Patents

Literature

33results about How to "High coordinate accuracy" patented technology

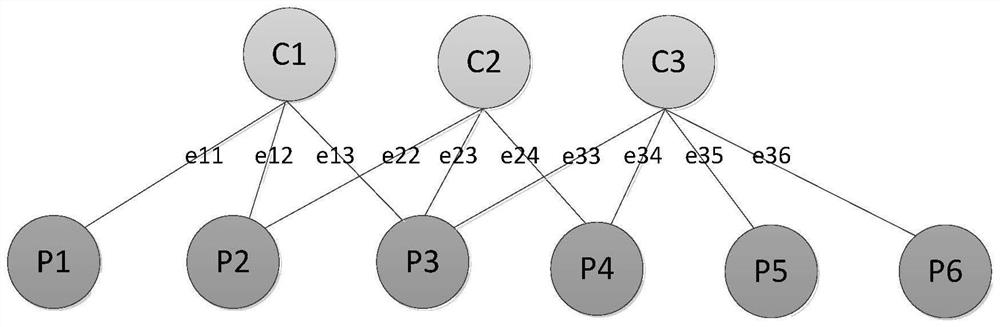

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

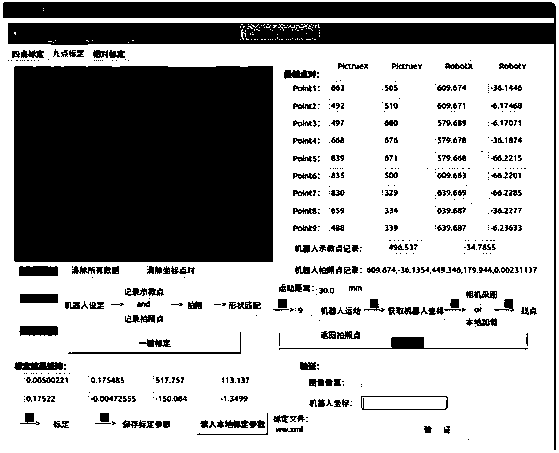

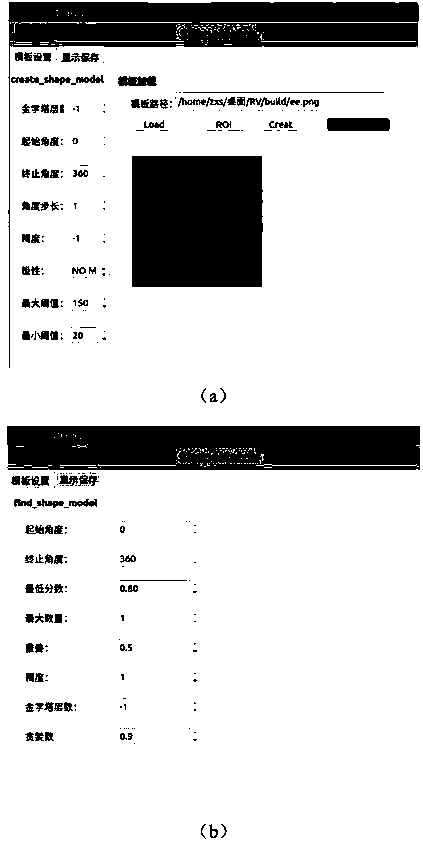

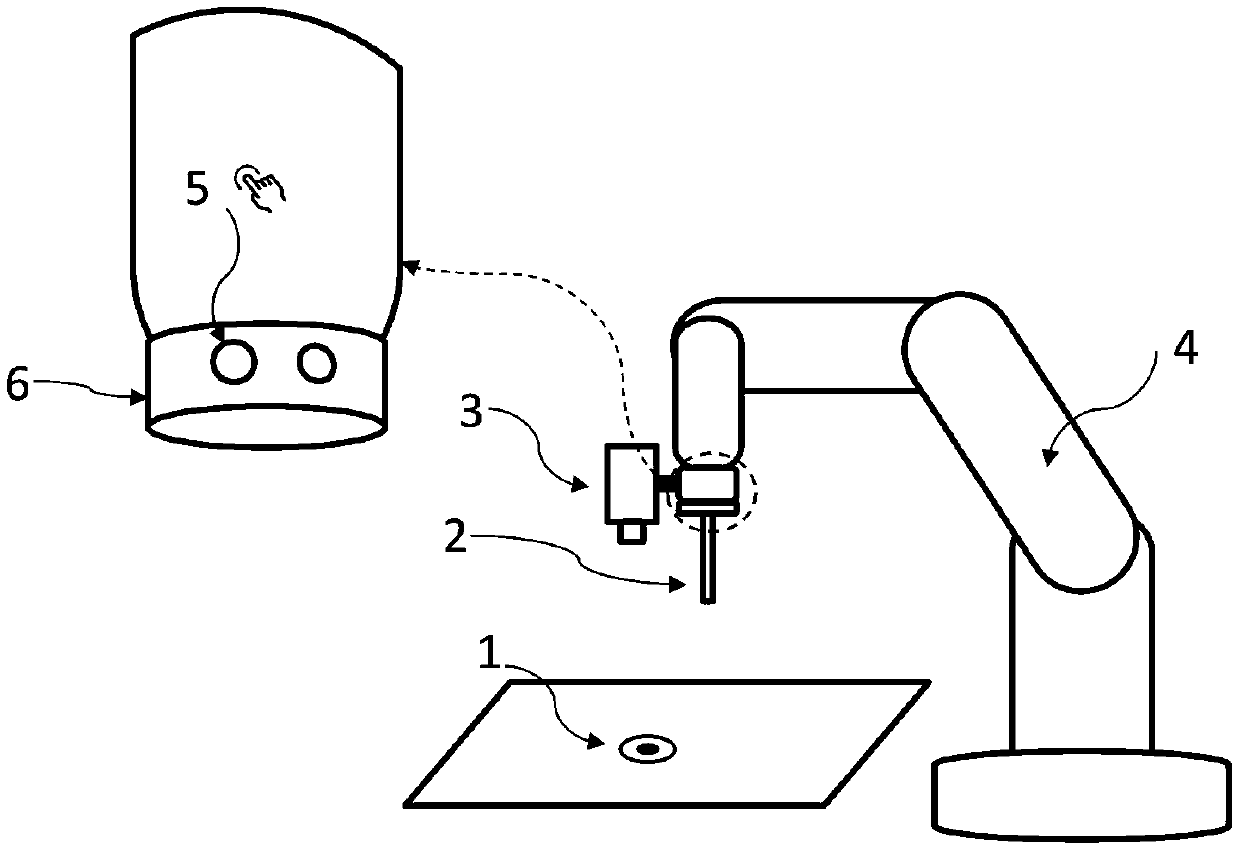

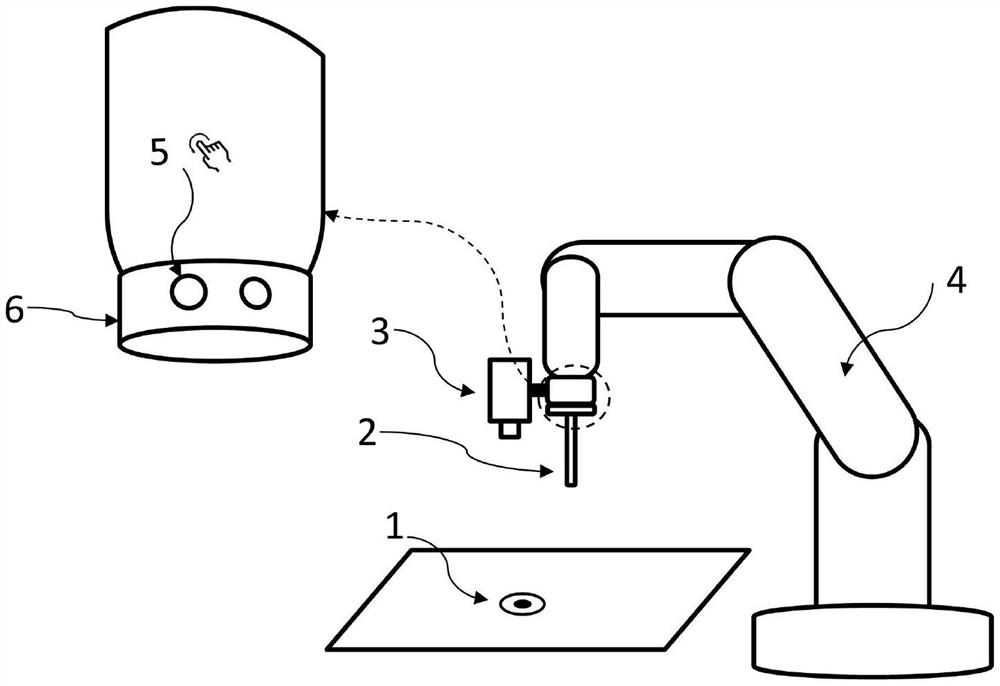

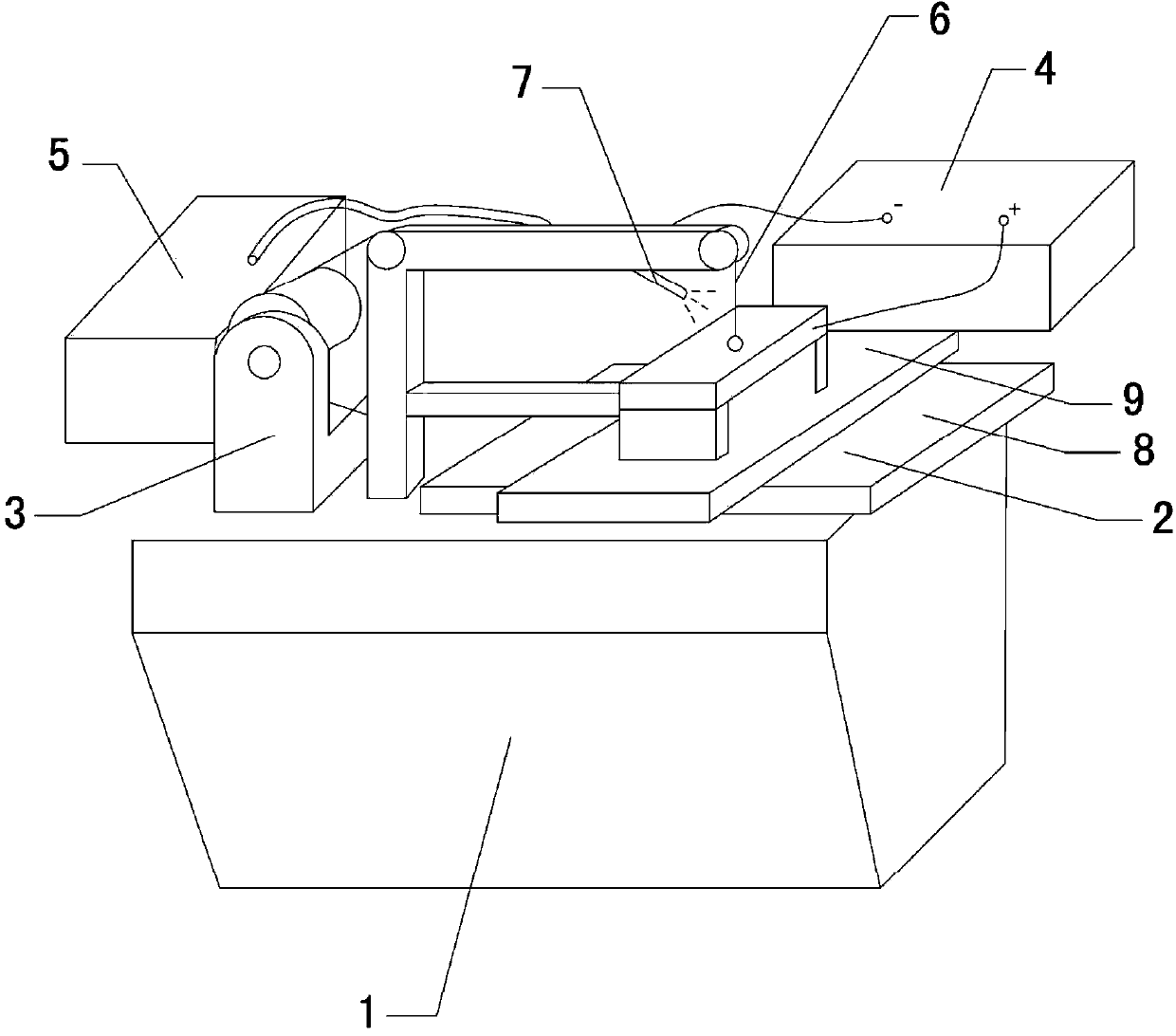

Collaborative robot hand-eye relation automatic calibration device and method

ActiveCN110497386AImprove calibration efficiencySimplify the calibration processProgramme-controlled manipulatorRobot handComputer graphics (images)

The invention provides a collaborative robot hand-eye relation automatic calibration device and method. The calibration device comprises a collaborative robot force control pulling teaching button, acalibration probe, a calibration plate with a marker and a calibration system, wherein the calibration system is mainly used for controlling the robot button to move according to a preset track; target points in the preset track automatically acquire pixel coordinates of the center point of the marker and coordinate dot pairs of a robot; and calibration parameters are calculated according to the obtained multiple dot pairs. The calibration method comprises the steps of placing the calibration plate; pulling the collaborative robot to a teaching point and recording coordinates of the robot; pulling the collaborative robot to an initial photographing point, recording the coordinates of the robot and configuring a matched template; controlling the robot to continuously change the photographing point and acquiring the coordinates of the robot and the pixel coordinate dot pairs of the marker; and calculating the calibration parameters. Through the collaborative robot hand-eye relation automatic calibration device and method, the hand-eye relation of the collaborative robot can be conveniently and quickly calibrated, the calibration precision is high, and the collaborative robot hand-eyerelation automatic calibration device and method have the important significance in industrial grabbing and application of the collaborative robot.

