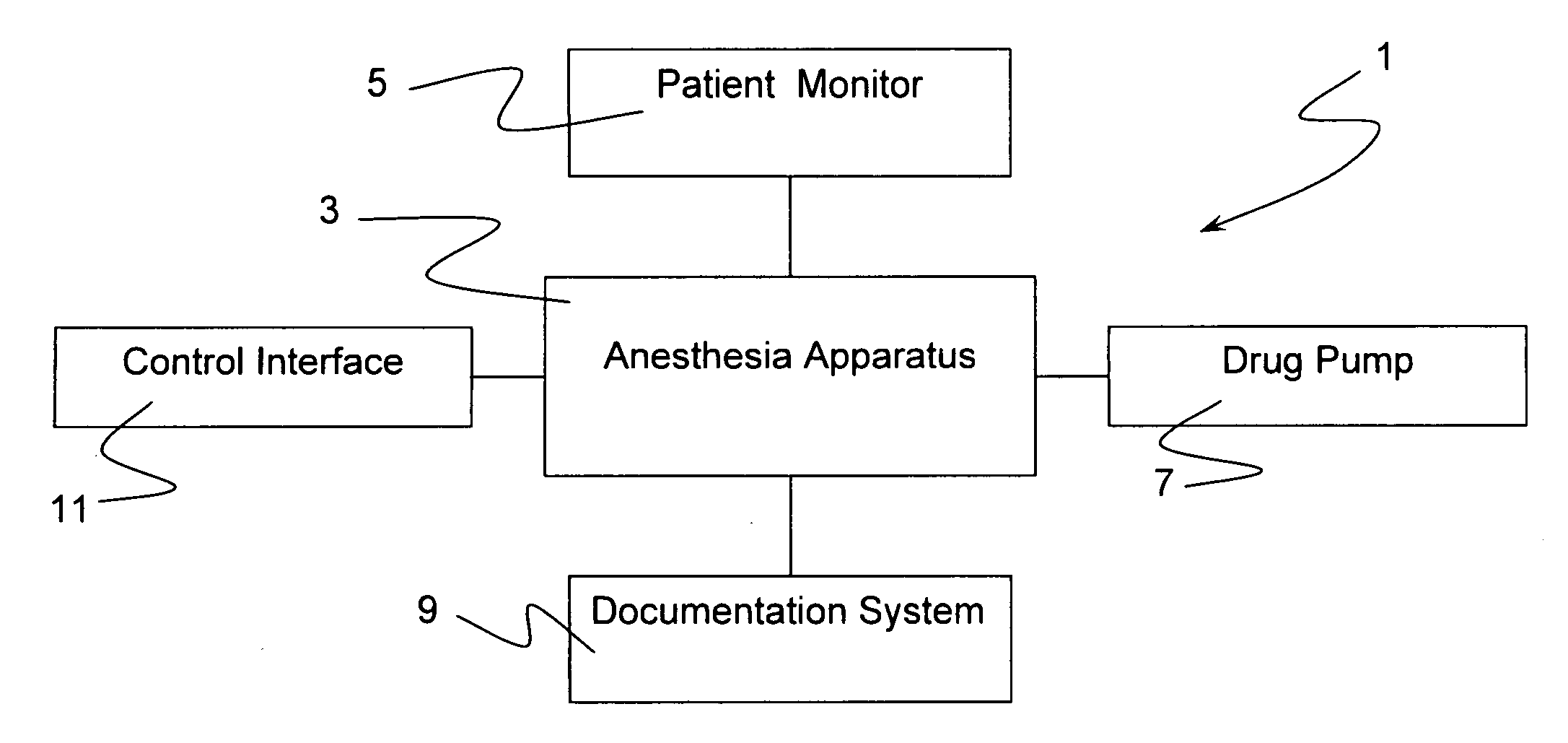

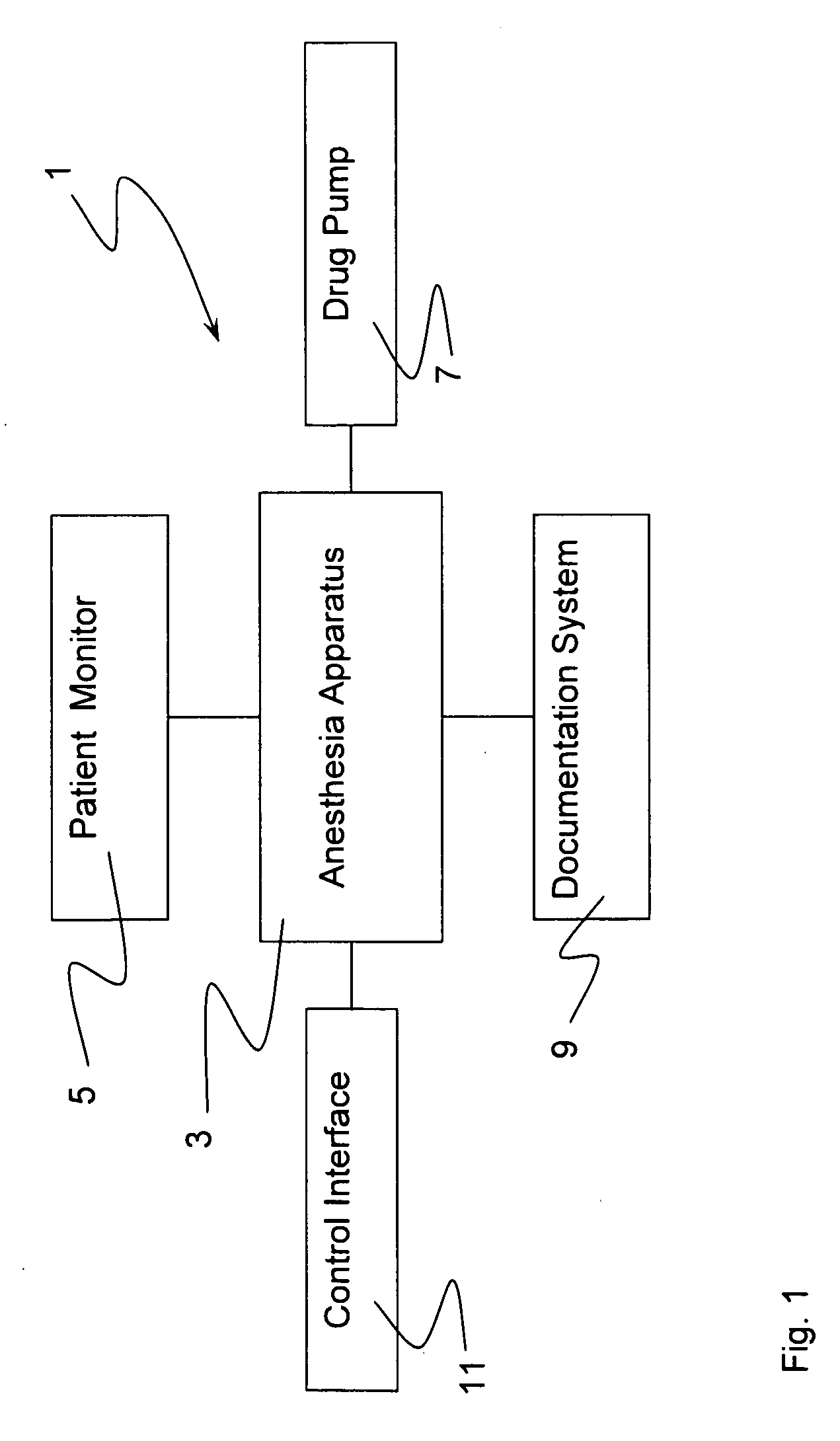

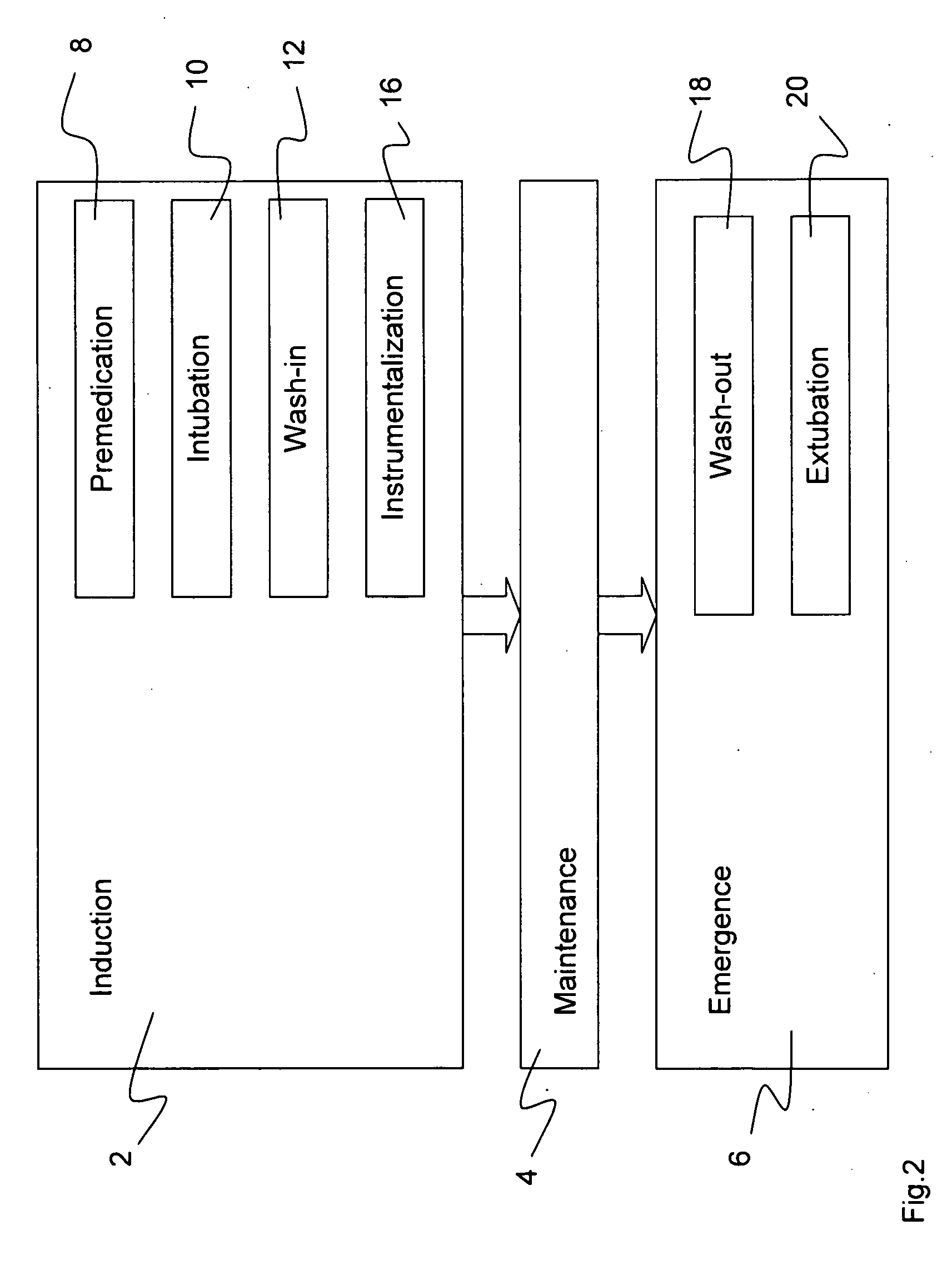

Medical workstation with integrated support of process steps

InactiveUS20100022849A1Simple classification and rating of parameter valueSure easyLocal control/monitoringDrug and medicationsWorkstationBiomedical engineering

A device (13) is provided for use with a treatment device for treating a patient. The device (13) includes a detection device (17) for detecting at least one transition of the patient's treatment from a first phase of treatment to a second phase of treatment. A signal device (25) for sending at least one signal when the transition is detected. It proposes, furthermore, a workstation equipped herewith.

