Medical ultrasonic cleaning machine

A technology of ultrasonic cleaning and cleaning machine, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of not being too high in temperature, collision, and damage to glass bottles, and achieve the goal of reducing the pollution index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

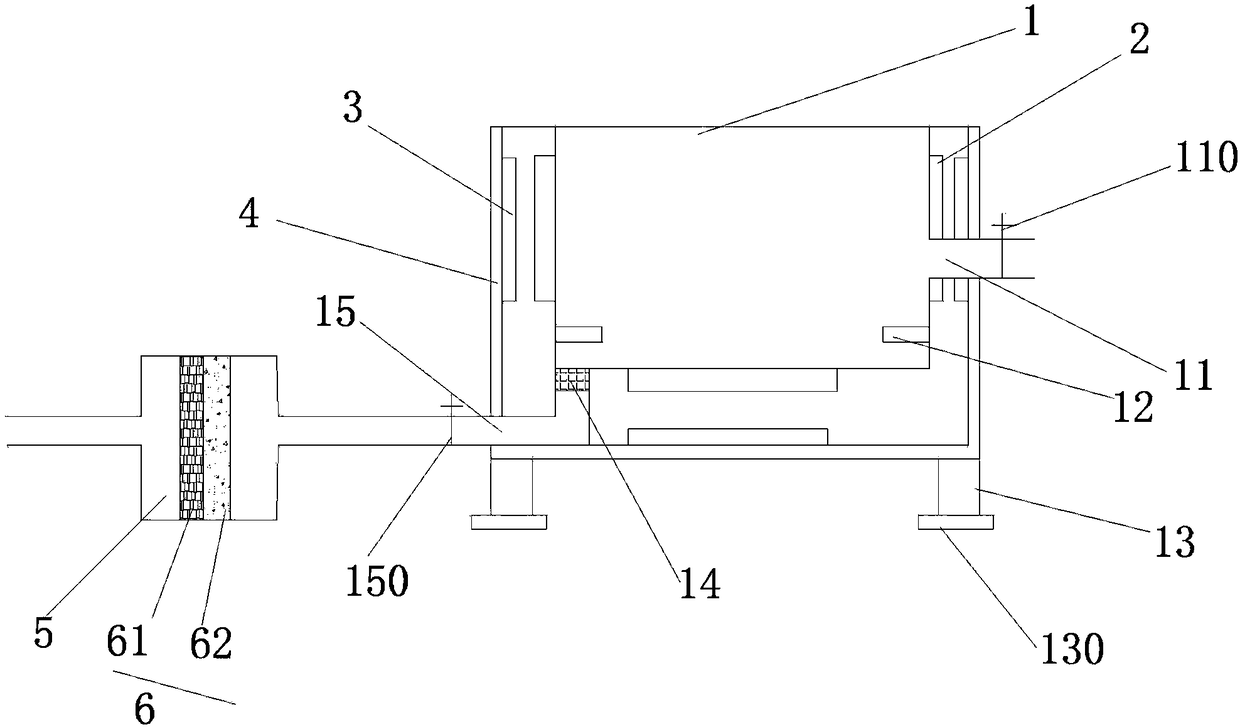

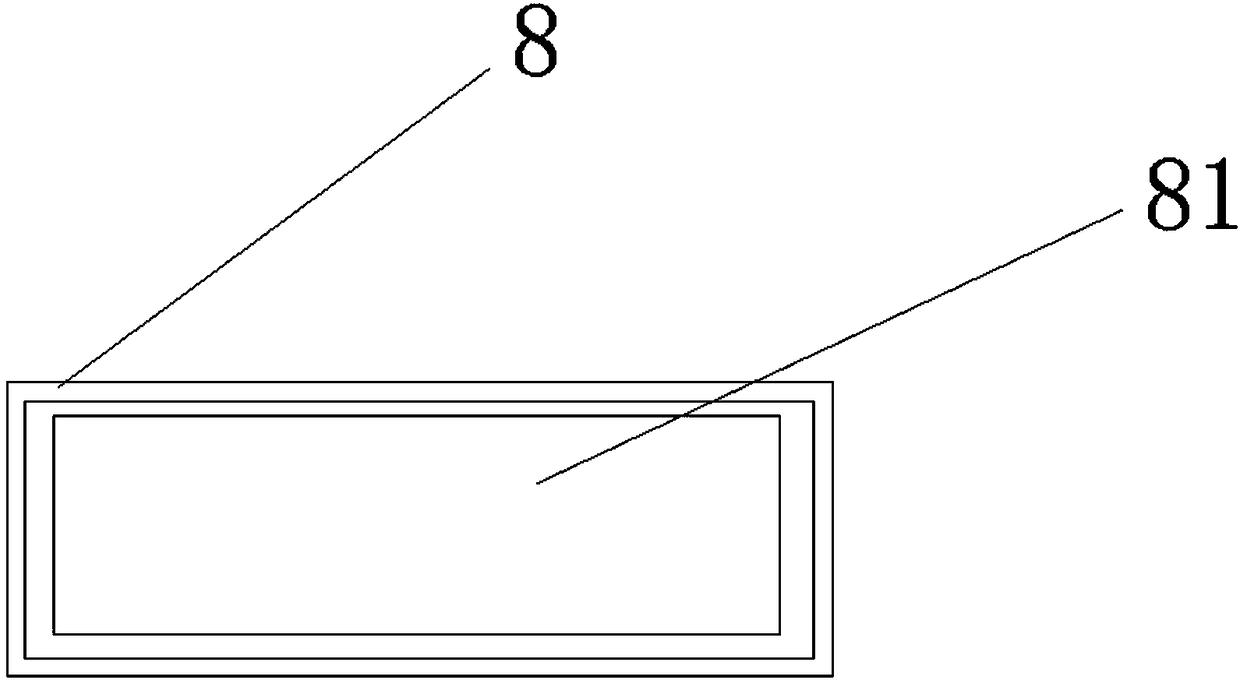

[0022] Such as Figure 1-3 As shown, a medical ultrasonic cleaning machine includes an ultrasonic cleaning box 1, and the ultrasonic cleaning box 1 is provided with an inner cavity, and each outer wall of the inner cavity is fixed with a sound insulation board 