Method for manufacturing a titanium alloy for biomedical devices

A biomedical, titanium alloy technology, used in the field of nails and joint prostheses, biomedical equipment, capable of solving specific shapes or parts or areas that are not easily accessible, harmful or unfavorable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

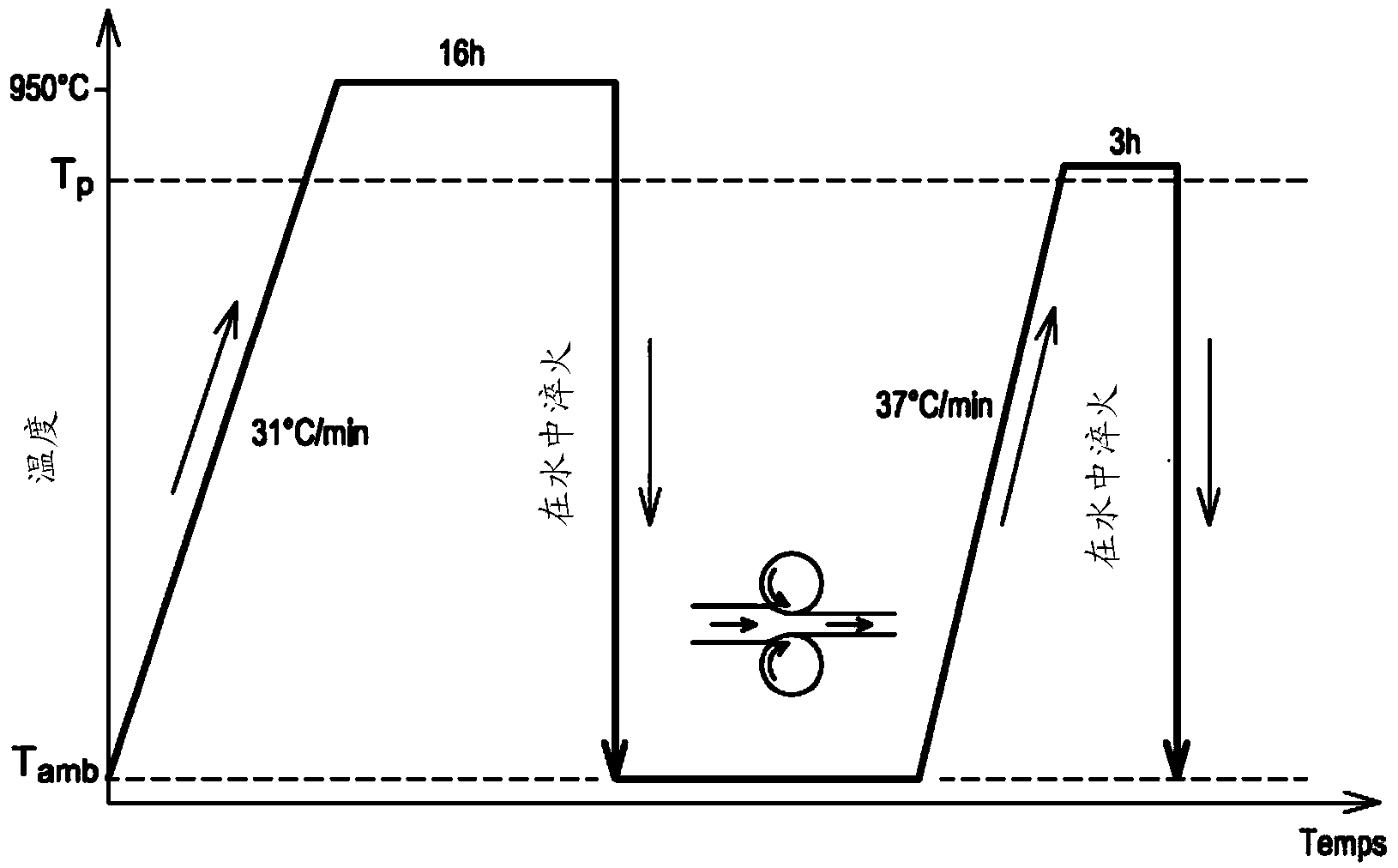

[0076] now refer to figure 1 The invention is described. figure 1 A schematic diagram showing the temperature variation as a function of time of an ingot comprising different compounds and intended to form an alloy with reference to successive steps of the method according to the invention.

[0077] In the initial step (not in figure 1 shown in ), the different amounts of metals that are constituents of the alloy to be produced are brought together in the proportions defined below. The mixture of metals is subjected to an initial melting operation at a temperature between 2000°C and 3000°C. Advantageously, this initial melting step is carried out in a cold crucible using semi-magnetic levitation and a high-frequency induction generator. Common or other rapid sintering techniques can also be used.

[0078] During the initial stage, it is important to ensure that a homogeneous mixture is produced without foreign element inclusions, doping or contamination. In this aspect, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com