An organic material transfer printing method in an organic light-emitting display

A light-emitting display and organic material technology, applied in the direction of copying/marking methods, printing, electric solid devices, etc., can solve the problems of abnormal OLED products, metal mask deformation, high defective rate, etc., and achieve small thermal expansion coefficient and small deformation , the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

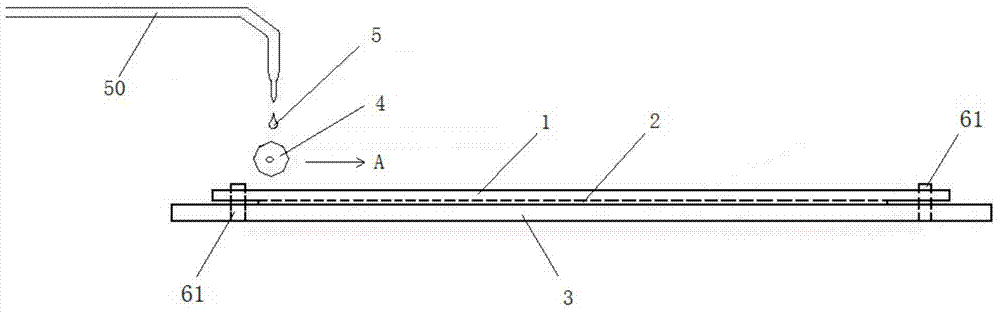

[0032] see figure 1 It is a transfer printing method of an organic material on an organic light-emitting display disclosed in the present invention, which is used to produce a monochrome device structure, and the organic material 5 is a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, An electron injection layer, comprising the steps of:

[0033] Step 1 - positioning the substrate 2 for transferring the organic material 5 on the fixed platform 3, the substrate 2 being a glass substrate;

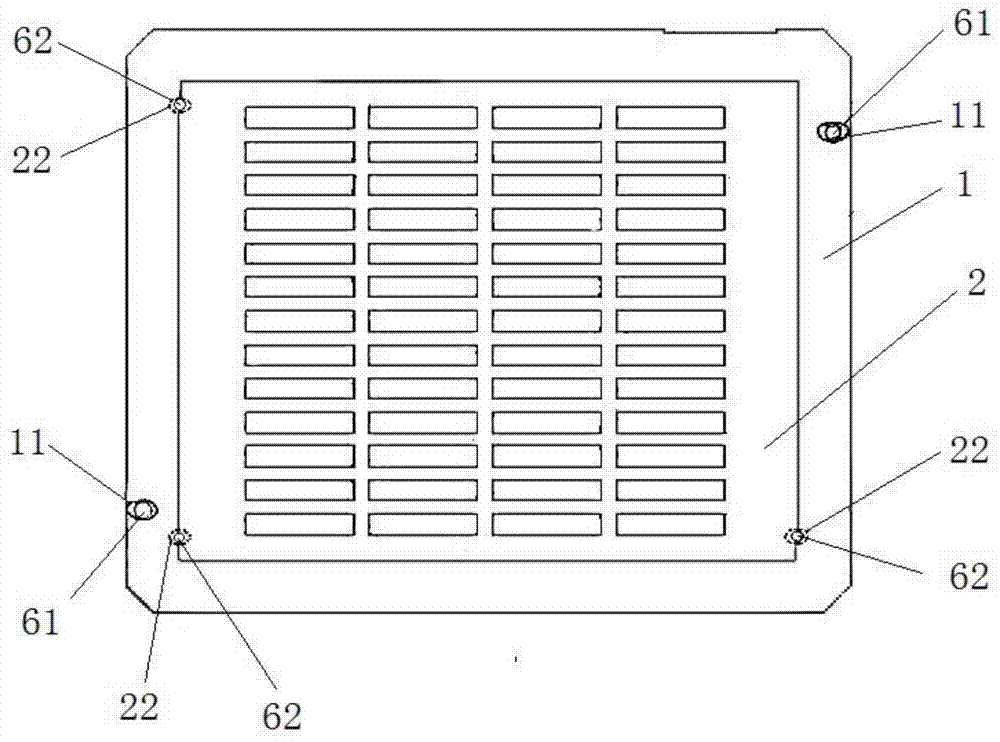

[0034] Step 2 - According to the final formed structure of the substrate 2, design a film mask 1 with a hollow figure shape, attach it to the substrate 2, and position the film mask 1 on the fixed platform 3;

[0035] Step 3 - dripping the liquid organic material 5 onto the roller 4 through the conduit 50;

[0036] Step 4 - lower the height of the roller 4 so that it has a suitable height between it and the substrate 2, through the circumfer...

Embodiment 2

[0047] The transfer printing method of the organic material on the organic light-emitting display of this embodiment is used to produce a multi-color or color device structure, and the organic material 5 is a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron The injection layer, wherein the multi-color light-emitting layer is a combination of multiple monochromatic light-emitting materials, and the light-emitting layer of the color device includes red light material, yellow light material, and blue light material respectively, and the color is formed through the combination of RGB.

[0048] Above-mentioned transfer printing method comprises the following steps:

[0049] Step 1 - positioning the substrate 2 for transferring the organic material 5 on the fixed platform 3, the substrate 2 being a glass substrate;

[0050] Step 2 - According to the final formed structure of the substrate 2, design a film mask 1 with a ho...

other Embodiment approach

[0057] In other implementation manners, the thin film mask 1 can be selected from thin films such as stainless steel thin films and ferroelectric thin films.

[0058] In addition, the liquid organic material 5 in step 3 can also be made in other ways, such as heating the organic material 5 to the melting point to form a molten organic material 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com