A kind of pretreatment method of tannery wastewater

A technology for tanning wastewater and pretreatment, which is applied in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , increase the processing load and maintenance difficulty of the subsequent adjustment tank and coagulation sedimentation tank, cannot effectively reduce the dosage of chemicals and the amount of sludge generated, etc., so as to facilitate comprehensive utilization and final disposal, facilitate stable operation, and reduce dosing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

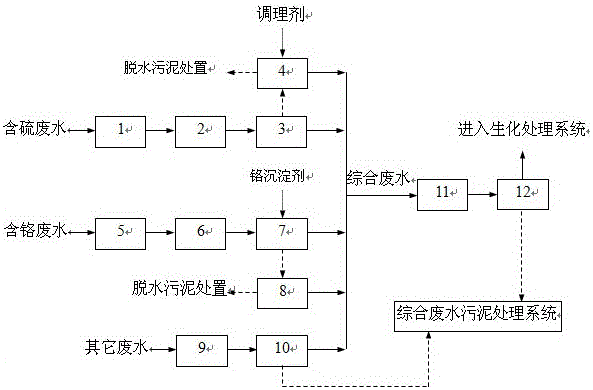

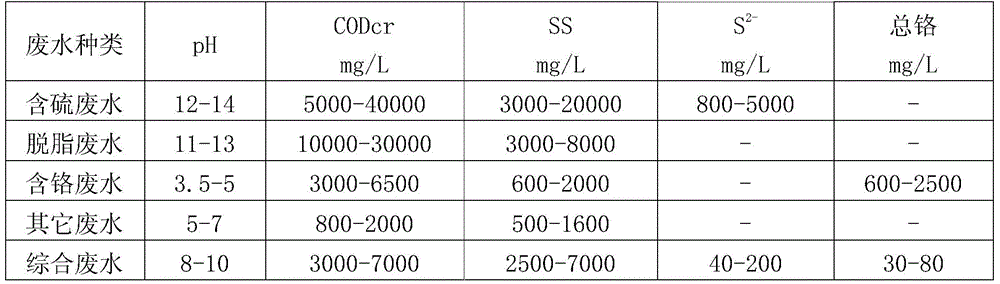

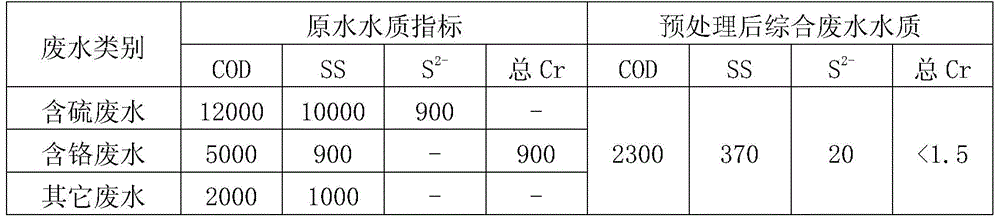

[0033] see figure 1 The process flow of the pretreatment method of the tannery wastewater of the present invention is shown, and the present embodiment comprises the following steps:

[0034] (1) After the sulfur-containing wastewater collected in the tanning production process is screened by the sulfur-containing wastewater grid 1 to remove large particles of debris, it flows to the sulfur-containing wastewater conditioning tank 2, and then is lifted to the sedimentation tank 3 for concentration and precipitation, and the precipitation is carried out for 6 hours. After (at least 6 hours) the supernatant is discharged into the comprehensive wastewater treatment system; after the concentrated sludge is adjusted to pH 10 by adding sulfuric acid (the maximum pH value is 10), the plate and frame filter press 4 is used for dehydration, The dehydration period is 4 hours, and the dehydrated clear liquid is discharged into the integrated wastewater treatment system, and the sludge is ...

Embodiment 2

[0041] see figure 1 The process flow of the pretreatment method of the tannery wastewater of the present invention is shown, and the present embodiment comprises the following steps:

[0042] (1) After the sulphur-containing wastewater collected in the tanning production process is screened by the grid 1 to remove large particles of debris, it flows to the sulphur-containing wastewater conditioning tank 2, and then is lifted to the sedimentation tank 3 for concentration and precipitation, and the supernatant is precipitated after 8 hours The liquid is discharged into the comprehensive wastewater treatment system; after the concentrated sludge is adjusted to pH 9 by adding sulfuric acid, it is dewatered by a plate and frame filter press 4, and the dewatering cycle is 3h, and the dewatered clear liquid is discharged into the comprehensive wastewater treatment system. Further disposal of sludge after outbound transportation;

[0043] (2) After the chrome-containing waste water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com