Substrate for photomask, photomask, method for manufacturing photomask and method for transfering pattern

A manufacturing method and pattern transfer printing technology, applied in microlithography exposure equipment, semiconductor/solid-state device manufacturing, optics, etc., can solve problems such as degradation, color turbidity, and insufficient overlapping precision of patterns for transfer printing, and achieve improved transfer Printing accuracy, the effect of improving coordinate accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

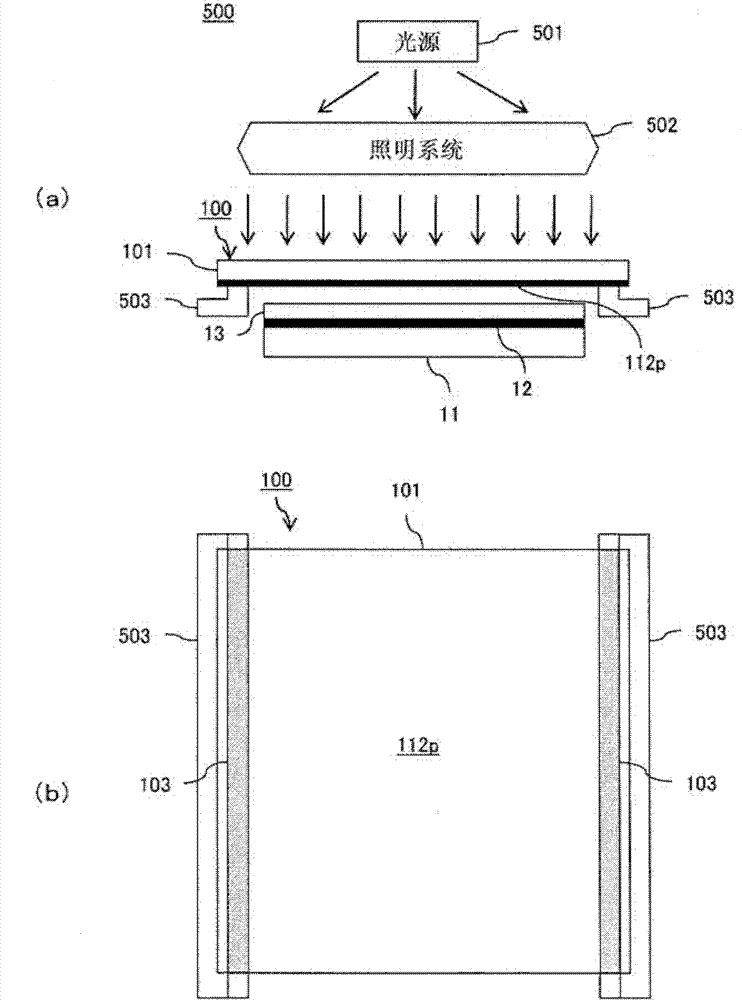

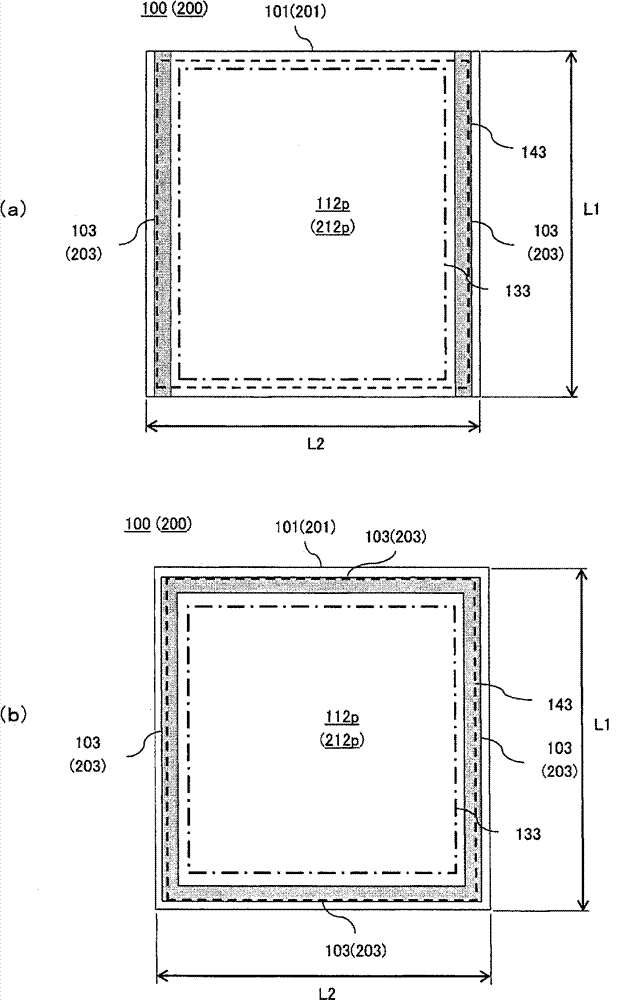

[0050] One embodiment of the present invention will be described below.

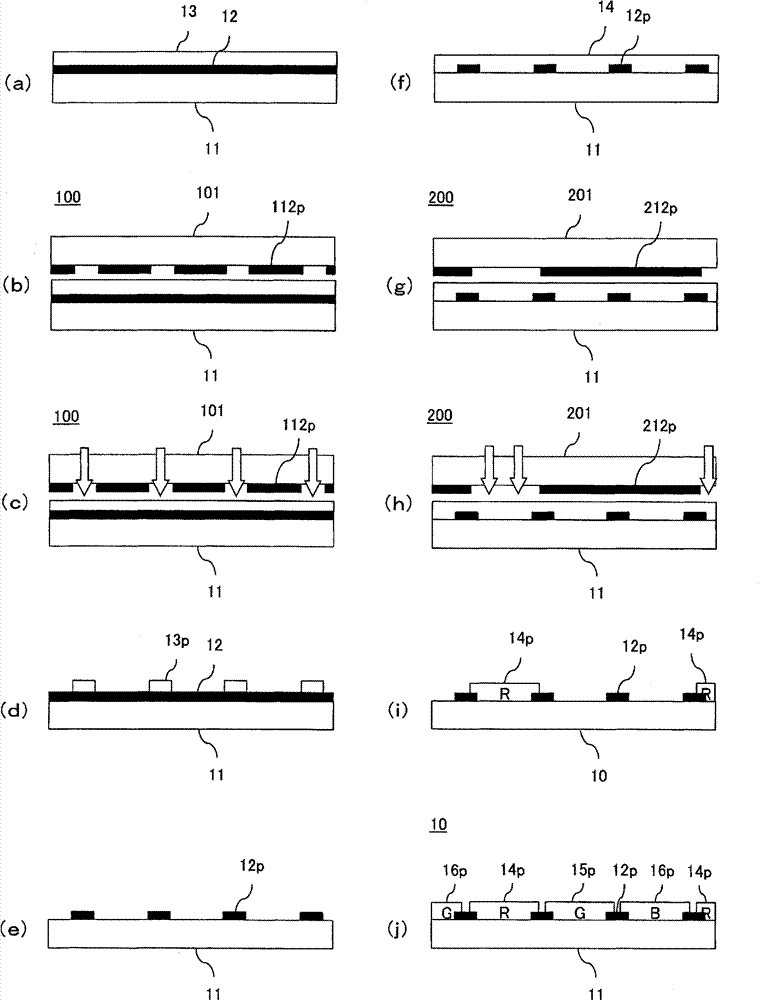

[0051] (1) Manufacturing process of color filter

[0052] First, refer to Figure 1 ~ Figure 3 The manufacturing process of the color filter used for a liquid crystal display device etc. is demonstrated. figure 1 It is a flowchart illustrating the outline of the manufacturing process of the color filter of this embodiment. figure 2 (a) is a side view illustrating the state of performing proximity exposure in the manufacturing process of the color filter of this embodiment, figure 2 (b) is its plan view. image 3 (a) is a top view illustrating the planar structure of the photomask of this embodiment, image 3 (b) is a top view illustrating the modified example.

[0053] Such as figure 1 As shown, the color filter 10 for a liquid crystal display device is manufactured by sequentially implementing the following steps: forming a black matrix layer 12p ( figure 1 (a)~(e)); And then form the color fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com