Owner:SIASUN CO LTD

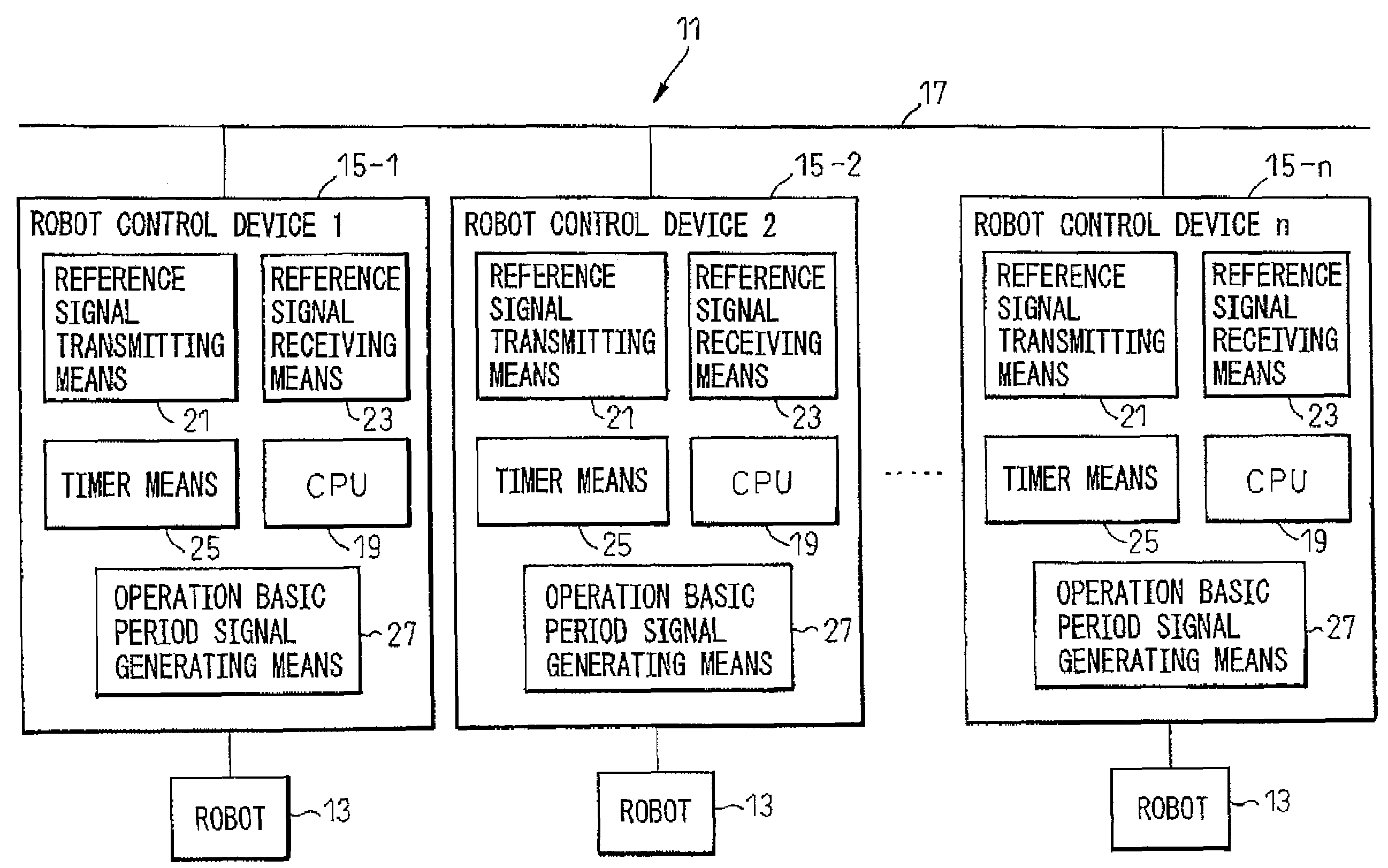

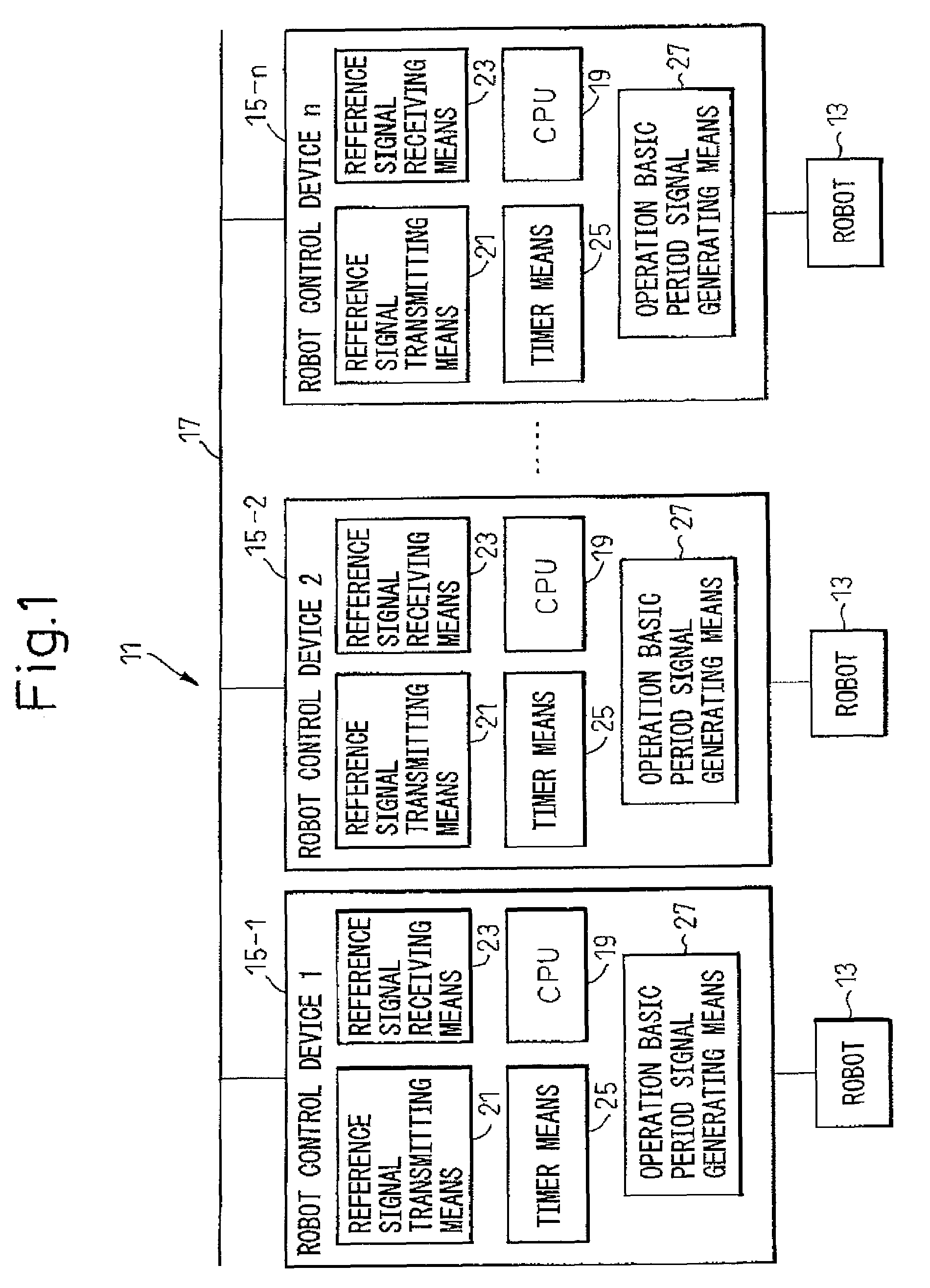

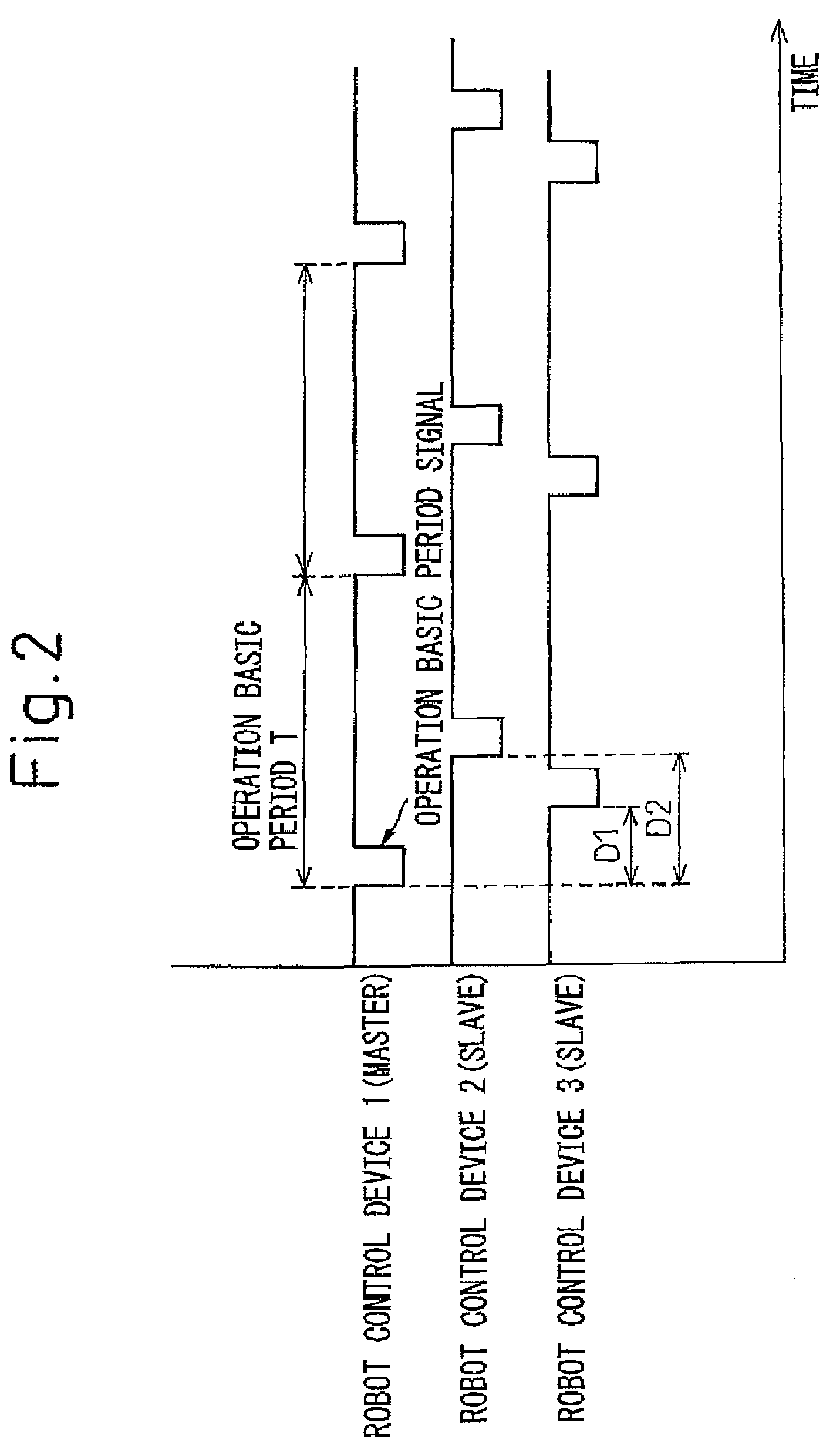

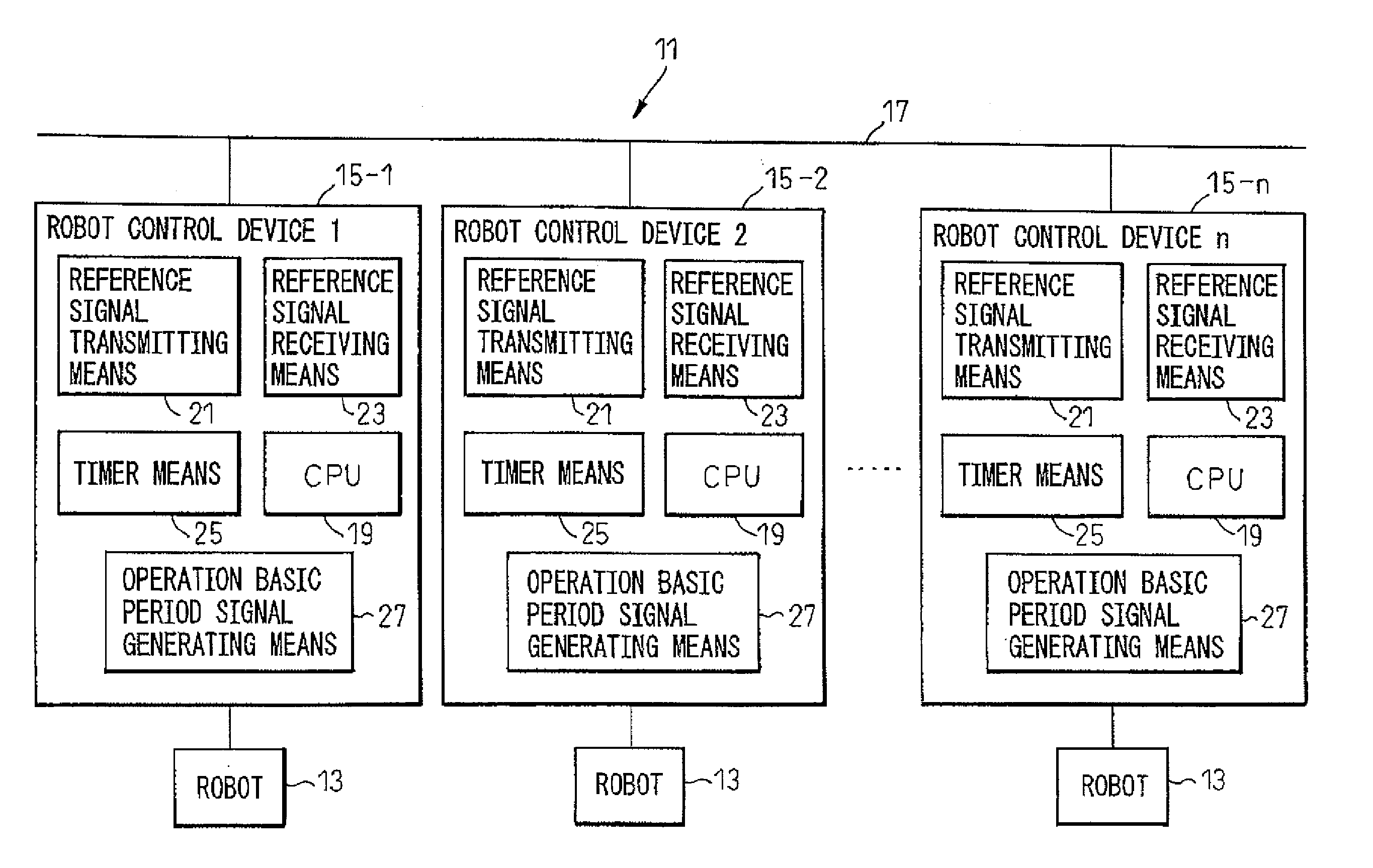

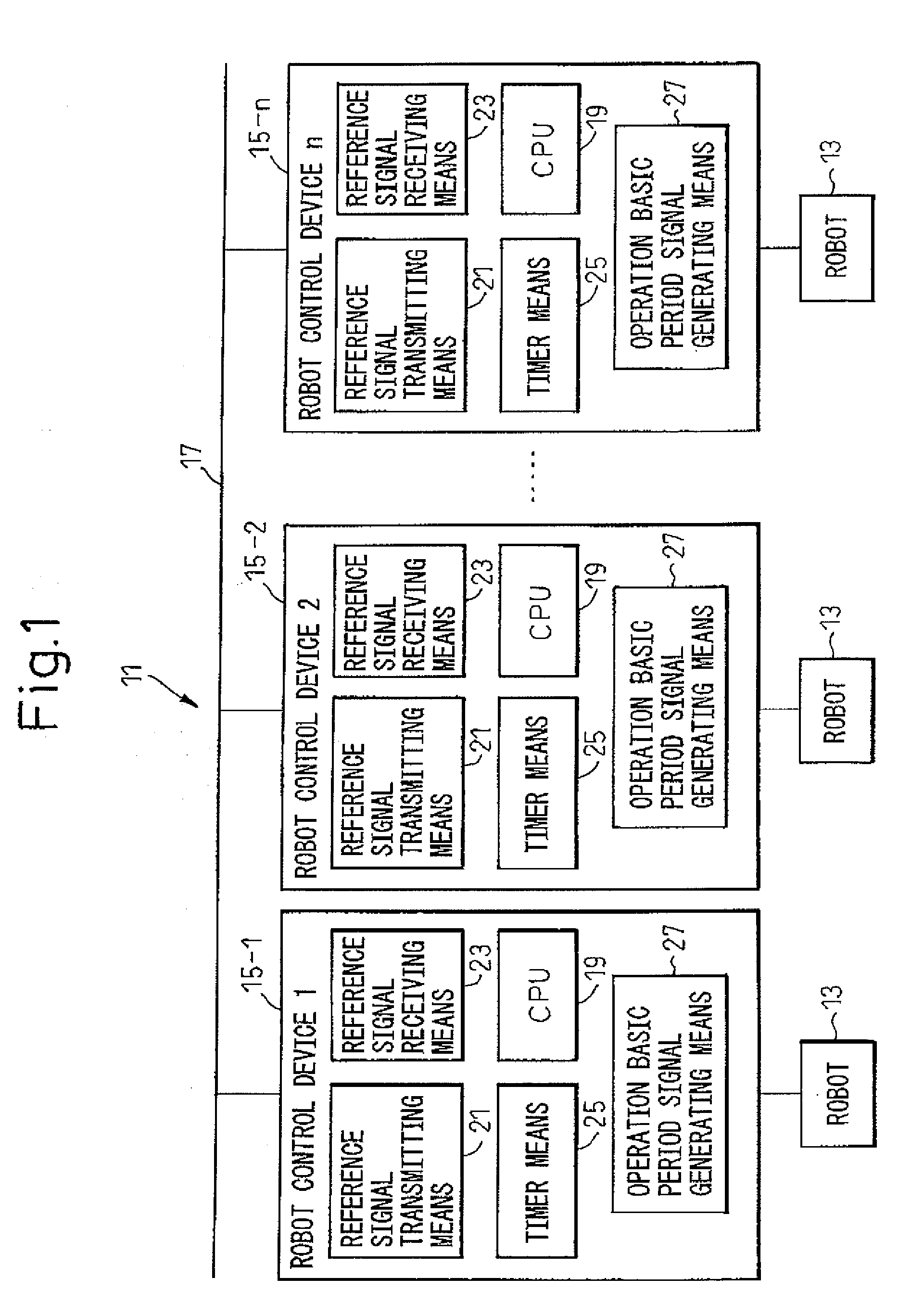

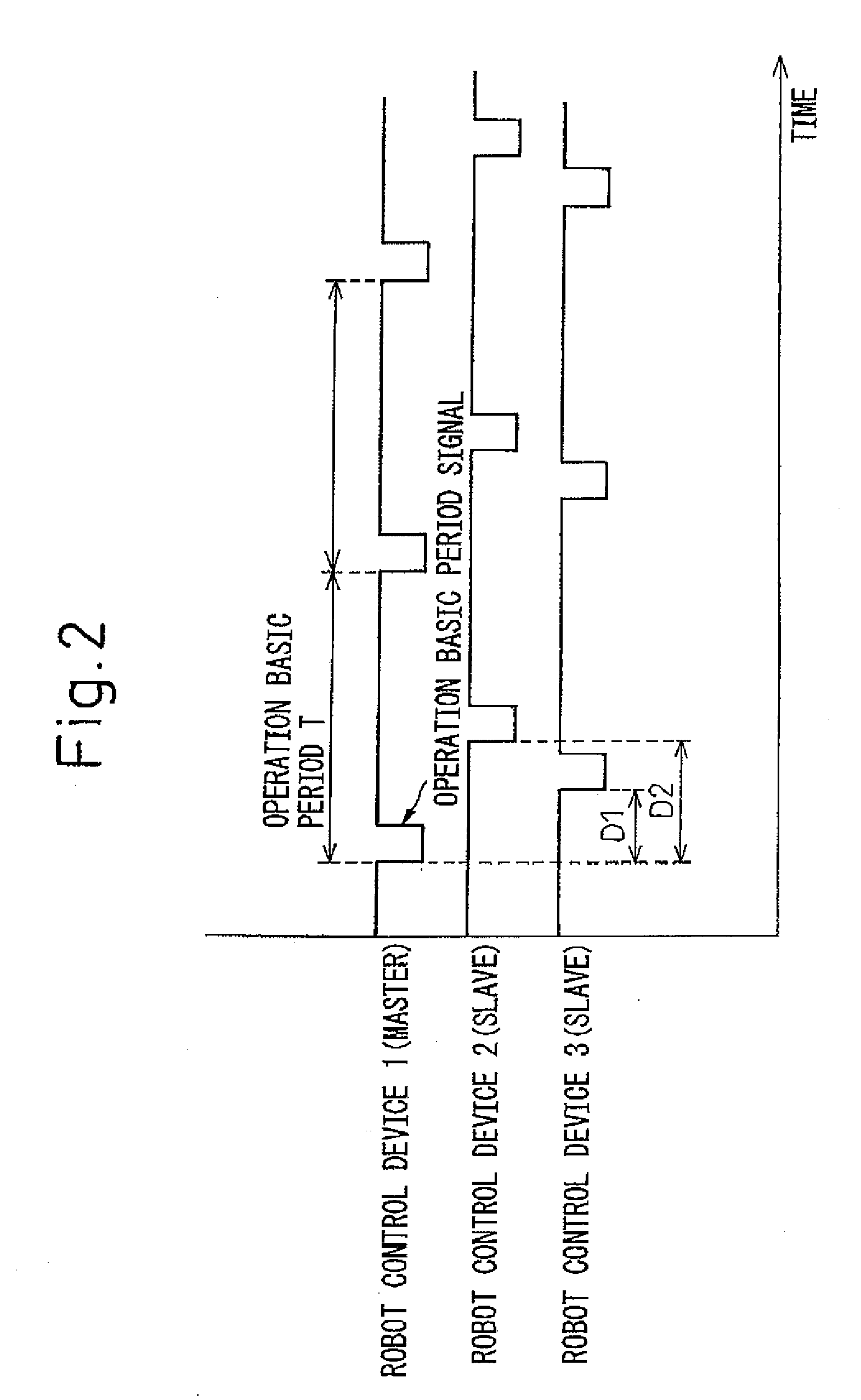

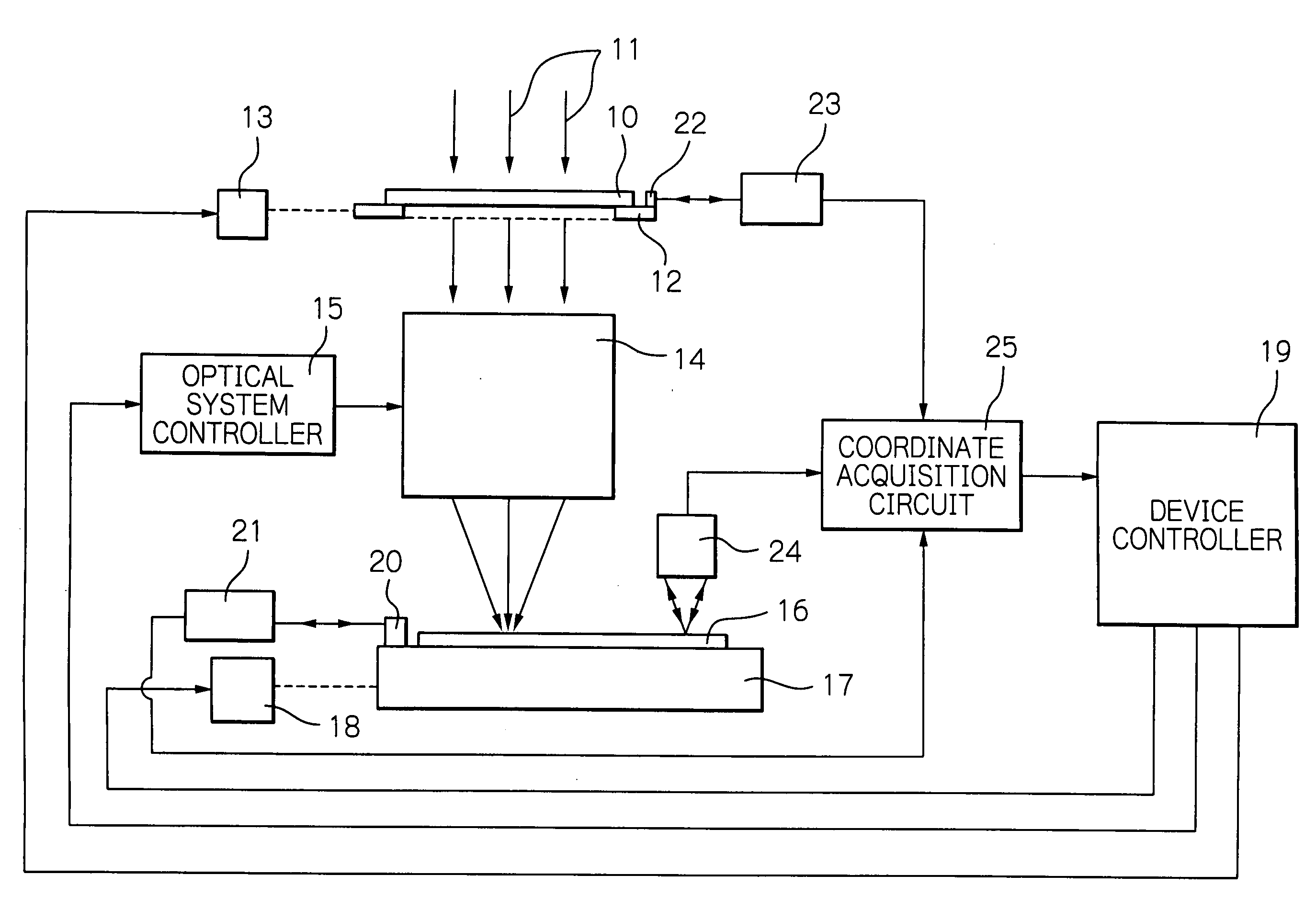

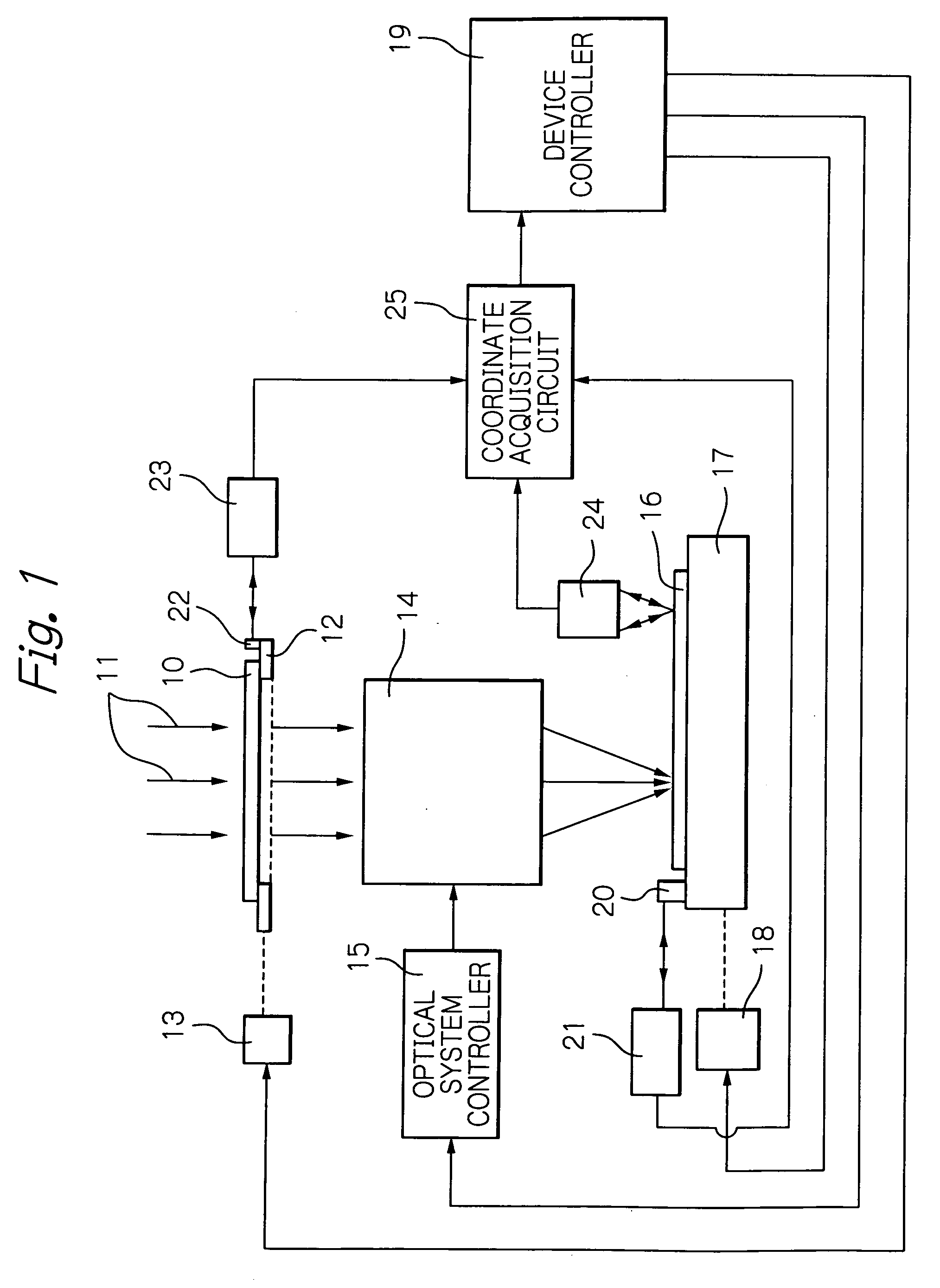

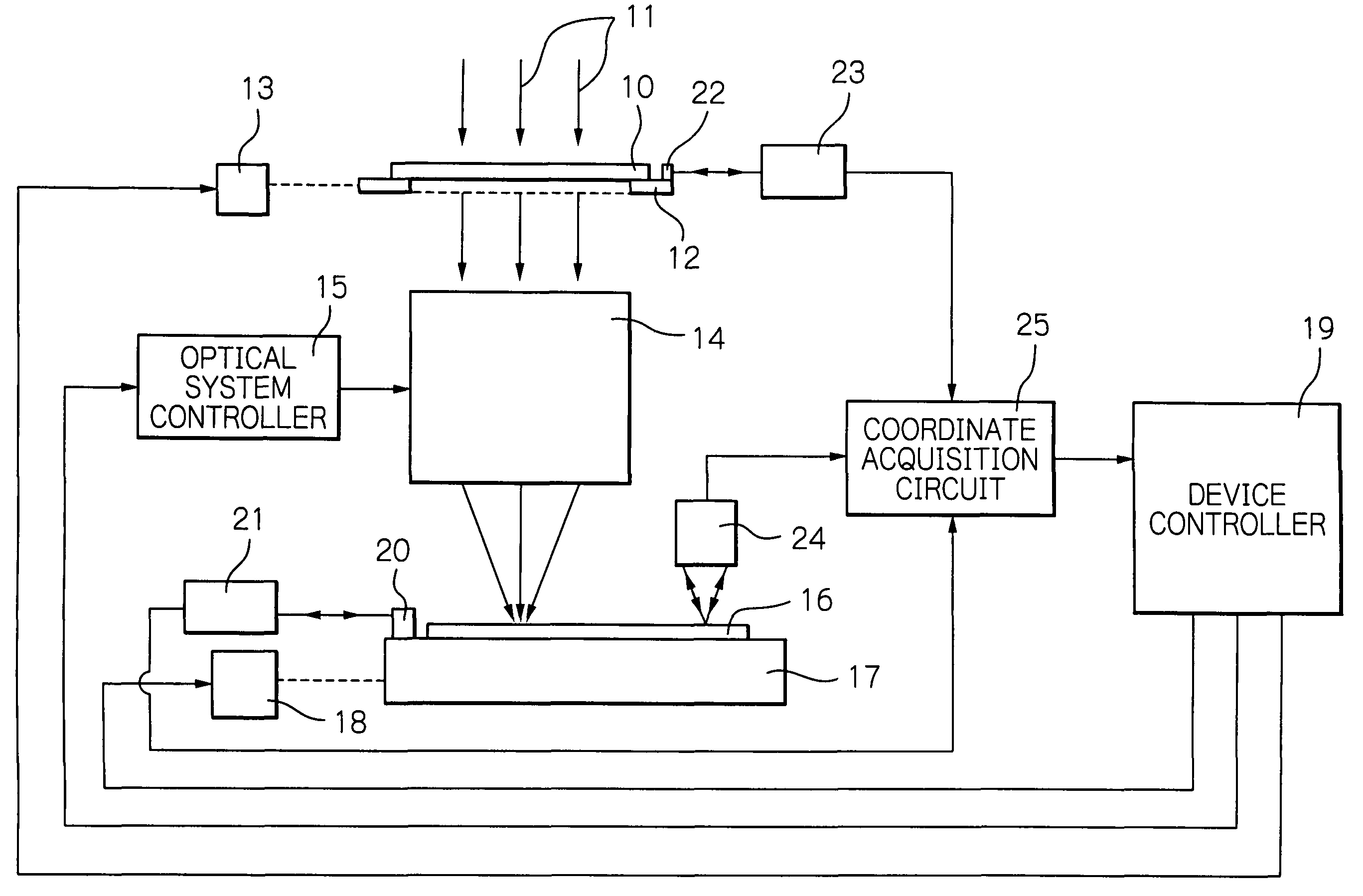

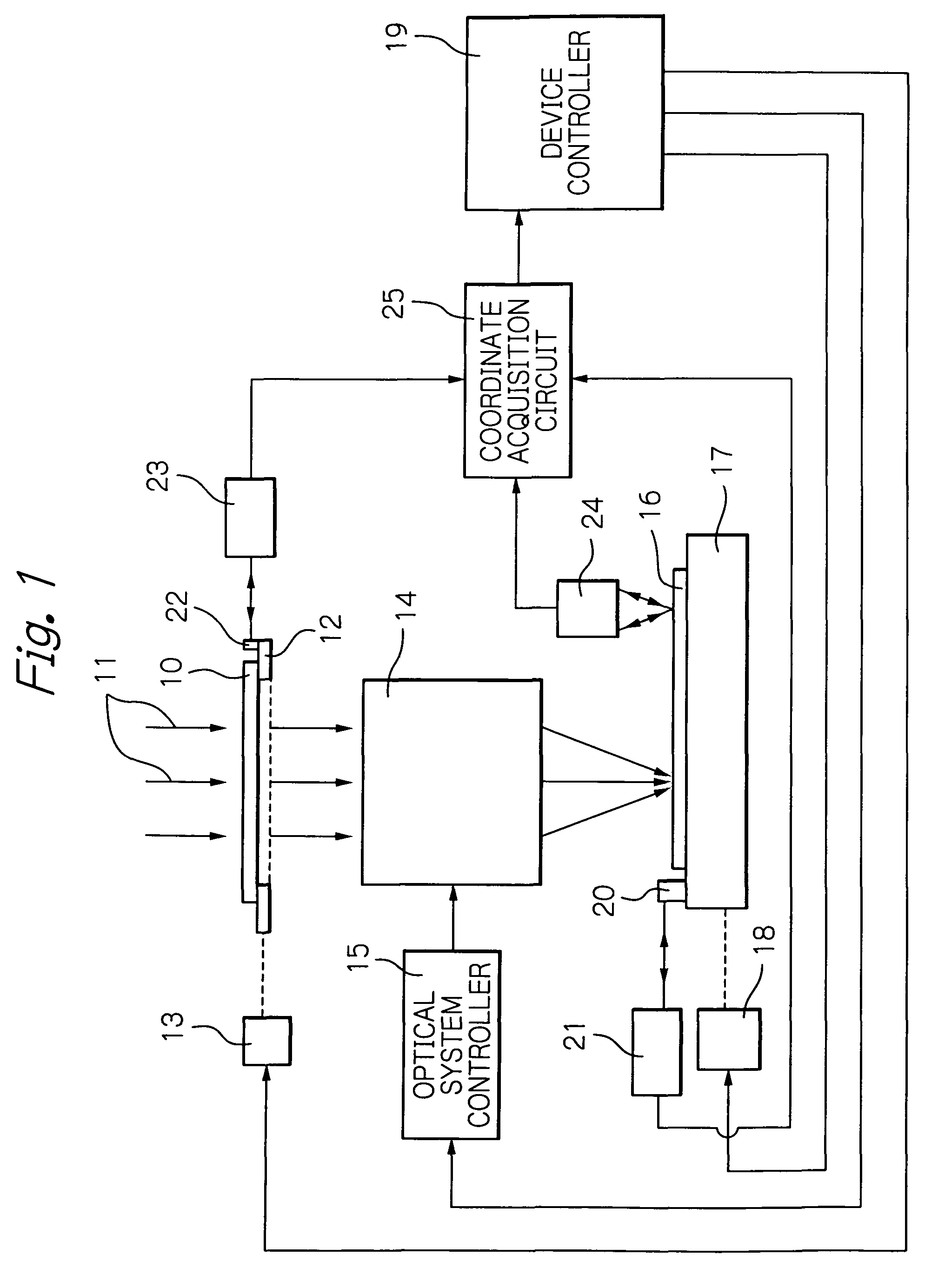

Robot coordinated control method and system

ActiveUS7330777B2High coordinate accuracyHigh precisionProgramme-controlled manipulatorComputer controlRobot controlDelay time

A reference signal is transmitted from one of a plurality of robot control devices connected by communication connecting device to the other robot control device. The timing of generation of an operation basic period signal in each of the other robot control devices is synchronized with the timing of generation of an operation basic period signal in the one of the plurality of robot control devices, based on a time interval from generation of the operation basic period signal until transmission of the reference signal in the one of the plurality of robot control devices, a time interval from generation of the operation basic period signal until reception of the reference signal in each of the other robot control devices, and a communication delay time required for communication between the one of the plurality of robot control devices and each of the other robot control devices.

