Oil-water medium corrosion inhibitor for corrosion control on oilfield-production oil gas water collection and transmission system

A technology of gathering and transportation system and corrosion control, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as more stringent requirements for corrosion inhibitor performance, high salinity of separated water, affecting crude oil dehydration, etc. To achieve the effect of good pharmaceutical effect, high input-output ratio, and low cost of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

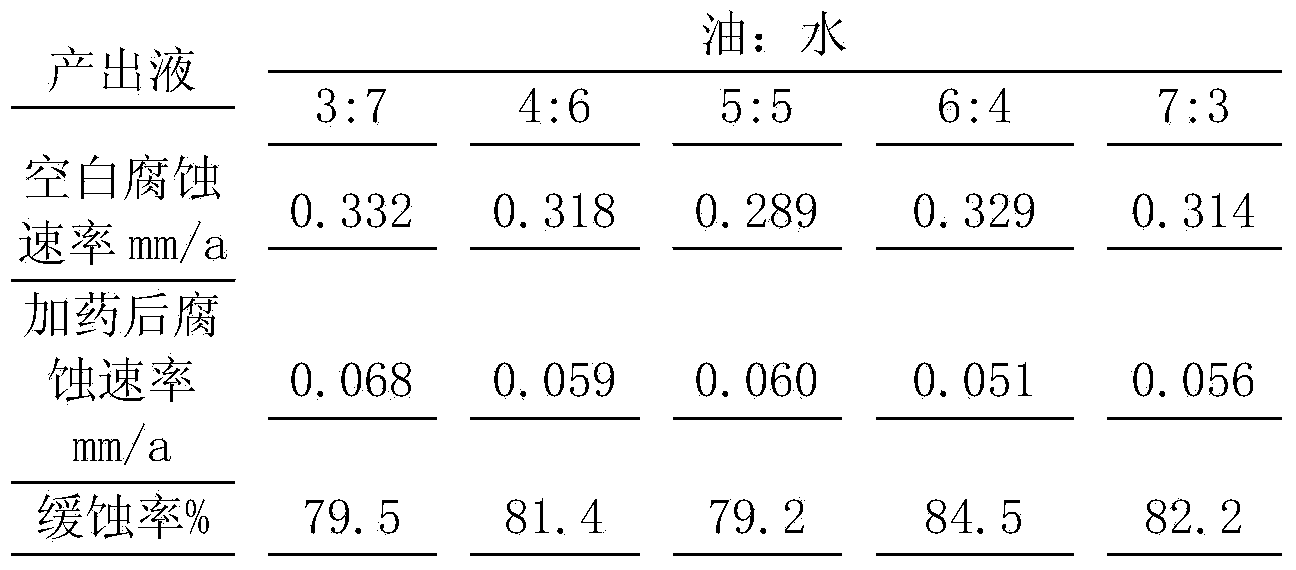

Embodiment 1

[0024] Formula composition: based on 100% of composition mass, 10% of bisquaternary ammonium salt of imidazoline and alkyl tertiary ammonium, 4% of mercaptoalkanoic acid, 5% of organic urea compound, 4% of thiocyanate, and quaternary ammonium salt of alkyl tertiary ammonium Ammonium salt 7%, fatty alcohol polyoxyethylene ether 3%, alkylphenol polyoxyethylene ether 2%, and the rest is water.

[0025] The synthesis process of the double quaternary ammonium salt of imidazoline and alkyl tertiary amine is: add dodecyl tertiary amine into the reaction kettle, then dropwise add equimolar p-dichlorobenzyl, and slowly heat up to 120°C after the dropwise addition , the stirring reaction time is 4 hours, and then equimolar naphthenic acid imidazoline is added dropwise, and the temperature is slowly raised to 150°C after the dropwise addition, and the stirring reaction time is 6 hours.

[0026] The optimized mass ratio of mercaptoalkanoic acid and its mixture is thioglycolic acid: mercap...

