Combined electric-control high-pressure one-way valve

A high-pressure one-way valve, compound technology, applied in the direction of control valve, sliding valve, valve details, etc., can solve the problems of control piston rod not working, complex structure of hydraulic control check valve, increasing control oil circuit, etc. Remote control, improved frequency response, reduced port effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

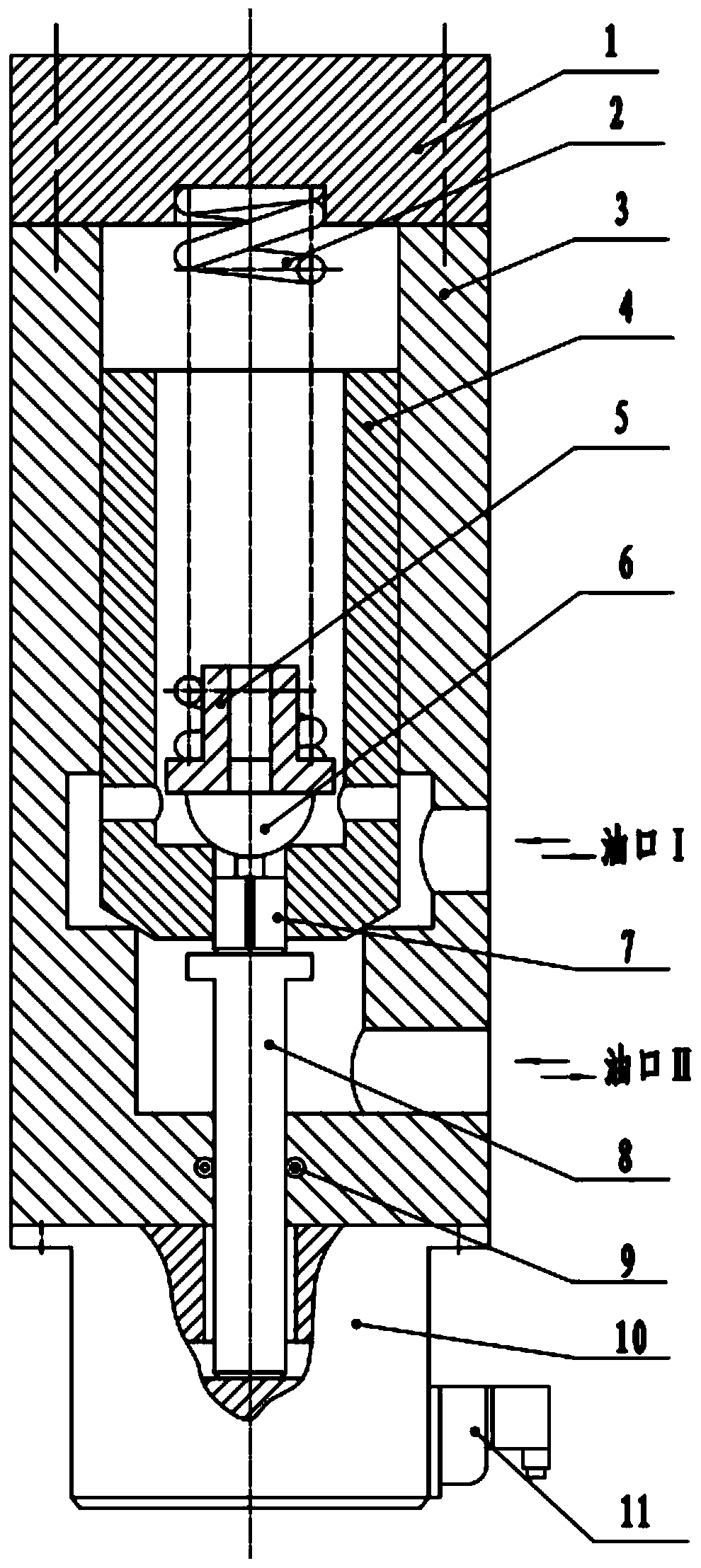

[0033] The utility model relates to a composite electronically controlled high-pressure check valve. This example figure 1 As shown: the one-way valve includes a valve cover 1 , a spring 2 , a valve body 3 , a main valve core 4 , an unloading valve core 6 , an unloading valve core rod 7 , a push rod 8 and an electromagnet 10 .