Owner:FANUC LTD

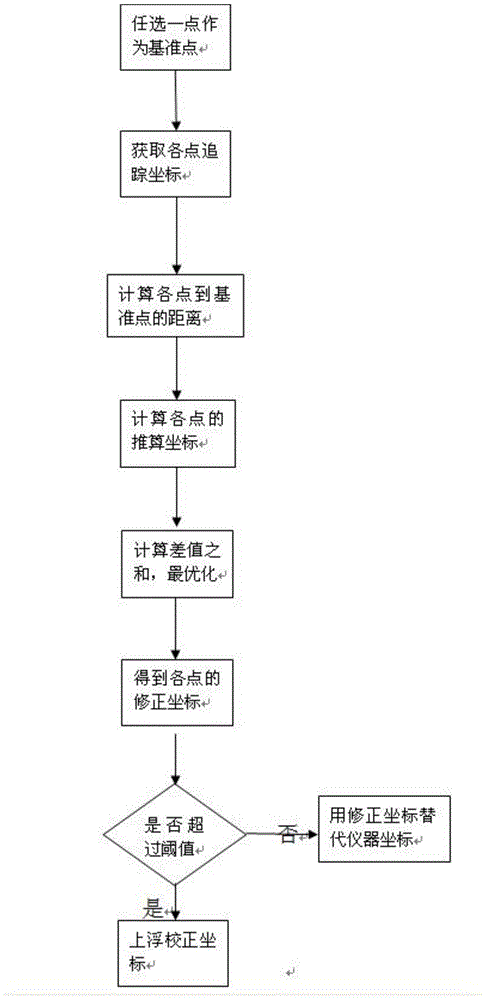

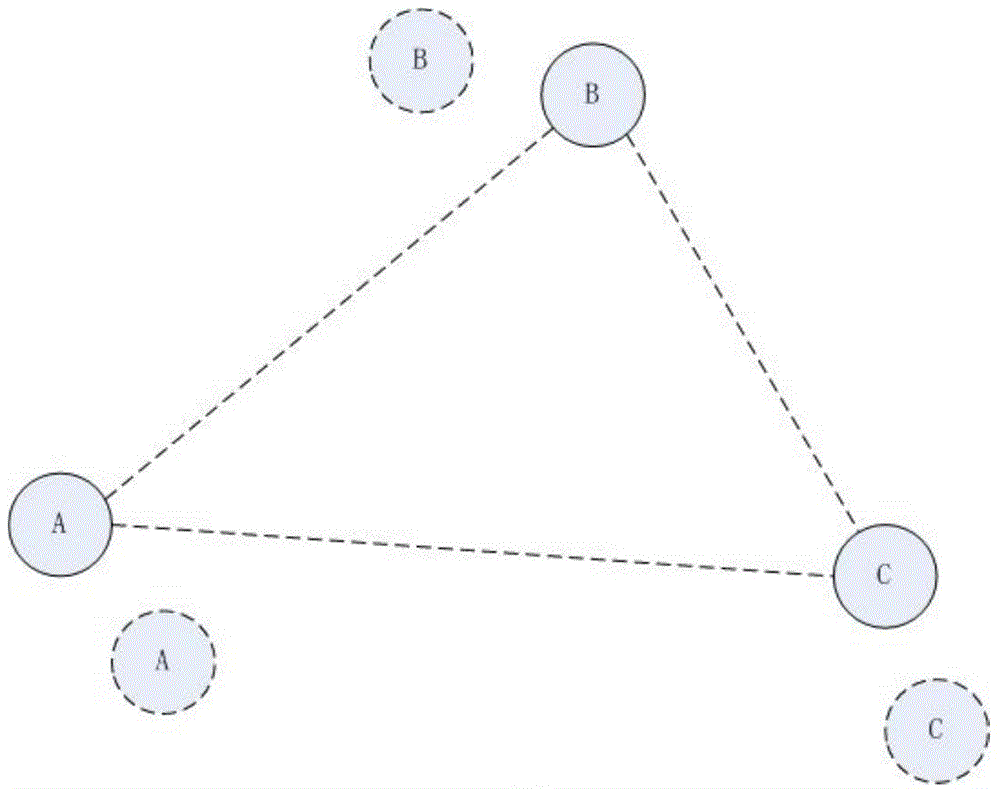

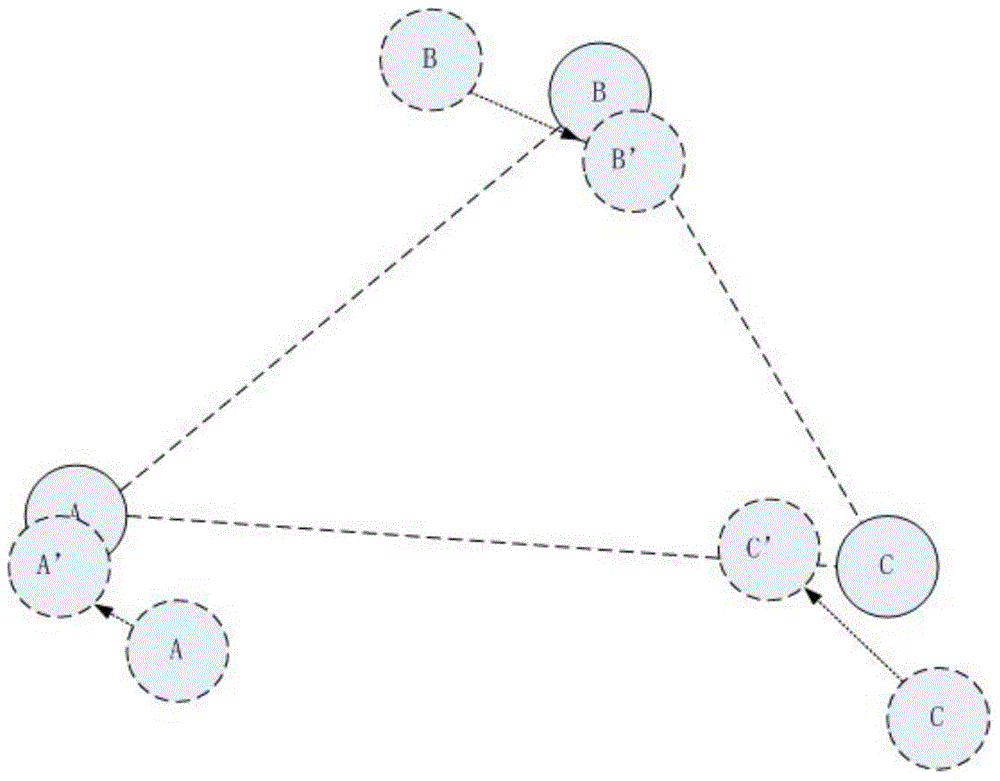

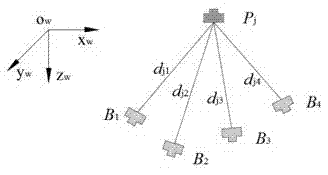

Relative-distance and tracking coordinate value combination multi-AUV self-locating method

InactiveCN103558622AProlong the effective working time underwaterHigh coordinate accuracyPosition fixationSatellite radio beaconingUnderwaterBuoy

The invention relates to a relative-distance and tracking coordinate value combination multi-AUV self-locating method, and belongs to the field of underwater wireless networks. According to the relative-distance and tracking coordinate value combination multi-AUV self-locating method, the distances among multiple underwater AUV nodes are used for correcting tracking coordinate values inside the nodes, so that the tracking error can be reduced, the effective underwater work time of the AUV nodes can be prolonged, and traditional water surface locating buoys or water bottom locating anchoring buoys are not required.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Robot coordinated control method and system

ActiveUS20070050085A1High precisionImprove accuracyProgramme-controlled manipulatorComputer controlEngineeringRobot control

A reference signal is transmitted from one of a plurality of robot control devices connected by communication connecting means to the other robot control device. The timing of generation of an operation basic period signal in each of the other robot control devices is synchronized with the timing of generation of an operation basic period signal in the one of the plurality of robot control devices, based on a time interval from generation of the operation basic period signal until transmission of the reference signal in the one of the plurality of robot control devices, a time interval from generation of the operation basic period signal until reception of the reference signal in each of the other robot control devices, and a communication delay time required for communication between the one of the plurality of robot control devices and each of the other robot control devices.

Owner:FANUC LTD

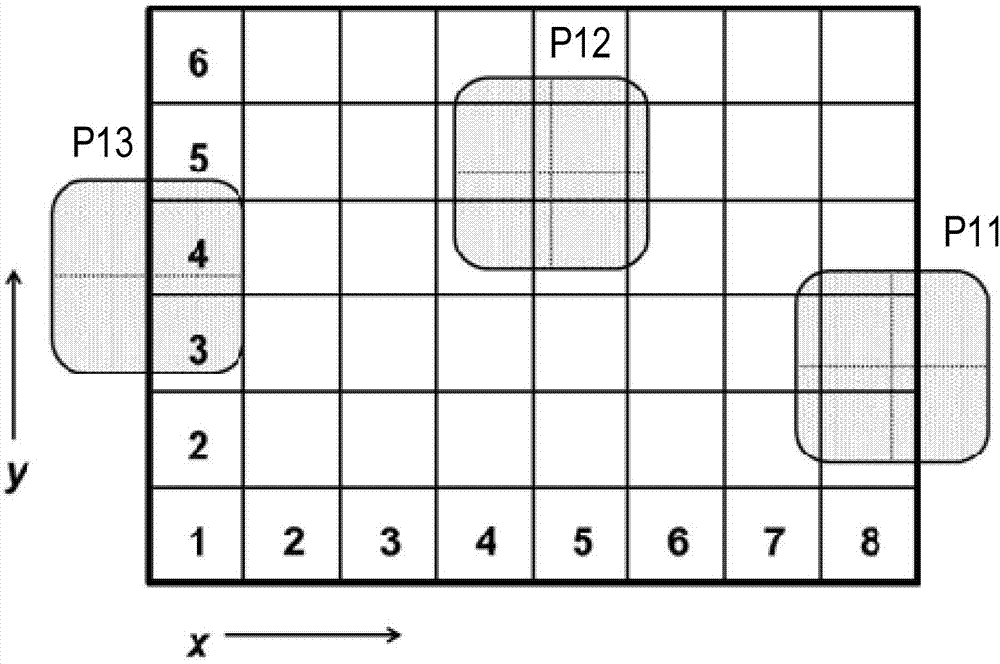

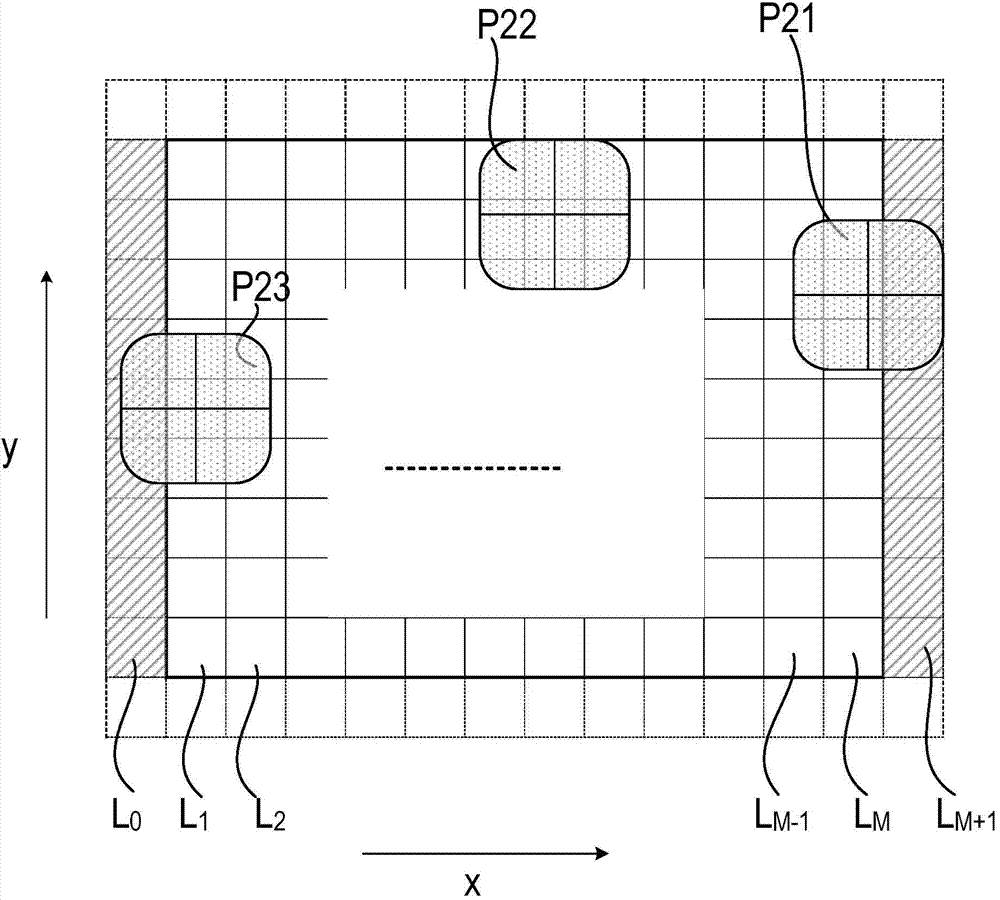

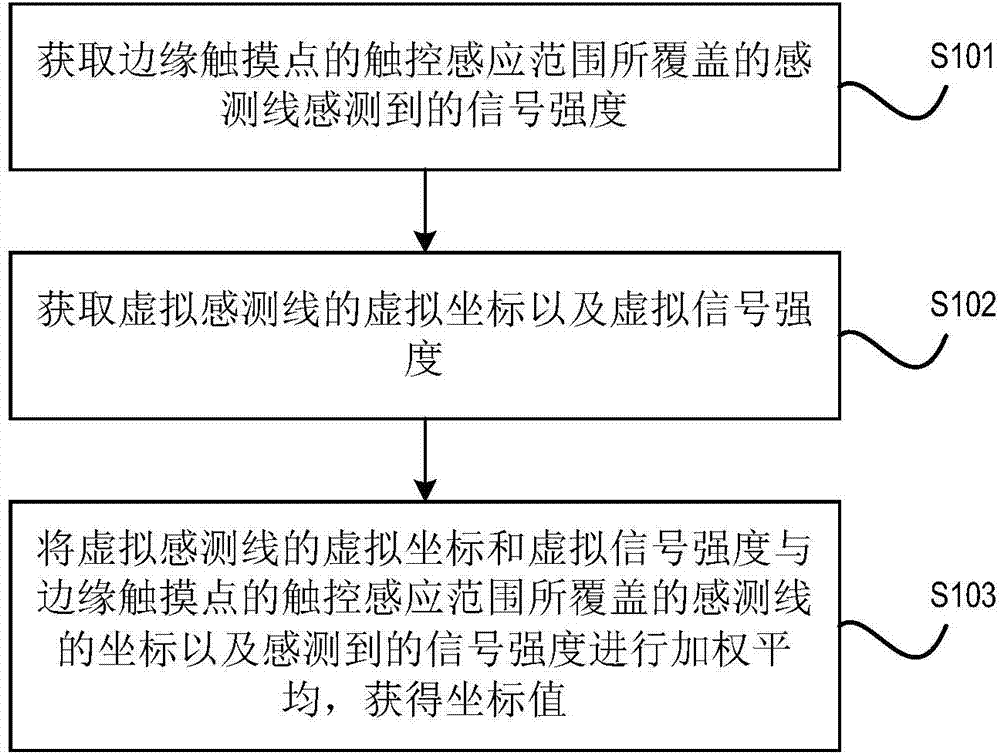

Method and device for improving accuracy of edge coordinates of projection-type capacitive touch panel

ActiveCN104777948AHigh coordinate accuracyInput/output processes for data processingCapacitanceUltimate tensile strength

A method for improving coordinate accuracy of a touch panel having sensing lines arranged to form an array includes the steps of: detecting existence of a touch point influencing at least one sensing line; determining existence of an edge sensing line; providing signal strengths to the at least one sensing line and a sensing line immediately adjacent to the at least one sensing line; generating a virtual sensing line extending out the touch panel and immediately adjacent to the at least one sensing line; providing a signal strength to the virtual sensing line; and obtaining actual coordinate of the touch point by weighing coordinates of the at least one sensing line, the sensing line immediately adjacent to the at least one sensing line and the virtual sensing line via system generated coordinates.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

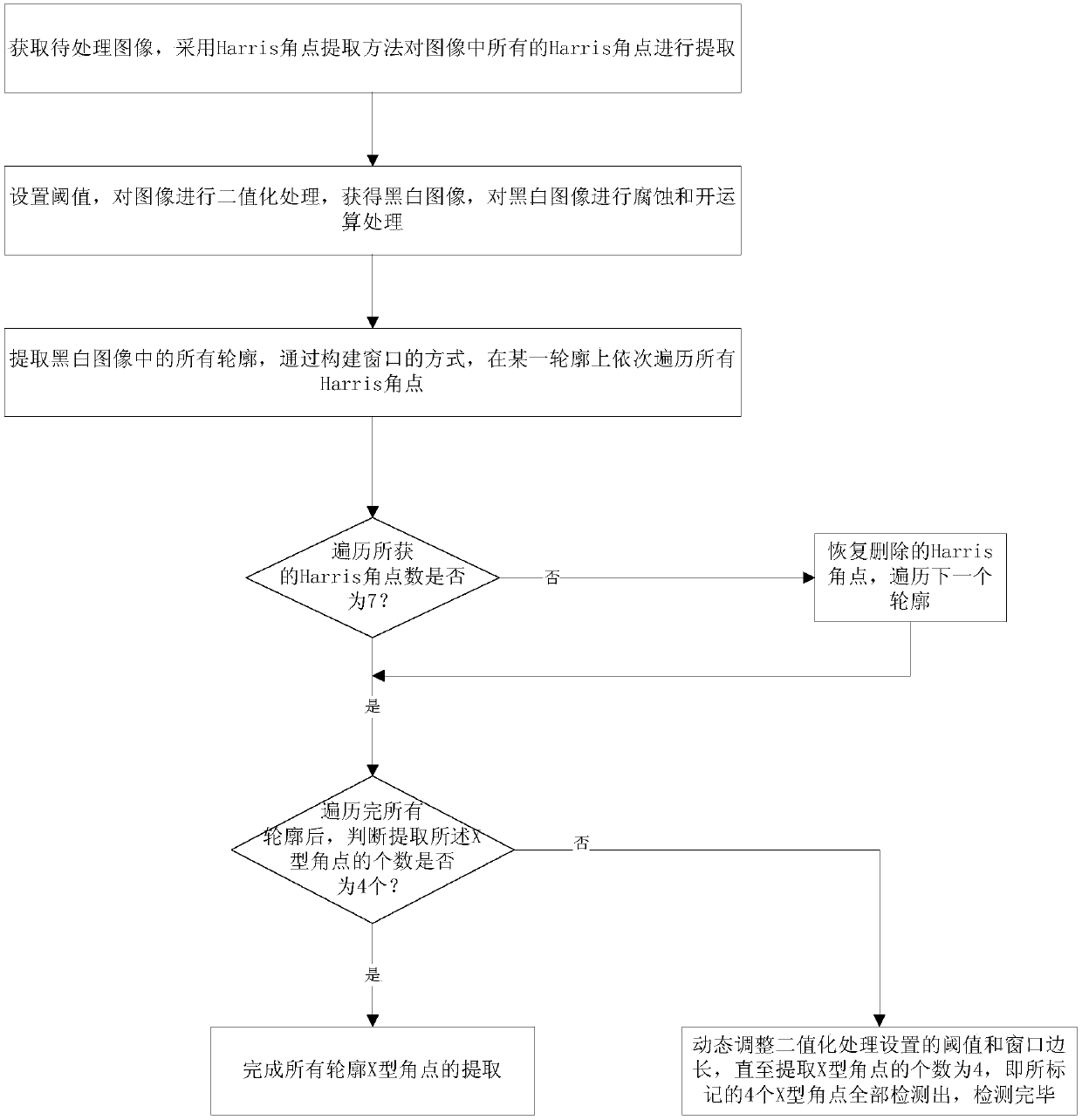

X-shaped corner extraction method based on image contour

InactiveCN108492306AHigh coordinate accuracyIncrease success rateImage analysisAngular pointCorner detection

The invention proposes an X-shaped corner extraction method based on an image contour, and relates to the technical field of visual detection. The method comprises the steps: sequentially traversing Harris corners on one contour through the construction of a window: taking a point which has the smallest coordinate mean value relative to seven corners as an X-shaped corner when the number of traversed corners is seven, carrying out the traversing of a next contour, extracting the X-shaped corner when the number of corners is four, and completing the extraction of X-shaped corners of all contours. The method can achieve the filtering of pseudo corners in an image, and can achieve the precise detection of a corner point in the image, wherein the detection precision can reach 0.09 pixels. Through the setting of the surrounding background of a corner, the method enables a mark point not to be affected by a feature point in an environment, and achieves the detection of the corner in a complex scene. Through combining with the advantages of Harris precise extraction and contour positioning, the method achieves the subpixel-level detection of a laid corner, and improves the coordinate precision of the corner. Through the dynamic adjustment of an image preprocessing threshold value, the method reduces the impact from the illumination in different scenes, and improves the corner detection success rate.

Owner:ANSTEEL GRP MINING CO LTD

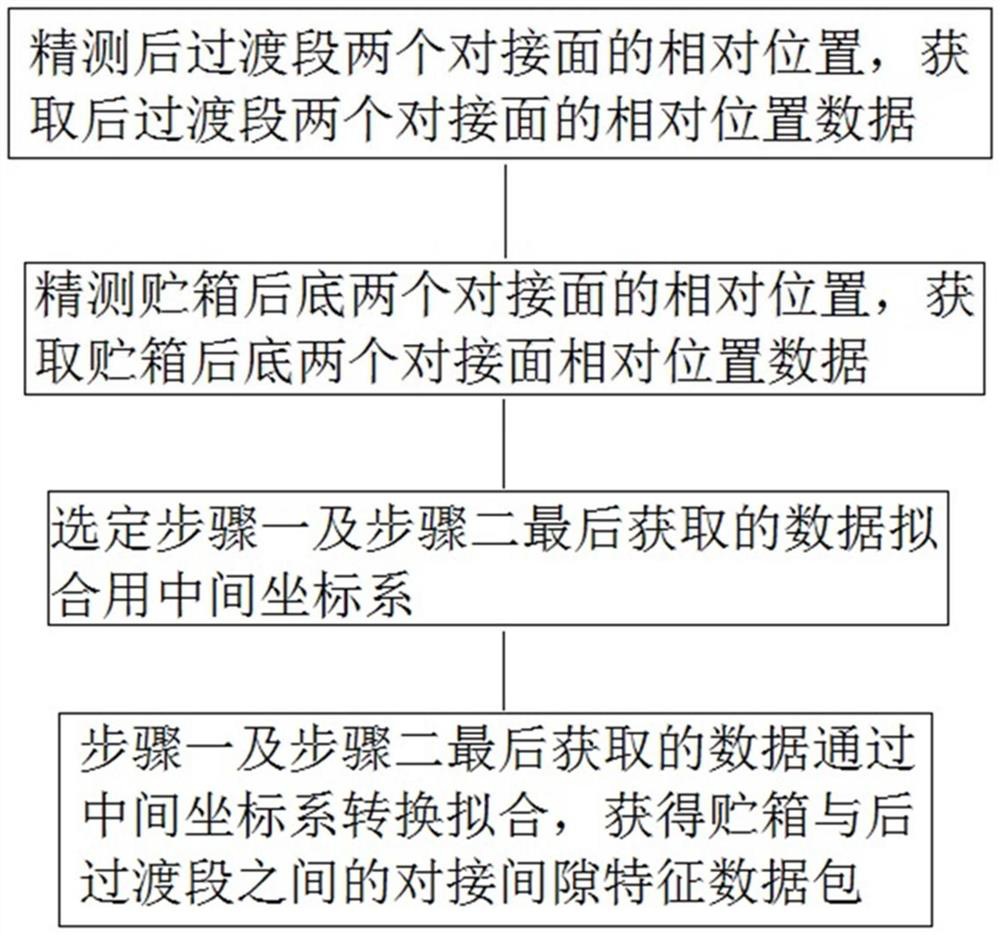

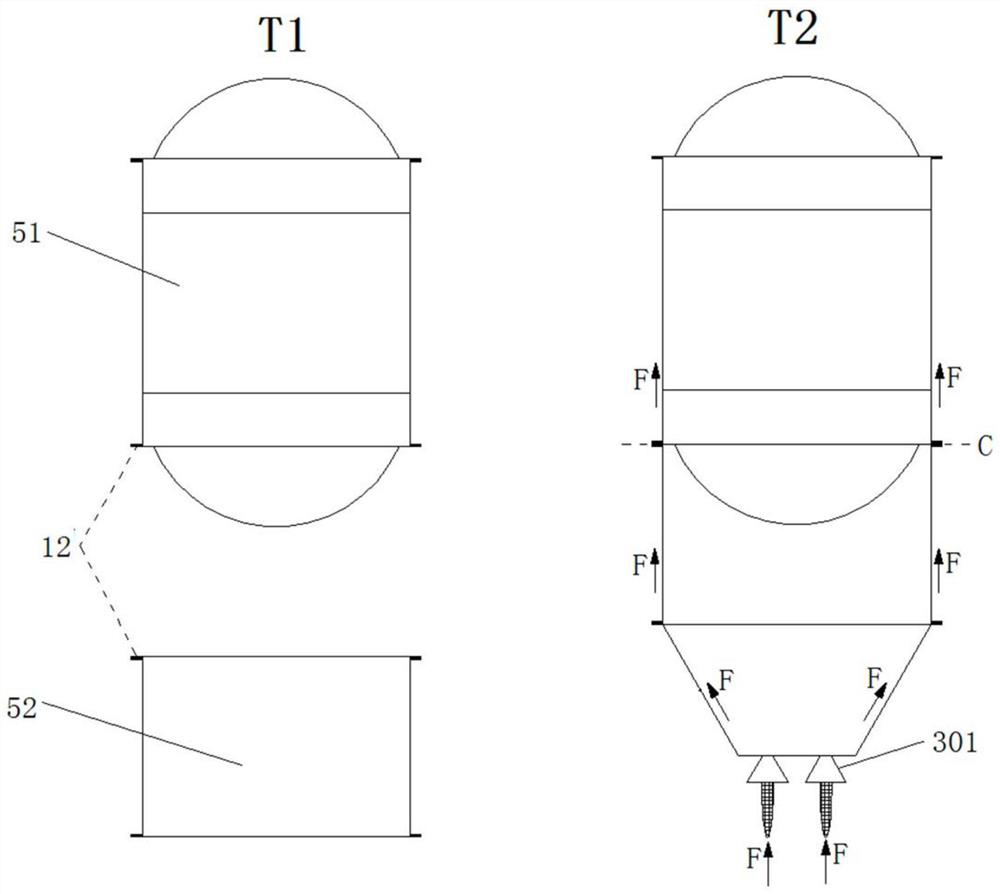

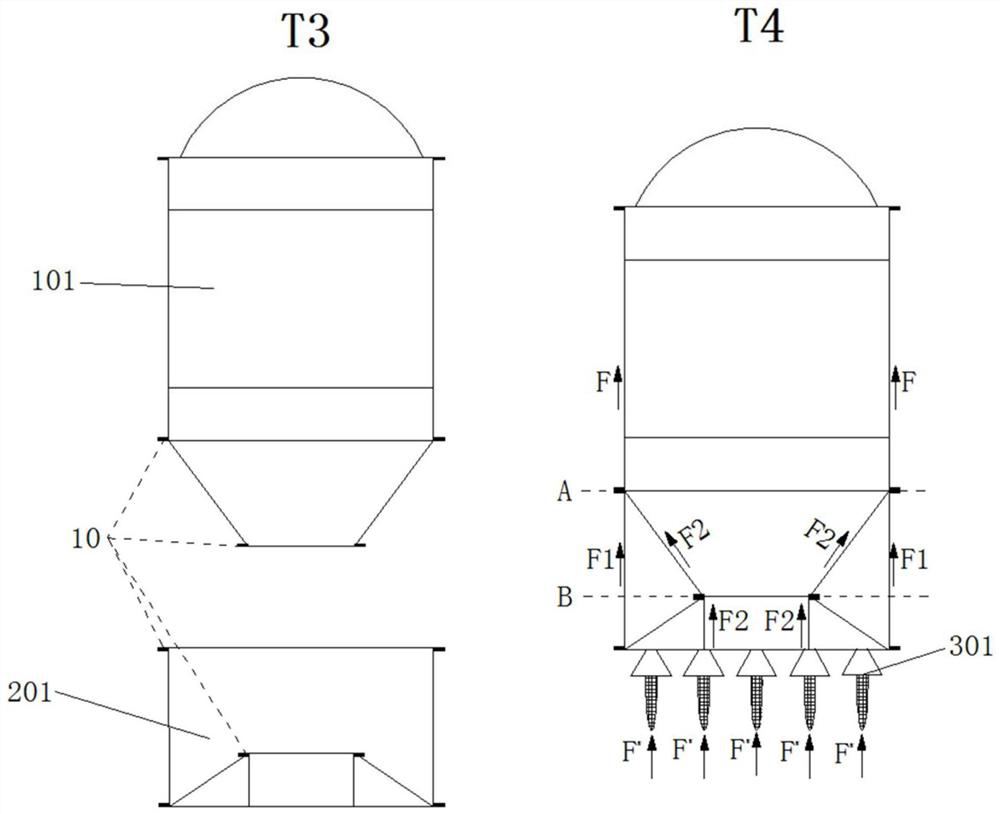

Carrier rocket section precise docking coordination method

ActiveCN112078829AHigh precisionReduce mistakesCosmonautic vehiclesCosmonautic propulsion system apparatusData packControl engineering

The invention provides a carrier rocket section precise docking coordination method. The method comprises the following steps of: step 1, precisely measuring the relative positions of a first end faceand a second end face, and obtaining data of the relative positions of the first end face and the second end face; step 2, precisely measuring the relative positions of a third end face and a fourthend face, and obtaining data of the relative positions of the third end face and the fourth end face; step 3, selecting an intermediate coordinate system for fitting of the data finally obtained in the step 1 and the step 2; and step 4, carrying out intermediate coordinate system conversion fitting of the data finally obtained in the step 1 and the step 2 to obtain a docking gap characteristic data packet between a storage tank and a shell section. The carrier rocket section precise docking coordination method solves the technical problems that defects such as lag of docking coordination nodes, prolonged development period and poor manual multi-point measurement precision exist in the docking process of a novel storage tank and a shell section in the prior art, and the docking effect is affected.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

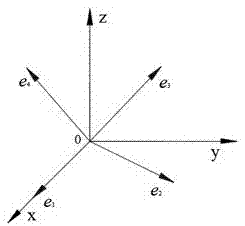

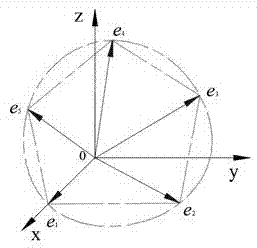

Optimal configuration method for positioning target point by using five to seven beacon points