Owner:DRAGERWERK AG

Cyrogenic treatment systems

ActiveCN105555215AEvenly distributedAvoid direct contactCatheterSurgical instruments for heatingRoom temperatureIntensive care medicine

Methods and apparatus for the treatment of a body cavity or lumen are described where a heated fluid and / or gas may be introduced through a catheter and into treatment area within the body contained between one or more inflatable / expandable members. The catheter may also have optional pressure and temperature sensing elements which may allow for control of the pressure and temperature within the treatment zone and also prevent the pressure from exceeding a pressure of the inflatable / expandable members to thereby contain the treatment area between these inflatable / expandable members. Optionally, a chilled, room temperature, or warmed fluid such as water may then be used to rapidly terminate the treatment session.

Owner:CHANNEL MEDSYST

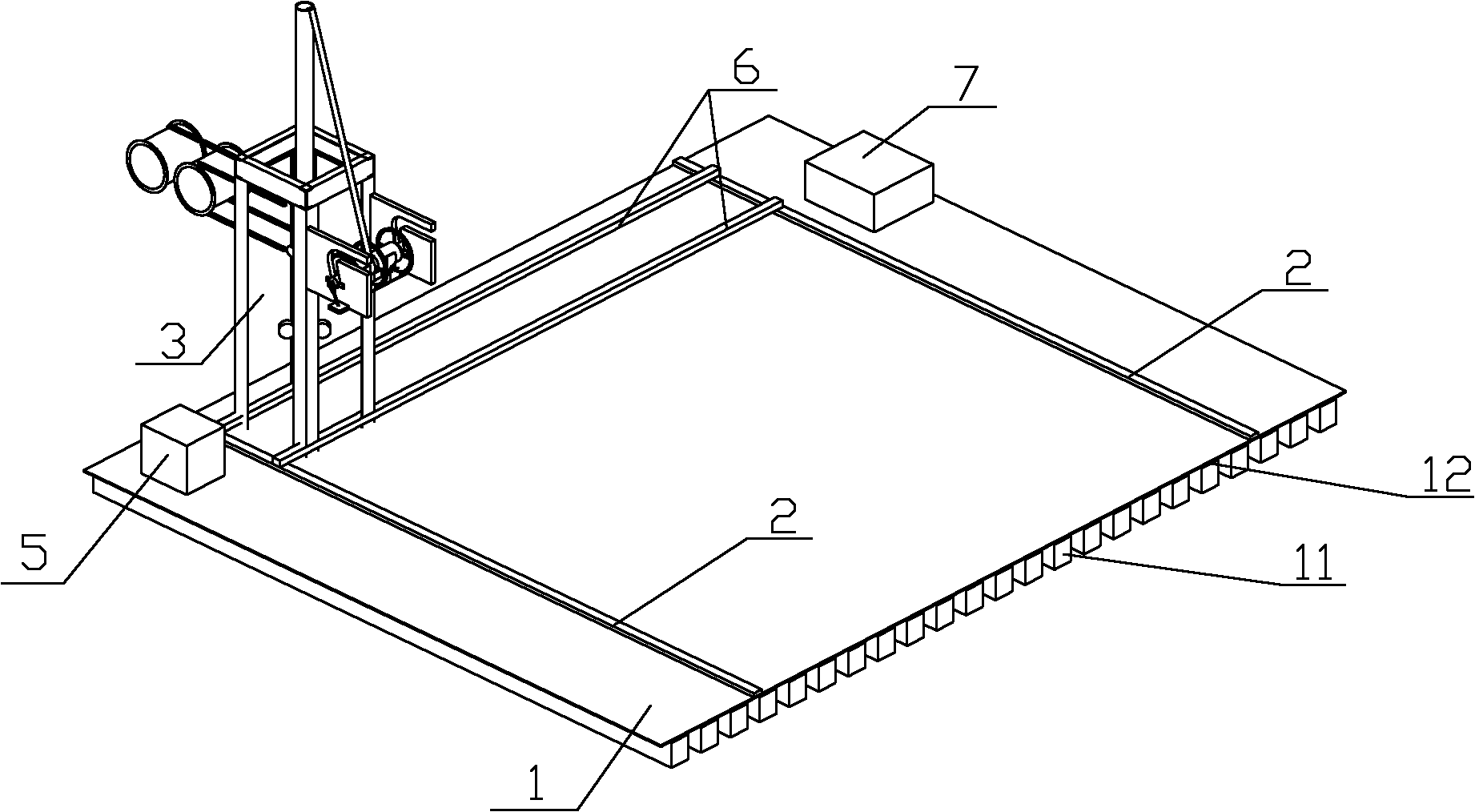

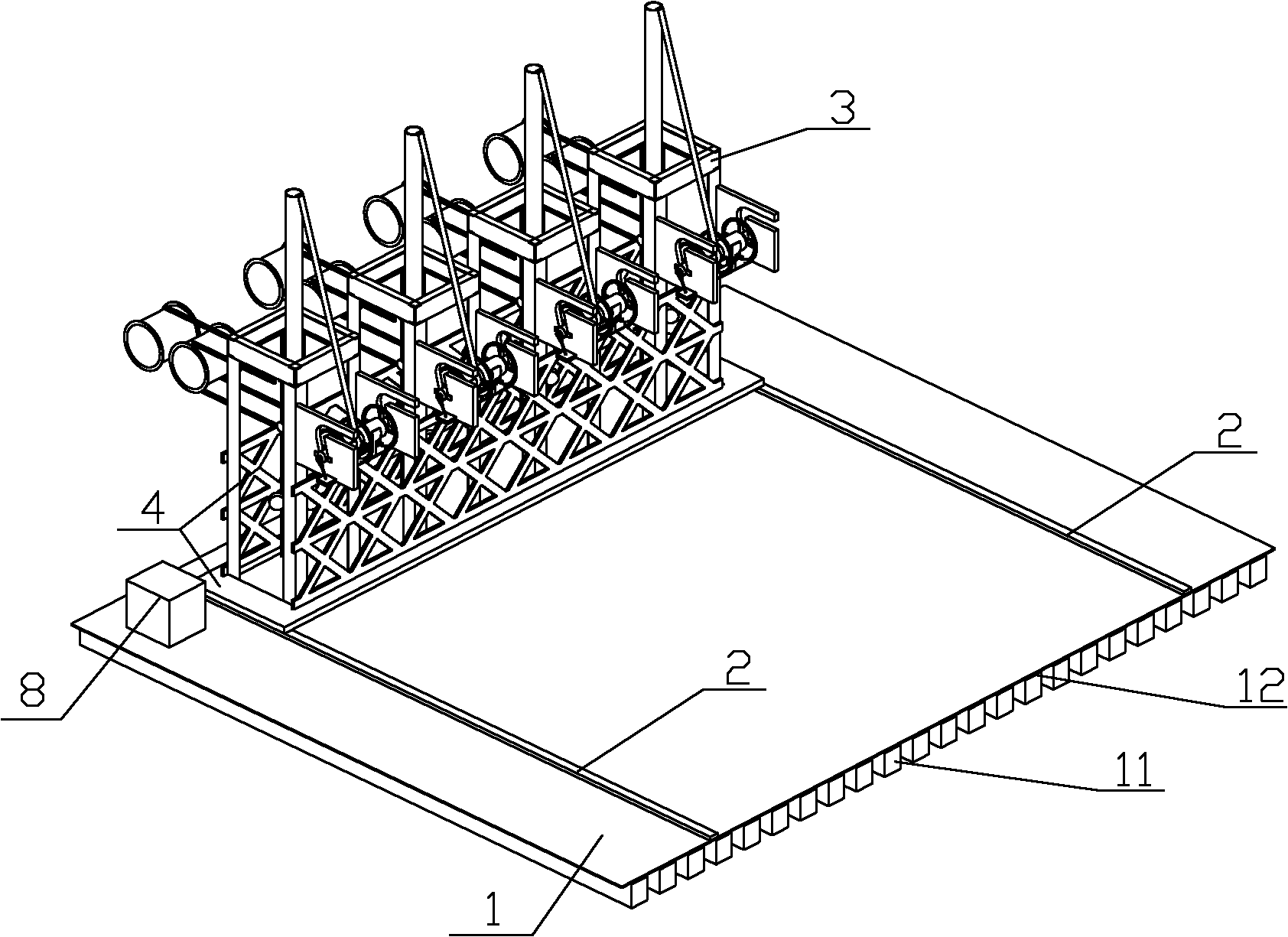

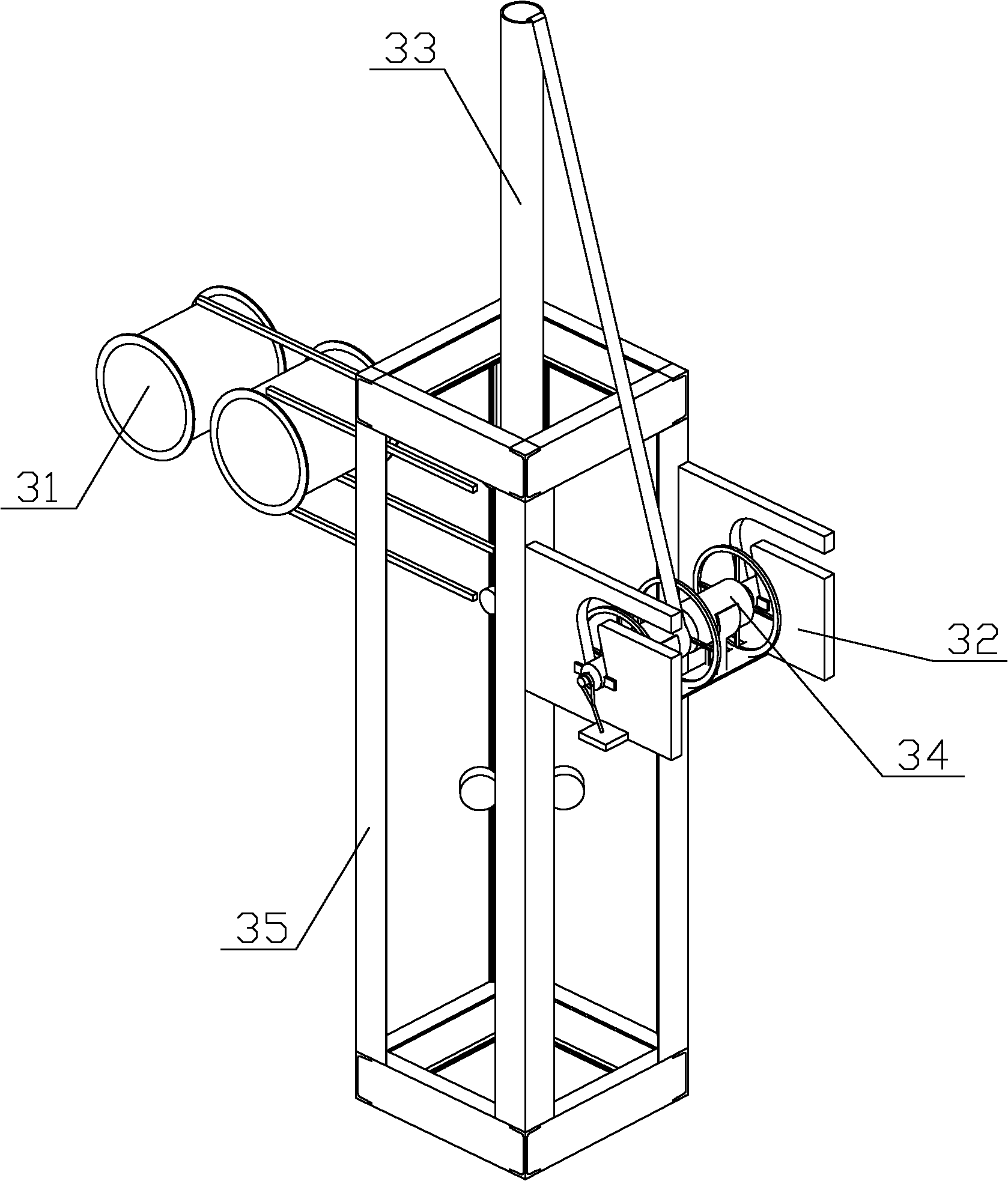

Mud-water amphibious plate-inserting device for soft foundation

InactiveCN102094412AConserve non-renewable resourcesSave resourcesSoil preservationEngineeringRenewable resource

