Chuck device

A chuck and jaw technology, applied in the field of chuck devices, can solve the problems of difficulty in processing and assembling parts, complex and difficult structure of components, and achieve adjustable moving speed, adjustable clamping force, and good clamping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

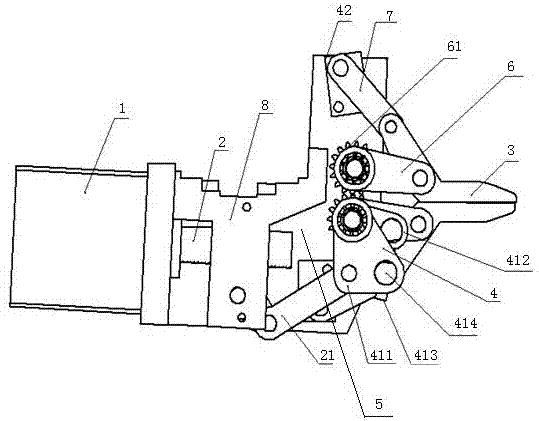

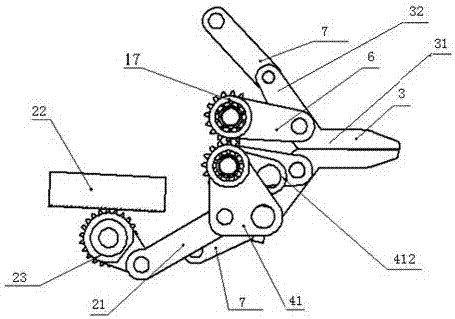

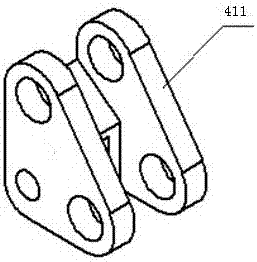

[0028] Such as Figures 1 to 7 Shown as an embodiment of a collet device of the present invention, the collet device includes a sequentially connected power source 1, a power transmission structure 2 for power transmission, a jaw structure 3, and a frame 5, and the jaw structure 3 is rotatably connected On the frame 5; the chuck device also includes an adjustment structure 4 for adjusting the grasping force of the jaw structure 3 and for fine-tuning the movable range of the jaw structure 3, and the adjustment structure 4 is connected with the jaw structure 3; The transmission structure 2 includes a link mechanism 21 for realizing the opening and closing motion track of the jaw structure 3 .

[0029] Wherein, the power transmission structure 2 includes a rack and pinion transmission mechanism 22 and a first gear 23 , and the power source 1 , the rack and pinion transmission mechanism 22 , the first gear 23 and the link mechanism 21 are connected in sequence. Such setting is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com