InactiveCN105447307AHigh coordinate accuracySpecial data processing applicationsInformaticsComputer visionComputer science

The present invention discloses an optimal configuration method for positioning a target point by using five to seven beacon points. The present invention comprises two parts, wherein the first part is respectively giving a target point and an optimal measurement configuration of five to seven beacon points; and the second part is when respectively the target point is given and the optimal measurement configuration is adopted by the five to seven beacon points, configuring an influence coefficient on coordinate precision of the target point. According to the optimal configuration method for positioning the target point by using five to seven beacon points provided by the present invention, an optimal solution of a spatial coordinate of the target point can be obtained by adopting the optimal measurement configuration, and using a coordinate of a beacon point and a distance between the target point and the beacon point.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

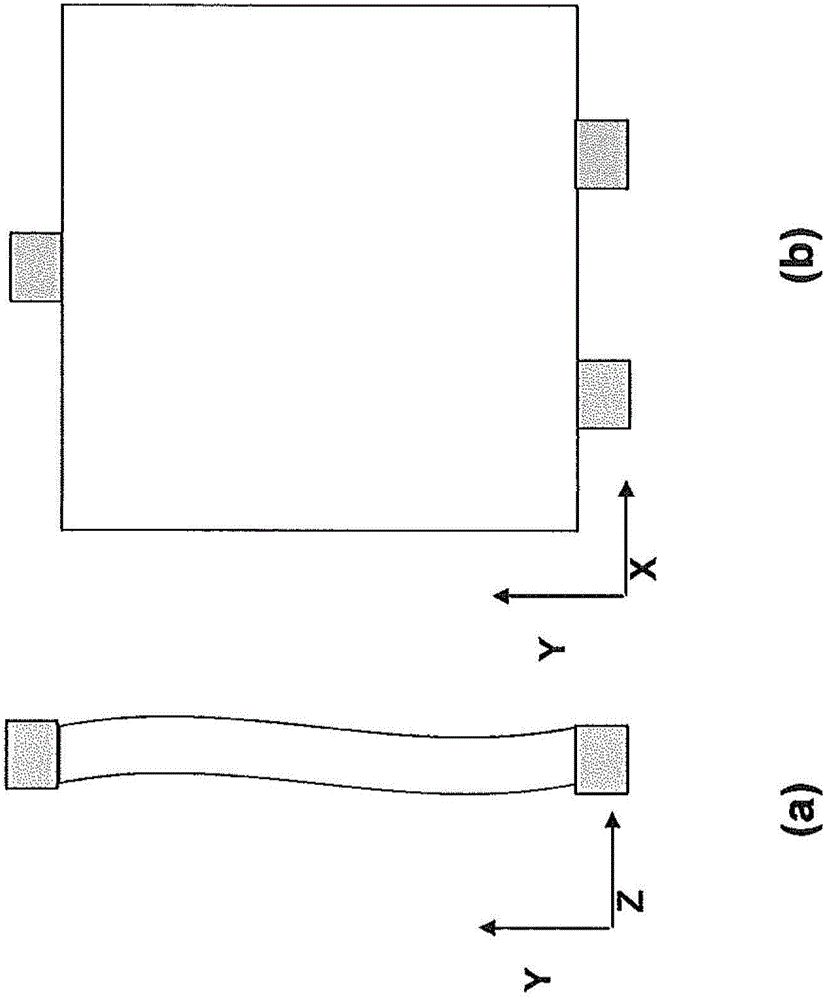

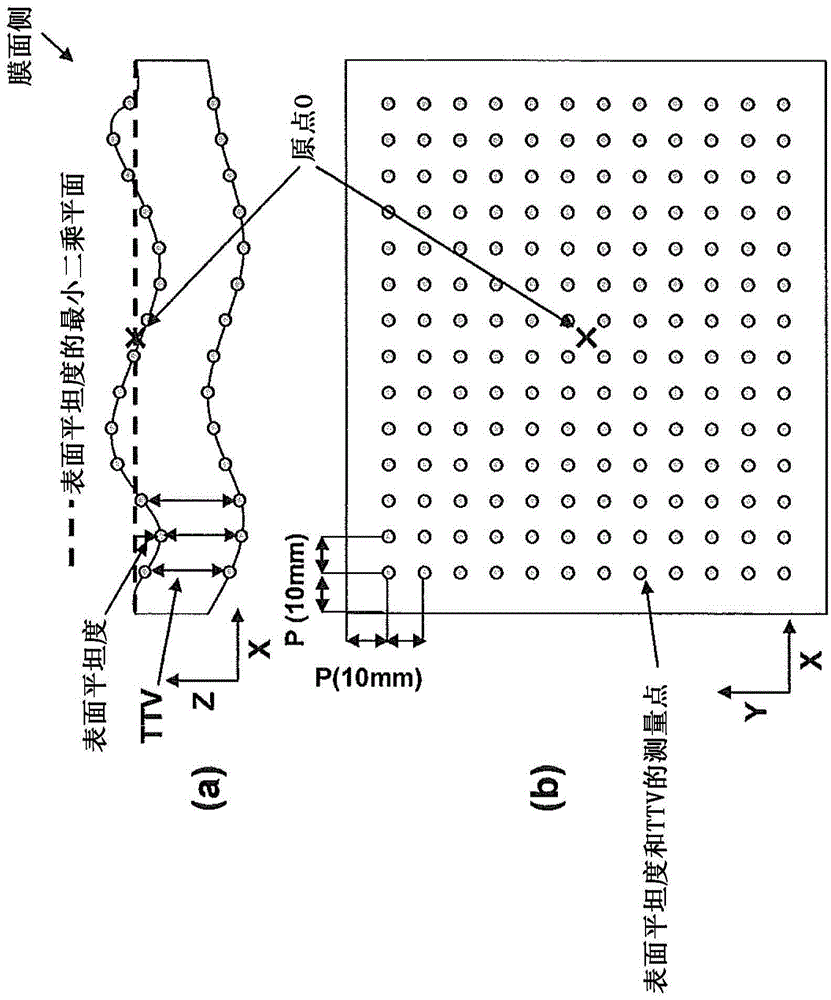

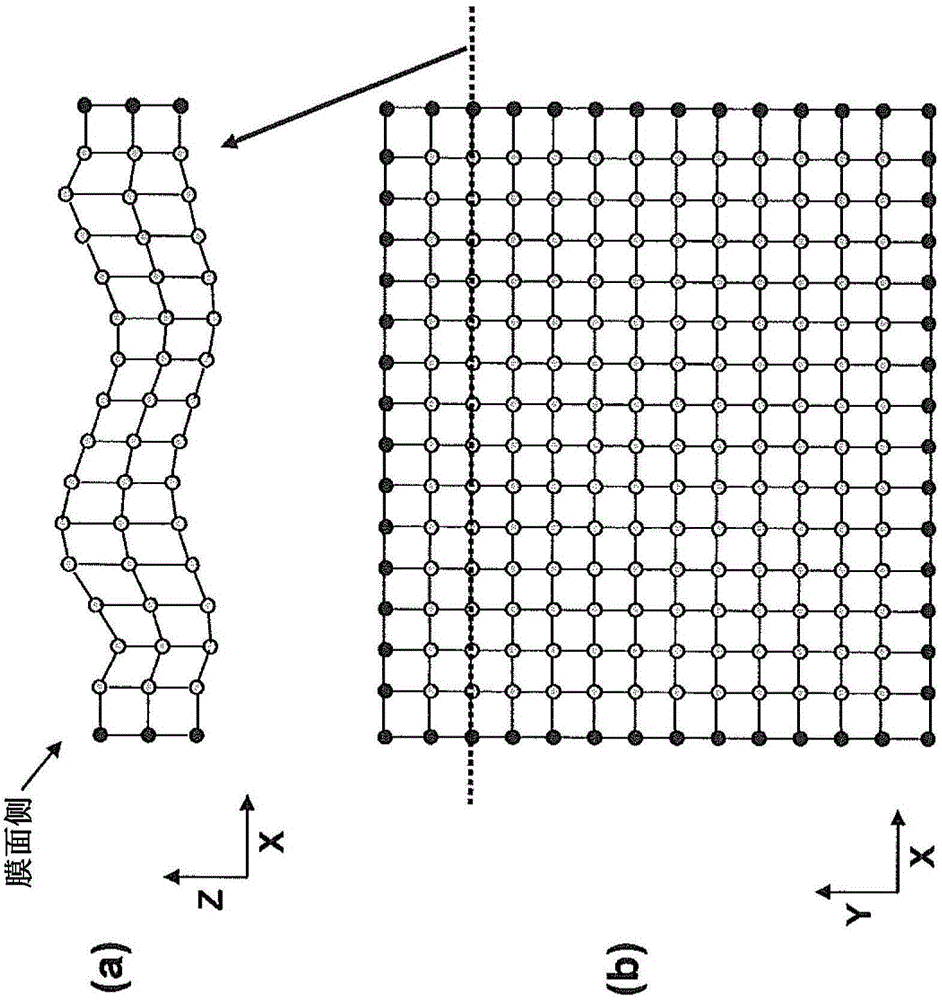

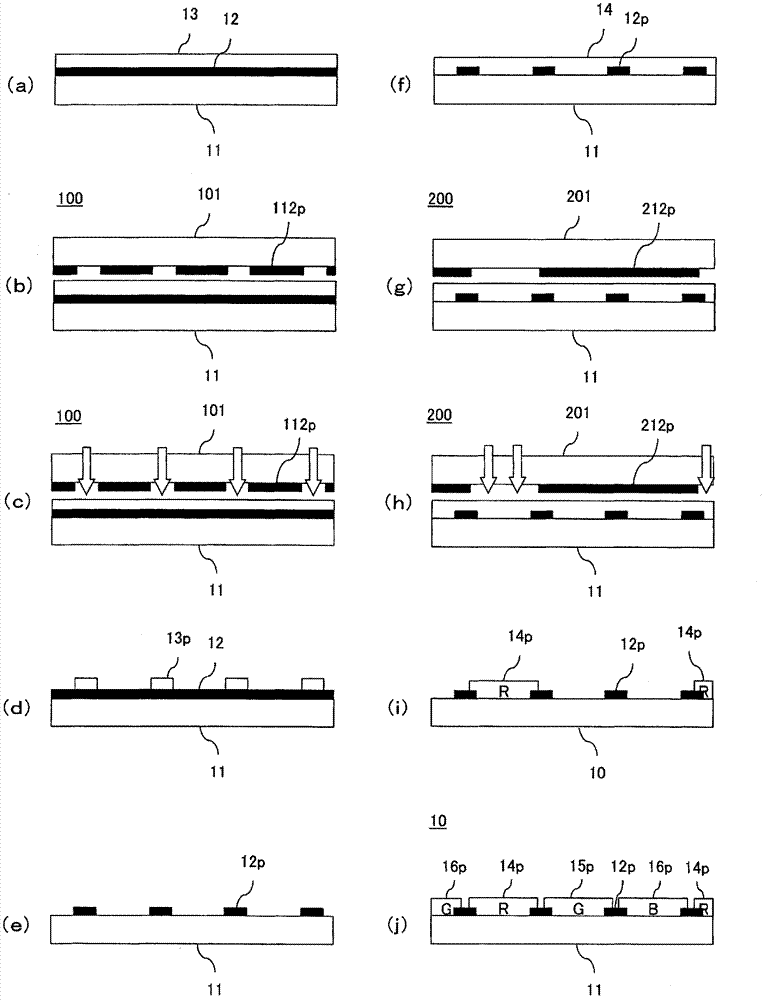

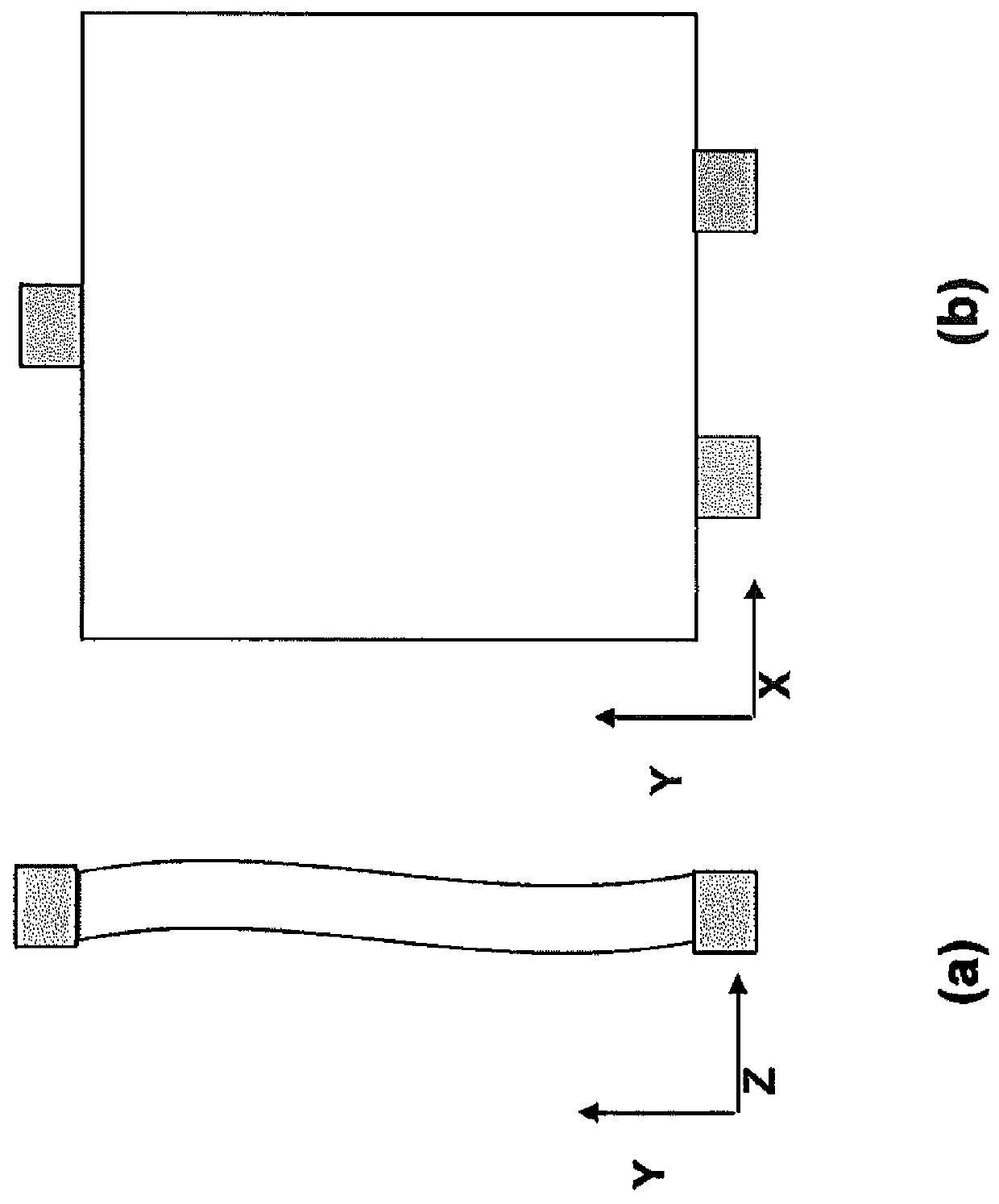

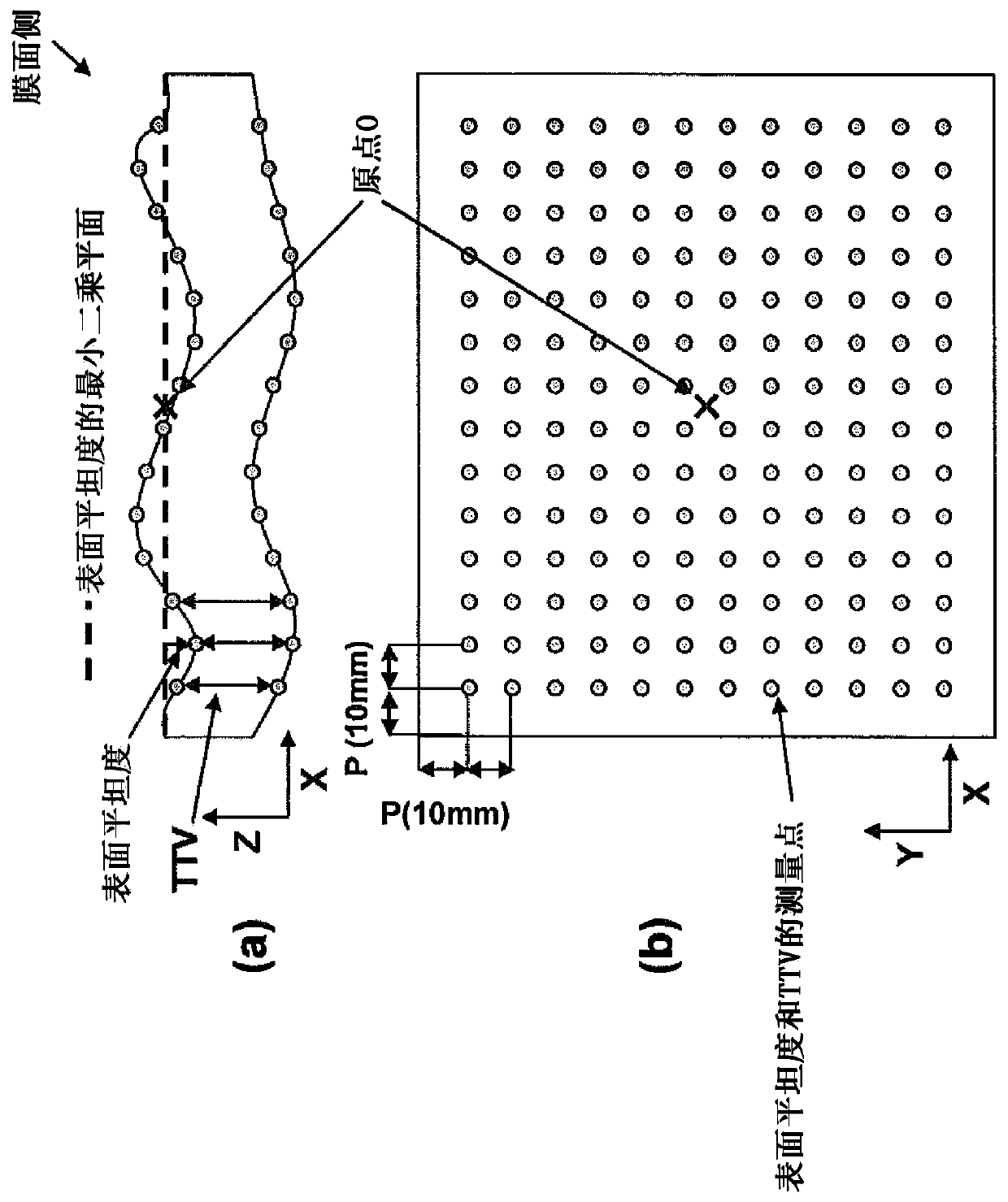

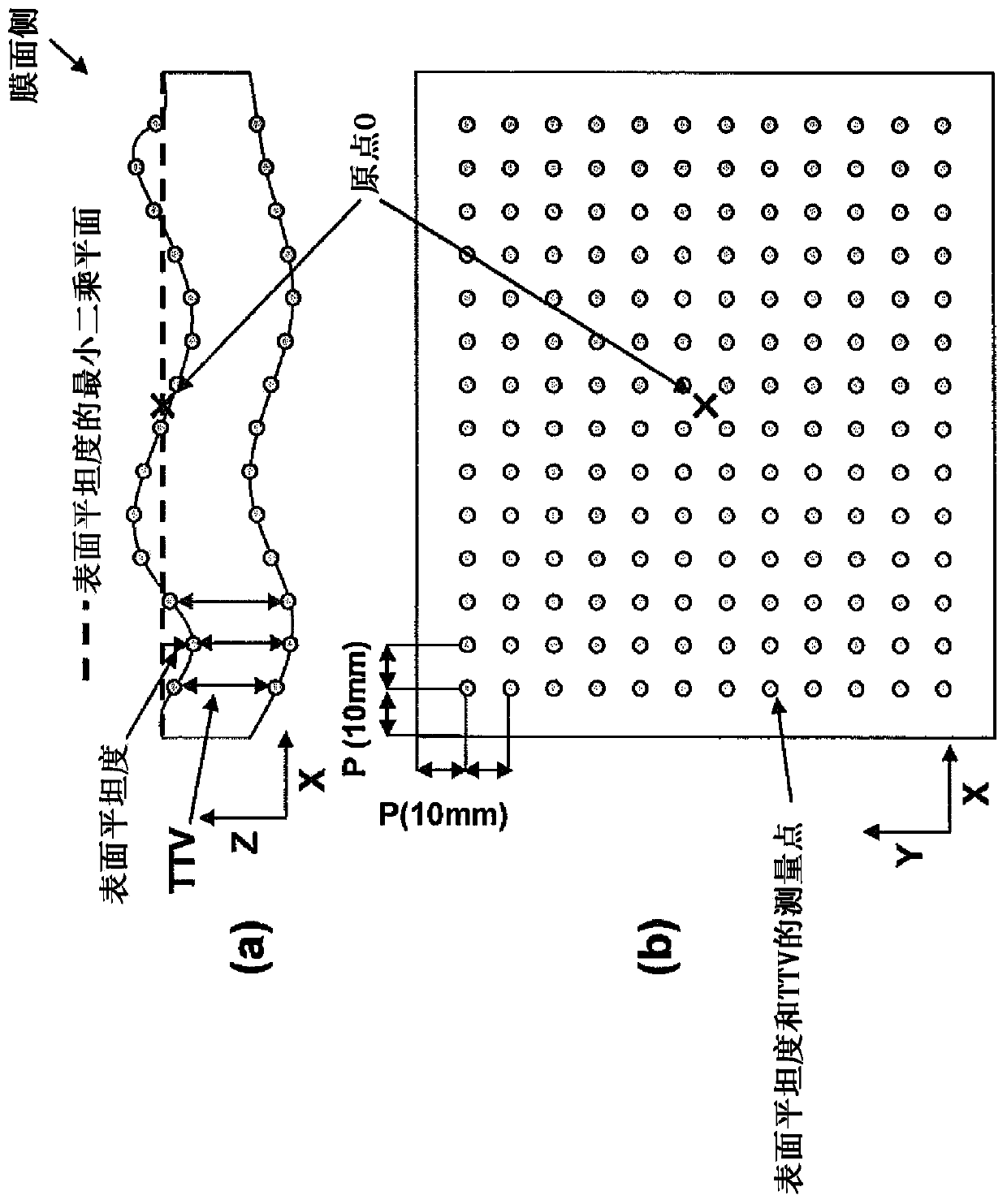

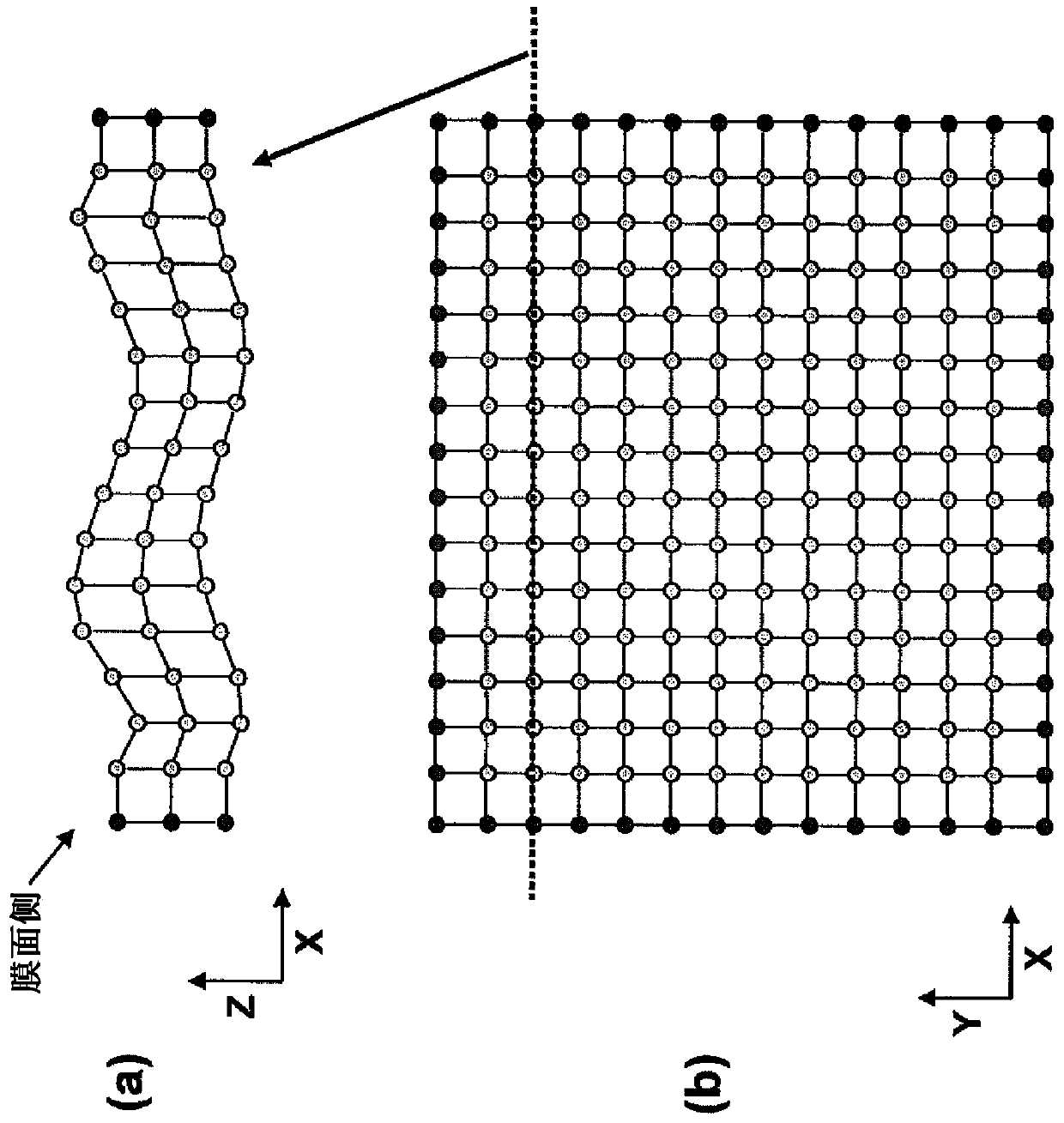

Photomask manufacturing method, photomask inspecting method, photomask inspecting apparatus, and drawing device

ActiveCN104423140AHigh coordinate accuracyThe preparation method is simple and easySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentPhysicsExposure

The invention provides a photomask manufacturing method, a photomask inspection method, a photomask inspection apparatus, and a drawing device, which are capable of improving the coordinate precision of a pattern formed on a transferred body. The photomask manufacturing method according to the invention comprises the steps of: preparing pattern design data (A); obtaining transferred face correction data (D) representing the deformation of a main surface due to the maintaining of a photomask to an exposure apparatus and the deformation other than the dead weight deflection component; obtaining height distribution data (E) in the drawing which represent the height distribution of the main surface under such a state that the photomask green body is loaded to a work table of the drawing device; obtaining drawing differential data through the difference between the height distribution data (E) in the drawing and the transferred face correction data (D); calculating a coordinate deviation value corresponding to the drawing differential data (F), and determining coordinate deviation value data (G) for drawing; and using the coordinate deviation value data (G) for drawing and the pattern design data (A) for a drawing process on the photomask green body.

