System and method for treatment and recovery of electronic electroplating wastewater

A technology for electroplating wastewater and electronics, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can achieve obvious economic and social benefits, reduce wastewater pollution index and wastewater turbidity, and improve the treatment effect and its operating life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

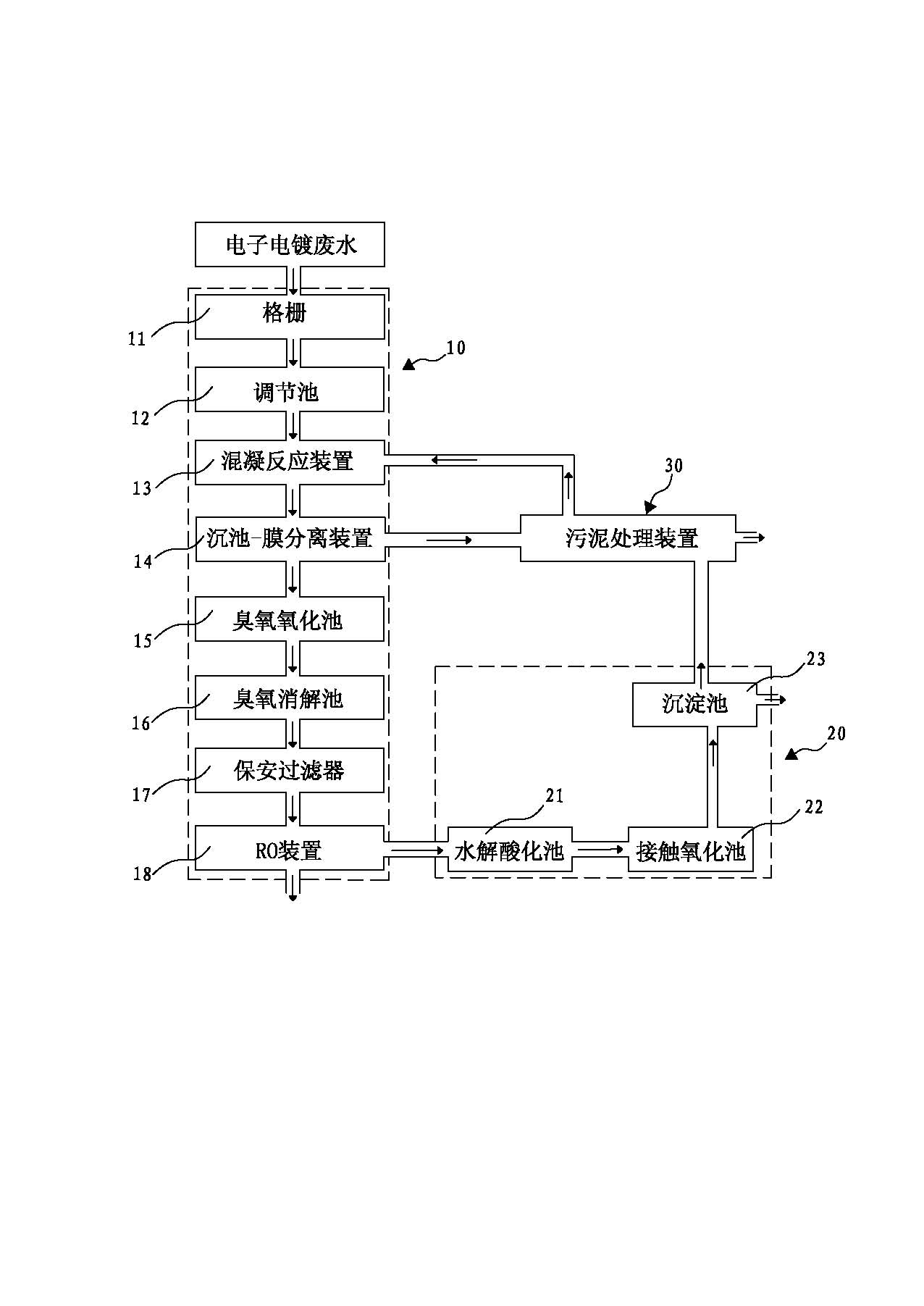

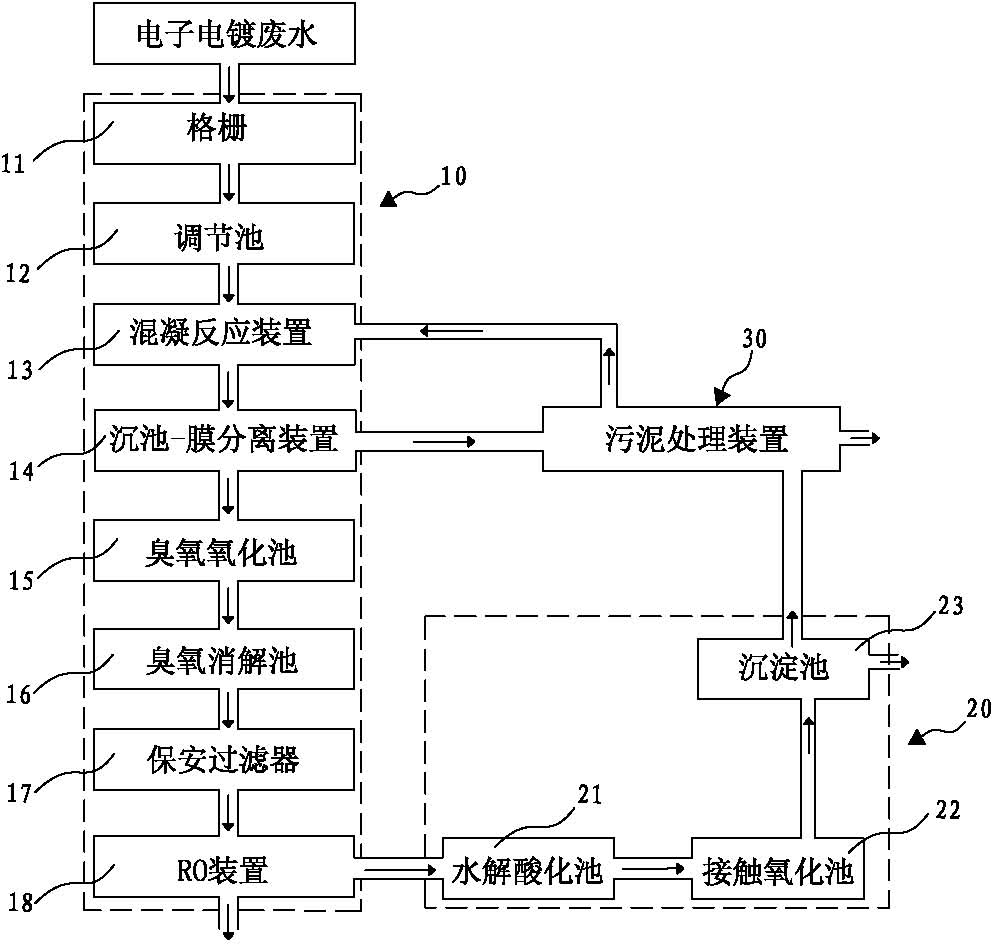

[0046] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a wastewater reuse treatment unit 10, an RO concentrated water treatment unit 20, and a sludge treatment device 30. The electronic electroplating wastewater reuse treatment unit includes a grid 11, a regulating tank 12, a coagulation reaction device 13, a precipitation-membrane separation device 14, an ozone oxidation tank 15, an ozone digestion tank 16, a security filter 17 and an RO device 18. The RO concentrated water treatment unit 20 includes a hydrolysis acidification tank 21, a contact oxidation tank 22, and a sedimentation tank 23.

[0047] The main function of the grille 11 is to intercept large pieces of dirt in the wastewater so as not to cause damage to the pump or process pipeline of the subsequent processing unit.

[0048] In order to ensure the continuity and stability of the treatment structure, the regulating tank 12 regulates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com