Corrosion inhibitor and preparation method thereof

A technology of corrosion inhibitors and surfactants, applied in the field of high temperature resistant corrosion inhibitors and its preparation, can solve the problems of inconvenient use of corrosion inhibitors, achieve good acid gas corrosion resistance, excellent resistance to general corrosion and localized corrosion , Good anti-H2S hydrogen embrittlement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 250mL three-necked grinding bottle with a condensing reflux tube, add sinapinic acid, diethylenetriamine and aluminum oxide as a catalyst, and at the same time add water-carrying agent xylene to stir and reflux, react for 4h to 6h, and the reaction temperature is 180 °C to 200 °C, distill off xylene under reduced pressure at 140 °C to obtain an intermediate product of imidazoline.

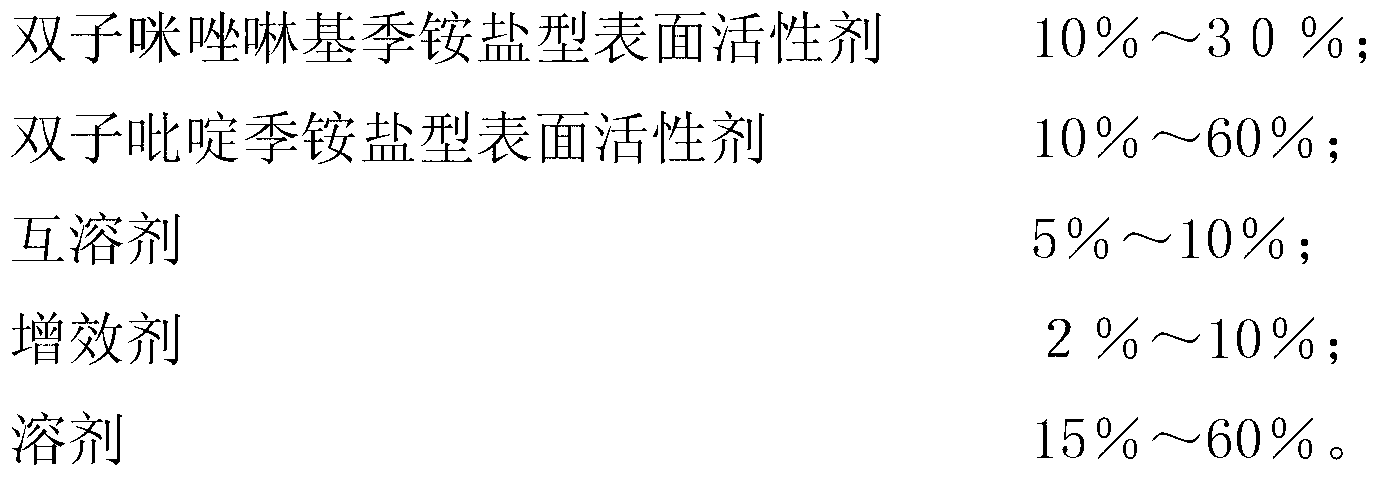

[0023] Add benzyl chloride to the above intermediate product and react at 90-100°C for 3 hours, then add 1,4 dichlorobutane to carry out splicing reaction, react for 3h-4h, and the reaction temperature is 80°C-90°C to obtain the final product It is a brown thick liquid, and the mass percentage of active ingredients is 81%-85%. The structural formula of the active ingredient is as follows:

[0024]

[0025] Gemini imidazoline quaternary ammonium salts with other structures can be obtained by replacing sinapinic acid with oleic acid or other fatty acids, which will not be repeated her...

Embodiment 2

[0027] Add pyridine and triethylamine to a 250mL three-neck ground flask with a condensing reflux tube, and at the same time add water-carrying agent xylene for stirring and reflux, react for 3h to 4h, and the reaction temperature is 140°C to 180°C, at 120°C The xylene was distilled off under reduced pressure to obtain the intermediate product of pyridine base.