Owner:HOYA CORP

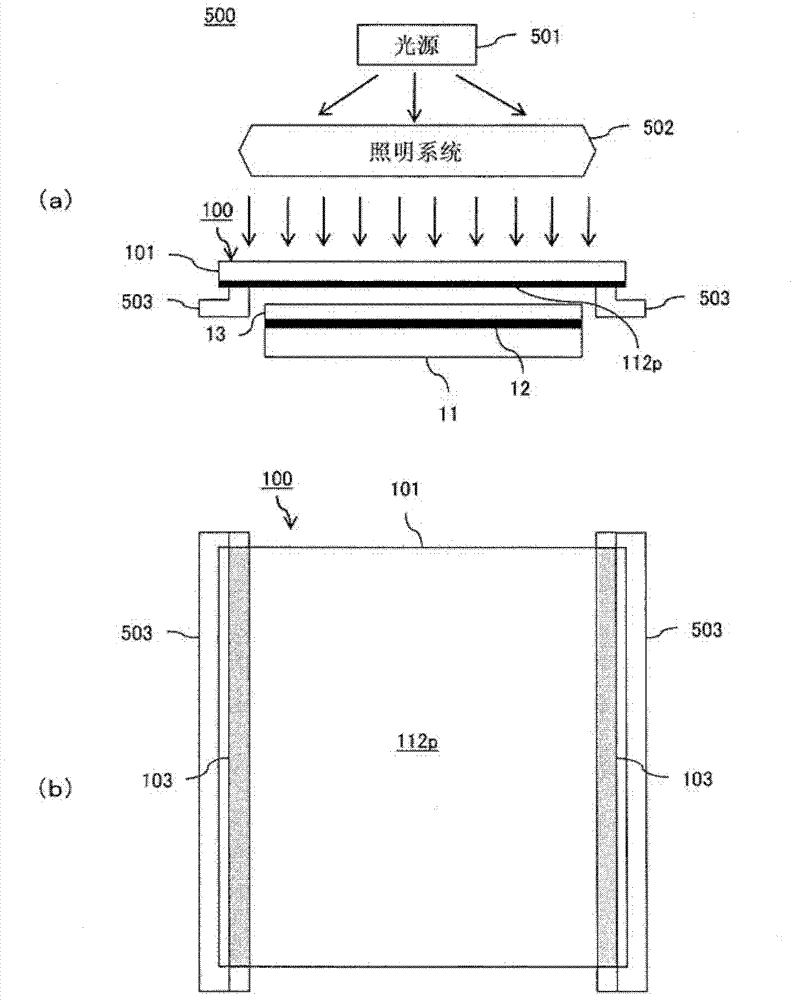

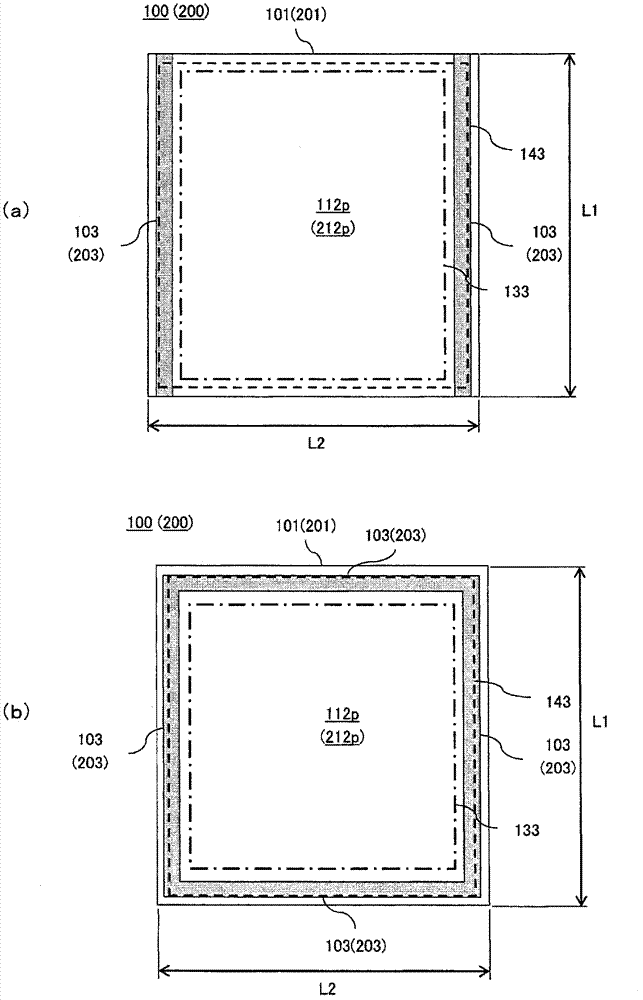

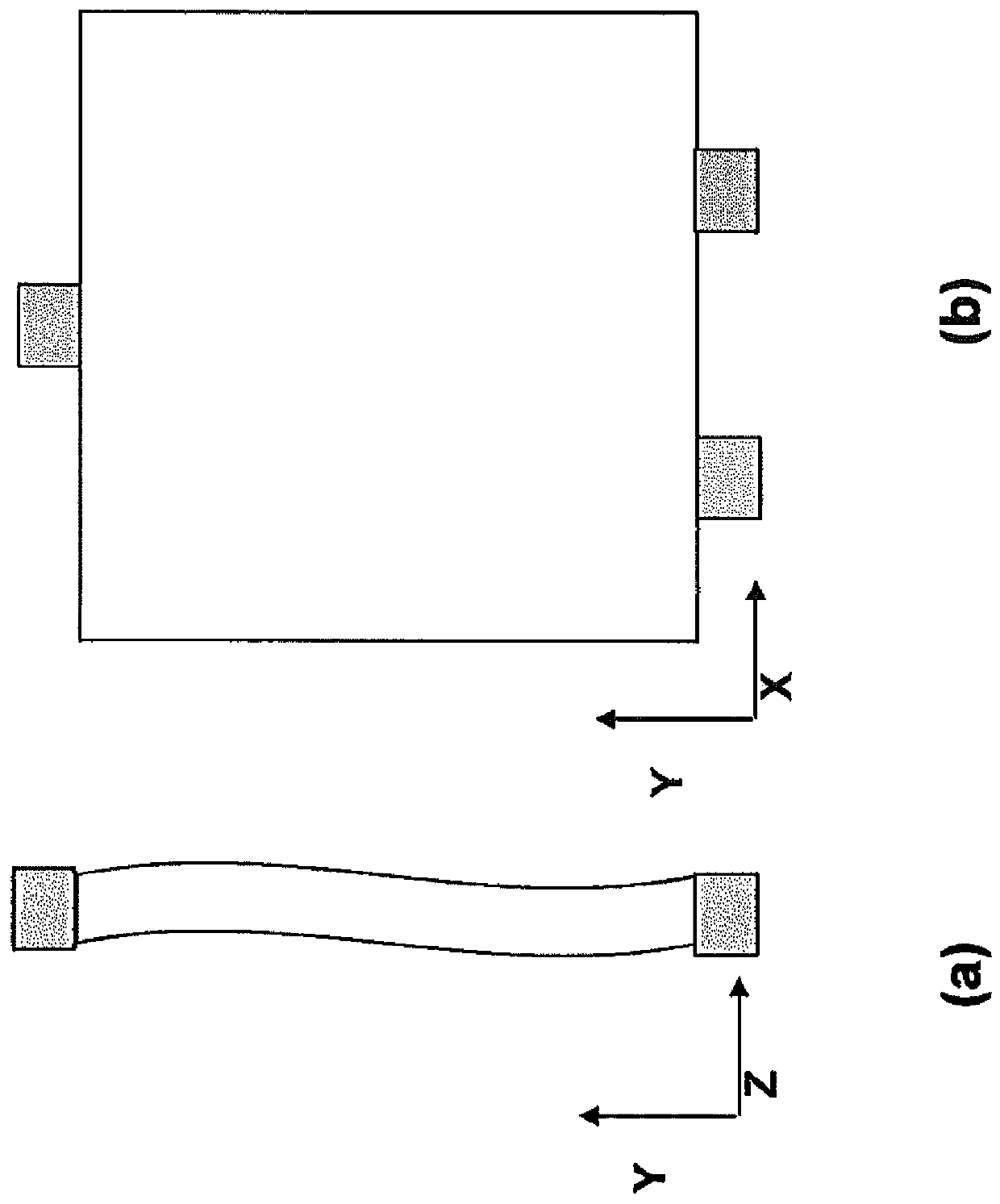

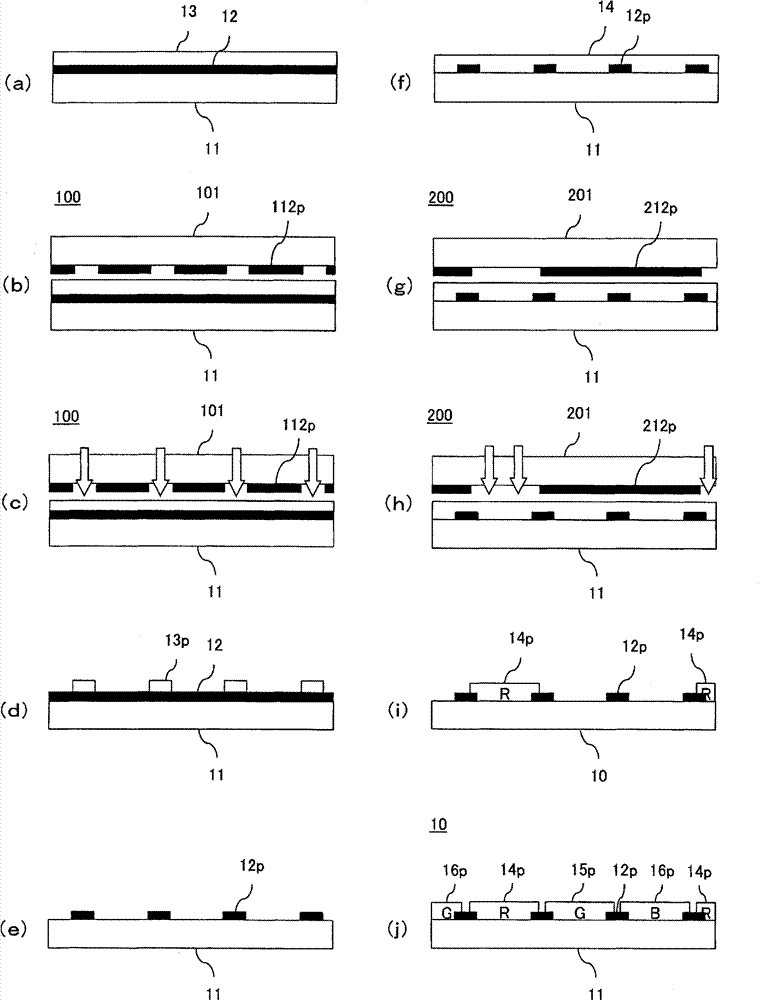

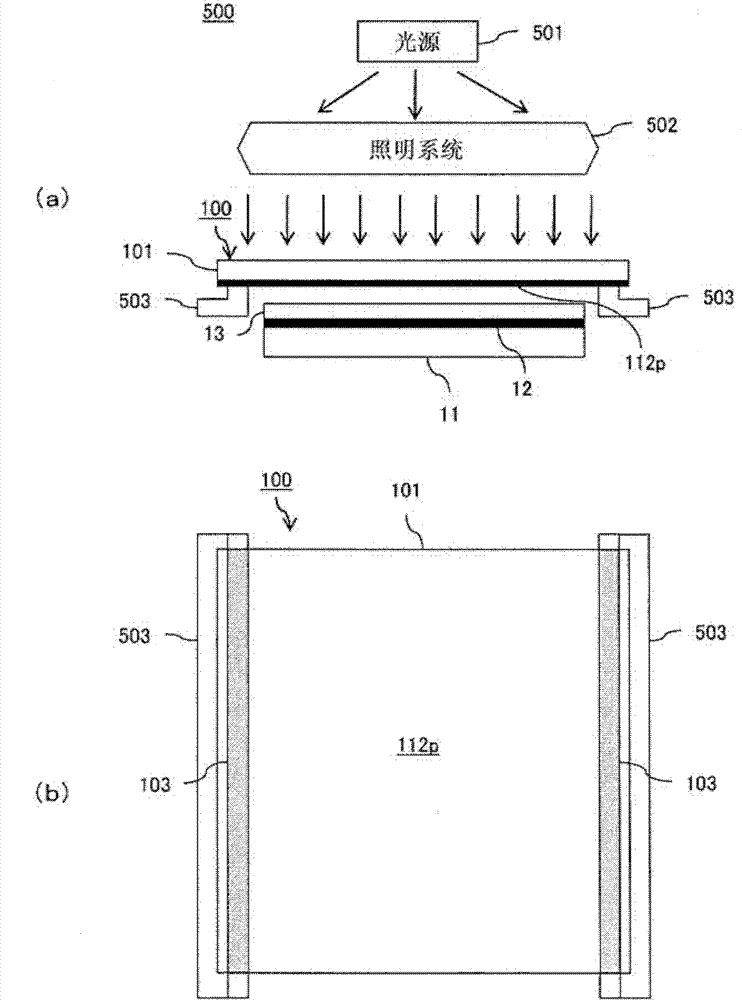

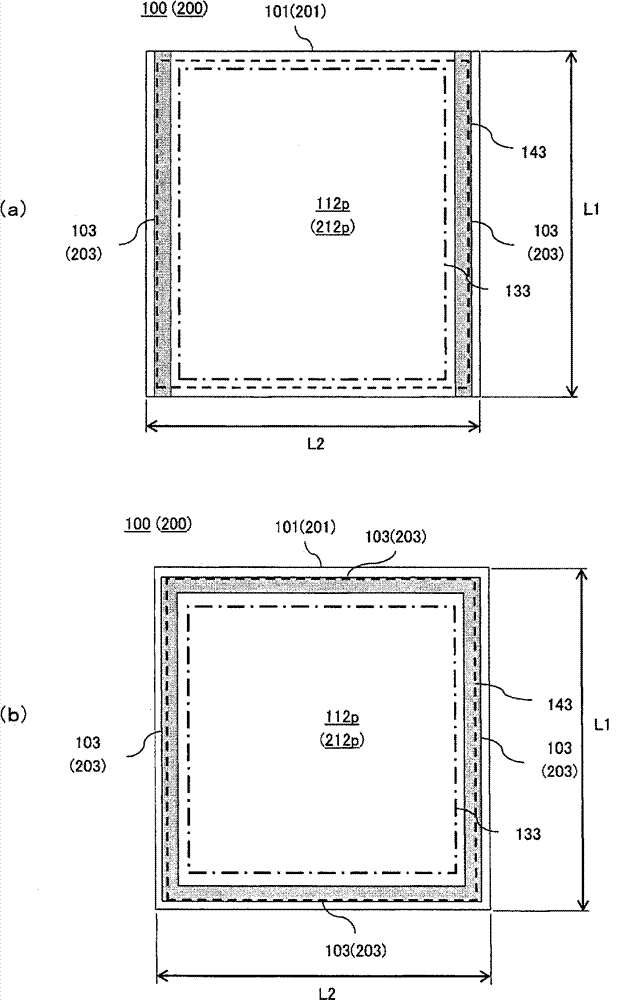

Substrate for photomask, photomask, method for manufacturing photomask and method for transfering pattern

ActiveCN102736402AHigh transfer accuracyHigh coordinate accuracyOptical filtersSemiconductor/solid-state device manufacturingEngineeringHeight difference

The invention provides a substrate for a photomask, the photomask, a method for manufacturing the photomask and a method for transfering a pattern, and transferring precision of the pattern is improved in proximity exposure. The photomask is provided with: a transparent substrate; and a transferring pattern formed by composing a shading film formed at the surface of the transparent substrate to be a predetermined transferring pattern, wherein, a worktable using a depicting machine supports the second main surface of the transparent substrate from the lower part; and the transferring pattern is formed, for the flatness of the second main surface of the transparent surface when no supporting part is sued to support the transparent substrate from the lower part, when the height difference between each arbitrary two points, is disposed to be Delta Zb([mu]m), Delta Zb<=(1 / T)*3.0.

Owner:HOYA CORP

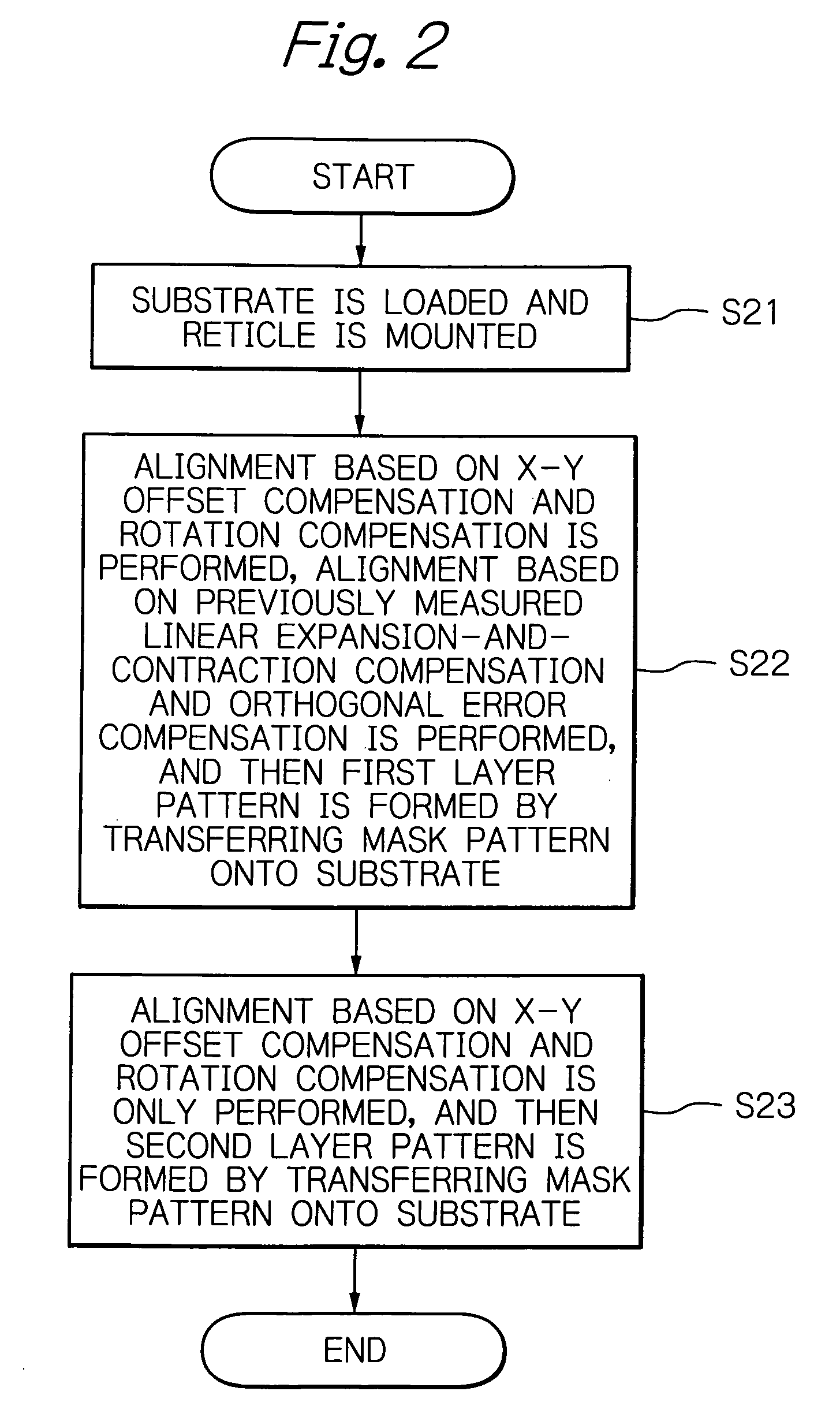

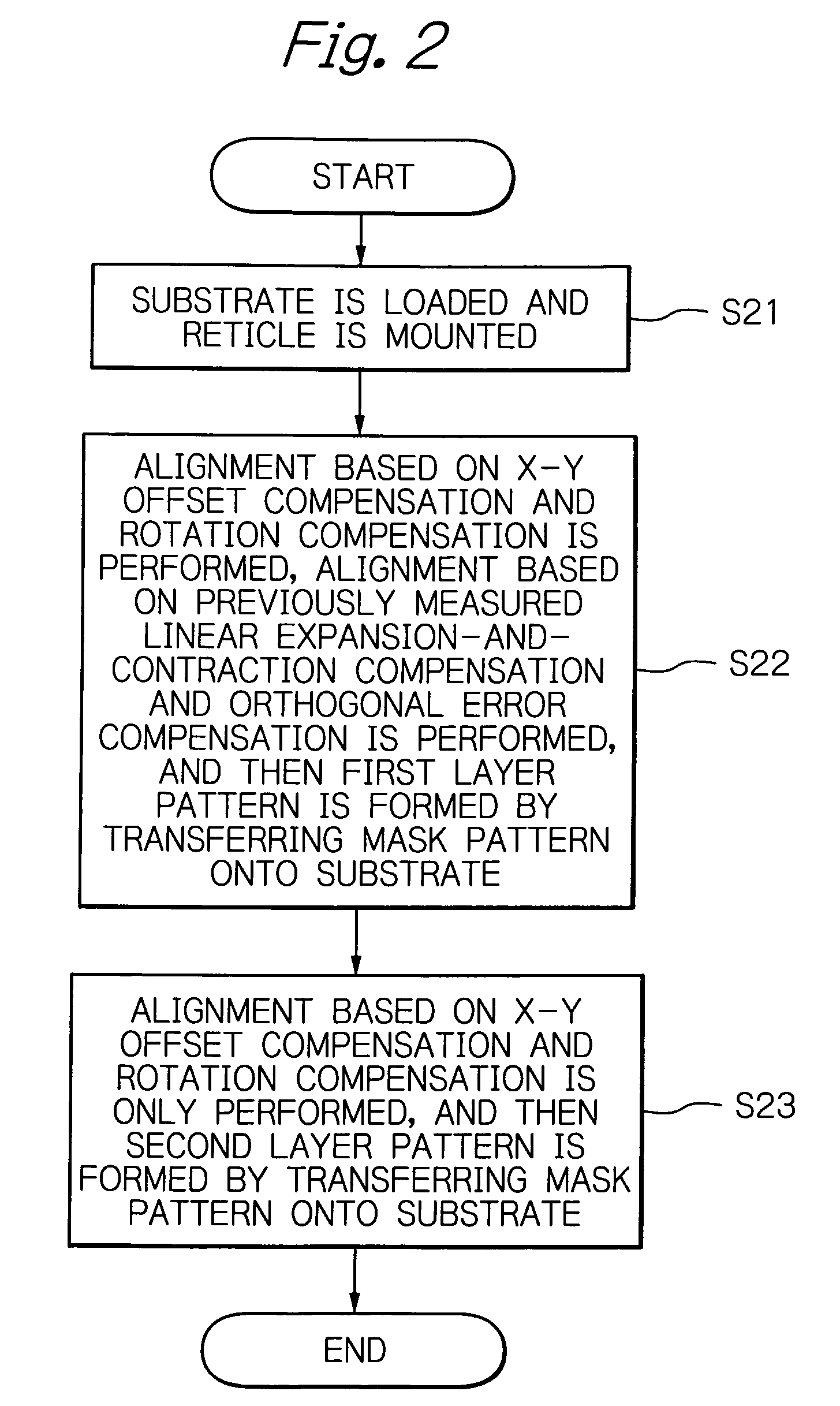

Alignment method and apparatus of mask pattern

InactiveUS20090284719A1Improve accuracyImprove accuracy in pattern-arrangement of the second layerPhotomechanical apparatusPhotographic printingRotation errorEngineering

An alignment method of mask patterns in patterning processes includes forming a first layer by transferring a first mask pattern onto a wafer or a layer formed on the wafer, and forming a second layer by transferring a second mask pattern onto the first layer. The method particularly includes a first alignment step of performing, when forming the first layer, alignment for minimizing offset between a center position of the wafer and a center position of the first mask pattern and a residual rotation error between the wafer and the first mask pattern, and alignment based on an amount of deviation of superposition of the second layer pattern on the first layer pattern. The deviation is caused by linear expansion and contraction of a wafer and caused by an orthogonal error between a wafer and a mask pattern, and also the deviation is obtained by measuring in advance in pattering processes successively performed for a plurality of wafers. The method also includes a second alignment step of performing, when forming the second layer, only alignment for minimizing offset between a center position of the first layer pattern and a center position of the second mask pattern and a residual rotation error between the first layer pattern and the second mask pattern.

Owner:TDK CORPARATION

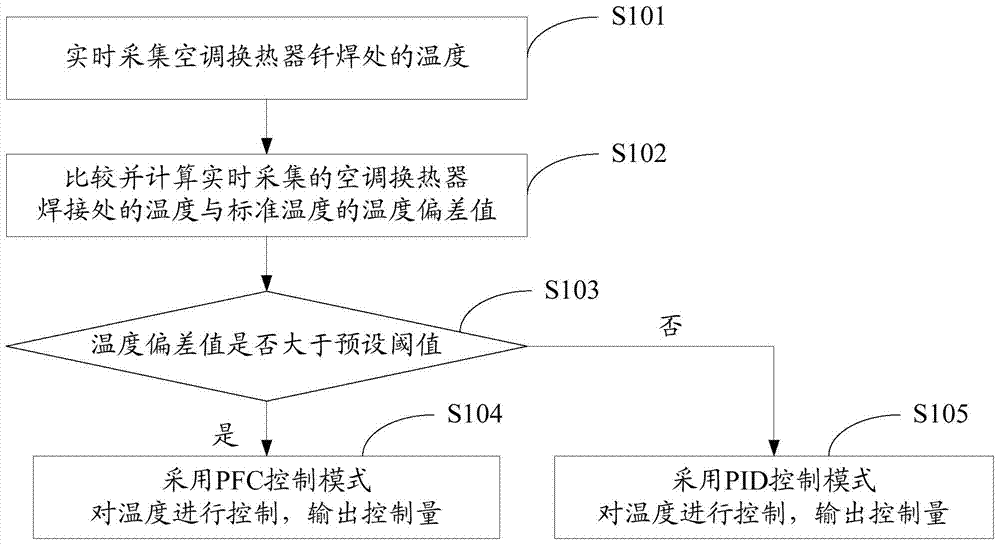

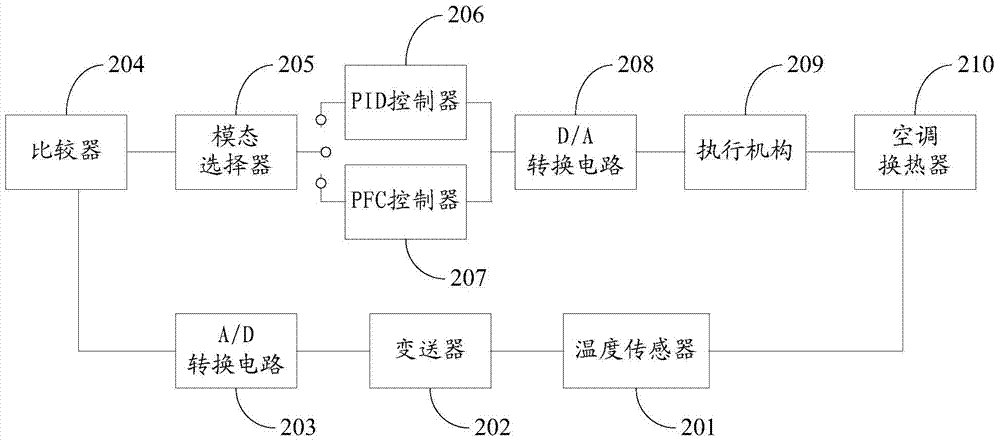

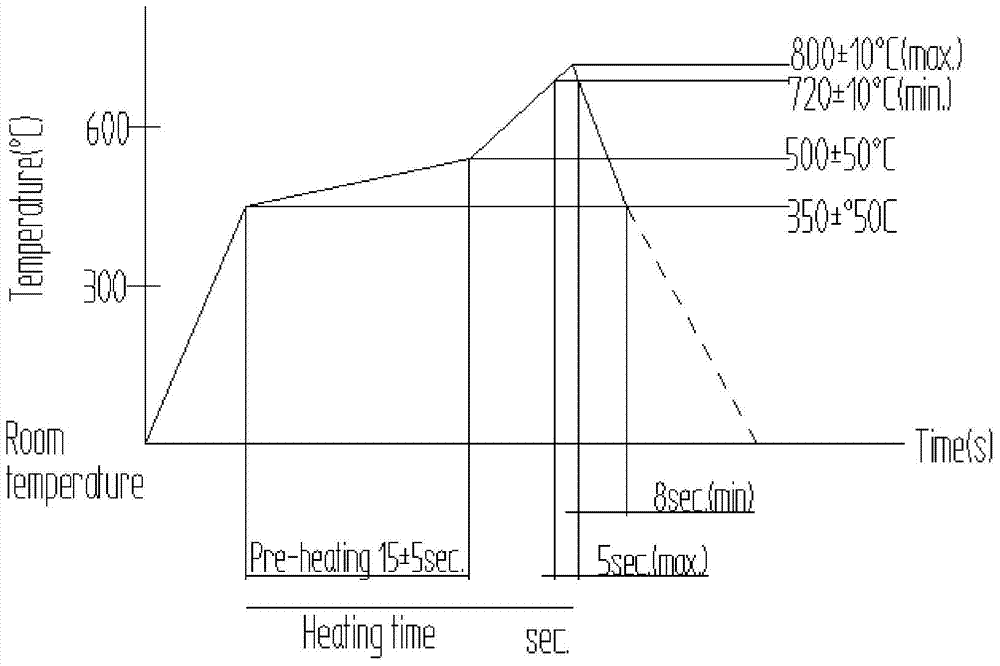

Method and system for temperature control of air-conditioner heat exchanger automatic brazing

ActiveCN103592974AQuality improvementImprove response efficiencyTemperatue controlTemperature controlControl system

The invention discloses a method and a system for temperature control of air-conditioner heat exchanger automatic brazing. The method comprises the steps of collecting the temperature of a brazing part of an air-conditioning heat exchanger in real time; comparing and calculating temperature deviation between the temperature, which is collected in real time, of the brazing part of the air-conditioning heat exchanger and a standard temperature; and judging whether the temperature deviation is greater than a preset threshold value or not, and if so, carrying out control on the temperature by adopting a PFC control mode and outputting a controlled variable; otherwise, carrying out control on the temperature by adopting a PID control mode and outputting a control variable. The invention further discloses a system for temperature control of air-conditioner heat exchanger automatic brazing. The method and the system disclosed by the invention combine the PFC control mode with the PID control mode, and improve the precision of temperature control, thereby improving the quality of the air-conditioning heat exchanger.