The invention discloses a mud-water amphibious plate-inserting device for a soft foundation, which comprises a plate-inserting machine, wherein the plate-inserting machine is arranged on a track, and the track is arranged on a floating body; and the plate-inserting machine comprises a bracket, a plastic drain board conveying device, an inserting tube and a bidirectional driving device thereof. By using the mud-water amphibious plate-inserting device to carry out soft foundation treatment, the invention cancels the phase of paving geotextiles and wattles or the phase of temporarily consolidating the superficial layer of a manually-inserted drain board in the traditional process, and omits a fine sand bedding layer and a coarse sand filtering layer, thereby saving the temporary consolidation treatment phase in the treatment procedure and saving a great quantity of nonrenewable resources and a lot of money; after mud is subjected to hydraulic reclamation, the plate inserting operation can be performed under the condition that water is adhered to the mud, thereby greatly shortening the construction period; and meanwhile, because the plate-inserting depth can reach more than 20 meters, plates can be inserted in place in one-step operation. Thus, a lot of money can be saved by only omitting the fine sand bedding layer and the coarse sand filtering layer; and compared with the traditional process, the construction time is greatly shortened.

Owner:TIANJIN TDBH NAVAL ARCHITECTURE & OCEAN ENG ACADEMY

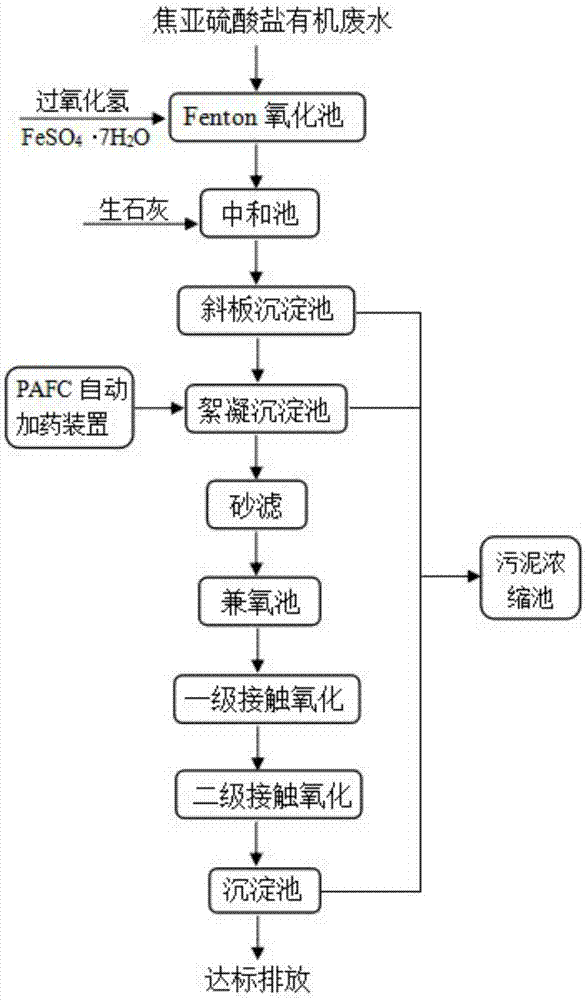

Physicochemical-biological combined treating method for high-concentration organic pyrosulfite wastewater

InactiveCN106865880AImprove biodegradabilityFacilitate solid-liquid separationWater contaminantsMultistage water/sewage treatmentHigh concentrationFenton reagent

The invention discloses a physicochemical-biological combined treating method for high-concentration organic pyrosulfite wastewater. The method comprises the following six steps: 1) Fenton oxidation; 2) neutralization with quicklime; 3) inclined-plate precipitation; 4) chemical flocculation; 5) filtering with quartz sand; and 6) biologically reinforced treatment with pyrosulfite-tolerant engineering bacteria. According to the invention, weak acidity of the organic pyrosulfite wastewater is made full use of, the strong oxidation effect of a Fenton reagent under the condition of weak acidity is given to play so as to oxidize pyrosulfite with toxicity into nontoxic sulfate, and macro-molecular organic matters in the wastewater can be degraded small molecules, so biodegradability of the wastewater is improved; and the domesticated engineering bacteria with salinity tolerance of 50 g / L are used as bacteria in a biologically reinforced treatment phase for three-stage biologically reinforced treatment so as to microfloras adaptive to environment, so degradation of the wastewater is efficiently realized under cooperation of the microfloras and effluent totally meets primary standards prescribed in Comprehensive Wastewater Discharge Standard in China.

Owner:CENT SOUTH UNIV

Reconfigurable dental model system for fabrication of dental appliances

The present invention provides a manipulable or reconfigurable dental model system and methods for its use to model a series of tooth configurations corresponding to sequential tooth movements during an orthodontic treatment. When a patient undergoes orthodontic treatment, teeth and bite configurations are realigned in a series of stages. Each stage represents a new pattern or dental configuration that will eventually lead to a proper final positioning of the entire dentition. Progress from the initial configuration, through the intermediate stages and finally to the final configuration may be accomplished using any one or a combination of different dental appliances. Of particular interest to the present invention, many of these appliances may be made using a dental mold representing the patient's dental configuration. In particular, thermoformable plastic positioning appliances which fit over the patient's teeth may be formed over a three-dimensional mold of the patient's dentition. When successive appliances are used throughout treatment to reposition the teeth from initial to final configuration, a new mold has typically been produced to fabricate the appliance for each stage. The present invention provides an apparatus and methods which employ a manipulable or reconfigurable mold to model patient dentition and gingiva at each stage of treatment.

