Tandem or parallel untreated sewage fiber and hair filter

A technology for hair filtration and sewage, which is applied in the direction of filtration separation, filtration treatment, membrane filter, etc. It can solve the problems of poor filtration effect, blockage of heat exchanger, and large footprint, so as to improve heat exchange efficiency and increase heat exchange efficiency , The effect of reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

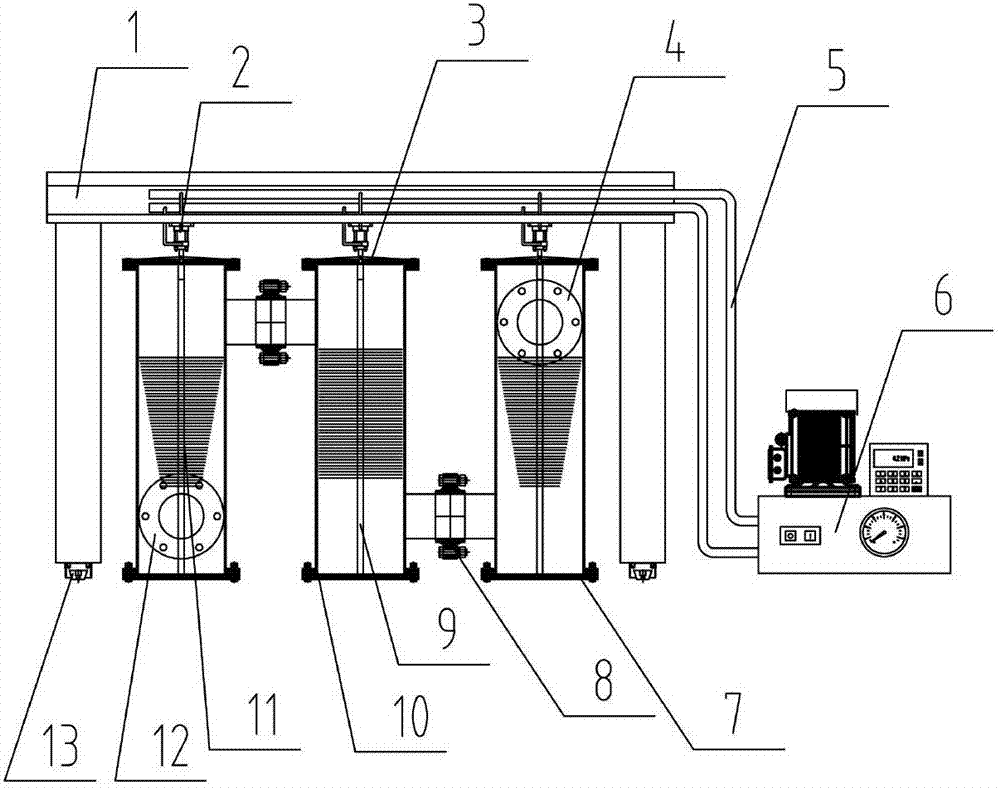

[0029] The raw sewage introduced into the system from the urban sewage canal, after mechanical coarse filtration, the diameter of the sewage particles is ≤3mm, which contains a large amount of flexible filamentous substances such as fibers, hairs, and plastic cloths, and these sewage enters the raw sewage fiber hair filter device Filter in the middle, and then enter the heat exchange equipment for heat exchange;

[0030] The mechanically coarsely filtered sewage enters the water inlet 12, and the sewage flows upward in the main body of the filter chamber 10. When the sewage flows through the conical steel wire filter brush 11, it will be scraped off the fibrous filamentous sewage with a large buoyancy and a large number. The matter enters the second filter cavity main body 10 through the connection port 8, at this time the sewage will flow upwards, the sewage will flow through the cylindrical steel filter brush 9, the sewage in the filter cavity main body 10 will flow downward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com