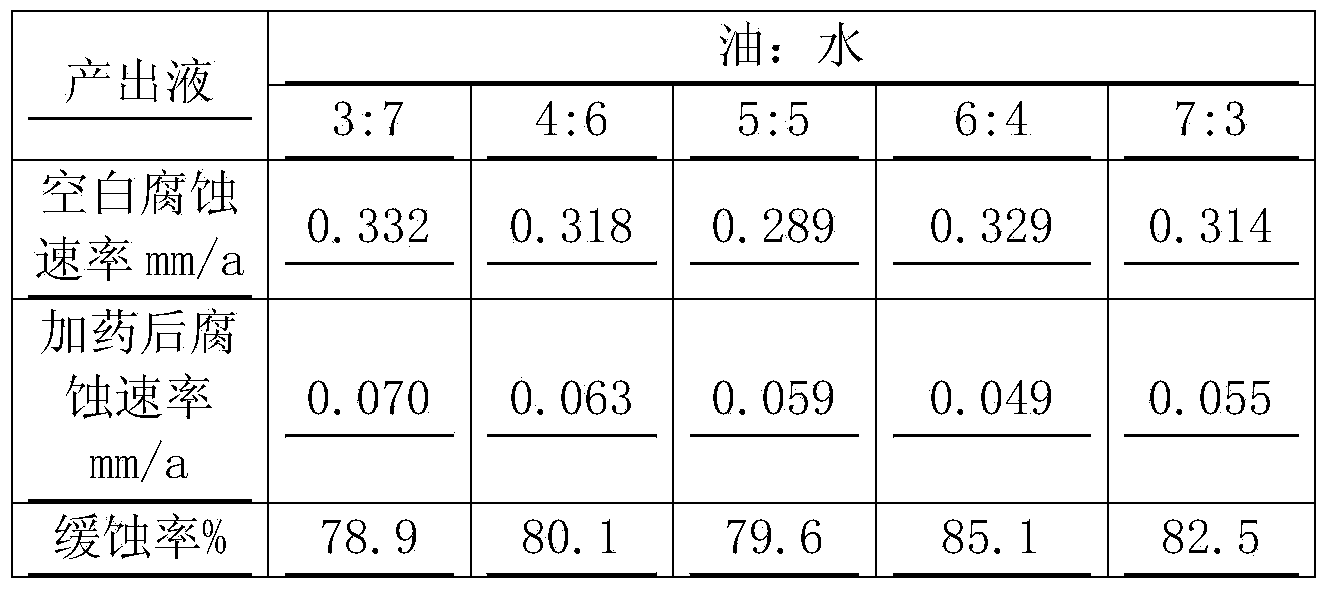

Embodiment 2

[0035] Formula composition: based on 100% of the composition mass, 12% of bisquaternary ammonium salt of imidazoline and alkyl tertiary ammonium, 3% of mercaptoalkyl acid, 4% of organic urea compound, 3% of thiocyanate, and quaternary ammonium salt of alkyl tertiary ammonium Ammonium salt 8%, fatty alcohol polyoxyethylene ether 2%, alkylphenol polyoxyethylene ether 4%, and the rest is water.

[0036] The synthesis process of the double quaternary ammonium salt of imidazoline and alkyl tertiary amine is as follows: add octaalkyl tertiary amine to the reaction kettle, then add equimolar p-dichlorobenzyl dropwise, and slowly heat up to 120°C after the dropwise addition, The stirring reaction time is 4 hours, and then equimolar oleic acid imidazoline is added dropwise, and the temperature is slowly raised to 150°C after the dropwise addition, and the stirring reaction time is 6 hours.

[0037] The mass ratio of the components in the optimized mixture of the mercaptoalkanoic acid i...

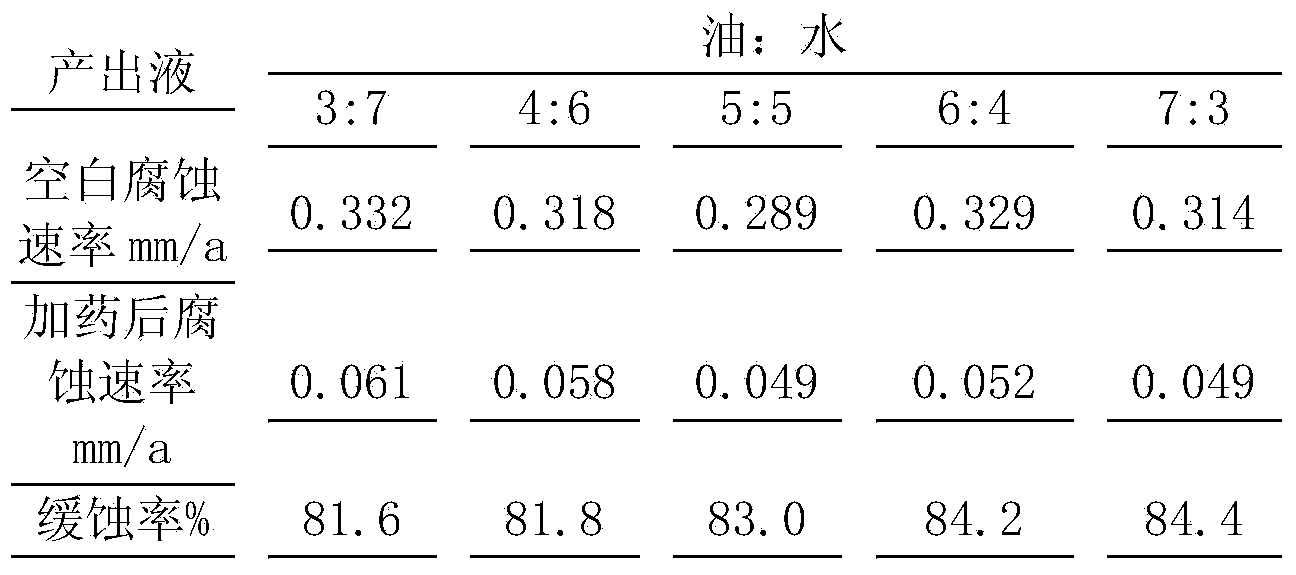

Embodiment 3

[0046] Formula composition: based on 100% of composition mass, 8% of imidazoline and alkyl tertiary ammonium diquaternary ammonium salt, 5% of mercaptoalkyl acid, 6% of organic urea compound, 5% of thiocyanate, alkyl quaternary ammonium Ammonium salt 10%, fatty alcohol polyoxyethylene ether 5%, and the rest is water.

[0047] Among them, the synthesis process of the double quaternary ammonium salt of imidazoline and alkyl tertiary amine is: add octaalkyl tertiary amine in the reaction kettle, then dropwise add equimolar p-dichlorobenzyl, slowly heat up to 120°C after the dropwise addition, The stirring reaction time was 4 hours, and then an equimolar imidazoline laurate was added dropwise, and the temperature was slowly raised to 150°C after the dropping, and the stirring reaction time was 6 hours.

[0048] The mass ratio of each component in the optimized mixture of mercaptoalkanoic acid is mercaptoacetic acid:mercaptopropionic acid=8:2.

[0049] The mass ratio of each compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com