Tapered travelling-wave electromagnetic wave concentrator

A concentrator and traveling wave technology, applied in the field of conical traveling wave electromagnetic concentrator, can solve the problems of large maintenance of moving parts and transmission system, unsatisfactory separation effect, complex structure of magnetic concentrator, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

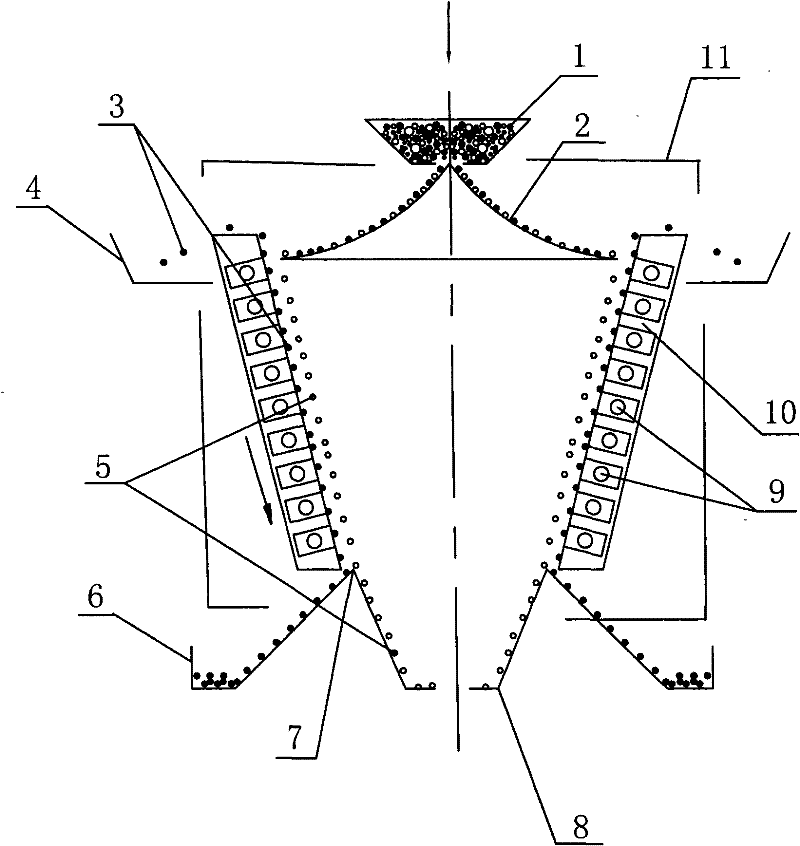

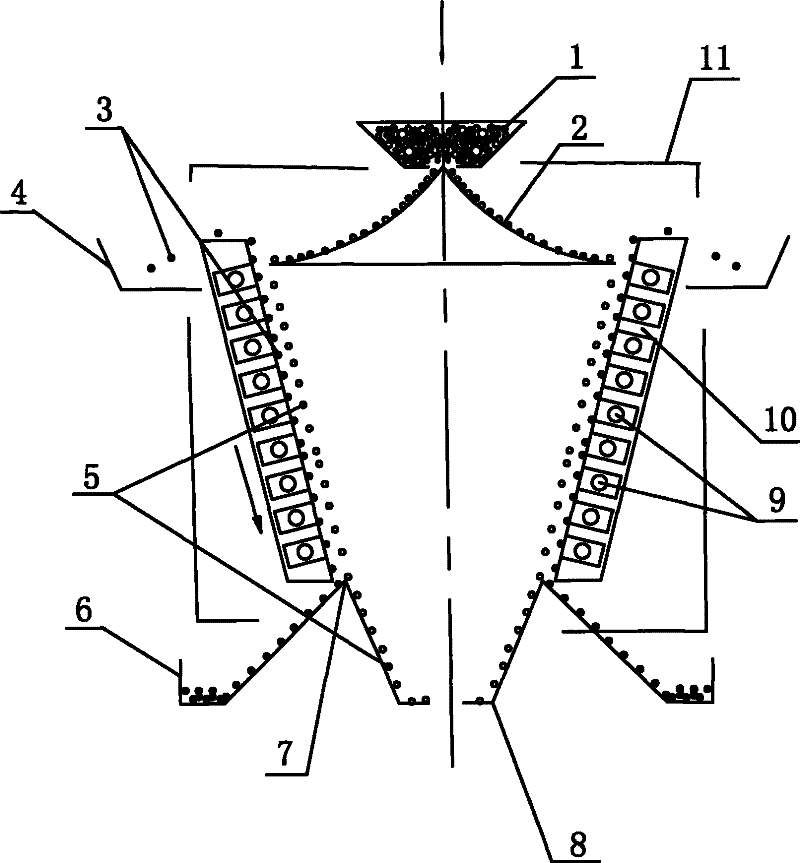

[0008] A conical traveling wave electromagnetic concentrator, comprising a frame 11, a feed hopper 1, a tailings hopper and a concentrate hopper, a material distribution cone 2 is arranged below the feed hopper 1, and the material distribution cone 2 is mounted on a conical linear motor On the upper opening end of the conical linear motor 10, an electromagnetic coil 9 is embedded in the groove of the conical linear motor 10. The inner side of the ore cone 7 and the ore-distributing cone 7 is a central conical tailings bucket 8, and the outer side of the ore-dividing cone 7 is the lower concentrate bucket 6. The magnetic ore 3 and the non-magnetic ore 5 enter from the feed hopper 1. After sorting, the magnetic ore 3 enters the upper and lower concentrate hoppers, and the non-magnetic ore 5 falls into the central conical tailings hopper 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com