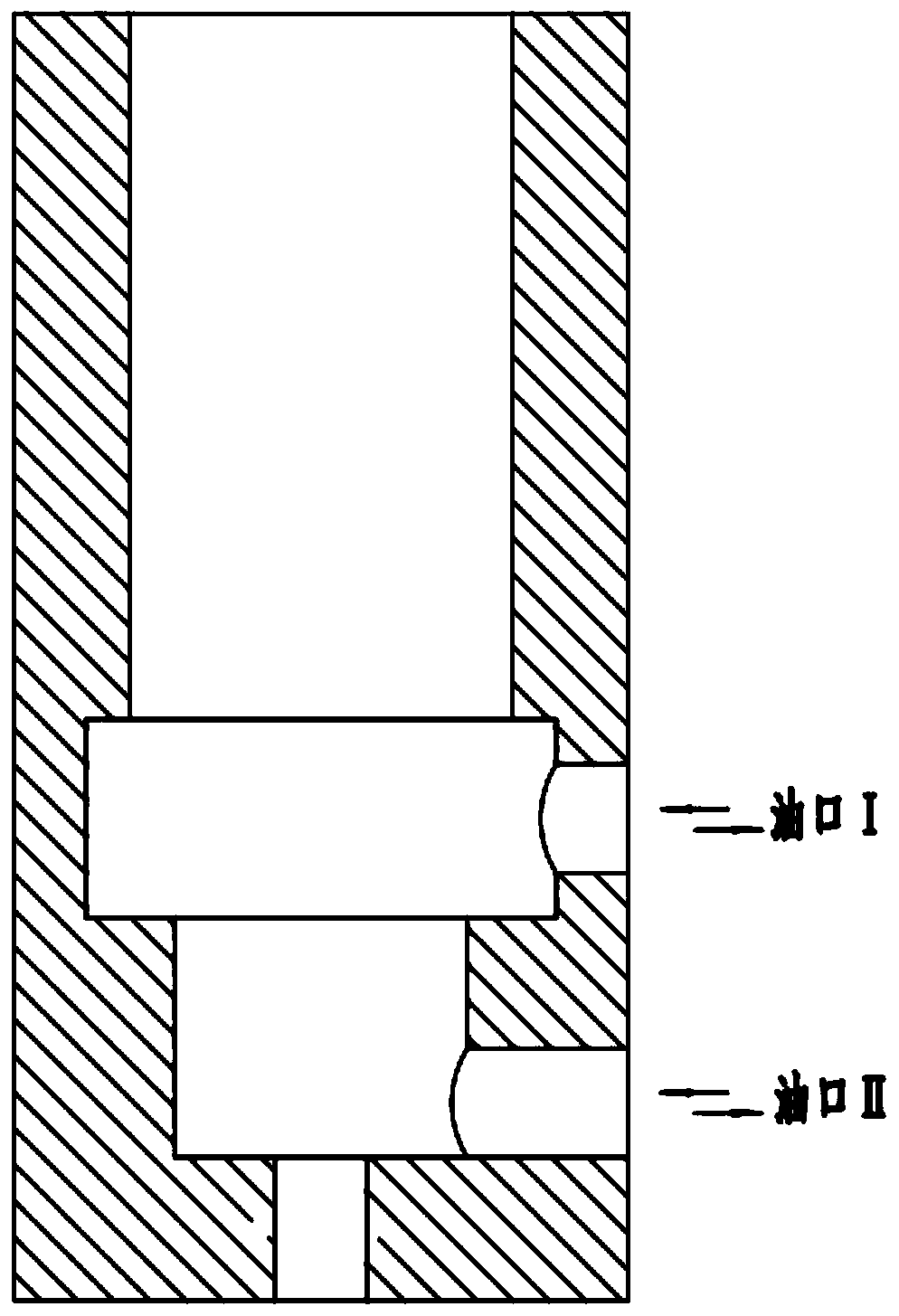

[0034] Such as figure 1 As shown, the open end of the valve body 3 is fixed with a valve cover 1, and the closed end of the valve body 3 is fixed with an electromagnet 10; the valve body 3 is equipped with a main valve core 4, and the main valve core 4 is sequentially equipped with an unloading valve from the inside to the outside. Core 6, spring seat 5 and spring 2. The lower part of the unloading spool 6 is located at the orifice of the stem through hole of the main spool 4, the spring seat 5 is installed on the upper end surface of the unloading spool 6, one end of the spring 2 is installed on the spring seat 5, and the spring 2 The other end is ...

Embodiment 2

[0049] A composite electronically controlled high-pressure check valve. Except following technical parameter, all the other are with embodiment 1:

