Resourceful treatment method and device for inorganic salts in industrial wastewater

A technology for industrial wastewater and treatment methods, applied in multi-stage water treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problem that the reduction of working costs has not achieved good results, and achieve the reduction of dosing costs , shorten the process flow, and achieve a large degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be clearly and completely described below.

[0030] In order to solve the above problems, the present invention provides a method and device for recycling inorganic salts in industrial wastewater.

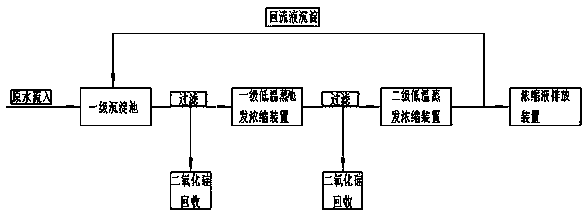

[0031] Such as figure 1 As shown, in order to achieve the technical purpose, the technical solution of the present invention is: a resource-based treatment method for inorganic salts in industrial waste water, characterized in that it comprises the following steps:

[0032] S1: Lead the raw water into the primary sedimentation tank, and then carry out preliminary precipitation, and precipitate and recover part of the silica;

[0033] S2: After the preliminary precipitation in step S1, the remaining clear liquid obtained after the preliminary precipitation is circulated to the first-level low-temperature evaporation concentration device, so that the soluble silicon in it is concentrated to supersaturation and then precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com