Owner:GREE ELECTRIC APPLIANCES INC

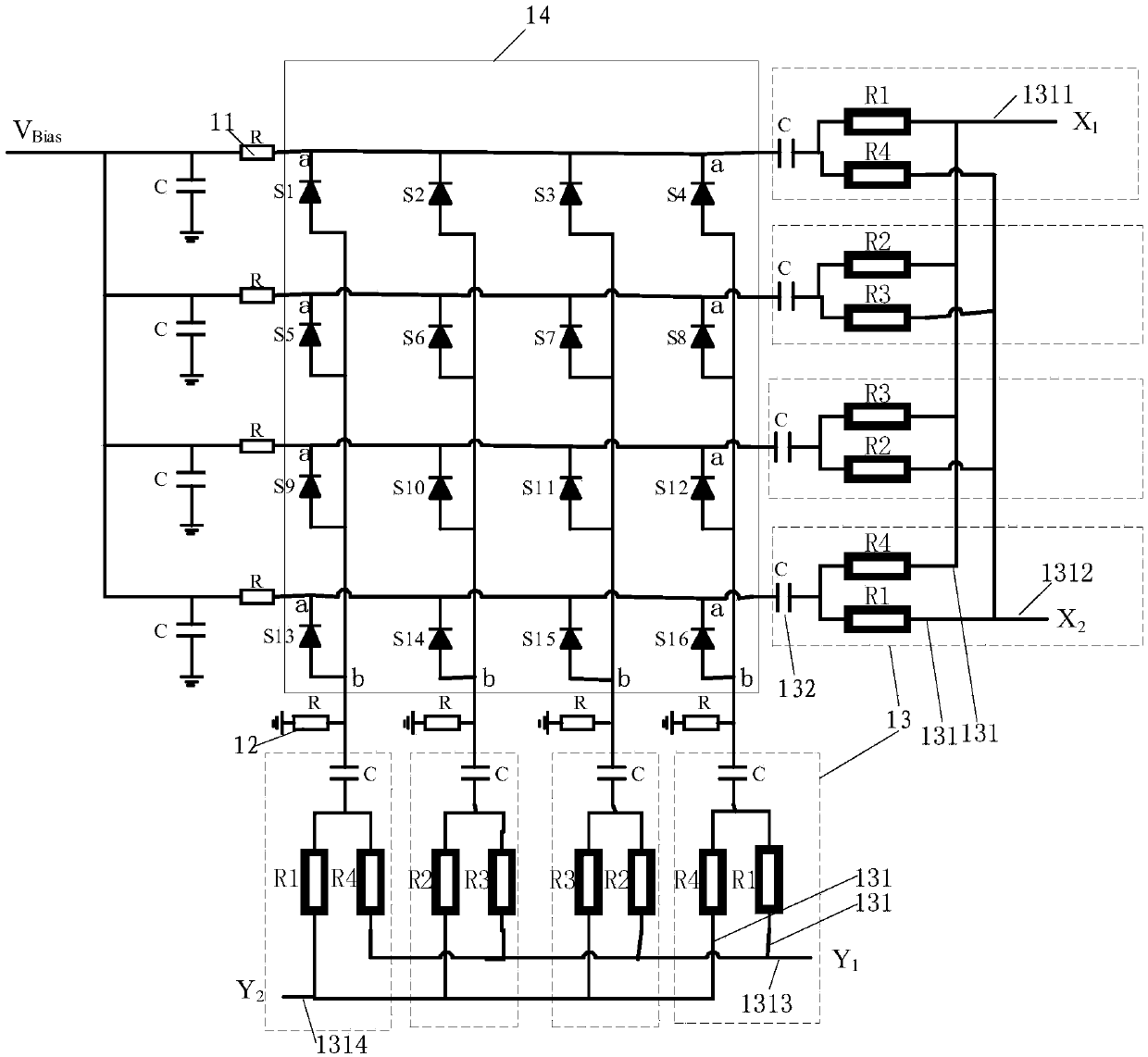

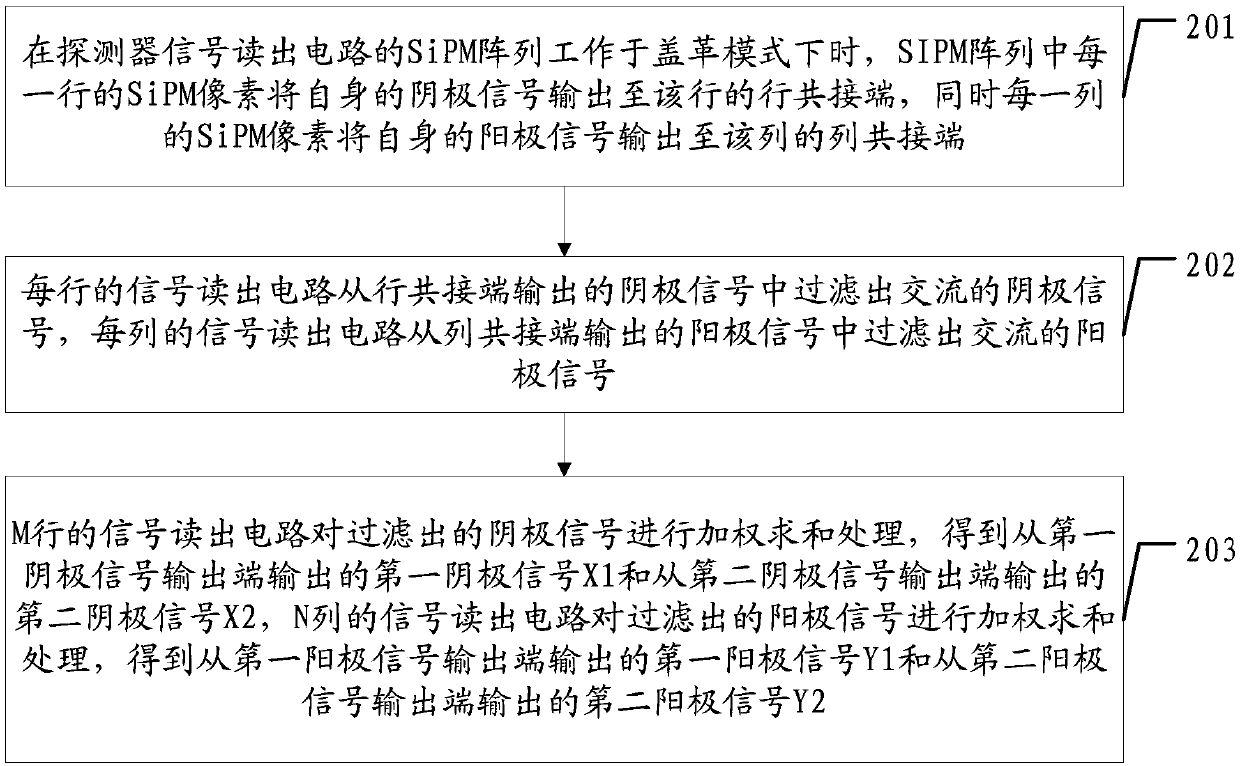

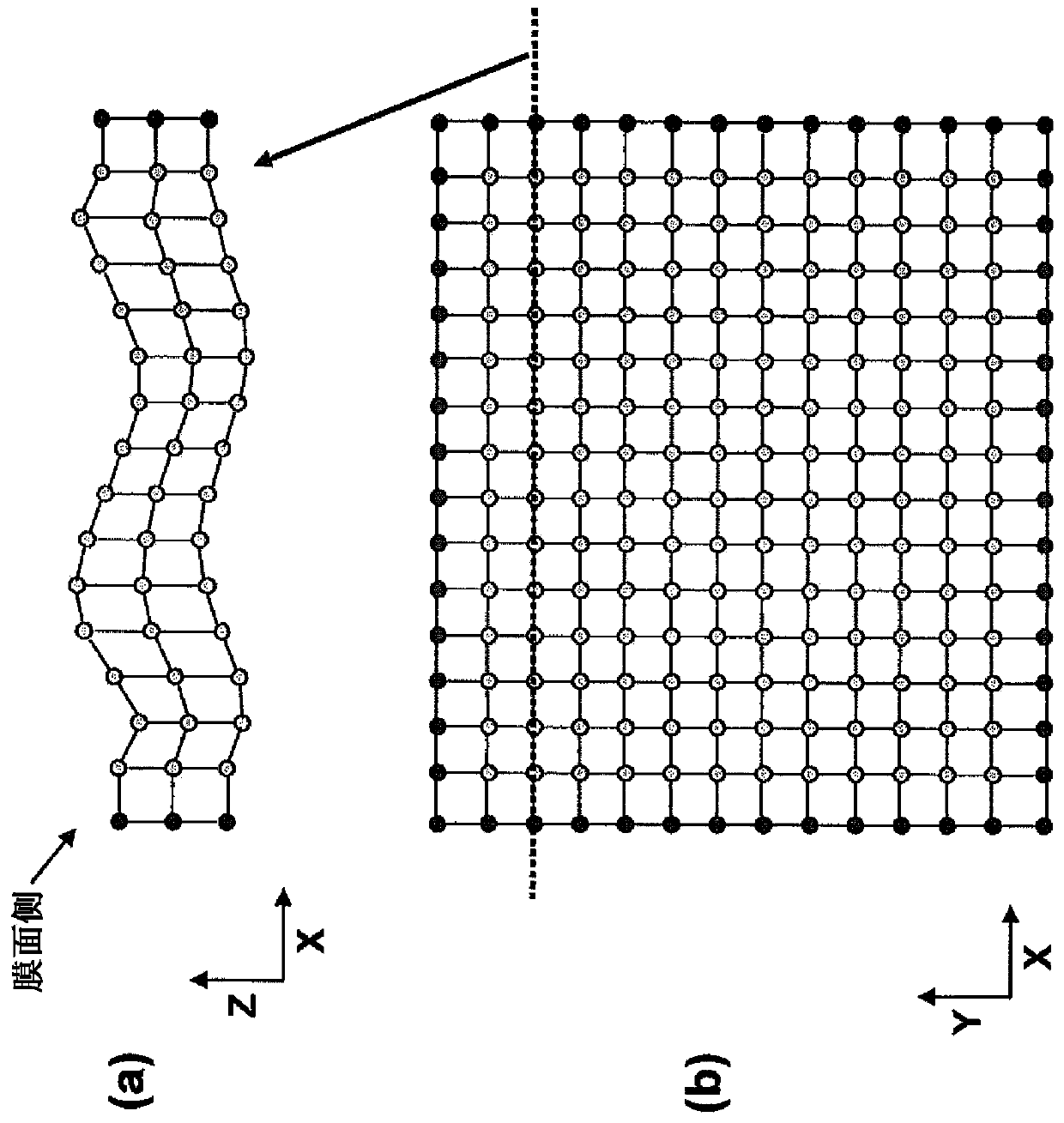

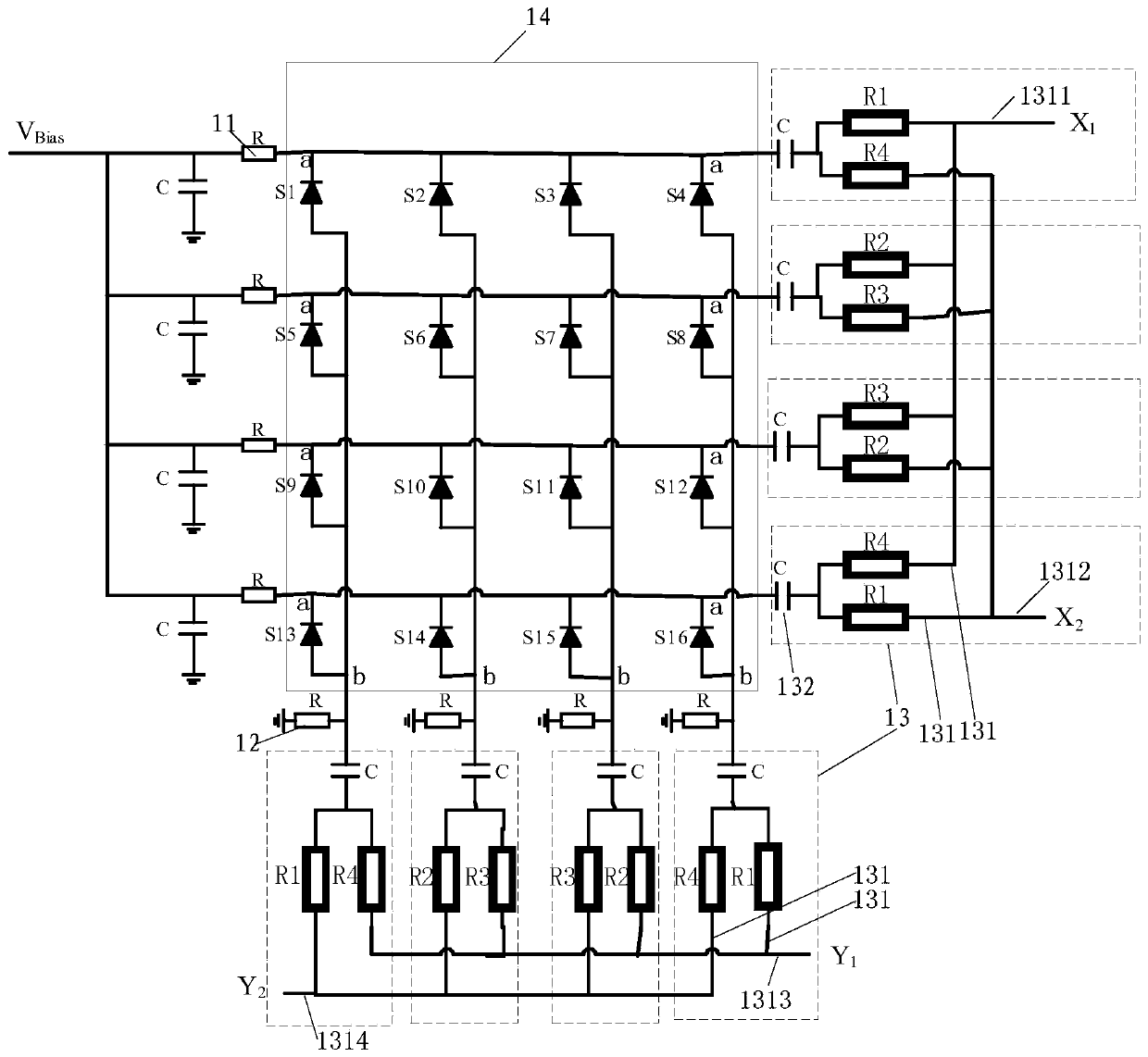

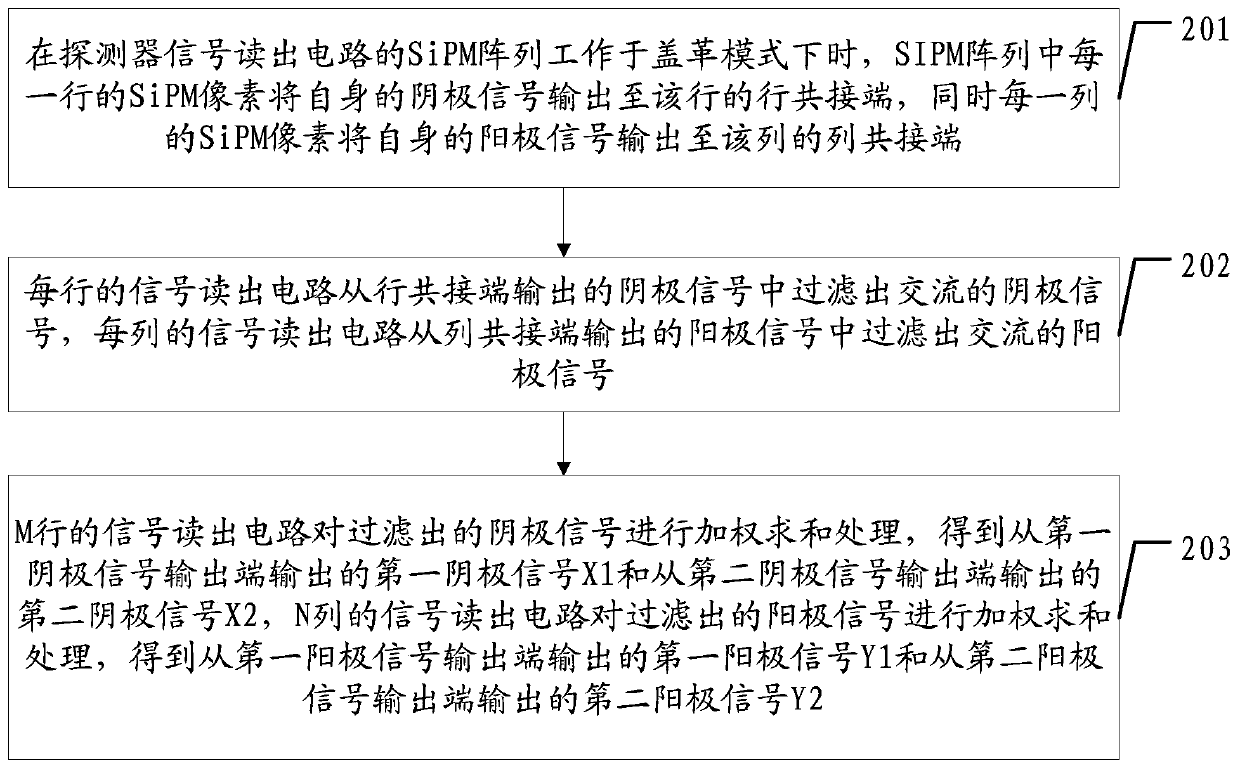

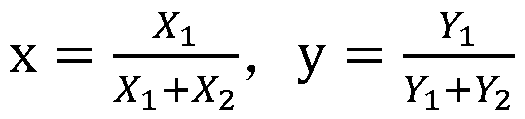

Detector signal readout circuit, detector and signal processing method

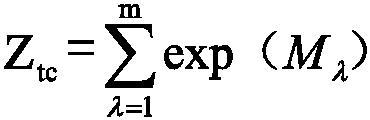

ActiveCN109597114AReduce complexityReduce areaX/gamma/cosmic radiation measurmentWeight coefficientScintillation crystals

The invention discloses a detector signal readout circuit, a detector and a signal processing method. Cathode signal output ends of each row of SiPM (Silicon Photomultipliers) pixels of an SiPM arrayare connected to form M row common connection ends, anode signal output ends of each column of the SiPM pixels are connected to form N column common connection ends, each row common connection end andeach column common connection end are connected with a signal readout circuit, in the case that the SiPM array is in a Geiger mode, the signal readout circuit can filter out alternating current signals of each row and each column, the M-row signal readout circuit can carry out weighted summation on the M-row cathode alternating current signals to obtain two row signals, the N-column signal readout circuit can carry out weighted summation on the N-column anode alternating current signals to obtain two column signals. According to the circuit, the detector and the method in the invention, setting of weight coefficients of the sub-circuits in the rows and columns enables the coordinate precision of the position of a scintillation crystal obtained through a gravity center method based on therow and column signals higher, also, large numbers of shunting resistors and analog amplifiers are not needed, so that the electronics complexity of the circuit and the area of the readout board are reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

A method for automatic calibration of hand-eye relationship of collaborative robots

ActiveCN110497386BImprove calibration efficiencySimplify the calibration processProgramme-controlled manipulatorRobot handComputer graphics (images)

Owner:SIASUN CO LTD

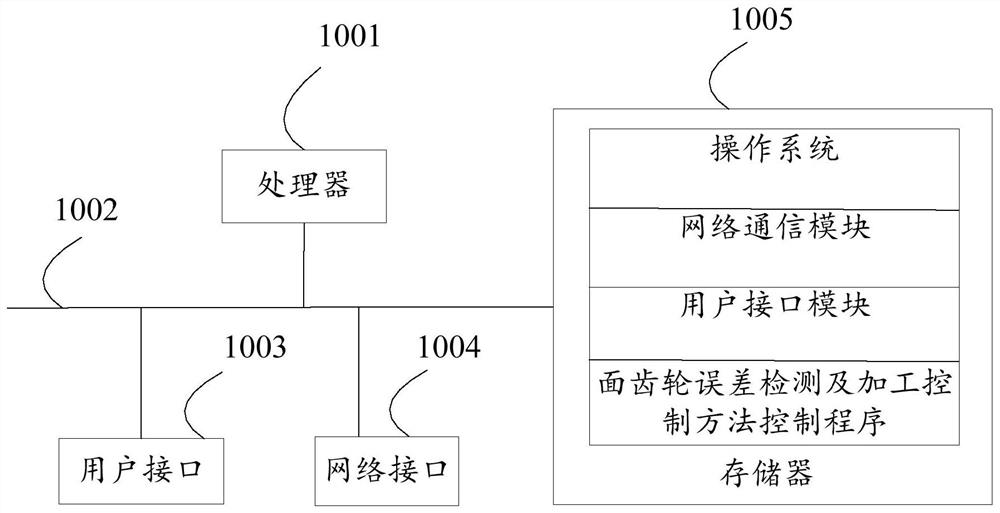

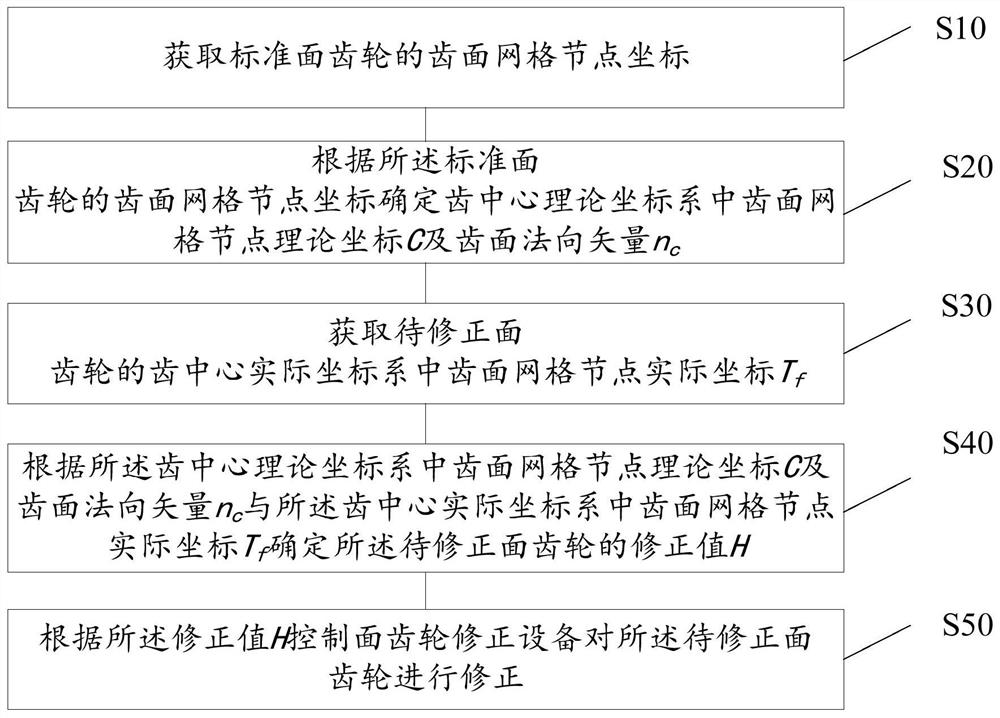

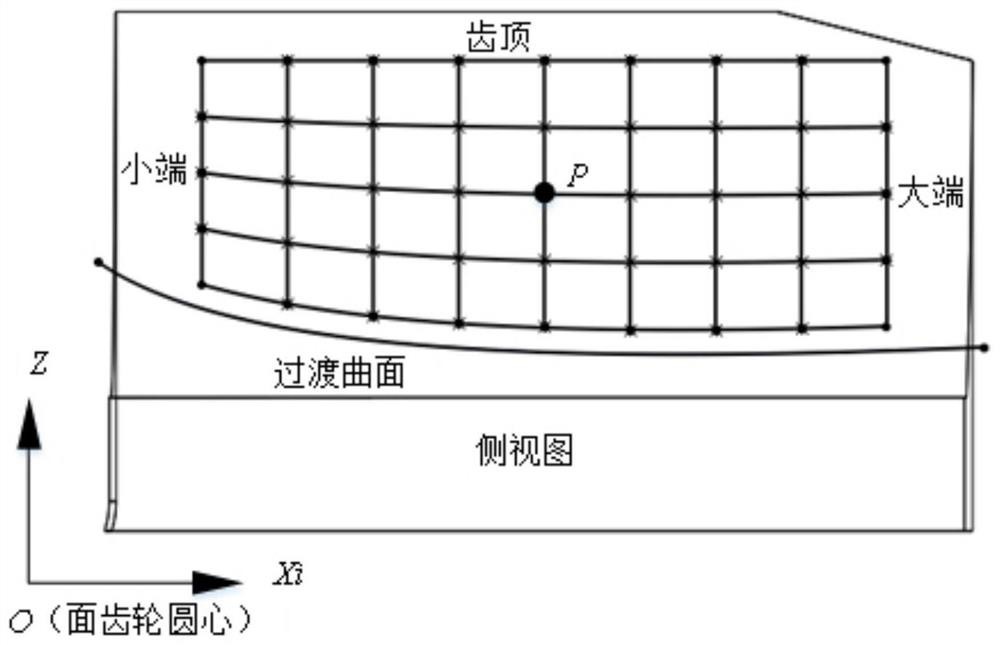

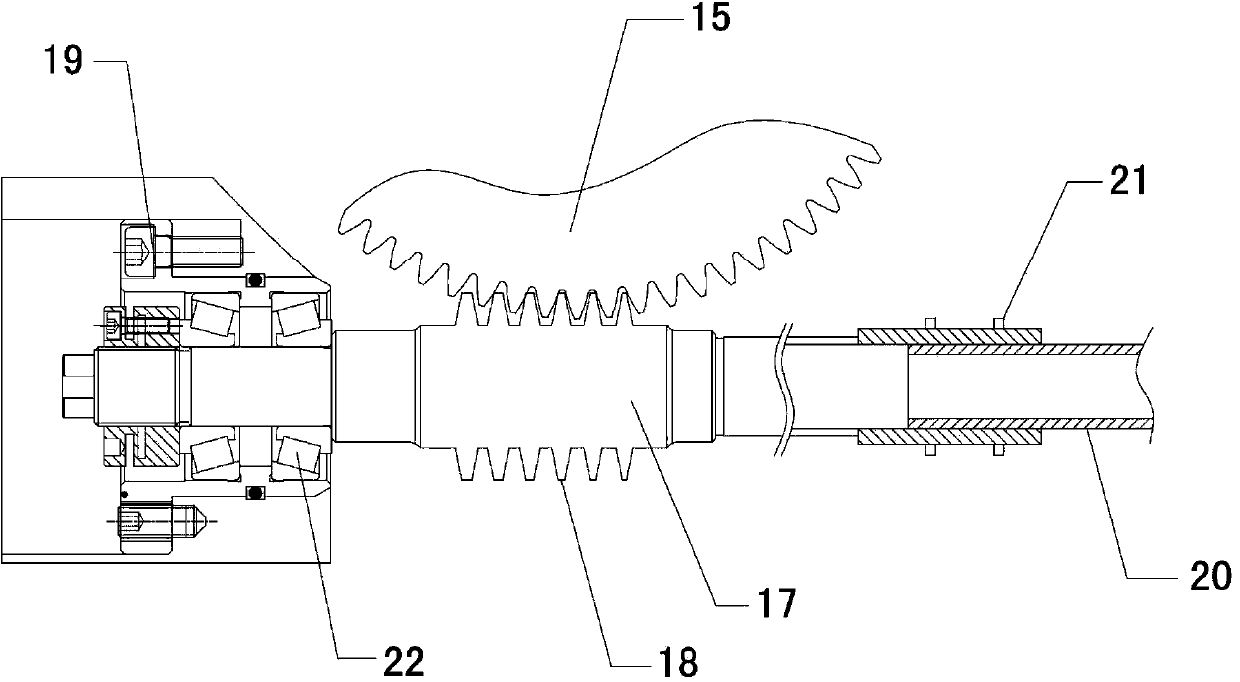

Face gear error detection and machining control method, device and system

ActiveCN113175903AHigh coordinate accuracyGuaranteed standardMeasurement devicesLaser beam welding apparatusMachine controlGear tooth