Owner:MILLER ROSS +1

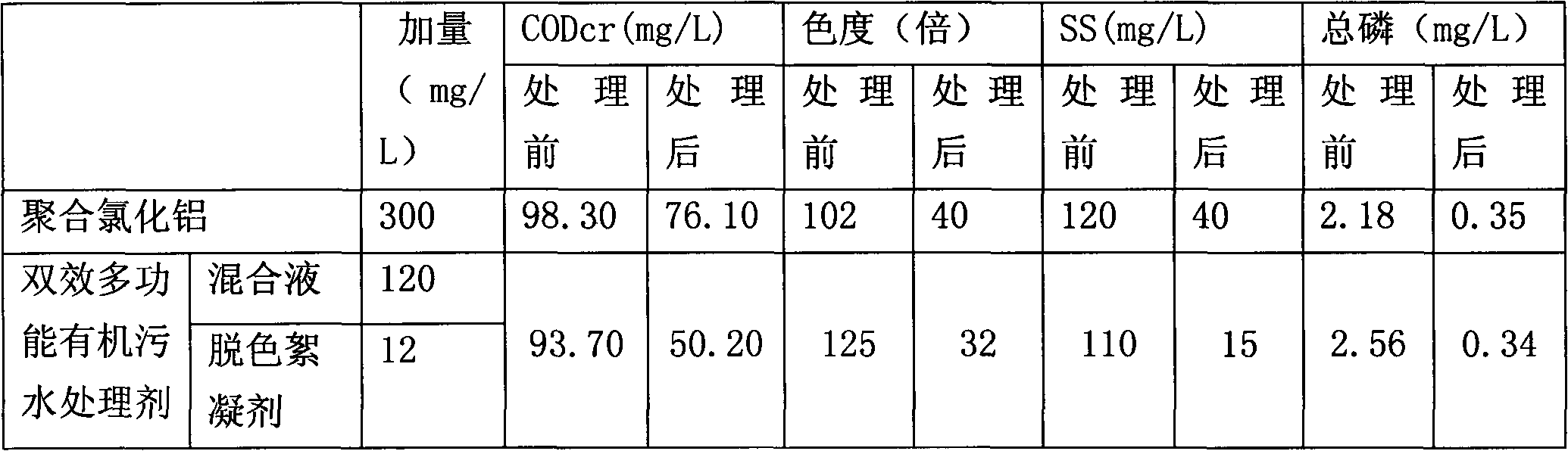

Double-effect multifunctional organic sewage treatment agent

InactiveCN103224275AReduce dosageImprove processing efficiencyWater/sewage treatment by flocculation/precipitationPapermakingTherapeutic effect

The invention relates to a double-effect multifunctional organic sewage treatment agent, which is composed of polymeric aluminum, a high efficiency pulping papermaking advanced treatment agent and an organic polymer decolouring flocculating agent. wherein, the high efficiency pulping papermaking advanced treatment agent is a mixture of polymeric ferric sulfate and activated diatomite according to ratio of 4:6, and the organic polymer decolouring flocculating agent is a dicyandiamide-formaldehyde series quaternary amines type cationic polymer. The treatment agent is mainly used in an advanced treatment phase of waste water at intermediate section during a pulping papermaking process, and can improve the disadvantages of large medicinal amount of current single ordinary water, poor treatment effect and high treatment cost. The treatment agent has the advantages of small dosage amount per ton of water, high treatment efficiency and stable chroma clearance. Under the condition that the medicine addition amount accounts for 50% of the that of polymeric aluminum, the index of COD, chroma, SS, total phosphorus and the like of outlet water can reach or is better than national relative standard, and the operation is stable.