[0050] The cone angle of the truncated cone is 35° to 45°;

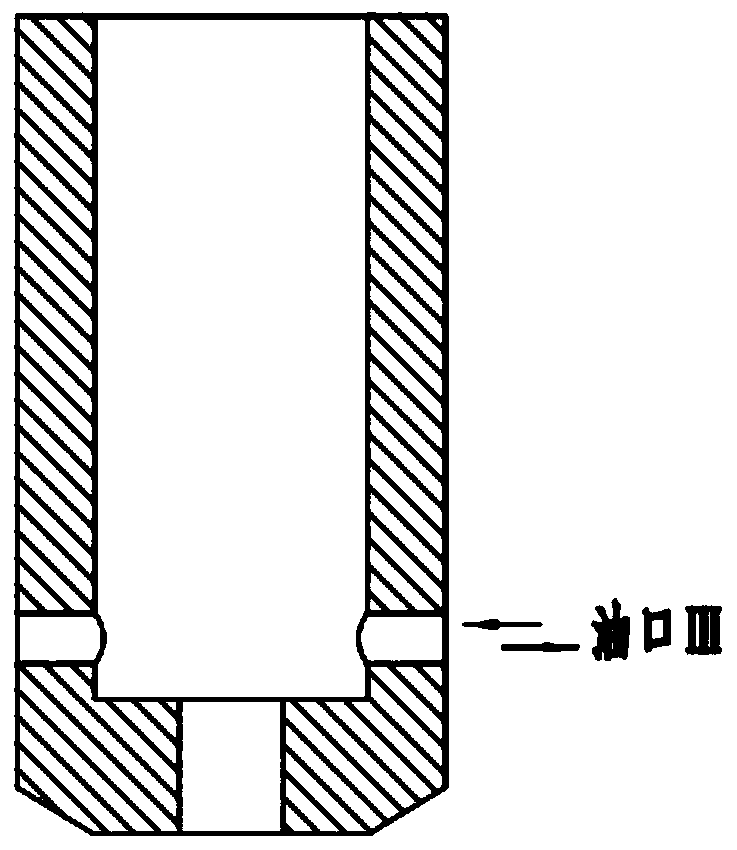

[0051] The inner end of the cavity of the main valve core 4 is provided with four oil ports III along the radial direction;

[0052] The diameter of the short cylinder of the unloading spool 6 is 0.25 to 0.3 times the diameter of the hemisphere;

[0053] The diameter of the small cylinder of the unloading valve core rod 7 is 0.35-0.4 times the diameter of the large cylinder of the unloading valve core rod 7 . Have 4 oil unloading grooves along the prime line direction on the large cylinder surface of unloading spool rod 7.

[0054] The electromagnet 10 is a proportional electromagnet.

[0055] Owing to adopting above-mentioned technical scheme, this embodiment has the following advantages compared with the prior art:

[0056] 1. When the external power supply is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com