Industrial brine resource utilization method and system

A concentrated brine and resource utilization technology, which is applied in the field of resource utilization of industrial concentrated brine, can solve the problems of large dosage and high cost of pretreatment chemicals, reduce the cost of dosing, reduce scaling problems, and improve the degree of resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of concentrated brine in a coal chemical enterprise is shown in Table 1, the main component is Na 2 SO 4 and NaCl.

[0026] Table 1 Water quality characteristics of concentrated brine in a coal chemical enterprise

[0027] project

quantity

pH

8-9

Na + (mg / L)

18130

K + (mg / L)

263

Ca 2+ (mg / L)

112

Mg 2+ (mg / L)

36

Cl - (mg / L)

15731

SO 4 2- (mg / L)

16713

HCO 3 - (mg / L)

95

TDS (mg / L)

49980

TOC (mg / L)

152

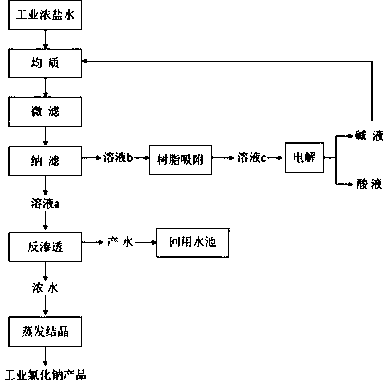

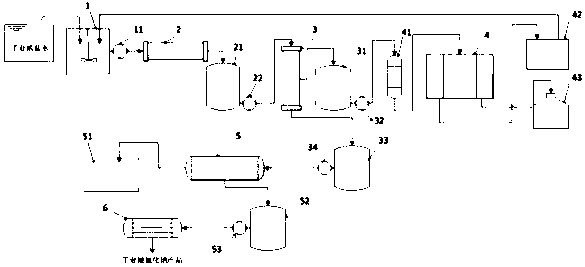

[0028] as attached figure 1 As shown, the steps of resource utilization of the concentrated brine are:

[0029] (1) Mix industrial concentrated brine and lye so that the pH of the mixed solution is 11.5, the lye is sodium hydroxide solution, and the volume ratio of concentrated brine to lye is 7:1;

[0030] (2) The mixed solution obtained in step (1) enters the microfiltration system to obtain microfiltration effl...

Embodiment 2

[0037] The composition of concentrated brine in a power plant is shown in Table 2, the main components are NaCl and NaCl 2 SO 4 .

[0038] Table 2 Water quality characteristics of concentrated brine in a power plant

[0039] project

quantity

pH

4-5

Na + (mg / L)

15520

K + (mg / L)

630

Ca 2+ (mg / L)

316

Mg 2+ (mg / L)

152

Cl - (mg / L)

11600

SO 4 2- (mg / L)

20800

TDS (mg / L)

49300

TOC (mg / L)

62

[0040] The steps of resource utilization of the concentrated brine are:

[0041] (1) Mix industrial concentrated brine with lye so that the pH of the mixed solution is 11.5, the lye is sodium hydroxide solution, and the volume ratio of concentrated brine to lye is 6:1;

[0042] (2) The mixed solution obtained in step (1) enters the microfiltration system to obtain microfiltration effluent;

[0043] (3) The microfiltration effluent of step (2) is adjusted to a pH valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com