Owner:RED WOOD SCI & TECH

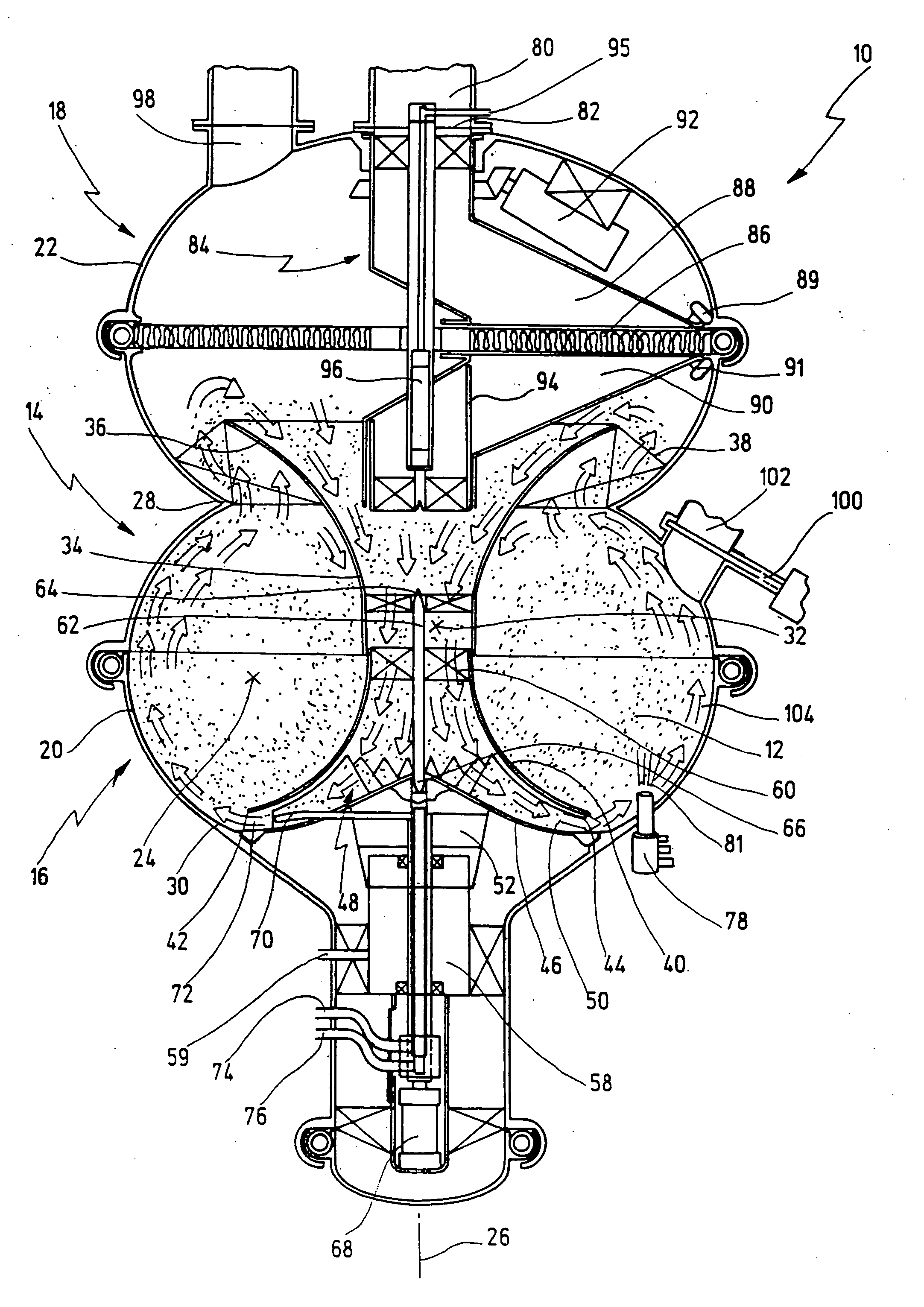

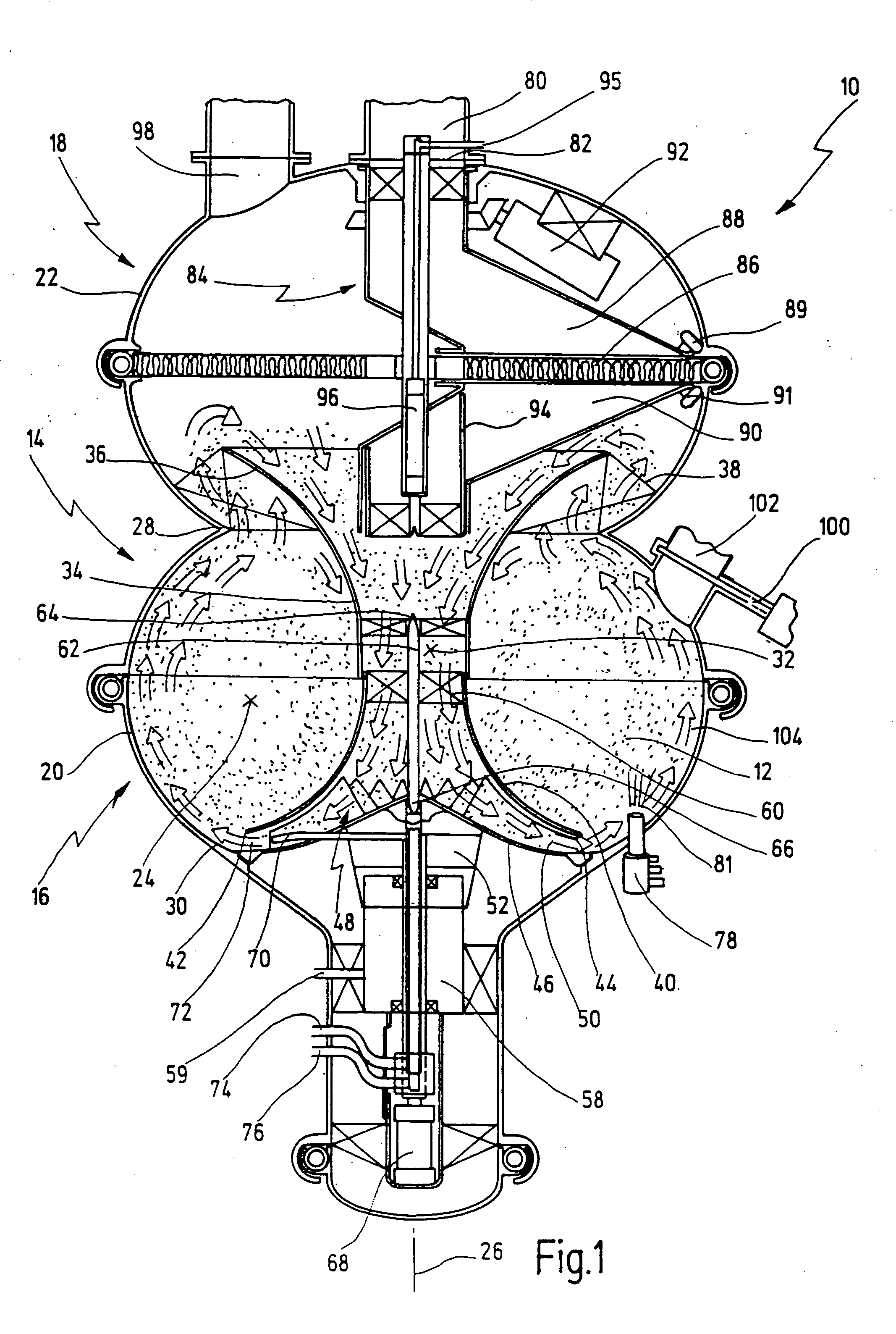

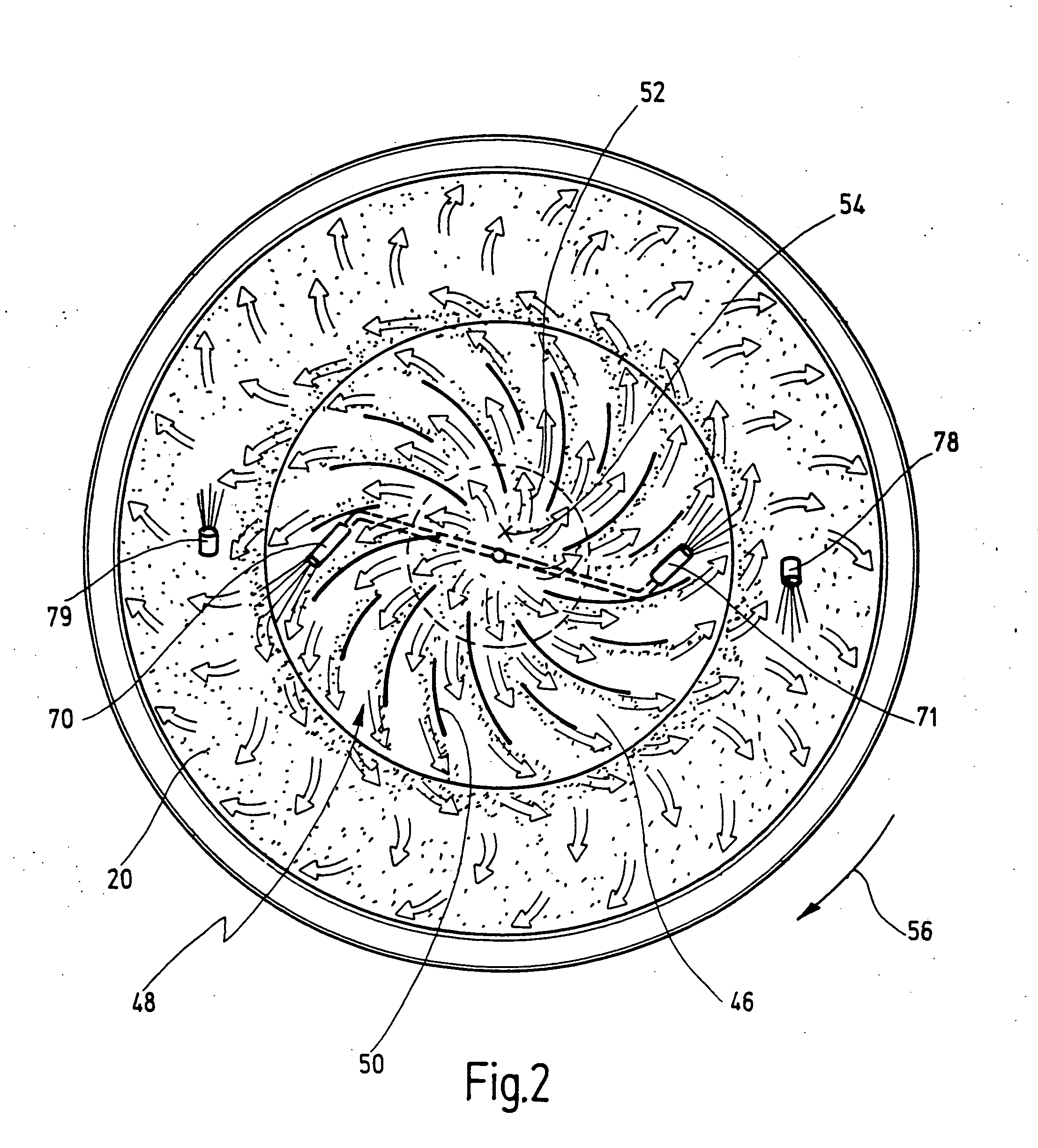

Method and apparatus for treating particulate-shaped material, in particular for mixing, drying, graduating, pelletizing and/or coating the material

InactiveUS20050145728A1Liquid surface applicatorsDrying solid materials with heatTreatment phasesEngineering

An apparatus for treating a particulate material, in particular for mixing, drying, granulating, pelletizing and / or coating the material, has a container which has a process chamber arranged around a longitudinal mid-axis of the container and formed as an annular chamber, and also a container central duct, separated from the process chamber, as a flow duct for process air, which duct opens into the lower region of the process chamber, an upper region of the process chamber being open. In at least one first operating state, the upper open region of the process chamber communicates with the container central duct so as to conduct process air, by the container central duct widening circumferentially towards the upper region of the process chamber and opening towards the process chamber. In a method for treating particulate material, the material is put into the container, and process air is introduced from the container central duct into the lower region of the process chamber and flows upwards in the process chamber in order to move the material in the process chamber. The process air emerges from the process chamber again from the upper region of the latter, the process air, at least in a first treatment phase, after emerging from the upper region of the process chamber, being led at least partly into the container central duct in a continued circulation-type flow and there being led downwards again, where it is introduced into the process chamber once more.

