Method and system for treating desulfurization wastewater in zero-discharge manner on basis of electrodialysis

A technology for desulfurization wastewater and treatment method, which is applied in gaseous discharge wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. problems, to reduce the cost of dosing and the workload of dispensing, ensure long-term stable operation, and reduce the effect of membrane fouling index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] Example 2:

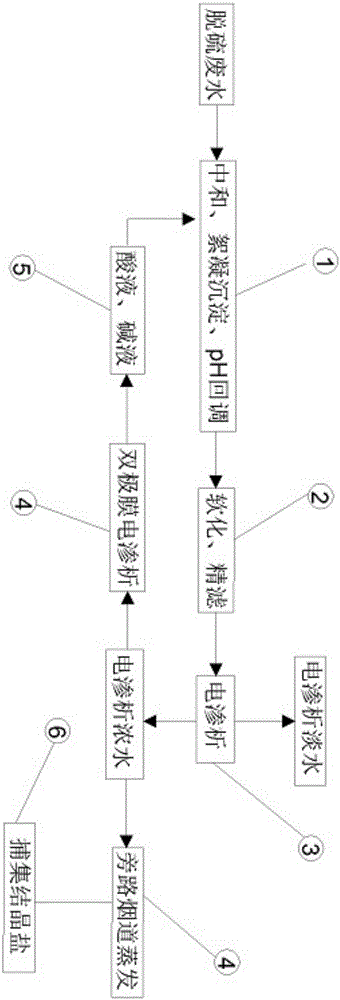

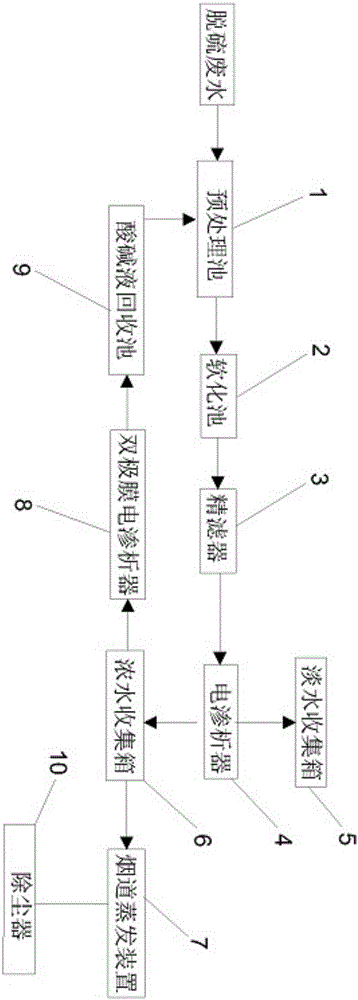

[0056] See figure 1 with figure 2 This example 2 uses 300L of flue gas desulfurization wastewater from another power plant, calcium ion concentration is 800mg / L, magnesium ion concentration is 5000mg / L, sulfate ion is 8520mg / L, chloride ion is 6530mg / L, and pH is 6.7. Wastewater: neutralize to pH=9.5 by adding alkali solution, flocculate and settle for 15 minutes, add 30g softener to the clarified liquid, pass through a multi-media precision filter, and then enter the electrodialysis treatment after the effluent passes through the pH adjustment. The electrodialysis uses 400* A homogeneous membrane stack of 800,50 pairs of membranes, an electrodialyzer of one stage and one stage, batch cycle treatment, 35L of electrodialysis concentrated water is used for bipolar membrane acid and alkali production to prepare lye with pH=12.2 , PH=2.4 acid solution for reuse in the pretreatment process. Take 250L conductivity of electrodialysis concentrated water to bypass f...

Example Embodiment

[0061] Example 3:

[0062] See figure 1 with figure 2 This example 3 uses 500L of flue gas desulfurization wastewater from another power plant, calcium ion concentration is 520mg / L, magnesium ion concentration is 3200mg / L, sulfate radical is 6300mg / L, chloride ion is 5500mg / L, and pH is 6.5 desulfurization Wastewater; through neutralization, flocculation and sedimentation, adding 20g softener, passing through a precision filter, the effluent enters the electrodialysis treatment, the electrodialysis adopts a homogeneous membrane stack of 400*800,70 pairs of membranes, one-stage electrodialysis It is carried out in batch cycle treatment mode, and 80L of electrodialysis concentrated water is used to make acid and alkali with bipolar membrane. Take 380L conductivity as electrodialysis concentrated water to bypass the flue evaporation equipment for atomization and evaporation.

[0063] System operation effect:

[0064] 1. The suspended matter in the neutralization tank is quickly prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com