Swing-type diameter-variable envelope forming full-section drill tool

A swinging, full-section technology, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of difficult manual excavation, complex cutter head structure, and large floor space, reducing preparation and transition time, Improve the effective use efficiency and occupy a small area of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

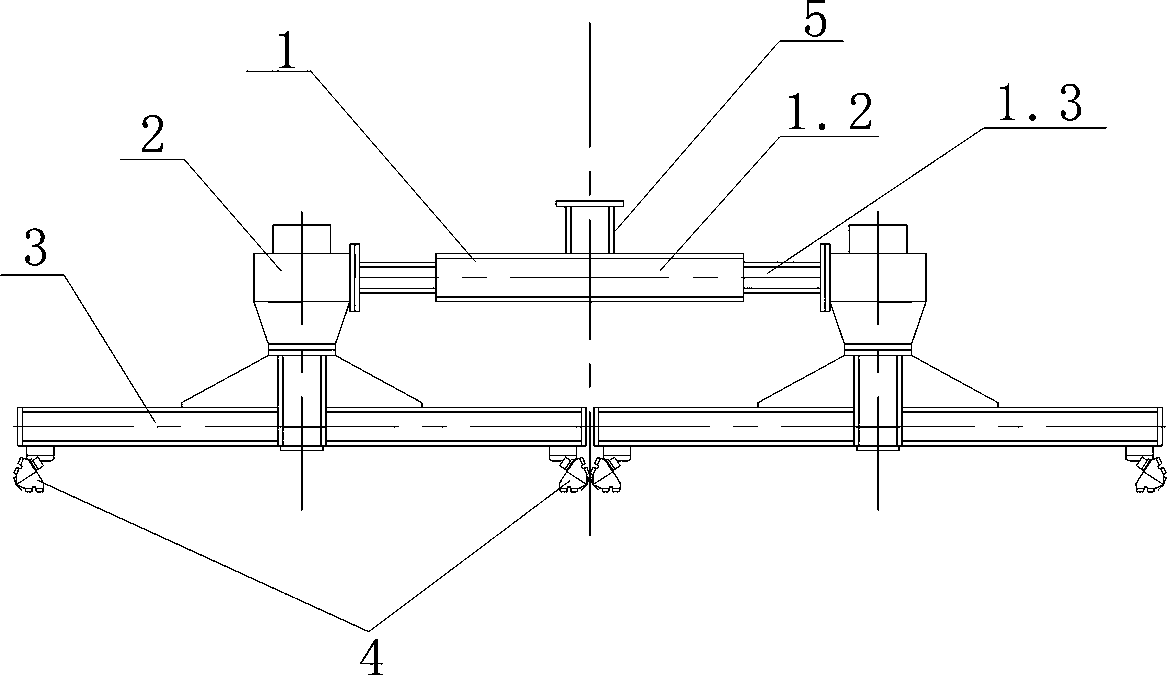

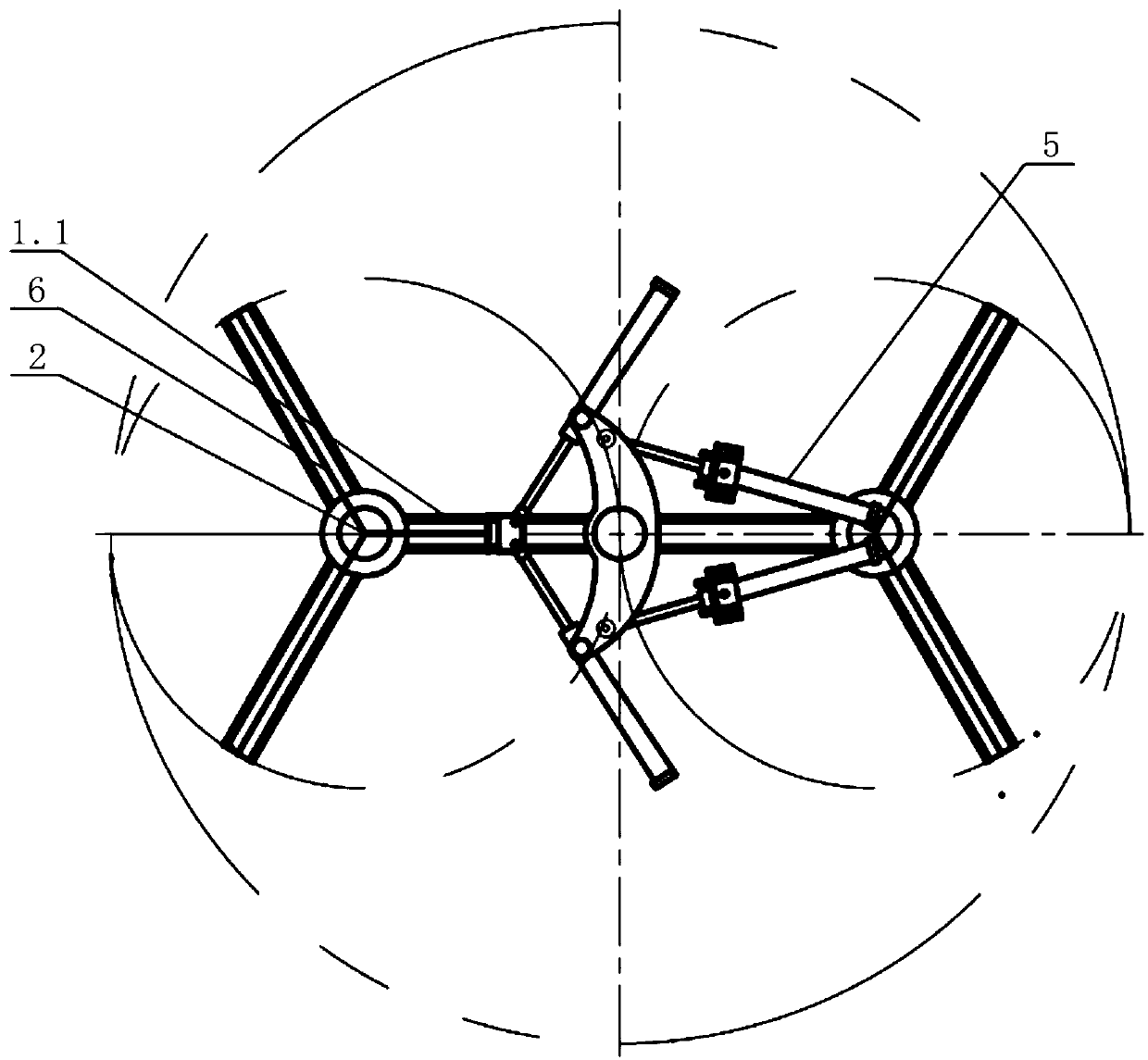

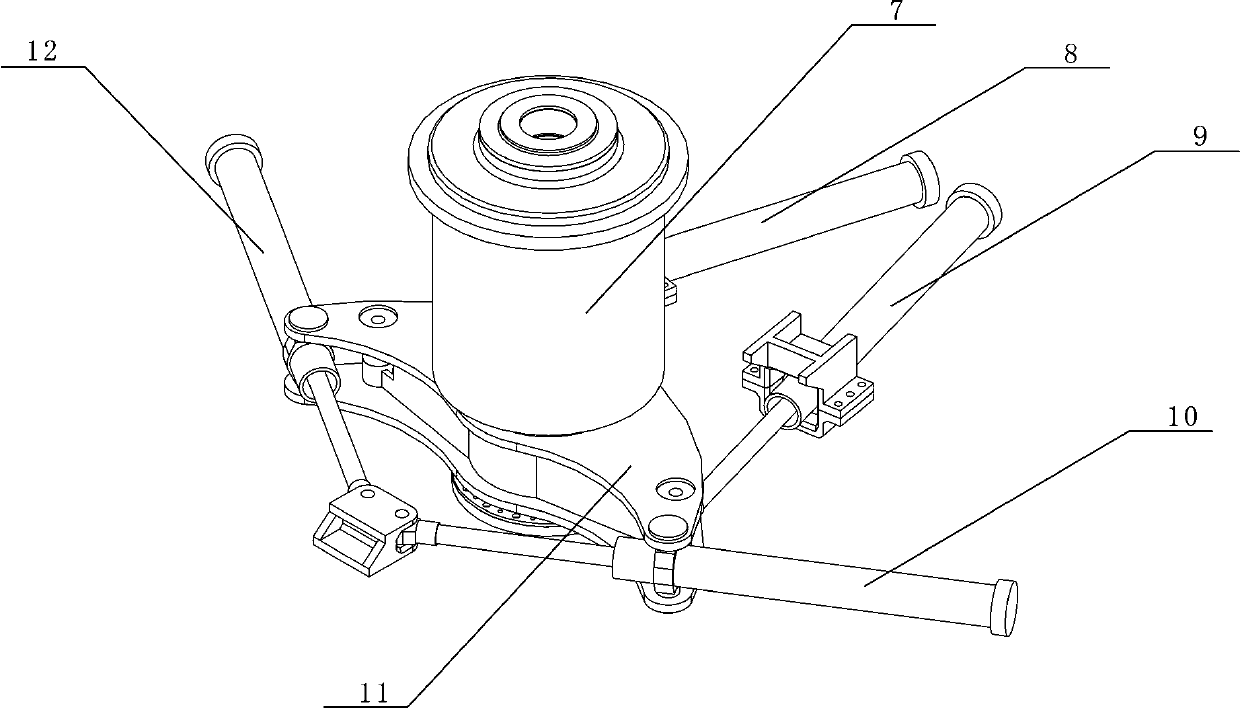

[0024] Such as Figure 1~6 , 11, the swing-type variable-diameter envelope forming full-section drilling tool includes a swing mechanism 5, a drill arm 1, a driving device 2 and a drill body 3, and the swing mechanism includes an outer shell 7, a first hydraulic pressure Cylinder 8, the second hydraulic cylinder 9, the third hydraulic cylinder 10 and the fourth hydraulic cylinder 12, a coaxial drive shaft 15 is installed in the outer shell 7, the upper and lower parts of the drive shaft are connected with the inner wall of the shell by bearings, and The lower part of the drive shaft protrudes from the outer casing, and the connecting plate 11 is set on the drive shaft outside the outer casing. The cylinder barrels of the first hydraulic cylinder 8 and the second hydraulic cylinder 9 are respectively hinged with two co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com