The invention provides a face gear error detection and machining control method, device and system. The face gear error detection and machining control method comprises the following steps: obtaining tooth surface grid node coordinates of a standard face gear; determining a tooth surface grid node theoretical coordinate C and a tooth surface normal vector nc in the tooth center theoretical coordinate system according to the tooth surface grid node coordinate of the standard surface gear; acquiring the actual coordinate Tf of a tooth surface grid node in the actual coordinate system of the tooth center of the to-be-corrected face gear; determining a correction value H of the to-be-corrected face gear according to the theoretical coordinate C and the tooth surface normal vector nc of the tooth surface grid node in the tooth center theoretical coordinate system and the actual coordinate Tf of the tooth surface grid node in the tooth center actual coordinate system; and controlling the face gear correction equipment to correct the to-be-corrected face gear according to the correction value H. According to the scheme, operation is easy, face gear detection and machining precision is improved, errors are reduced, and meanwhile the method is suitable for error detection and control of tooth surfaces of different face gears.

Owner:HUBEI UNIV OF ARTS & SCI

Method for joint measurement of slope monitoring reference point and IGS tracking station

PendingCN110488323AHigh precisionHigh coordinate accuracySatellite radio beaconingOpen-pit miningSlope monitoring

The invention belongs to the technical field of open-pit mining, and particularly relates to a method for joint measurement of a slope monitoring reference point and an IGS tracking station. The method is characterized by comprising the following steps of (1) reference network observation, (2) reference point data processing and (3) a data processing process and results. With the acquisition of high-precision reference station starting coordinates as a target, GAMIT software is used to perform joint measurement processing on base station data, the high-precision geocentric three-dimensional coordinates of the reference station are obtained as the starting point by studying a combination of different joint measurement IGS stations, processing methods, and processes, and regular re-examinations are conducted to check the stability of the reference point in a large scale space range.

Owner:ANSTEEL GRP MINING CO LTD

Method for manufacturing photomask, inspection method, and inspection device

ActiveCN110058488AHigh coordinate accuracyThe preparation method is simple and easySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringPhotomask

The invention provides a method for manufacturing a photomask, an inspection method and an inspection apparatus, which can improve the coordinate accuracy of a pattern formed on a transferred object.The method for manufacturing a photomask comprises the steps of: preparing pattern design data (A); obtaining transfer surface correction data (D) indicating the amount of deformation of the main surface due to the holding of the photomask to the exposure device and the amount of deformation other than the deadweight deflection component; obtaining drawing height distribution data (E) representingthe height distribution of the main surface in a state where the photomask blank is placed on a workbench of a drawing device; drawing differential data (F) are obtained through the difference between the height distribution data (E) and the transfer surface correction data (D) during drawing; calculating a coordinate deviation amount corresponding to the drawing differential data (F), and obtaining coordinate deviation amount data (G) for drawing; and a drawing step in which drawing is performed on the photomask blank using the coordinate deviation amount data (G) for drawing and the patterndesign data (A).

Owner:HOYA CORP

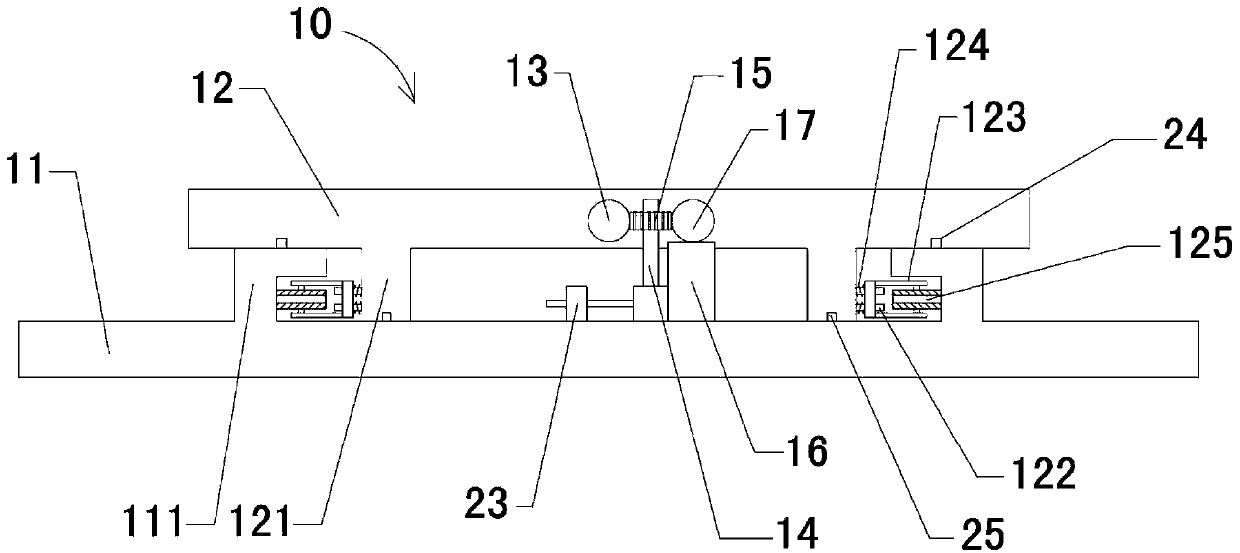

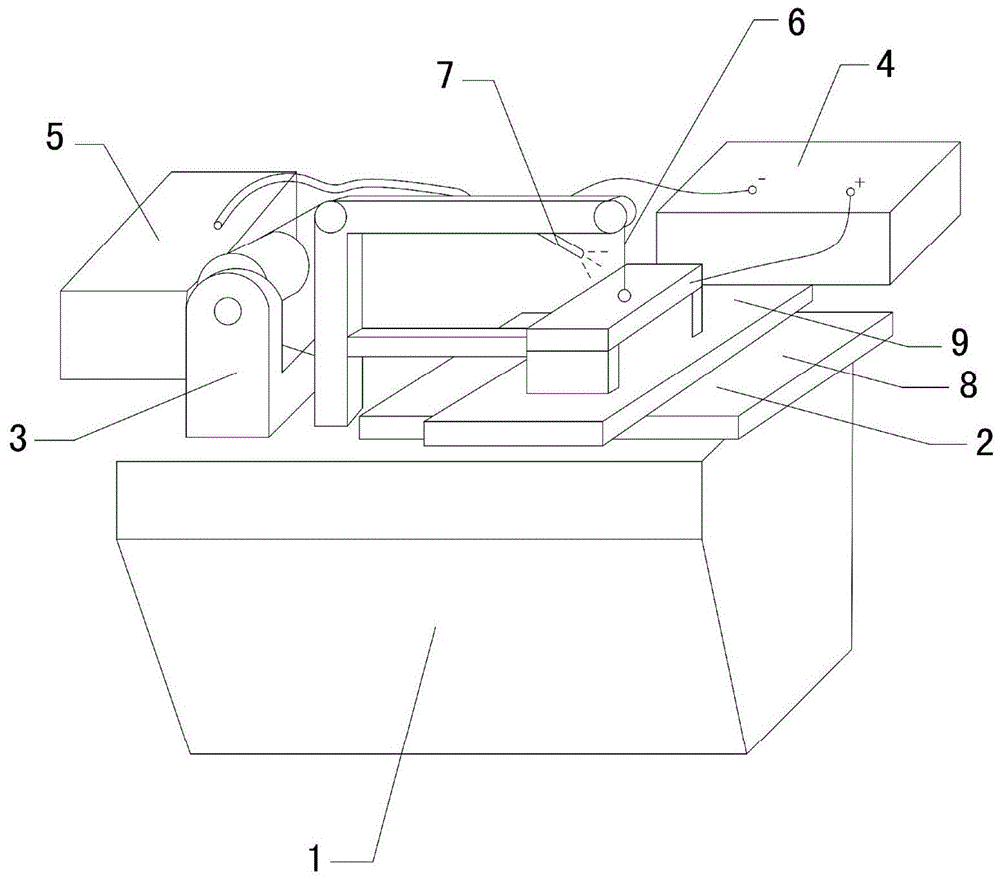

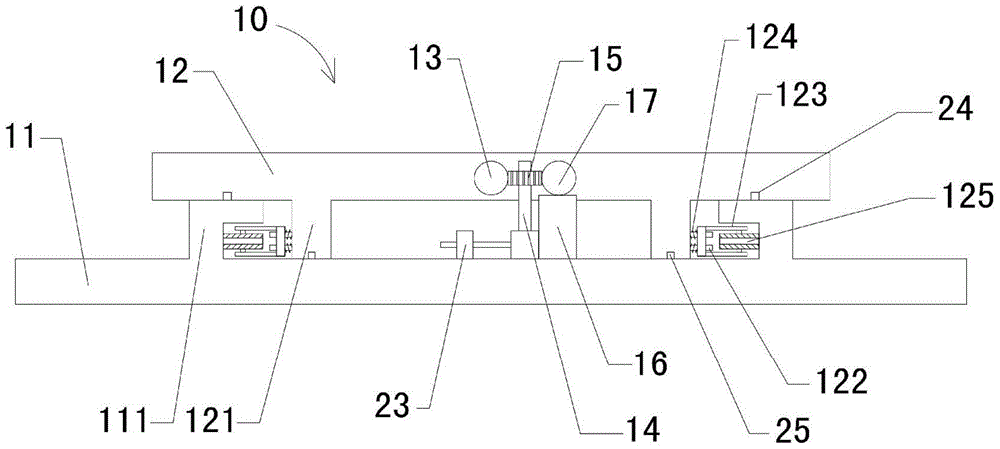

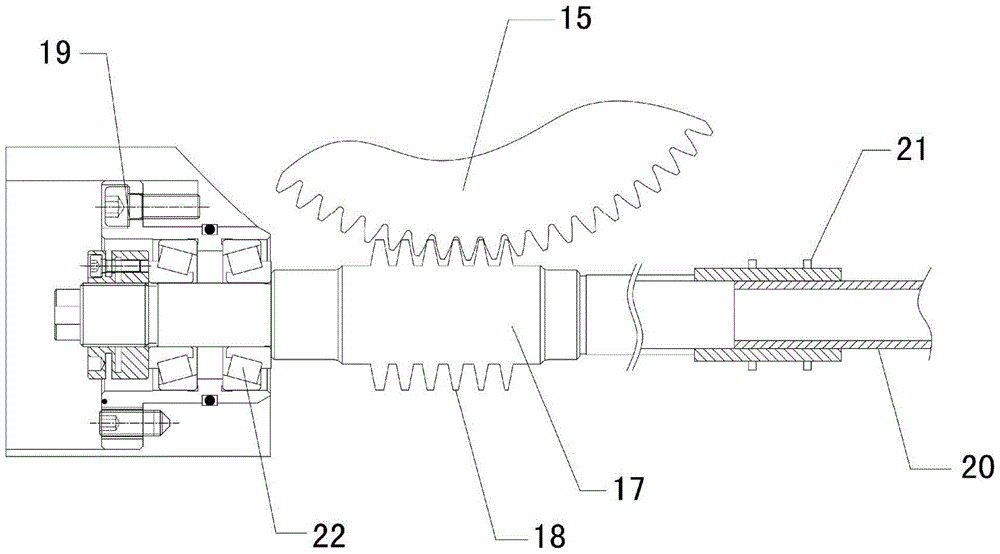

Novel CNC wire cutting machine

The invention relates to a novel CNC wire cutting machine which can effectively improve the coordinate accuracy of a horizontal plate and a longitudinal plate. The novel CNC wire cutting machine comprises a machine tool body, a workbench, a wire walking mechanism, a high-frequency pulse power supply, a liquid supply system and an electrode wire. The workbench comprises a horizontal plate, a longitudinal plate and a displacement device. The horizontal plate is arranged on the top face of the machine tool body through the displacement device. The longitudinal plate is arranged on the top of the horizontal plate through the displacement device. The displacement device comprises a bottom plate and a top plate. A thread rod is fixed at the end of the top plate in a parallel mode. A middle rotating shaft is vertically arranged on the bottom plate. A worm wheel is arranged on the middle rotating shaft through a bearing. The worm wheel is meshed with a thread face of the thread rod. A motor box is arranged on the bottom plate. The motor box comprises a speed reducing motor, a worm and a worm adjusting sleeve. One end of the worm is arranged at the output end of the speed reducing motor. Spiral-shaped gear teeth meshed with the worm wheel are arranged on the worm. The thickness of the gear teeth are gradually increased from one end to the other end in the axial direction. The other end of the worm moves relatively in the axial direction in a worm adjusting sleeve.

Owner:TAICANG SHUNCHANG FORGE

RGBY-based shadow elimination method

InactiveCN105869121AImprove performanceAdaptableImage enhancementImage analysisLight spotRGB color model

The invention discloses an RGBY-based shadow elimination method. Firstly, background difference of a gray Y channel and a high threshold of a sampling threshold method in a fixed background are used for extracting a rough moving target and a shadow thereof; in combination with a gray low threshold and an RGB color model, Gaussian blur is carried out on an RGB channel in a light spot extracted by the high threshold; and recursive integral processing is then carried out, and RGB after integral processing is converted into a Y signal. According to the shadow elimination method provided by the invention, the performance is excellent; the adaptability is strong; the shadow part in a contour of the moving object extracted in the fixed background can be quickly and accurately eliminated in various conditions; influences from the shadow are eliminated; and thus, the coordinate precision of the moving object in the fixed background is improved.

Owner:国网吉林省电力有限公司延边供电公司 +1

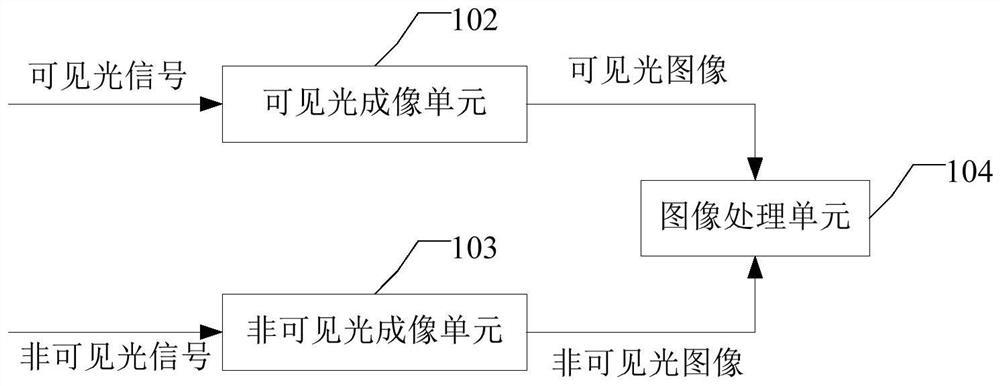

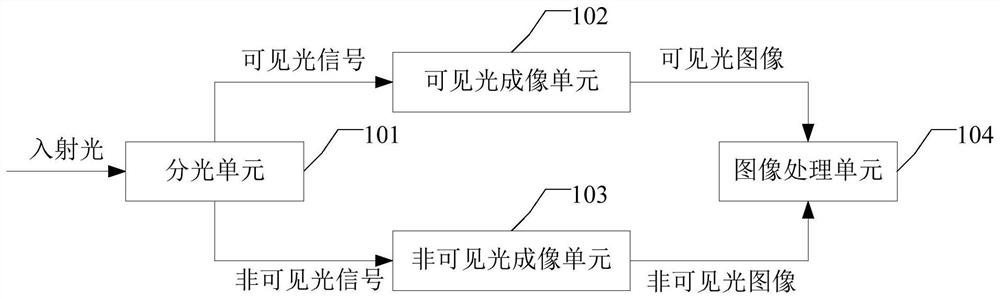

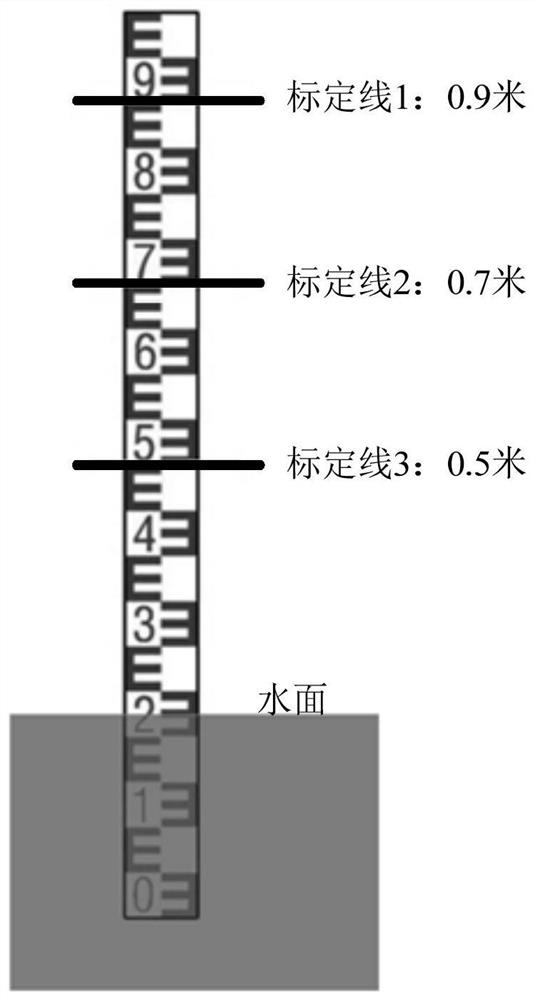

Image acquisition equipment, water level detection equipment, water level detection method and storage medium

PendingCN112444302AImprove accuracyHigh coordinate accuracyLevel indicators by dip membersMachines/enginesContrast levelImaging processing

The embodiment of the invention provides image an image acquisition equipment, water level detection equipment, a water level detection method and a storage medium. The image acquisition equipment comprises a visible light imaging unit which is used for imaging a visible light signal reflected by a water gauge, and obtaining a visible light image of the water gauge, an invisible light imaging unitwhich is used for imaging an invisible light signal reflected by the water gauge to obtain an invisible light image of the water gauge, and an image processing unit which is used for determining coordinates of a water line in the invisible light image of the water gauge and calculating water level data according to the calibration data in the visible light image of the water gauge and the coordinates of the water line in the invisible light image of the water gauge. A water area has high absorptivity to non-visible light, the contrast ratio of the water area and the water gauge in the non-visible light image is high, and and therefore, influence of various external factors on the image definition is reduced, so that the accuracy of the water line detected in the non-visible light image ishigh, and the accuracy of a water level detection result is improved.

Owner:HANGZHOU HIKVISION SYST TECH

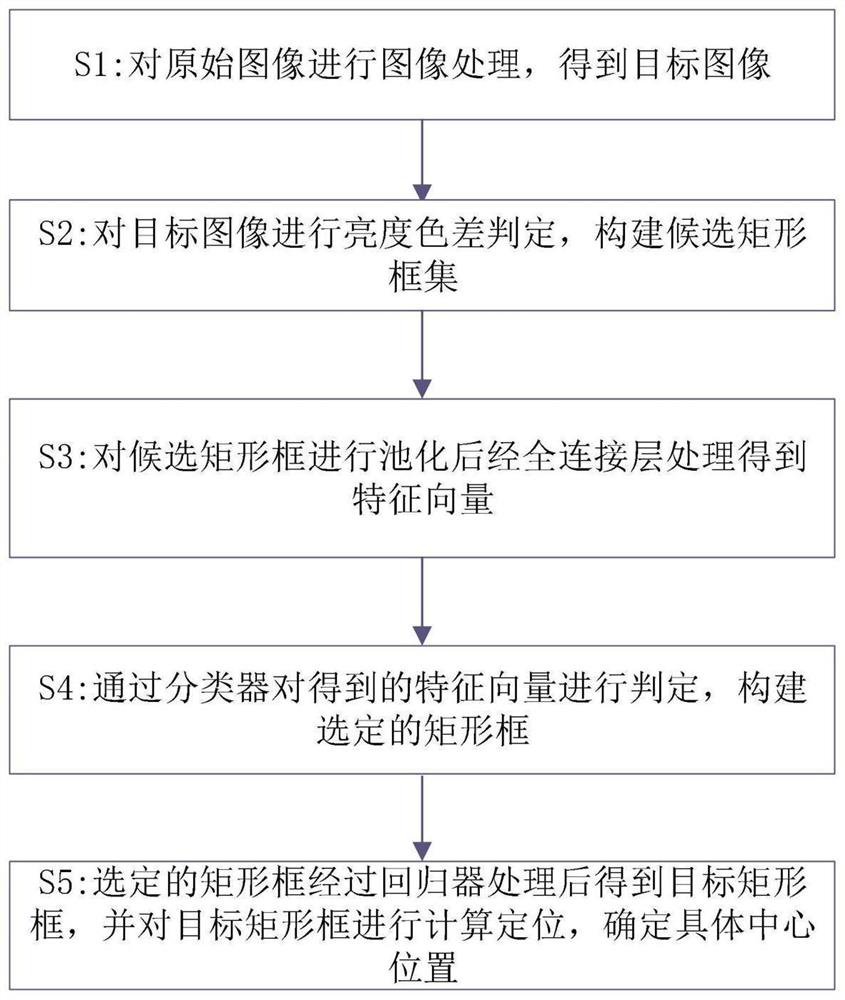

Method for detecting and positioning target surface impact point based on convolutional neural network

PendingCN114119720ASmall amount of calculationHigh coordinate accuracyImage enhancementImage analysisImage resolutionColor difference

Owner:工学智能科技(合肥)有限公司

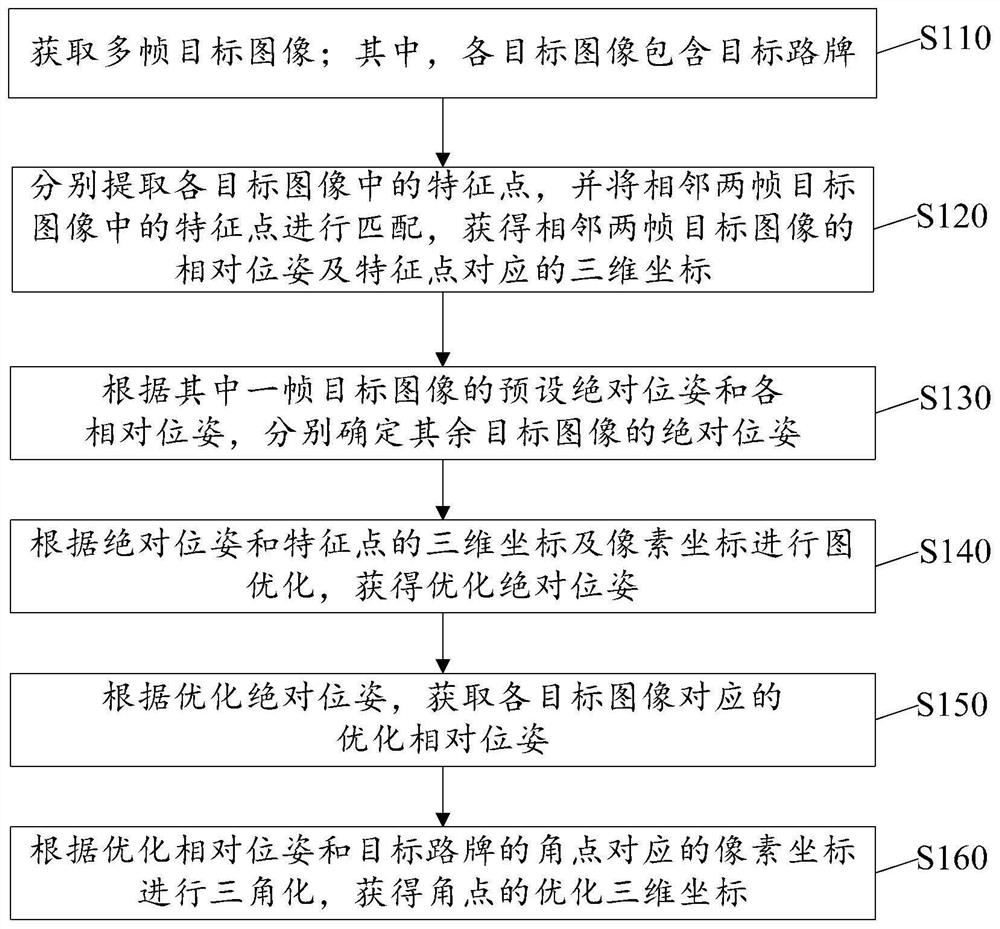

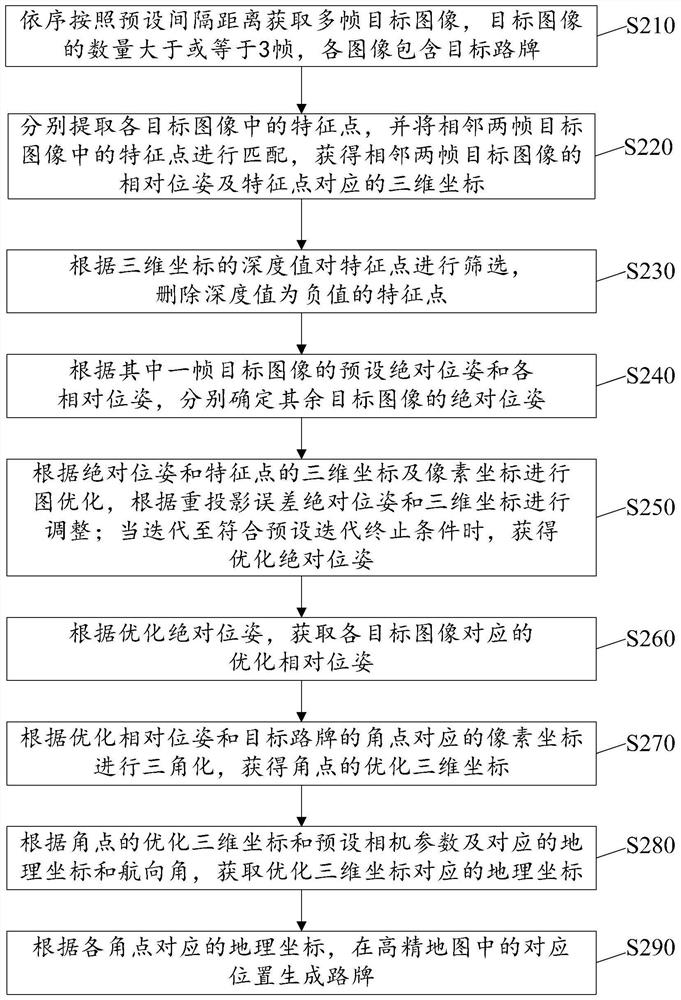

Guideboard generation method and device and electronic equipment

PendingCN114820784AGenerate accuratelyHigh coordinate accuracyImage analysisPattern recognitionComputer graphics (images)

The invention relates to a guideboard generation method and device and electronic equipment. The method comprises the following steps: acquiring multiple frames of target images; respectively extracting feature points in each target image, and matching the feature points in two adjacent frames of target images to obtain relative poses of the two adjacent frames of target images and three-dimensional coordinates corresponding to the feature points; according to a preset absolute pose and each relative pose of one frame of target image, respectively determining absolute poses of other target images; performing graph optimization according to the absolute pose and the three-dimensional coordinates and the pixel coordinates of the feature points to obtain an optimized absolute pose; obtaining an optimized relative pose corresponding to each target image according to the optimized absolute pose; and triangulation is carried out according to the optimized relative pose and the pixel coordinates corresponding to the angular points of the target guideboard, and optimized three-dimensional coordinates of the angular points are obtained. According to the scheme provided by the invention, the coordinate precision of the guideboard angular points can be improved, and the method has relatively high robustness so as to deal with the processing of each guideboard.

