Double-effect multifunctional organic sewage treatment agent

An organic sewage, multi-functional technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of inability to guarantee the chromaticity, large amount of sludge, low treatment efficiency, etc., and achieve stable chromaticity removal rate and high treatment efficiency. , the effect of small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

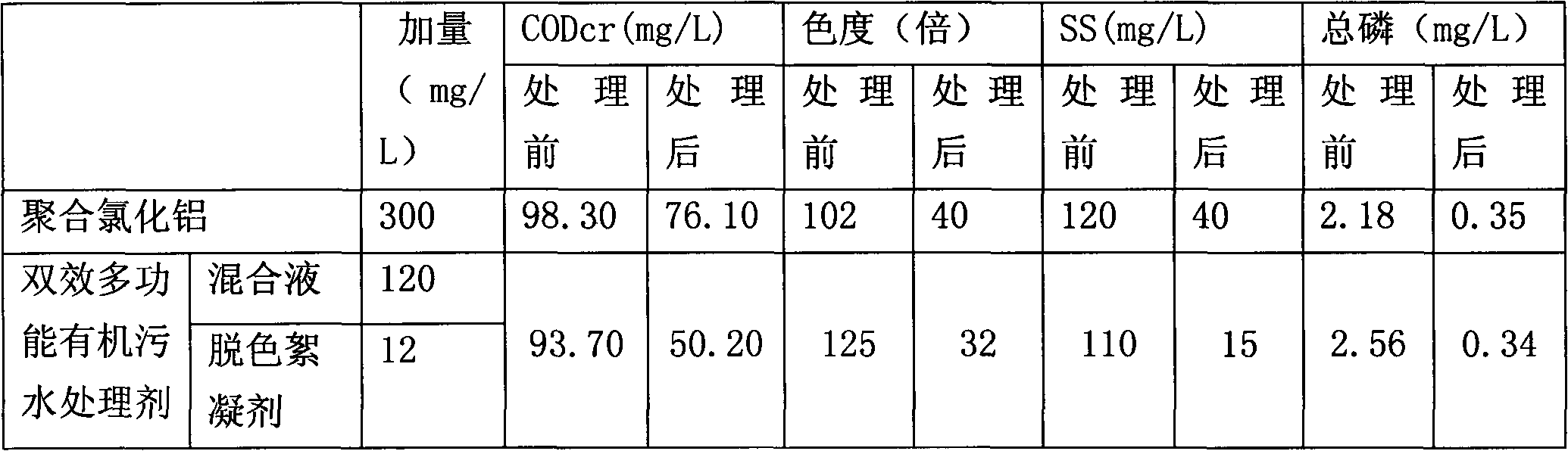

[0008] Specific implementation mode one: In this implementation mode, taking the secondary sedimentation tank effluent of a bamboo pulp and papermaking middle section wastewater as an example, the polyaluminum chloride in the double-effect multifunctional organic sewage treatment agent and the high-efficiency pulping and papermaking advanced treatment agent are mixed respectively according to 10 % concentration, the organic polymer decolorizing flocculant is prepared according to the concentration of 5%. The controlled dosage is: polyaluminum chloride, high-efficiency pulping and papermaking advanced treatment agent mixed solution 100-150mg / L, organic polymer decolorizing flocculant 10-25mg / L. The CODcr of the treated wastewater is 40-60mg / L, the chroma is 32-40 times, the SS is 12-20mg / L, and the total phosphorus is 0.1-0.5mg / L. In order to meet the national standards for the discharge of pulping wastewater.

[0009] The treatment method in this embodiment is air flotation, ...

specific Embodiment approach 2

[0011] Specific implementation mode two: In this implementation mode, taking the effluent of the secondary sedimentation tank of a certain reed paddle papermaking middle section wastewater as an example, the polyaluminium chloride in the double-effect multifunctional organic sewage treatment agent and the high-efficiency pulping and papermaking advanced treatment agent are mixed respectively according to 15 % concentration, the organic polymer decolorizing flocculant is prepared according to the concentration of 3%. The controlled dosage is: polyaluminum chloride, high-efficiency pulping and papermaking advanced treatment agent mixed solution 150-400mg / L, organic polymer decolorizing flocculant 10-60mg / L. The treated wastewater CODcr is 60-75mg / L, and the chroma is 30-45 times.

[0012] The treatment method in this embodiment is a sedimentation tank, and the pH of the secondary sedimentation effluent is 6.90-8.10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com