Method for deeply purifying and recovering hyperhaline fluoric-u radioactive waste solution

A radioactive waste liquid, deep purification technology, applied in radioactive purification, chemical instruments and methods, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

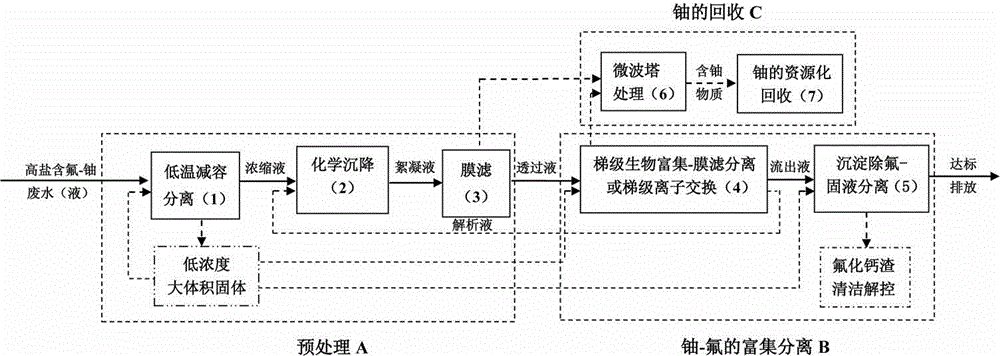

[0030] Example 1 High-salt fluorine-containing uranium radioactive wastewater with an initial influent salt content of 8%, an initial uranium concentration of 900 mg / L, and a fluorine concentration of 15 g / L enters a high-salt fluorine-containing uranium wastewater of the present invention The deep purification and recovery method of (liquid), which includes three processing sections of pretreatment A, enrichment and separation of uranium-fluorine B and recovery of uranium C in sequence. The salt content in the final wastewater after treatment is ≤0.1%, the uranium concentration is - ≤10mg / L.

[0031] ①Pretreatment A The pretreatment section includes low-temperature volume reduction separation, chemical sedimentation and membrane filtration units connected in sequence. The low-temperature treatment temperature of the low-temperature volume reduction separation unit is -70°C and the treatment time is 2 hours; The agent is soluble phosphate, uranium: phosphate=20:1 (mass concent...

Embodiment 2

[0034] Example 2 The fluorine-uranium-containing radioactive wastewater with an initial influent salt content of 2%, an initial uranium concentration of 800 mg / L, and a fluorine concentration of 8 g / L enters a high-salt fluorine-containing-uranium wastewater of the present invention (liquid ) deep purification and recovery method, which includes three processing sections of pretreatment A, enrichment and separation of uranium-fluorine B and recovery of uranium C in sequence. The salt content in the final wastewater after treatment is ≤0.1%, the uranium concentration is - ≤10mg / L.

[0035] ①Pretreatment A The pretreatment section includes low temperature volume reduction separation, chemical sedimentation and membrane filtration units connected in sequence, in which the low temperature treatment temperature of the low temperature volume reduction separation unit is -25°C, and the low temperature treatment time is 0.5h; The precipitating agent is soluble vanadate, uranium: vanad...

Embodiment 3

[0038] Example 3 High-salt fluorine-containing uranium radioactive wastewater with an initial influent salt content of 4%, an initial uranium concentration of 500 mg / L, and a fluorine concentration of 5 g / L enters a high-salt fluorine-containing uranium wastewater of the present invention The deep purification and recovery method of (liquid), which includes three processing sections of pretreatment A, enrichment and separation of uranium-fluorine B and recovery of uranium C in sequence. The salt content in the final wastewater after treatment is ≤0.1%, the uranium concentration is - ≤10mg / L.

[0039] ①Pretreatment A The pretreatment section includes low temperature volume reduction separation, chemical sedimentation and membrane filtration units connected in sequence, in which the low temperature treatment temperature of the low temperature volume reduction separation unit is -50°C, and the low temperature treatment time is 1.5h; The precipitating agent is soluble silicate, ur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com