Owner:ZHIDAO NETWORK TECH (BEIJING) CO LTD

Method for manufacturing photomask, method for manufacturing display device, and drawing device

ActiveCN104423140BHigh coordinate accuracyThe preparation method is simple and easySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentDisplay deviceEngineering

Owner:HOYA CORP

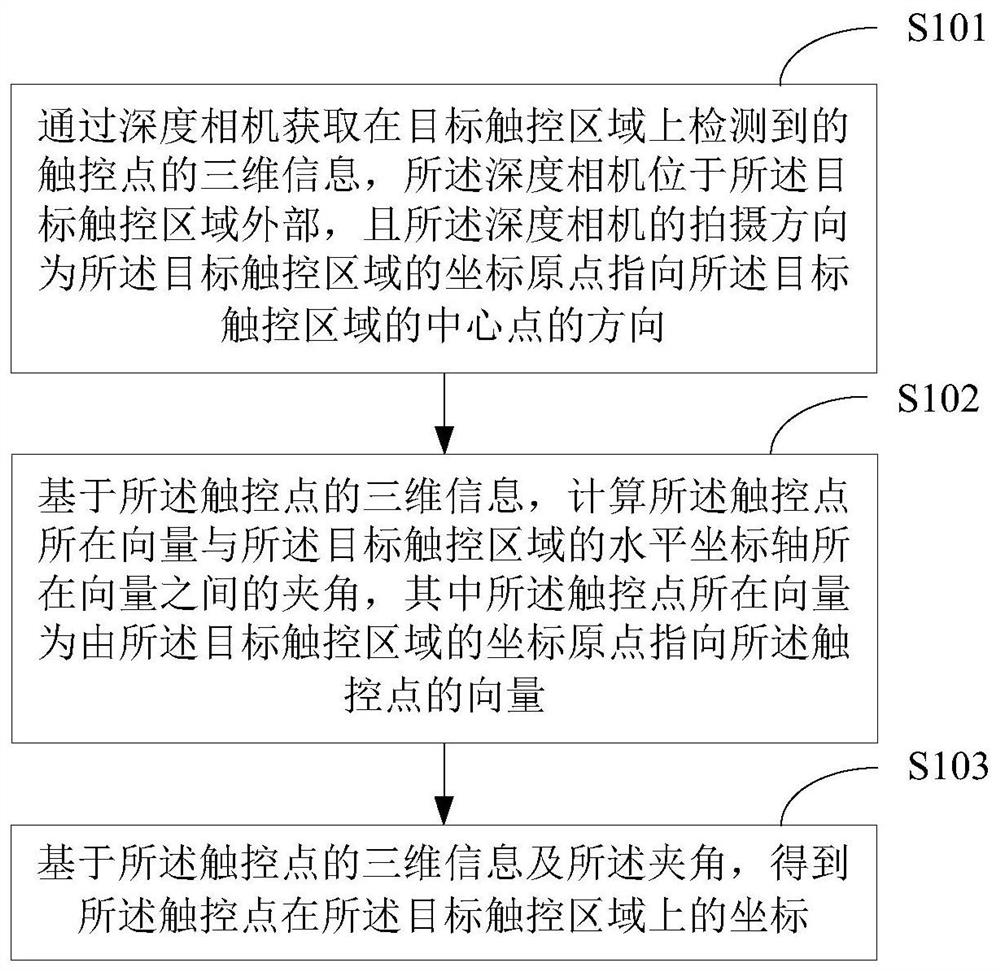

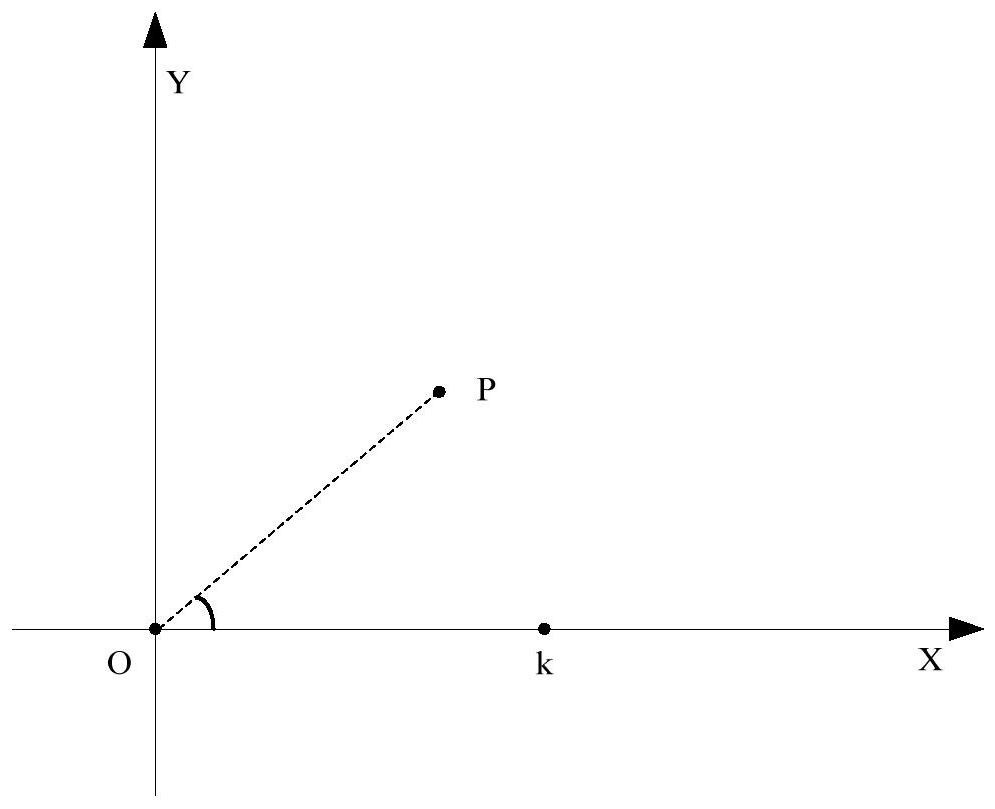

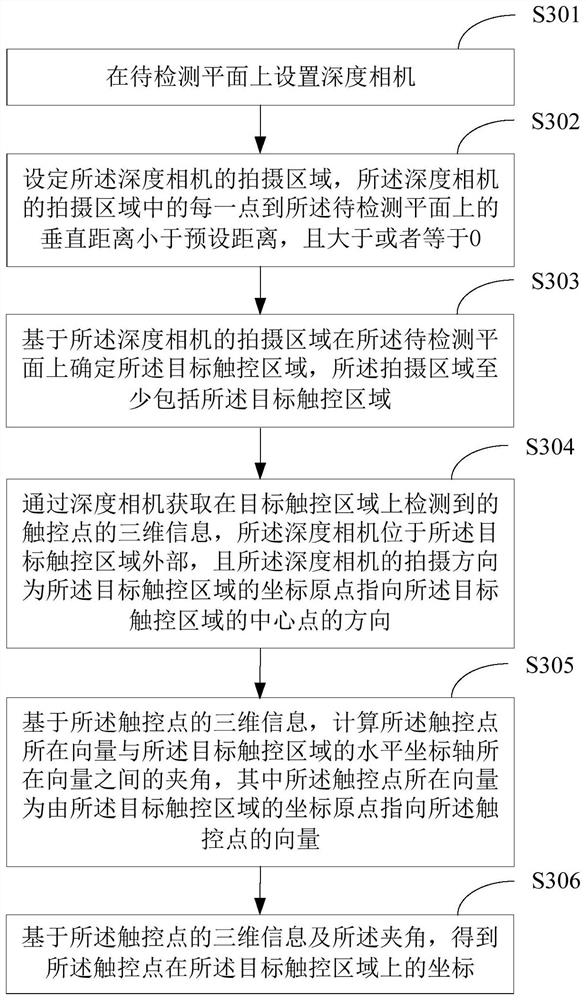

Touch control positioning method and device and terminal equipment

InactiveCN112181211AReduce hardware costsImprove convenienceInput/output processes for data processingMedicineComputer graphics (images)

The invention is suitable for the technical field of touch control, and provides a touch control positioning method and device and terminal equipment. The method comprises the steps: obtaining the three-dimensional information of a touch control point detected on a target touch control region through a depth camera which is located outside the target touch control region, wherein the shooting direction of the depth camera is the direction that the origin of coordinates of the target touch area points to the central point of the target touch area; based on the three-dimensional information of the touch point, calculating the included angle between the vector where the touch point is located and the vector where the horizontal coordinate axis of the target touch area is located, wherein thevector where the touch point is located is the vector pointing to the touch point from the origin of coordinates of the target touch area; obtaining coordinates of the touch point on the target toucharea based on the three-dimensional information of the touch point and the included angle. According to the method disclosed in the invention, the touch control positioning cost can be reduced.

Owner:TCL CORPORATION

Substrate for photomask, photomask, method for manufacturing photomask and method for transfering pattern

ActiveCN102736402BHigh transfer accuracyHigh coordinate accuracyOptical filtersSemiconductor/solid-state device manufacturingEngineeringHeight difference

The invention provides a substrate for a photomask, the photomask, a method for manufacturing the photomask and a method for transfering a pattern, and transferring precision of the pattern is improved in proximity exposure. The photomask is provided with: a transparent substrate; and a transferring pattern formed by composing a shading film formed at the surface of the transparent substrate to be a predetermined transferring pattern, wherein, a worktable using a depicting machine supports the second main surface of the transparent substrate from the lower part; and the transferring pattern is formed, for the flatness of the second main surface of the transparent surface when no supporting part is sued to support the transparent substrate from the lower part, when the height difference between each arbitrary two points, is disposed to be Delta Zb([mu]m), Delta Zb<=(1 / T)*3.0.

Owner:HOYA CORP

New cnc wire cutting machine

Owner:TAICANG SHUNCHANG FORGE

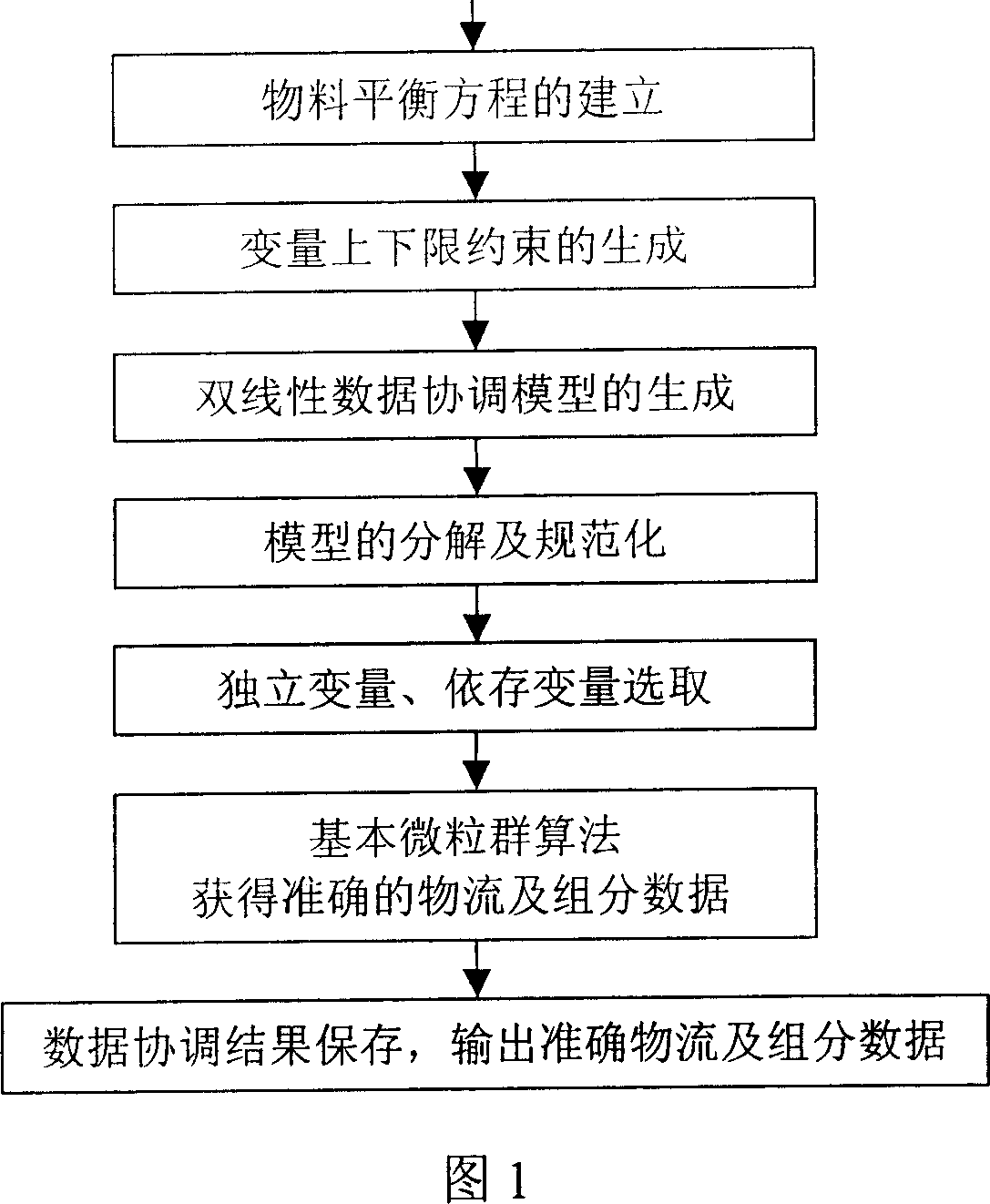

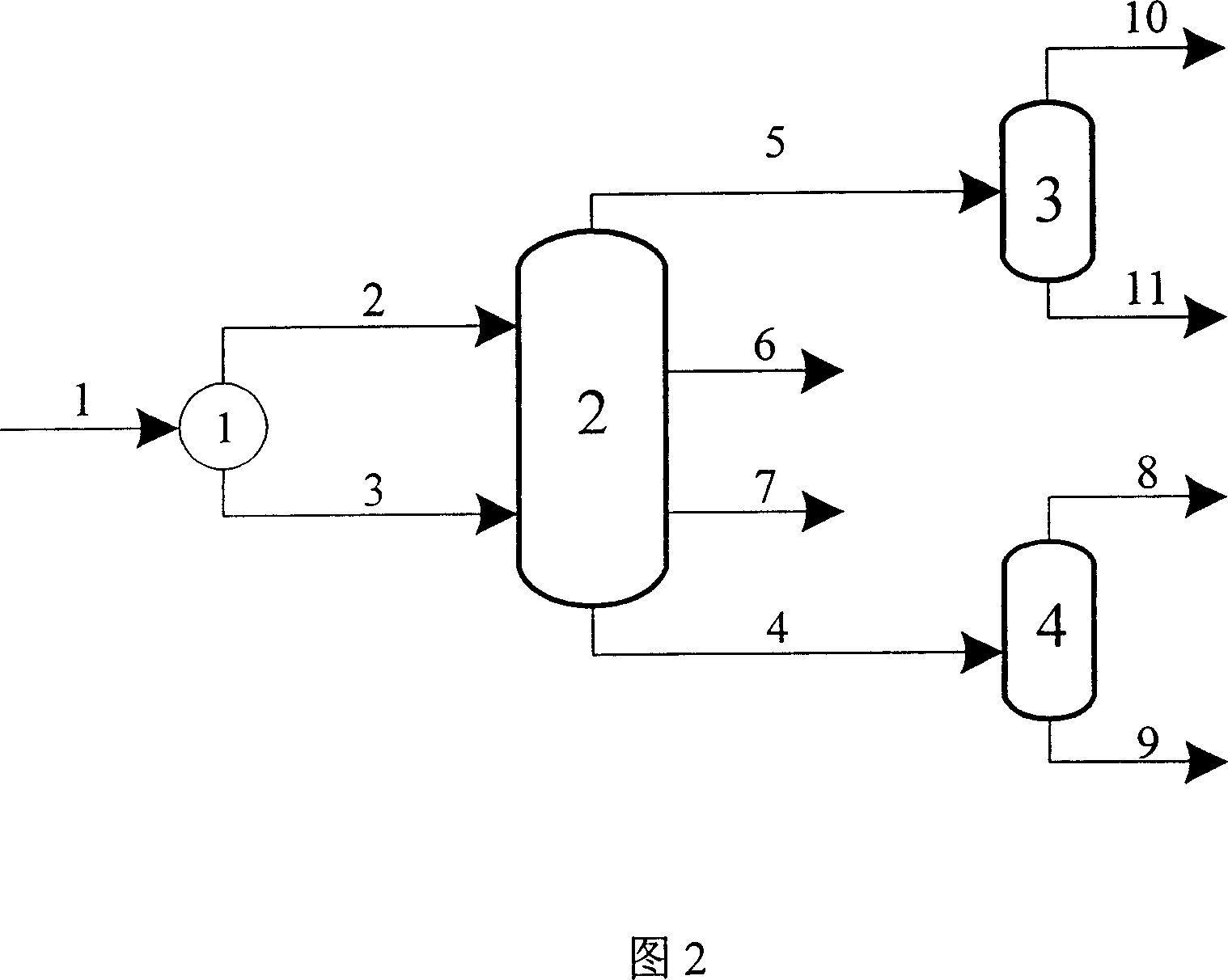

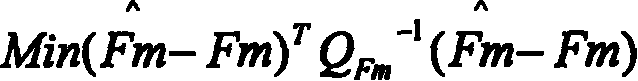

Bilinear data coordinating method

InactiveCN1920703ASure easyHigh coordinate accuracyAdaptive controlLower limitDimensionality reduction

Owner:ZHEJIANG UNIV

A detector signal readout circuit, detector and signal processing method

ActiveCN109597114BReduce complexityReduce areaX/gamma/cosmic radiation measurmentComputer hardwareScintillation crystals

The invention discloses a detector signal readout circuit, a detector and a signal processing method. Cathode signal output ends of each row of SiPM (Silicon Photomultipliers) pixels of an SiPM arrayare connected to form M row common connection ends, anode signal output ends of each column of the SiPM pixels are connected to form N column common connection ends, each row common connection end andeach column common connection end are connected with a signal readout circuit, in the case that the SiPM array is in a Geiger mode, the signal readout circuit can filter out alternating current signals of each row and each column, the M-row signal readout circuit can carry out weighted summation on the M-row cathode alternating current signals to obtain two row signals, the N-column signal readout circuit can carry out weighted summation on the N-column anode alternating current signals to obtain two column signals. According to the circuit, the detector and the method in the invention, setting of weight coefficients of the sub-circuits in the rows and columns enables the coordinate precision of the position of a scintillation crystal obtained through a gravity center method based on therow and column signals higher, also, large numbers of shunting resistors and analog amplifiers are not needed, so that the electronics complexity of the circuit and the area of the readout board are reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

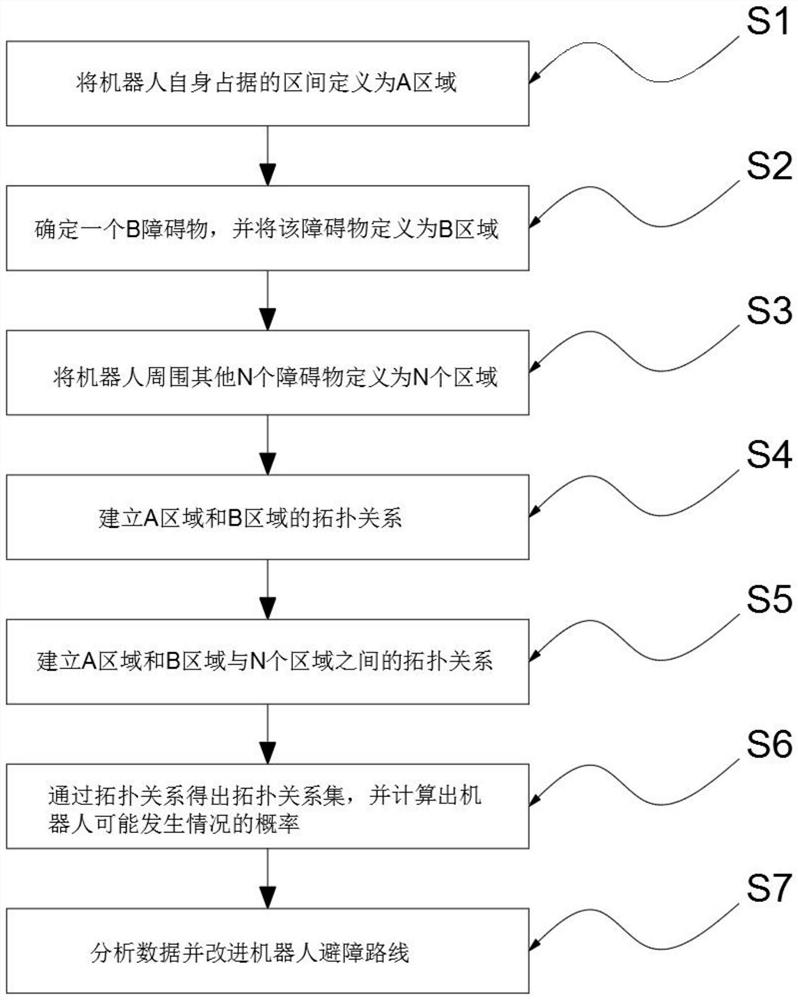

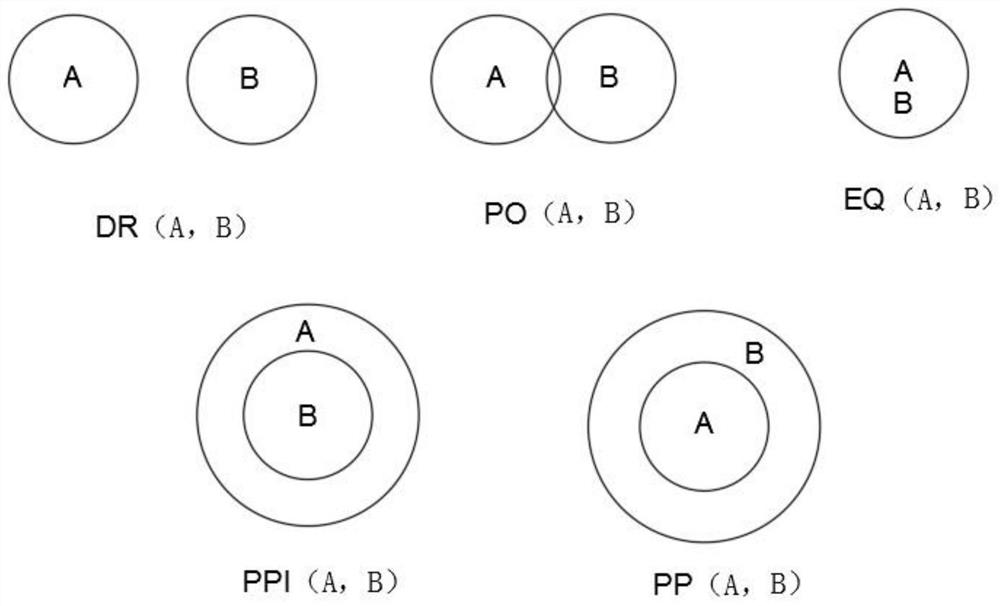

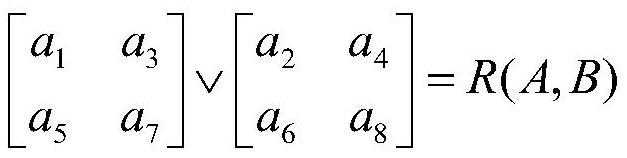

Robot Obstacle Avoidance Algorithm Based on Topological Relationship

ActiveCN110007680BImprove accuracyHigh coordinate accuracyPosition/course control in two dimensionsComputational probabilityAnalog robot

Owner:JILIN AGRICULTURAL UNIV +1

Alignment method and apparatus of mask pattern

InactiveUS7782441B2Improve accuracy in pattern-arrangement of the second layerHigh coordinate accuracyPhotomechanical apparatusPhotographic printingEngineeringRotation error

An alignment method of mask patterns includes forming a first layer by transferring a first mask pattern onto a wafer, forming a second layer by transferring a second mask pattern onto the first layer, and particularly a first alignment step, forming the first layer, which performs alignment for minimizing offset between a center position of the wafer and a center position of the first mask pattern and a residual rotation error between the wafer and the first mask pattern and additional alignment for compensating an amount of possible deviation of superposition of the second layer pattern on the first layer pattern, and a second alignment step, forming the second layer, which performs only alignment for minimizing offset between a center position of the first layer pattern and a center position of the second mask pattern and a residual rotation error between the first layer pattern and the second mask pattern.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com