Treatment process of low-temperature and low-turbidity water with iron and manganese exceeding standards

A treatment process, iron and manganese technology, applied in the field of sewage treatment, can solve the problems that sand filter cannot be 100% filtered, ferric manganese is difficult to adsorb and precipitate, and the chromaticity of factory water will exceed the standard, so as to increase the coagulation effect and reduce manual labor. Strength, the effect of improving the quality of the factory water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

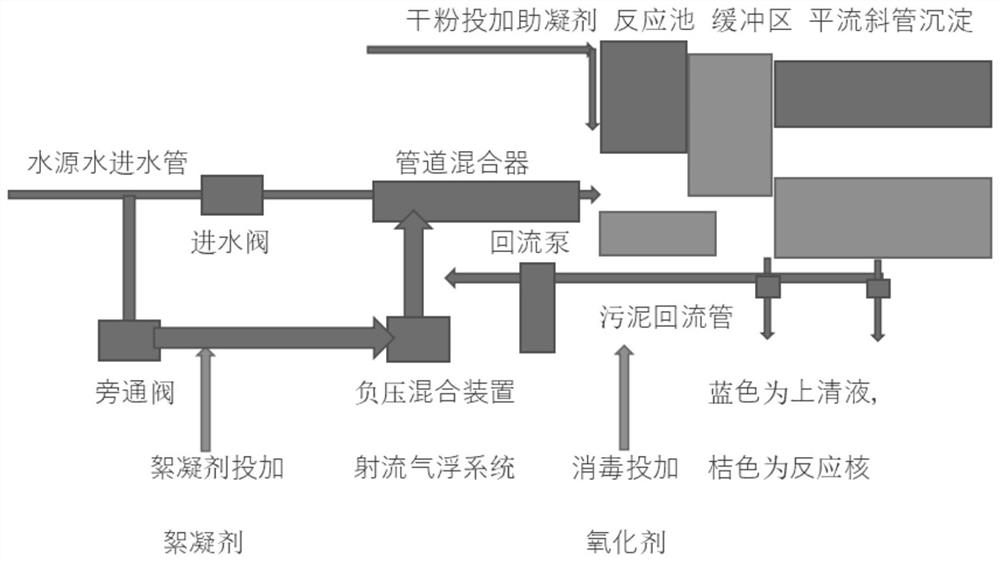

[0032] A treatment process for water with low temperature, low turbidity, and iron and manganese exceeding standards, including water source water air flotation treatment, adding water source water reaction core, adding quicklime powder to the water source water inlet, adding oxidant to the water source water inlet pipeline, and adding water source water Automatic Control System.

[0033] The water source water air flotation treatment is specifically as follows: when the water source water condition has a pressure of 2.5Mpa or more, use the pressure difference induced by the source water to carry out full air flotation or bypass valve control of the source water at a rate of not less than 30%. The flow part is treated by air flotation process.

[0034] The source water reaction core is selected from any one or several of yellow mud slurry, pe particles, activated carbon, and lime particles.

[0035] When increasing the source water reaction core, the filter backwash water bac...

Embodiment 2

[0046] A treatment process for water with low temperature, low turbidity, and iron and manganese exceeding standards, including water source water air flotation treatment, adding water source water reaction core, adding quicklime powder to the water source water inlet, adding oxidant to the water source water inlet pipeline, and adding water source water Automatic Control System.

[0047] The water source water air flotation treatment is specifically as follows: when the water source water condition has a pressure of 2.5Mpa or more, use the pressure difference induced by the source water to carry out full air flotation or bypass valve control of the source water at a rate of not less than 30%. The flow part is treated by air flotation process.

[0048] The source water reaction core is selected from any one or several of yellow mud slurry, pe particles, activated carbon, and lime particles.

[0049] When increasing the source water reaction core, the filter backwash water bac...

Embodiment 3

[0060] A treatment process for water with low temperature, low turbidity, and iron and manganese exceeding standards, including water source water air flotation treatment, adding water source water reaction core, adding quicklime powder to the water source water inlet, adding oxidant to the water source water inlet pipeline, and adding water source water Automatic Control System.

[0061] The water source water air flotation treatment is specifically as follows: when the water source water condition has a pressure of 2.5Mpa or more, use the pressure difference induced by the source water to carry out full air flotation or bypass valve control of the source water at a rate of not less than 30%. The flow part is treated by air flotation process.

[0062] The source water reaction core is selected from any one or several of yellow mud slurry, pe particles, activated carbon, and lime particles.

[0063] When increasing the source water reaction core, the filter backwash water bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com