Movable electrode (cathode) for stainless steel inner tube electropolishing

An electropolishing, stainless steel tube technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of gas not in time, high viscosity, small current flow area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to be able to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail.

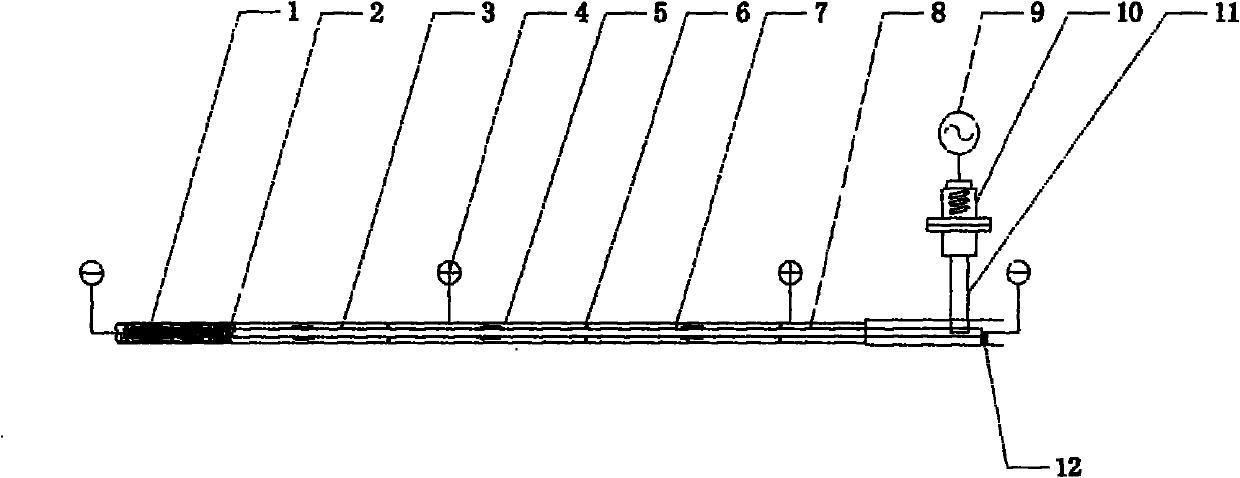

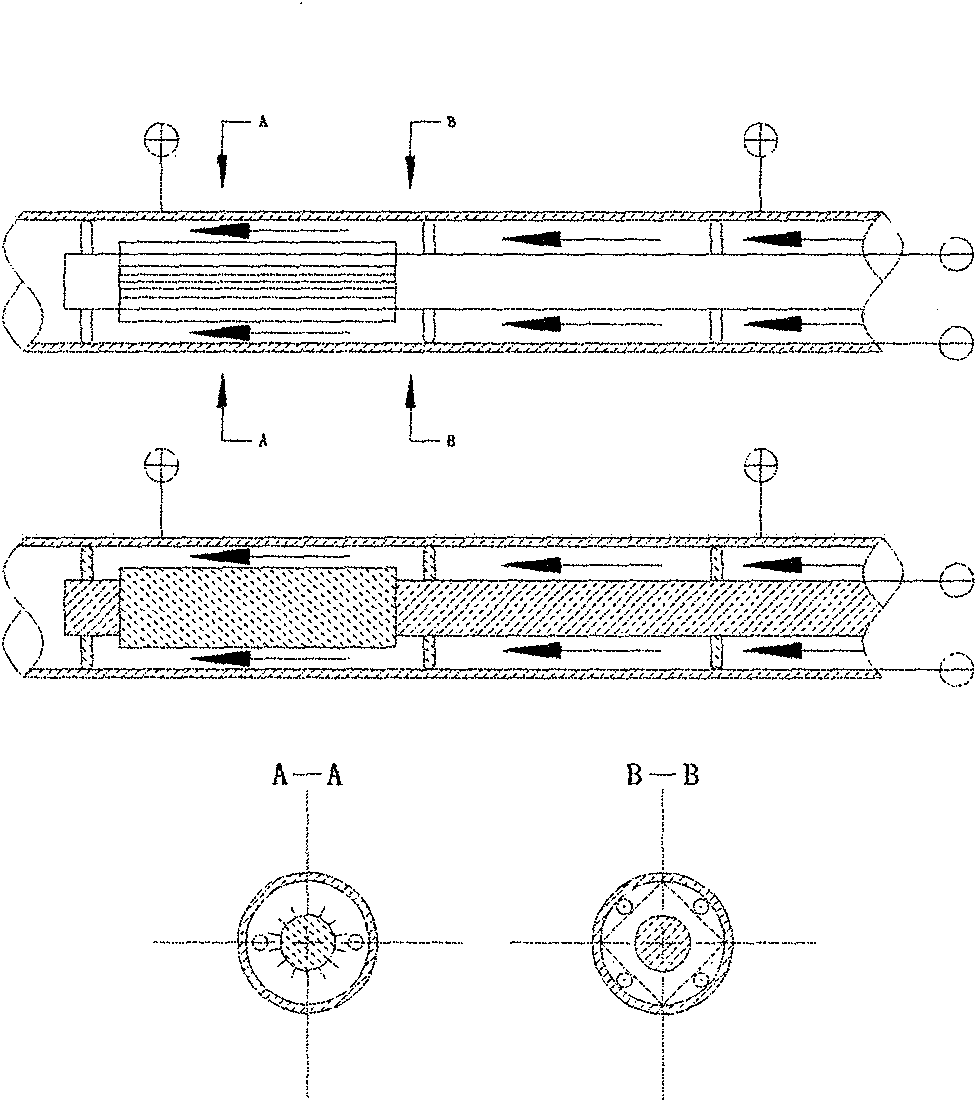

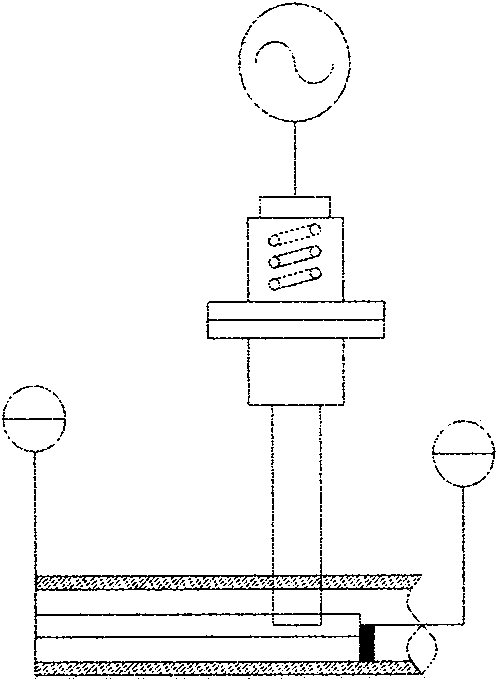

[0030] See Figure 1 ~ Figure 4 As shown, the movable auxiliary electric (cathode) electrode for electrolytic polishing of the stainless steel inner tube of the present invention includes a movable auxiliary electric (cathode) electrode 7, a pulling device 11, and a PID fuzzy automatic control system; the movable auxiliary electric (cathode) ) Pole 7 includes auxiliary electric (cathode) pole 1, support frame 6, connecting rod 3; said pulling device 11 includes stepping motor 10, frequency converter 11, limit switch 12, voltmeter, ammeter, overcurrent voltage protection device , Emergency stop button, etc.; the manual automatic control system includes PLC, data collector, frequency converter, PID fuzzy control software, manual automatic switch button, etc.; the auxiliary electric (cathode) pole 1 is located in fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com