Driving structure for sinking-method rotation-type vertical shaft tunnelling machine

A driving structure and roadheader technology, which is applied in the direction of drilling driving devices, shaft equipment, and sinking in boreholes. It can solve problems that affect construction quality, cannot achieve full-section cutting, and cannot adjust the trajectory of motion, and achieve repeated crushing. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

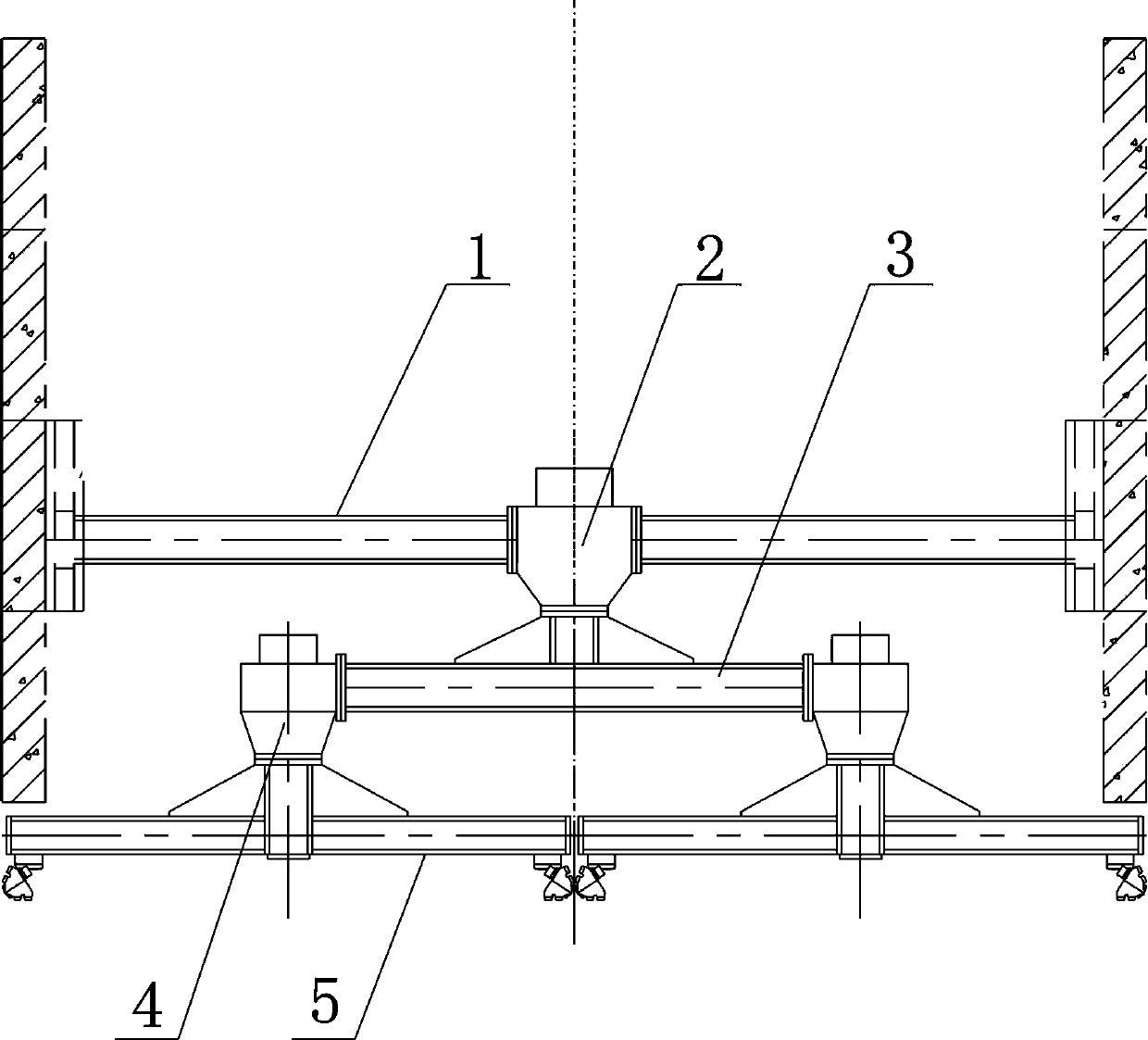

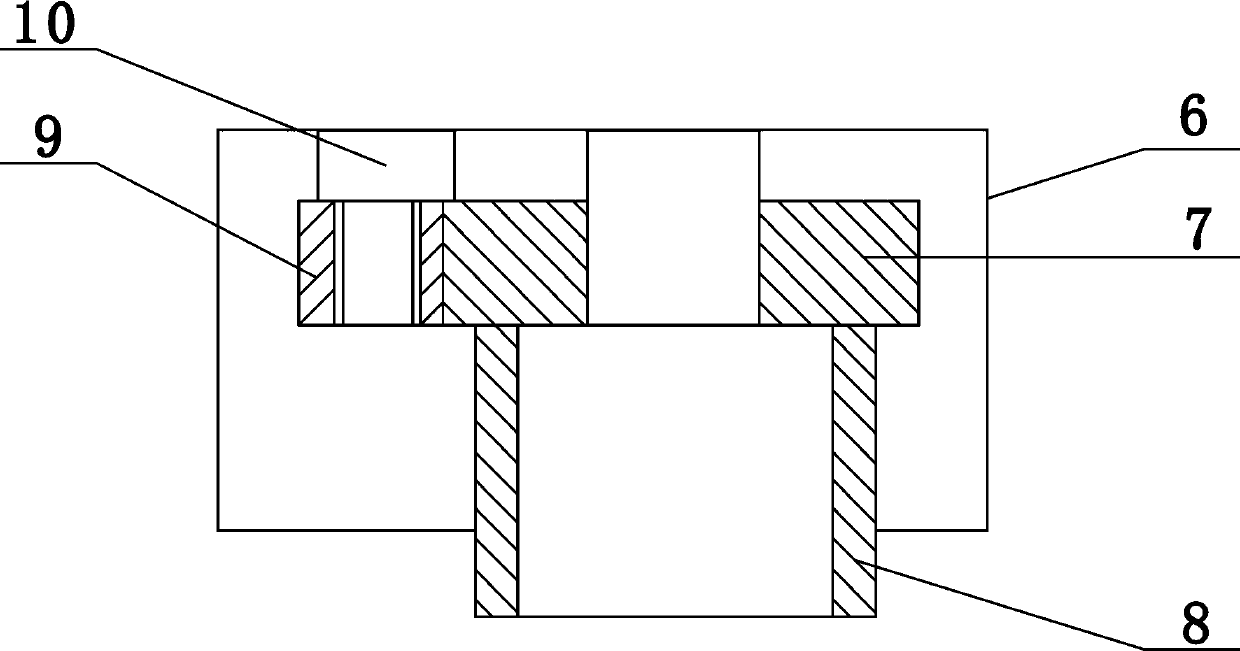

[0016] combined with Figure 1-2 The driving structure for the submerged rotary shaft boring machine includes a drilling arm 3 and a driving mechanism. The driving mechanism includes a main driving device 2 and a secondary driving device 4 of the same structure. The outside of the main driving device 2 is connected to the shaft boring machine. On the drilling frame 1, the bottom of the main driving device 2 is connected with a drilling arm 3, and a plurality of secondary driving devices 4 are arranged at intervals on the drilling arm 3. The main driving device 2 includes a first outer box body 6, and is installed on the first The main drive motor 10 and the first gear box in the outer box body 6, the first outer box body 6 is installed in the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com