4, and the sound attenuation board 81 The surface is provided with a semiconductor condensation plate 3, and each inner wall of the inner cavity is provided with a heating wire 2;

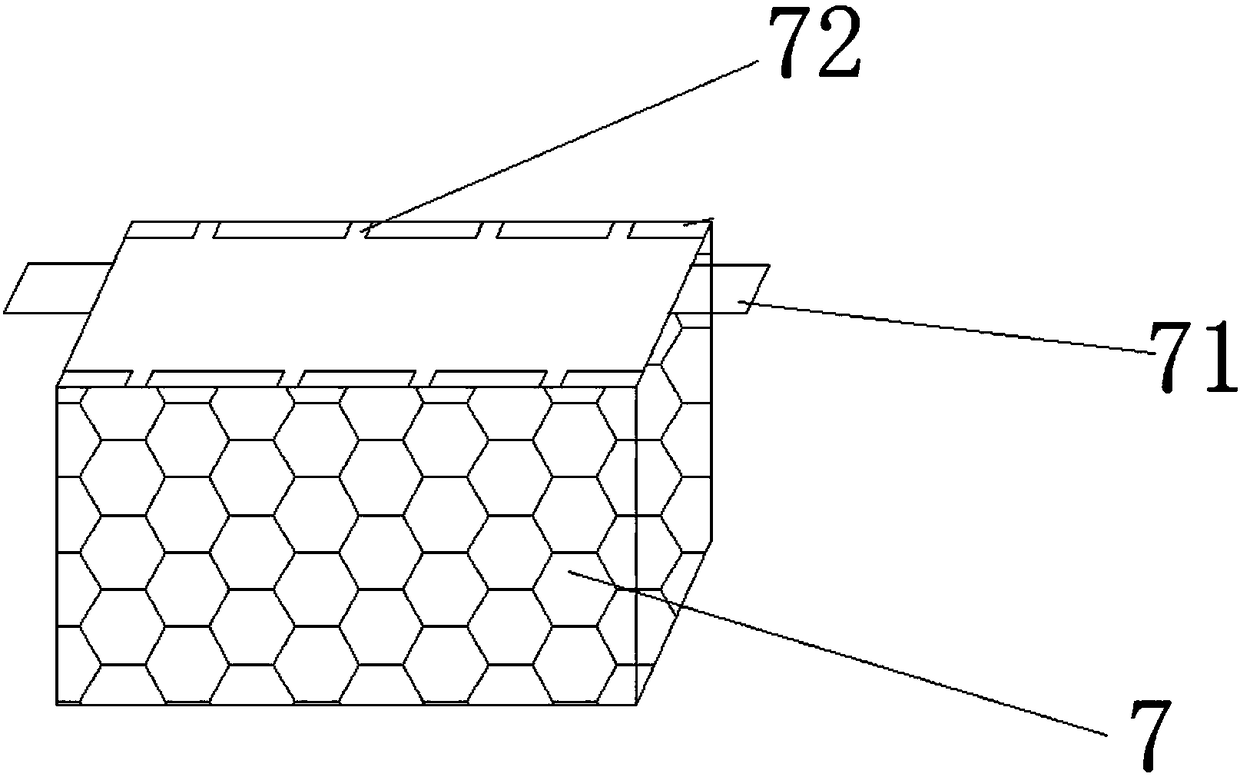

[0023] The bottom of the ultrasonic cleaning box 1 is provided with a water outlet hole, the right side wall of the ultrasonic cleaning box 1 is provided with a water inlet hole, and each side wall of the ultrasonic cleaning box 1 is provided with a fixing rod 12 perpendicular to each side wall , the fixed rod 12 is used to support the cleaning basket 7, and the two sides of the cleaning basket 7 are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com