Gear grinding and deburring device

A technology for deburring and gear removal, which is used in grinding drives, grinding/polishing safety devices, grinding machines, etc., and can solve problems such as uneven grinding of gear tooth grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

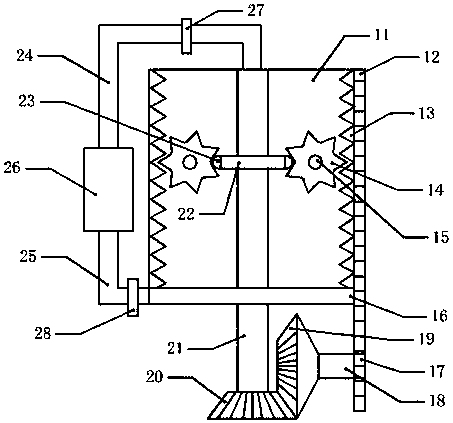

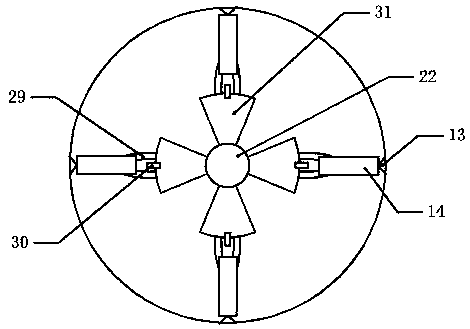

[0016] The reference signs in the drawings of the description include:

[0017] Mandrel 11, first rack 12, second rack 13, gear 14, transverse shaft 15, collecting tank 16, spur gear 17, first rotating shaft 18, first bevel gear 19, second bevel gear 20, second Rotating shaft 21, grinding wheel 22, air bag 23, air intake pipe 24, exhaust pipe 25, blower 26, one-way air intake valve 27, one-way air extraction valve 28, fine sandpaper 29, one-way air intake hole 30, frosted fan blade 31 .

[0018] Such as figure 1 The shown gear grinding and deburring device includes a mandrel 11, a hollow second rotating shaft 21 is installed in the central position of the mandrel 11, and 50 air outlet holes are provided on the second rotating shaft 21, and a hollow frosting is fixedly installed on the middle of the second rotating shaft 21. wheel 22, such as figure 2 The shown grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com