Adjustable type fixed clamping and conveying system and method for aluminum profile machining

A technology of aluminum profile processing and conveying system, applied in the field of aluminum profile processing, can solve the problem of inconvenient use of the device, and achieve the effects of convenient height, improved use effect, and convenient transportation and movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

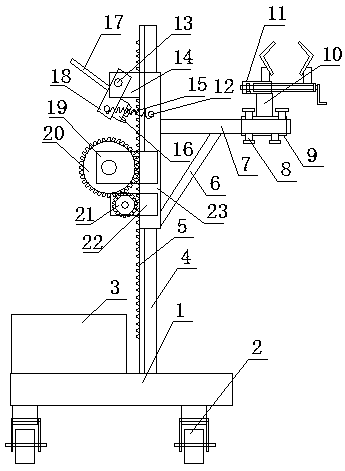

[0020] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

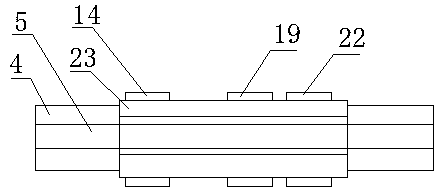

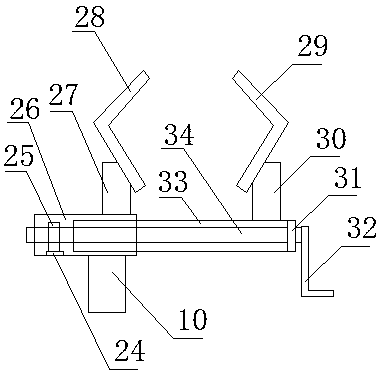

[0021] Such as figure 1 , figure 2 The adjustable fixed clamping and conveying system for processing aluminum profiles shown includes a mobile platform plate 1, and a supporting square column 4 is fixedly connected to the middle right side of the mobile platform plate 1; a conveying rack is welded to the middle left side of the supporting square column 4 5; the other side of the support square column 4 away from the conveying rack 5 is snapped into and installed with a movable frame 23; the two outer walls of the movable frame 23 are respectively welded with a column support plate 14, a large gear support plate 19 and a Pinion support plate 22; column support plate 14 is provided with column plate 18, and the upper part of column plate 18 utilizes column fixing stud 13 to be supported and installed; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com