Banknote printing gravure ink wastewater treatment process

A technology for gravure printing ink and wastewater treatment, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Production and other issues, to achieve the effect of benefiting cost control, shortening processing costs, and reducing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

[0039] In the picture:

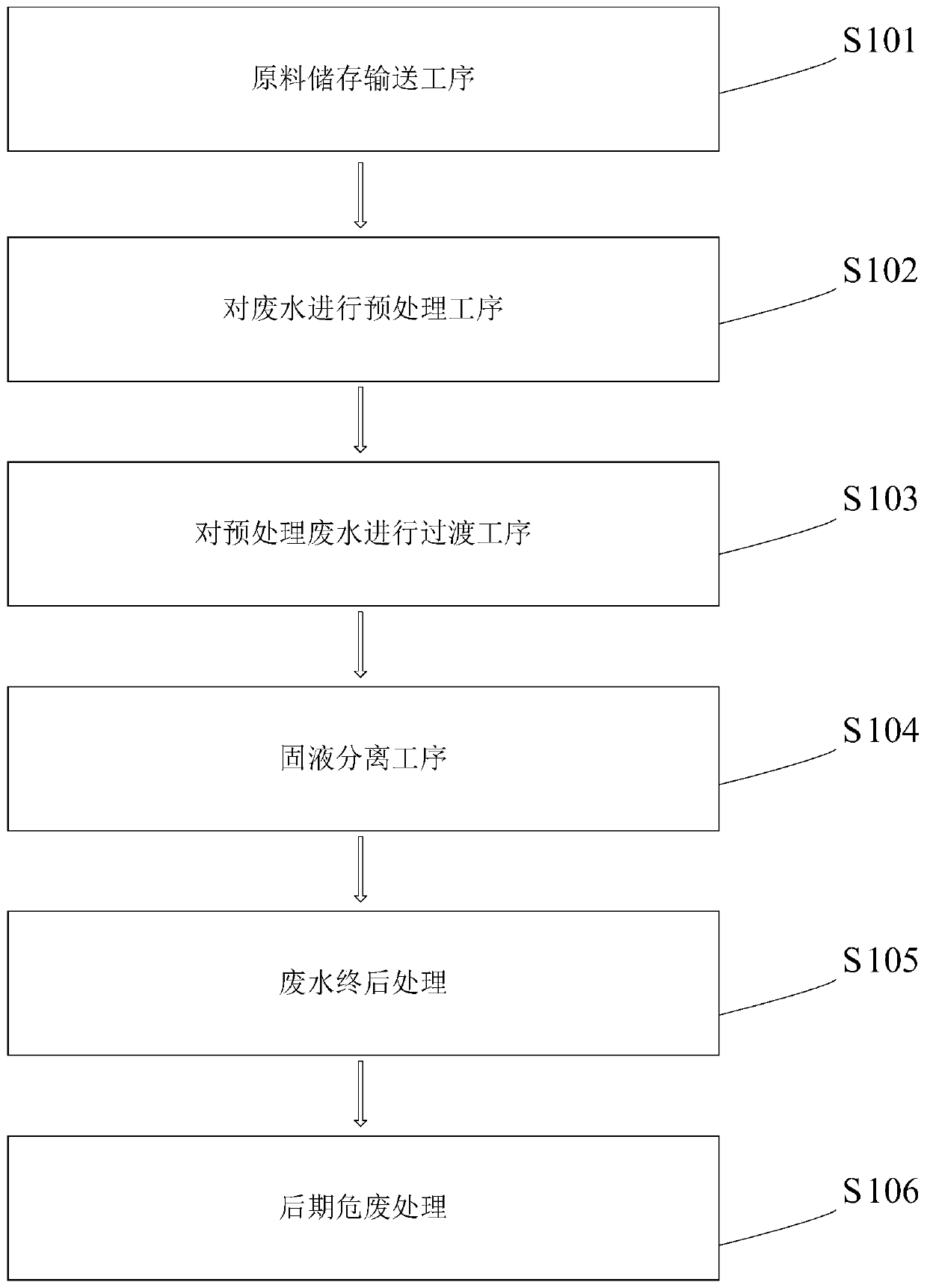

[0040] as attached figure 1 shown

[0041] A kind of banknote printing gravure printing ink wastewater treatment process specifically comprises the following steps:

[0042] S101: Raw material storage and transportation process, the storage and transportation system mainly includes two kinds of reaction chemical storage and quantitative pumping to the downstream system: one is neutralizing conditioner liquid, the main component is ferric sulfate, and adding polymerization within a reasonable quality range Ferric sulfate, ferrous sulfate and sodium sulfate can quickly solidify the ink and reduce the PH and COD in the ink wastewater; the other is a flocculant, which makes the suspended particles in the water and Destabilization and flocculation of water-soluble substances containing negatively charged groups have obvious effects in decolorization, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com