Oil well polished rod kinetic energy dosing device

A technology of dosing device and polished rod, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of ineffective dosing of oil well casing, inability to achieve stable addition of chemicals, uneven use of chemicals, etc. , to achieve the effect of reducing the cost of dosing, simple installation and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

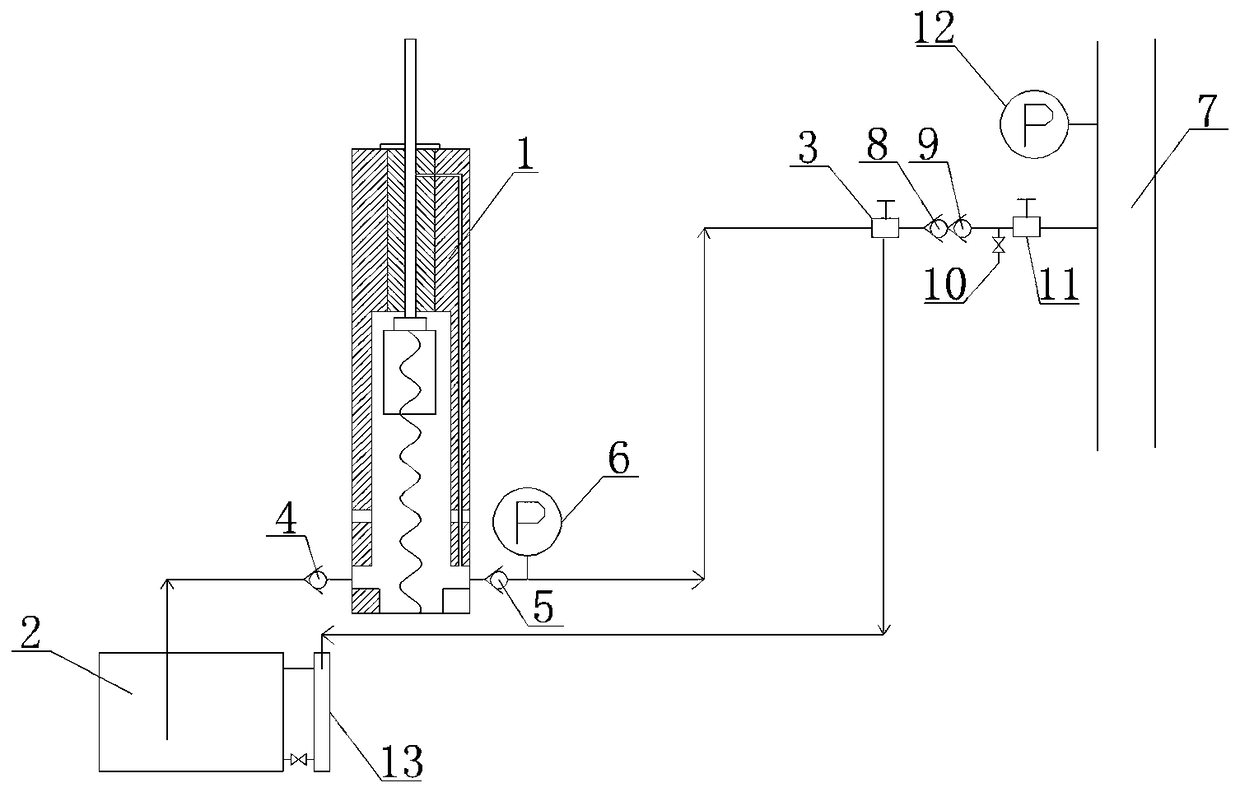

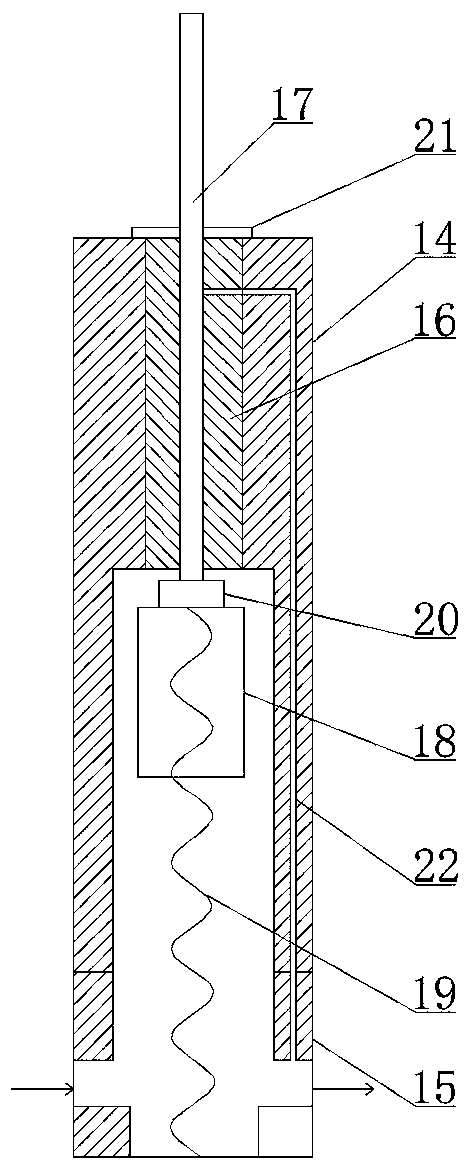

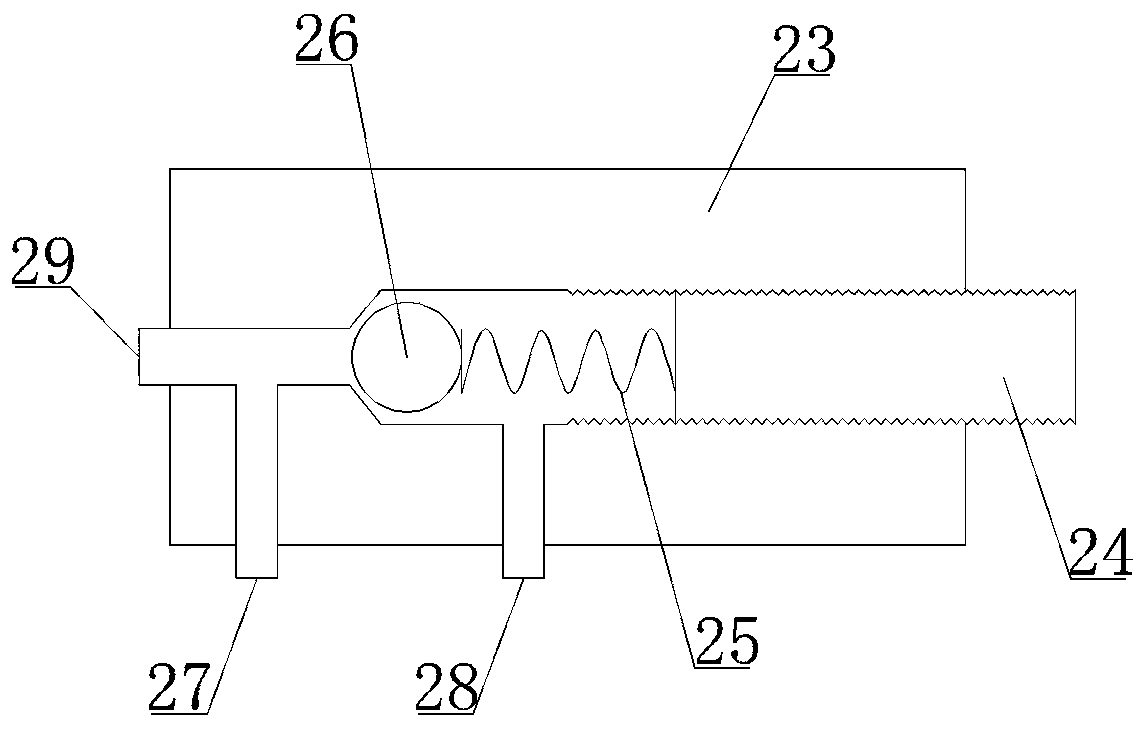

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Oil well polished rod kinetic energy dosing device, including oil well polished rod kinetic energy dosing device, including dosing pump 1, dosing barrel 2, pressure regulating valve 3, characterized in that: the inlet pipeline of the dosing pump 1 is connected to the dosing barrel 2, The inlet of the dosing pump 1 is provided with a one-way valve A4, the outlet pipeline of the dosing pump 1 is connected to the pressure regulating valve 3, the outlet of the dosing pump 1 is provided with a one-way valve B5, and a pressure gauge A6 is arranged behind the one-way valve B5 , the outlet pipeline of the pressure regulating valve 3 is connected to the well pipeline 7, the well pipeline 7 is provided with a pressure gauge B12, and the outlet of the pressure regulating valve 3 is successively provided with a check valve C8, a check valve D9, a purge valve 10, The on-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com