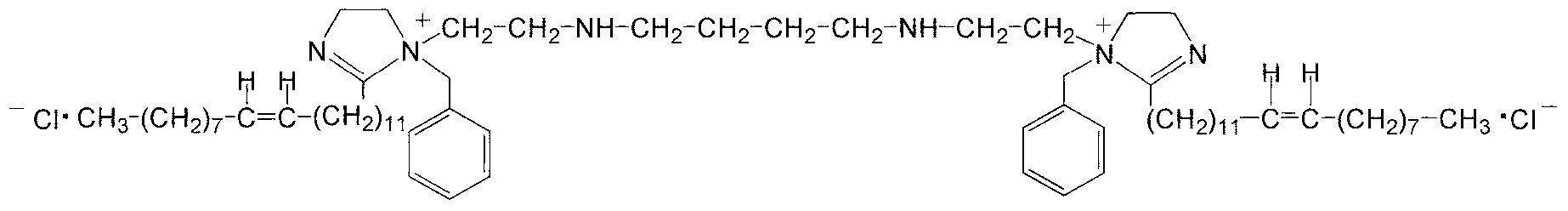

[0028] Add benzyl chloride to the above intermediate product, react at 120-140°C for 3-4 hours, then add 1,4 dichlorobutane to carry out splicing reaction, react for 2h-3h, and the reaction temperature is 80°C-90°C , the final product obtained is a brown thick liquid, and the mass percentage of the active ingredient is 79%-81%. The structural formula of the active ingredient is as follows:

[0029]

[0030] Gemini pyridinium quaternary ammonium salts of other structures can be obtained by replacing pyridine with pyridine homologues, which will not be repeated here.

Embodiment 3

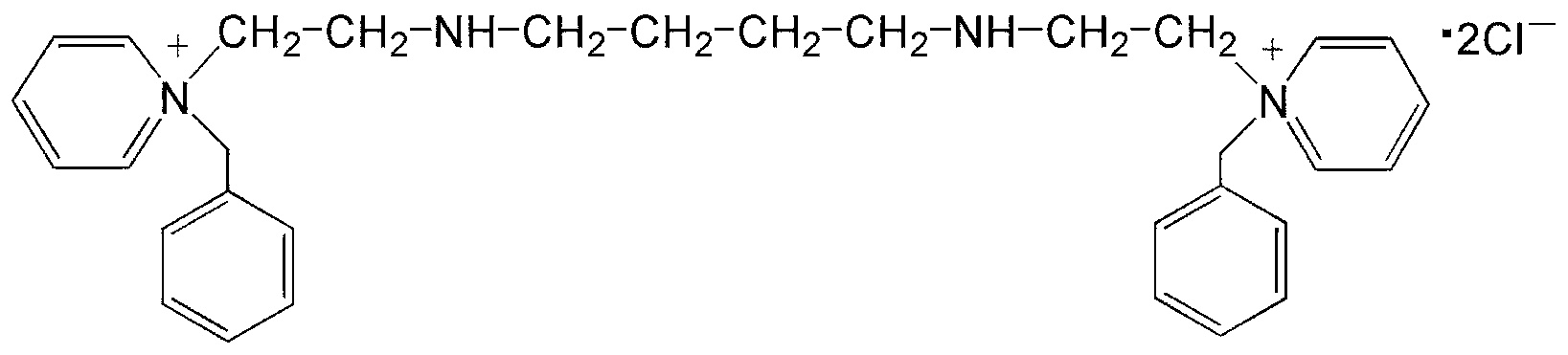

[0032] In the reactor, add the following components in mass percentage successively:

[0033]

[0034] Stir well at 50-60°C for 1-2 hours to prepare corrosion inhibitor.

[0035] The performance test of the corrosion inhibitor obtained in this example was carried out at 90°C, and the results are shown in Table 1:

[0036] Table 1 Performance test of the corrosion inhibitor obtained in Example 1

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com