Owner:HUTTLIN HERBERT

Semi-coke wastewater treatment method

ActiveCN107827315AReduce organic contentImprove biodegradabilityFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesCarbonizationHydrolysis

The invention relates to the field of semi-coke wastewater treatment, in particular to a semi-coke wastewater treatment method. The method comprises a pretreatment phase and a biochemical treatment phase, wherein the pretreatment phase comprises the following steps of enabling semi-coke wastewater to be successively subjected to oil removing treatment, acid stripping treatment, deamination treatment and dephenolization treatment to obtain pretreated wastewater, wherein the acid stripping treatment is performed in an acid stripping tower, the deamination treatment is performed in a deaminationtower, and the dephenolization treatment is performed in a carbolic oil extraction tower; the biochemical treatment phase comprises the following steps of enabling the pretreated wastewater to successively pass through a hydrolysis acidification pool, a biochemical reaction pool, a settling pool, a coagulative precipitation pool and a film treatment device to obtain dialysis water and concentratedwater, wherein the dialysis water enters a cooling segment of a vertical carbonization furnace, and the concentrated water enters a preheating segment of the vertical carbonization furnace. The acidstripping tower, the deamination tower and the carbolic oil extraction tower jointly cooperate with another process in a specific process condition, so that the semi-coke wastewater can be recycled for quenching coke, the quality of an obtained semi-coke product meets a standard, the cycle use of the semi-coke wastewater is realized, and the environmental pollution is reduced.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com